Non Toxic Wood Glue: 8 Safe, Strong Choices for Indoor Projects

Non toxic wood glue is the best place to start when you want strong joints without harsh fumes. This wood glue matters when you’re building indoors and breathing close to the work. Most of the time, you’re not trying to eat the stuff. You just want low odor, fewer harsh solvents, and a glue line you can trust. The trick is learning what labels really mean, and which glue types fit your project.

You’ll learn the glue types commonly considered “safer,” how to read labels without guessing, and how to avoid the technique mistakes that cause weak joints. If you’re shopping for glue today, you’ll also get a short product shortlist at the end.

Contents Here

- 1 Quick Review: The 8 Picks for the Best Non Toxic Wood Glue

- 2 What “non toxic” means in wood glue

- 3 Reviews of the 8 Non Toxic PVA Wood Adhesive

- 3.1 Titebond 5066F Original Wood Glue

- 3.2 Titebond 1416 III Ultimate Wood Glue

- 3.3 Gorilla Ultimate Waterproof Wood Glue

- 3.4 Snailmart Heavy Duty Wood Glue

- 3.5 Weldbond Extra Strength Non Toxic Wood Glue

- 3.6 Weldbond All Purpose Non Toxic Glue

- 3.7 Elmer’s E7000 Carpenter’s Non Toxic Wood Glue

- 3.8 Boncart Super Strong Non Toxic Wood Glue

- 4 A quick, reliable way to pick a safer glue

- 5 Non-toxic leaning wood glue types (what to use, and when)

- 6 How to read labels like a woodworker (not like a marketer)

- 7 Safe use that keeps the air cleaner (and the joint stronger)

- 8 Special notes for kids’ projects and kitchen builds

- 9 Storage and shelf life (so your glue doesn’t quietly fail)

- 10 Common problems and quick fixes

- 11 FAQs on Non Toxic Wood Glue

- 12 Last Words

Quick Review: The 8 Picks for the Best Non Toxic Wood Glue

- Titebond 5066F Original Wood Glue

- Titebond 1416 III Ultimate Wood Glue

- Gorilla Ultimate Waterproof Wood Glue

- Snailmart Heavy Duty Wood Glue

- Weldbond Extra Strength Non Toxic Wood Glue

- Weldbond All Purpose Non Toxic Glue

- Elmer’s E7000 Carpenter’s Non Toxic Wood Glue

- Boncart Super Strong Non Toxic Wood Glue

What “non toxic” means in wood glue

In woodworking, “non toxic” usually points to lower odor and fewer volatile solvents during use. Many water-based glues fit that description. But a label can still hide important details.

Here’s the practical way to think about it:

- Wet glue safety: fumes, skin irritation, eye contact, and cleanup.

- Cured glue safety: the hardened glue line after full cure.

- Indoor air concerns: what evaporates while the glue sets and cures.

Even water-based glues can irritate skin, especially with repeated contact. And “non toxic” never means “safe to ingest.” If you’re timing a build for kitchen use or kid handling, curing matters. Use this reference for planning: full cure timing for common wood glues.

Reviews of the 8 Non Toxic PVA Wood Adhesive

Titebond 5066F Original Wood Glue

A low VOC wood glue for indoor use that sets fast for clean joinery

Titebond Original is the classic interior carpenter’s glue for a reason. It’s built for fast set and short clamp time, with water cleanup and a reputation for bonds that can be stronger than the wood in the joint. It’s a solid pick when you’re doing cabinet parts, tray frames, face frames, or indoor furniture repairs and you want predictable behavior.

$21.99 at AmazonWhat it does well:

- Fast initial tack helps parts stop skating around during clamp-up.

- Sands cleanly once cured, which matters for tray edges and trim.

- Plays nicely with most finishing schedules because it’s unaffected by finishes once cured (your squeeze-out still needs cleanup, though).

Where it’s not the right tool:

- It’s not water resistant, and the listing says it’s not intended for exterior use or moisture-prone spots.

