Best Waterproof Wood Glue 2026: 8 Top Picks for Strong, Wet-Safe Joints

Best waterproof wood glue is the difference between a patio chair that lasts years and one that pops apart after the first wet season. The trick is matching the glue to the water exposure, the joint fit, and how much working time you need. I’ll walk you through ratings (Type I/II and D3/D4), glue types, and the exact glue-up habits that keep joints solid.

Contents Here

- 1 Fast Review: The Top 10 Waterproof Wood Glue

- 2 Waterproof vs water-resistant wood glue

- 3 Glue families that actually hold up around water

- 4 The scorecard I use when comparing waterproof adhesives

- 5 Which waterproof wood glue fits your project

- 6 Reviews of the 8 Best Waterproof Wood Glue

- 6.1 Grizzly One Waterproof Wood Glue

- 6.2 West System 105A Epoxy Resin + 206

- 6.3 System Three T-88 Epoxy Adhesive

- 6.4 Titebond 1416 III Ultimate Waterproof Wood Glue

- 6.5 Franklin International 1412 Titebond-3 Glue

- 6.6 Gorilla Ultimate Waterproof Wood Glue

- 6.7 Loctite 1451588 Tan PL Premium Polyurethane Tube

- 6.8 Boncart Super Strong Waterproof Wood Glue

- 7 Buying guide: choose fast with these checks

- 8 How to get a waterproof wood glue joint step by step

- 9 Common waterproof-glue mistakes I see

- 10 Storage and shelf life: keep your glue working

- 11 FAQs on Waterproof Wood Glue

- 11.1 What’s the difference between waterproof and water-resistant wood glue?

- 11.2 What does ANSI/HPVA Type I mean, and is it truly waterproof?

- 11.3 How long should I clamp wood when using waterproof wood glue?

- 11.4 How long does waterproof wood glue take to fully cure before outdoor use?

- 11.5 Can I glue damp wood, or does the wood need to be completely dry?

- 11.6 Which glue works best for oily woods like teak or ipe—PVA, polyurethane, or epoxy?

- 11.7 Can I stain or paint over waterproof wood glue without blotching?

- 12 Final Reflections

Fast Review: The Top 10 Waterproof Wood Glue

- Grizzly One Wood Glue

- West System 105A Epoxy Resin

- System Three T-88 Epoxy Adhesive

- Titebond 1416 III Ultimate Wood Glue

- Franklin International 1412 Titebond-3 Wood Glue

- Gorilla Ultimate Waterproof Wood Glue

- Loctite 1451588 Tan PL Premium Polyurethane Tube

- Boncart Super Strong Wood Glue

Also read this if you need a reliable adhesive for repairing wooden chairs and tables.

Waterproof vs water-resistant wood glue

A lot of bottles use “waterproof” loosely. In real shop terms, water-resistant glues handle humidity and splashes. Waterproof-rated glues are built to survive much harsher water and heat cycles without the bond line letting go. That difference matters most on outdoor furniture, exterior trim, and anything that sees repeated wet-dry swings.