- It’s not for structural or load-bearing work.

- Temperature matters: don’t glue below 50°F, and don’t let it freeze.

Shop-use notes that actually help:

If you stain your projects, treat glue squeeze-out like a problem you prevent, not fix later. The file notes the masking tape trick near joints, and that’s a real-world move. You can also read more on stain issues here: why glue lines show up under stain.

Specifications:

- Type: Water-based PVA wood glue (liquid)

- Best use: Interior woodworking, furniture, home repair

- Water resistance: Not water resistant

- Full cure: 24 hours

- Cleanup: Water cleanup; non-toxic notes included

Titebond 1416 III Ultimate Wood Glue

A food-safe wood glue for cutting boards with a waterproof formula

Titebond III is the “reach for it when the project might get wet” option in the Titebond lineup. It’s a water-based glue that’s still waterproof, and it passes ANSI/HPVA Type I for water resistance. It also has a big selling point for kitchen projects: FDA approval for indirect food contact (think cutting boards and utensils).

$35.89 at AmazonWhat it does well:

- Waterproof bond plus resistance to heat, mildew, and many solvents makes it a strong outdoor-capable choice.

- A longer open time helps on bigger glue-ups where you need breathing room.

- Sands without softening, which helps you keep edges crisp.

Limits to respect:

- It’s not for continuous submersion or use below a waterline.

- It’s not for structural/load-bearing jobs.

- Don’t use it below 47°F, and keep it from freezing.

Who it fits:

If you build trays, cutting boards, plant stands, or outdoor décor, this is the glue that lets you sleep at night. If you’re still sorting out the “food safe” question, pair it with your finishing plan: what “food safe” means for glue lines.

Specifications:

- Type: Water-based wood glue (liquid)

- Best use: Interior + exterior woodworking, furniture

- Water resistance: Waterproof

- Rating: ANSI/HPVA Type I (noted in product context)

- Viscosity: 4,200 cps

- Tensile strength: 1,750 psi

- Full cure: 24 hours

- Cleanup: Water cleanup

- Food contact: FDA approved for indirect food contact

Gorilla Ultimate Waterproof Wood Glue

A non toxic wood glue waterproof formula for outdoor wood projects

Gorilla’s Ultimate Waterproof is a PVA glue aimed at people who want Type I waterproof performance with a longer working time. The listing calls out about 15 minutes before it grabs hard, which can be a lifesaver on larger assemblies. It dries to a natural tan color and is designed to be sandable and paintable without the foaming mess some people hate.

$11.32 at AmazonWhat it does well:

- ANSI/HPVA Type I waterproof rating is the headline feature here.

- Extended working time helps with panel glue-ups, tray bottoms, and tricky alignment.

- A natural bond line and no foaming is a big plus for clean joinery.

- Soap-and-water cleanup from hands is a friendly touch (still wash up promptly).

Small cautions:

Because it dries tan, it can be more visible on very light woods if squeeze-out isn’t cleaned. If you’ve ever had glue show through a finish, you already know the drill: clean early, scrape later, and don’t sand glue into the grain. This helps when you’re dealing with hardened mess: remove dried glue without tearing up the wood.

Specifications:

- Type: PVA (polyvinyl acetate), water-based (liquid)

- Best use: Indoor + outdoor woodworking and repairs

- Water resistance: Waterproof; passes ANSI/HPVA Type I

- Working time: About 15 minutes before strong bond forms

- Full cure: 24 hours

- Color when cured: Natural tan

- Finish behavior: Sandable and paintable; no foaming noted

- Cleanup: Warm soap and water from hands (per details)

Snailmart Heavy Duty Wood Glue

A clear non toxic wood glue for crafts, school builds, and quick repairs

Snailmart is positioned as a heavy-duty, crack-resistant PVA emulsion that’s meant to be controllable and tidy. The details say it dries clear, is non-toxic, and works on porous materials like wood, paper, cardboard, and fabric. That makes it a possible crossover glue for families who do both woodworking and crafts.

$11.99 at AmazonWhat it does well:

- Creamy consistency can be easier for beginners to place neatly.

- Dries clear, which is helpful on craft joints and visible seams.

- Multi-material use (wood + paper/fabric/cardboard) makes it flexible for DIY.

Read this part carefully (cons):

True outdoor exposure unless the packaging backs up a waterproof rating.

Specifications:

- Type: PVA emulsion (cream)

- Best use: Crafts, DIY, furniture assembly, general repairs

- Compatible materials: Wood, paper, cardboard, fabric (porous materials)

- Water resistance: Listed as water resistant (details also mention “waterproof” claims)

- Viscosity: Moderate

- Finish: Dries clear / transparent finish

- Pack: 3-pack, 100g each

- Safety notes: Solvent-free, non-toxic, “eco-friendly” positioning

Weldbond Extra Strength Non Toxic Wood Glue

A non toxic PVA wood adhesive for furniture repair and trim work

Weldbond Extra Strength is positioned as a serious wood-bonding adhesive for furniture repair, cabinetry, and trim. The key specs you provided are high viscosity and a very high listed tensile strength (3700 psi), plus a 24-hour full cure.

$14.99 at AmazonWhat it does well:

- Thicker glue body can reduce drips and help on vertical surfaces.

- “Extra strength” positioning makes it a good candidate for repair work where you want a firm, permanent bond.

- The listing frames it as a dependable choice for trim work and cabinetry.

Not ideal for:

Outdoor work unless you confirm water-resistance specs on the packaging. If you’re choosing glue for furniture repairs specifically, this page can help you match glue to the job: what to use for chair and furniture repairs.

Specifications:

- Type: PVA wood glue (liquid)

- Best use: Furniture repair, cabinetry, trim, DIY woodworking

- Viscosity: High viscosity

- Volume: 420 ml

- Tensile strength: 3,700 psi (listed)

- Full cure: 24 hours

- Water resistance: Not water resistant

- Color: White

Weldbond All Purpose Non Toxic Glue

A non toxic gel wood glue for laminates, mosaics, and mixed materials

Weldbond All Purpose is a different animal than standard carpenter’s glue. It’s a clear, non-toxic gel designed to bond an unusually wide range of materials—wood, glass, ceramics, tile, stone, and more. The listing also says it’s water resistant, weatherproof, odorless, non-flammable, and emits no fumes, and that it can set in about 20 minutes with no clamping required for some carpentry uses.

$9.99 at AmazonWhat it does well:

- Dries crystal clear, which is great for visible craft joints.

- Multi-surface bonding makes it a smart “one bottle” glue for mixed projects.

- The gel format can reduce runny mess on vertical or detailed work.

Where it shines:

If you do mosaics, tile accents, decorative tray inlays, or wood-to-nonwood bonding, this is the one in your list that’s built for that life. For wood-only joinery, you’ll still often prefer a traditional PVA because it’s made for wood fiber penetration.

Not ideal for (cons):

Heavy structural wood joints where clamp pressure and wood-fiber bonding are the priority.

Specifications:

- Type: All-purpose adhesive (gel)

- Color: Clear; dries crystal clear

- Best use: Wood, glass, ceramic, tile, porcelain, stone, foam, cork, mosaics

- Viscosity: High

- Water resistance: Water resistant; weatherproof

- Set time: “Fast setting” in about 20 minutes; no clamping required (for some uses)

- Full cure: 24 hours

Elmer’s E7000 Carpenter’s Non Toxic Wood Glue

A safe wood glue for wooden toys and small home repairs

Elmer’s E7000 is a compact carpenter’s glue that’s clearly aimed at home repair and basic carpentry. The details include a 20–30 minute clamp time and 24 hours to full bond, along with soap-and-water cleanup while wet. It’s also listed as waterproof, which is a strong claim for a small bottle glue.

$8.00 at AmazonWhat it does well:

- The 4 oz bottle is handy for small repairs and occasional use.

- Clear guidance on clamp time helps beginners.

- Easy cleanup makes it family-friendly for quick fixes.

Practical advice:

If you’re doing repairs, prep matters more than brand. Remove old glue, scuff the surface lightly, and clamp evenly. If glue gets on skin, don’t reach for harsh chemicals—start here: how to remove glue from your hands safely.

Cons:

- Limited detail on open time and temperature limits

- For outdoor builds, confirm waterproof rating on the bottle label too

Specifications:

- Type: Carpenter’s wood glue (liquid)

- Best use: Carpentry and home repairs

- Bottle size: 4 oz

- Clamp time: 20–30 minutes

- Full cure: 24 hours to full bond

- Water resistance: Waterproof (listed)

- Cleanup: Soap and water when wet; scrape/sand when dry

- Safety notes: Non-toxic; no harmful fumes (per details)

Boncart Super Strong Non Toxic Wood Glue

An eco friendly water-based wood glue that dries clear for neat indoor work

Boncart is presented as a high-strength PVA glue that dries clear and is marketed as waterproof for indoor/outdoor use. It also includes a nice usability detail: a precision nozzle and brushes for controlled application, plus a stated 20–30 minute clamp time and 24-hour full cure.

$9.99 at AmazonWhat it does well:

- Clear-dry is great when you’re trying to keep joints visually quiet.

- Low viscosity can flow well into tight joints and small repairs.

- The included applicators (nozzle/brushes) are useful for neat work on small parts.

A realistic caution:

“Waterproof” gets used loosely in listings. If you’re building something that lives outdoors, look for a recognized rating on the label (Type I/Type II wording or similar). If it’s truly waterproof and clear-dry, it could be a nice fit for outdoor décor and patio pieces. And If it’s only water resistant, it’s still useful—just plan accordingly.

Specifications:

- Type: PVA wood glue (liquid)

- Color/finish: Clear; dries clear

- Viscosity: Low viscosity

- Water resistance: Waterproof (listed)

- Clamp time: 20–30 minutes

- Full cure: 24 hours

- Best use: Crafts, DIY, furniture assembly, wood repairs, woodworking

- Extras: Precision nozzle + brushes for even application

A quick, reliable way to pick a safer glue

If you don’t want to overthink it, start with three questions: Where will this live, who will handle it, and what will it face?

Step 1: Match the glue to the environment

- Indoor, normal humidity: water-based PVA is usually the easiest “safer” choice.

- Occasional splashes: choose a water-resistant formula and finish the project well.

- Outdoor exposure: the “non toxic” priority often conflicts with durability needs.

If you’re building serving trays or tiered trays, your finish makes a big difference. Here’s a good companion piece for that side of the job: how to seal a wooden serving tray for easy cleaning.

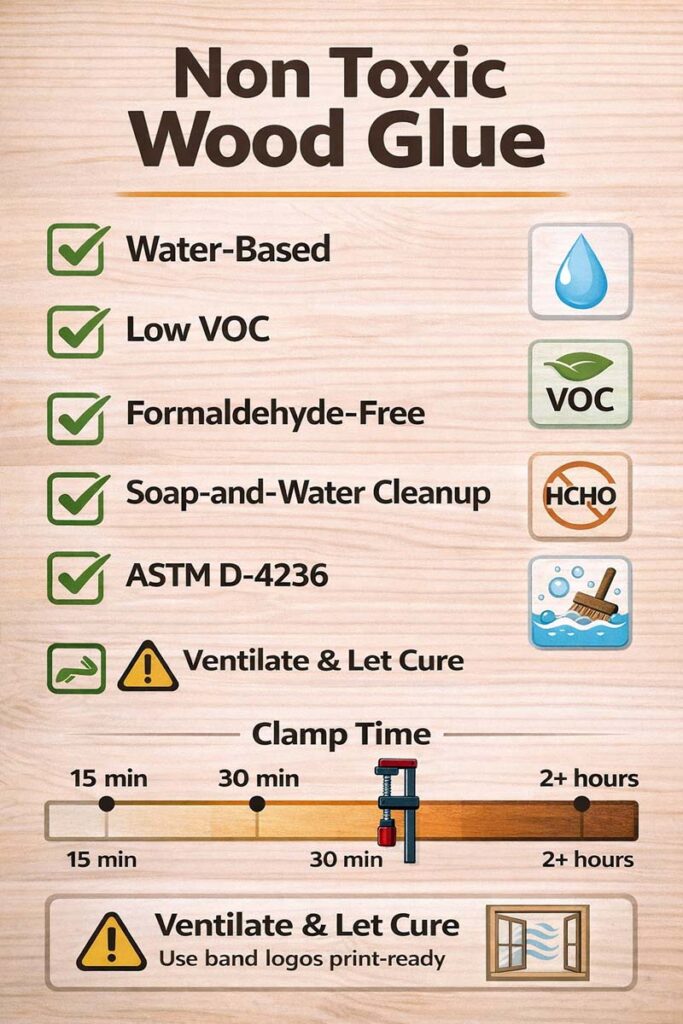

Step 2: Look for clear language on the label

The most helpful phrases are simple and direct:

- Water-based

- Low VOC / Zero VOC (when the brand states it clearly)

- Formaldehyde-free (when stated)

- Soap-and-water cleanup

Some brands also reference labeling standards like ASTM D-4236. It’s not a magic badge, but it can signal more responsible hazard labeling.

Step 3: Choose a glue type that fits your workflow

If you work slowly, longer open time helps. If you’re new to clamping, a forgiving glue is worth it. When clamp timing is fuzzy, this keeps you out of trouble: a simple clamp schedule for strong glue joints.

Non-toxic leaning wood glue types (what to use, and when)

PVA carpenter’s glue (yellow or white)

This is the workhorse for indoor projects. It’s typically water-based, low odor, and easy to clean up while wet. For most tray builds, cabinet parts, and furniture repairs, PVA is the practical starting point.

Best fit:

- Wood-to-wood joinery

- Edge-glued panels

- Indoor furniture and décor builds

Common limits:

- Not meant for plastic or metal

- Performance drops in cold shops

- Water exposure depends on the specific formula

If you want the basics without chemistry overload, this background helps: what PVA glue is and how does its works.

Acrylic/latex-style wood glues (often sold for specialty uses)

These are also often water-based and can work well for certain craft builds, laminations, and mixed-material projects. They vary a lot from brand to brand, so the data sheet matters more here.

Best fit:

- Specialty bonding where the label lists your materials

- Projects that benefit from a little flexibility

Common limits:

- Some struggle with oily woods

- Open time and tack feel can be unpredictable

If you’re bonding painted parts, don’t guess—test first. This explains the usual failure points: why glue can fail on painted surfaces.

Hide glue (traditional, repair-friendly, and often a good low-odor option)

Hide glue is valued because it’s reversible and repairable, which is a big deal for antiques and fine woodworking. Many people also like it when they’re trying to minimize modern chemical exposure.

Best fit:

- Repairs and restorations

- Projects you may want to disassemble later

- Fine joinery where reversibility matters

Common limits:

- Heat and moisture can weaken it

- Some forms have shorter working time

If you’re deciding between hide glue and PVA, this side-by-side comparison is useful: hide glue versus modern wood glue for repairs.

Polyurethane glue (strong, but usually not the first “non toxic” pick)

Polyurethane glues can handle moisture better, but they often come with stronger odor and stricter handling notes. They also expand as they cure, which can cause mess and joint issues if clamping is light.

If your top priority is lower odor indoors, this usually isn’t the first choice.

How to read labels like a woodworker (not like a marketer)

Waterproof vs water-resistant

Don’t lump these together. Some glues handle occasional splashes. Others are made for repeated wet exposure. If the label references a recognized rating system, take that more seriously than vague wording.

For kitchen builds, the glue choice is only part of the safety picture. Cured glue lines are typically stable, but they’re not a “food coating.” This clarifies the usual question: is cured wood glue considered food safe.

Work time, clamp time, and full cure

A glue can feel dry and still be weak inside the joint. Most glue failures come from moving on too soon.

Read the given below articles when you need clean timing:

- How long wood glue typically takes to dry

- How long to wait before sanding glue joints

- How long wood glue takes to set

“Low VOC” claims and SDS checks

If you’re sensitive to odor, look for clear VOC language and formaldehyde-free statements. When it matters, the SDS is where details usually live. If a brand is vague, I treat that as uncertainty, not reassurance.

Safe use that keeps the air cleaner (and the joint stronger)

This is the part most articles rush, but it matters.

Prep matters more than brand

- Dry-fit first, so you’re not scrambling during open time.

- Remove dust after sanding.

- Avoid oily contamination on the glue surfaces.

Apply enough glue to wet the surfaces

You want coverage, not puddles. Starved joints are common with beginners. This helps you dial it in: how much glue to apply for a strong bond.

Clamp evenly, then let it rest

Clamping should bring the joint together without squeezing out everything. If you’re unsure when to remove clamps, use this: how long to keep clamps on wood glue joints.

Clean squeeze-out while it’s still wet

A damp rag is usually enough for water-based glue. Once it cures, removal takes more care. If you’re dealing with dried glue, this keeps the wood safe: remove dried glue without damaging the surface.

Special notes for kids’ projects and kitchen builds

Kids’ builds

Choose low-odor, water-cleanup glue, supervise closely, and don’t let kids stress joints early. If glue gets on skin, skip harsh solvents. This is the safe approach: how to get wood glue off skin gently.

Kitchen items

Plan for full cure and a durable finish. Glue lines shouldn’t be treated as a food surface, even when cured. For finishes, people often ask about topcoats too. This answers one of the big ones: is polyurethane safe after it cures fully.

Storage and shelf life (so your glue doesn’t quietly fail)

Most water-based glues hate freezing and extreme heat. Keep the cap sealed, store it at moderate temperature, and don’t trust glue that looks separated, chunky, or stringy.

If you want a quick check for “is this still usable,” start here: signs wood glue has expired.

Common problems and quick fixes

“My glue didn’t hold”

This is usually one of these:

- Dusty surfaces

- Not enough glue coverage

- Weak or uneven clamping

- Joint moved before cure

If you’re deciding whether you need a different adhesive for a repair, these comparisons help: wood glue versus epoxy for tough repairs and wood glue versus construction adhesive for mixed jobs.

“The glue line won’t take stain”

Some glues resist stain and show up as pale lines. Prevent it by cleaning squeeze-out early and sanding correctly. This explains what’s happening: why some glue lines won’t accept stain.

FAQs on Non Toxic Wood Glue

Is wood glue toxic?

Some wood glues can irritate skin and lungs while wet. Many water-based carpenter’s glues are lower odor, but you still want basic ventilation and sensible handling.

How long does wood glue take to dry?

Dry time depends on glue type, temperature, wood moisture, and clamp pressure. Many joints set in hours, but full cure often takes longer. Use this reference: how long does wood glue take to set.

Does wood glue work on plastic?

Most wood glues are meant for wood-to-wood bonds. For plastic, you usually need a different adhesive type: can you use wood glue on plastic successfully.

Is wood glue waterproof?

Some formulas are waterproof, many are only water-resistant. Check the label for exterior ratings and don’t rely on vague marketing terms for outdoor builds.

How do you remove dried wood glue?

Mechanical removal is usually safest: careful scraping, sanding, and patience. Chemicals can damage wood or finishes. Here’s the safer method: how to remove wood glue without damaging wood.

Last Words

Non toxic wood glue is easiest to choose when you focus on glue type, clear labeling, and correct technique. Water-based PVA is the common low-odor choice for indoor woodworking. Hide glue can be excellent for repairable builds. Whatever you buy, prep the wood well, clamp evenly, and give the joint full cure time.