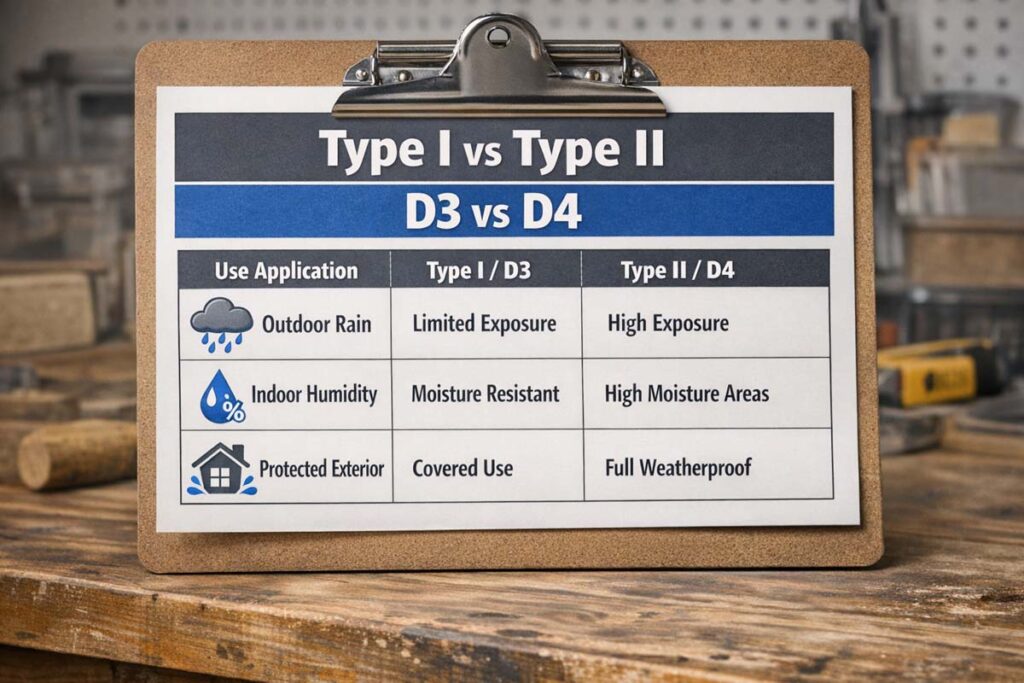

ANSI/HPVA Type I vs Type II ratings

If you’re buying in North America, Type ratings are a quick way to cut through marketing.

- Type I is the “tougher” category people mean when they say waterproof. It’s intended for severe water exposure.

- Type II is water-resistant. It’s often fine for kitchens, bathrooms, and protected outdoor pieces.

Type ratings aren’t magic, though. A sloppy joint or rushed clamp time can still fail.

EN 204 D3 vs D4 ratings

If you see D-ratings (common on European glues):

- D3 is water-resistant for interior damp conditions and protected exterior use.

- D4 is the higher-durability class meant for frequent moisture and exterior exposure, assuming the project design and finish make sense.

If your project will sit in the rain, you’re usually shopping in the Type I / D4 neighborhood, then confirming the glue type matches your needs.

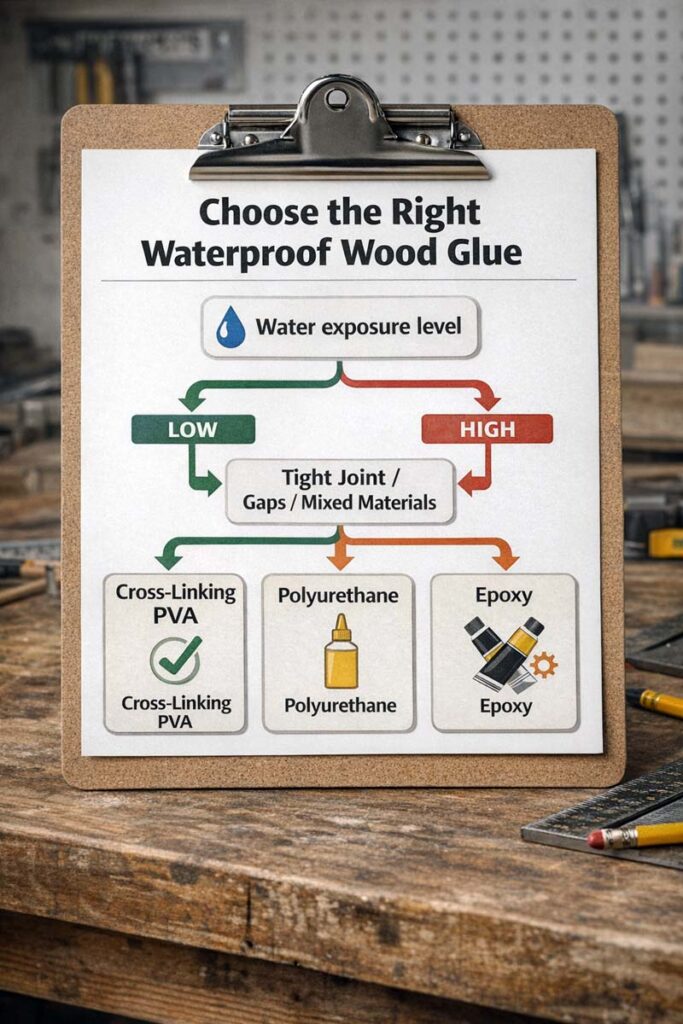

Glue families that actually hold up around water

Before you shop, it helps to understand what you’re buying. “Wood glue” can mean a few different chemistries, and they behave differently in wet conditions.

Cross-linking PVA for tight wood-to-wood joints

This is what most woodworkers reach for first because it’s easy to apply and cleans up with water while wet. The stronger “outdoor” versions are modified so they cross-link as they cure. They’re best when your joinery is clean and tight, like edge glues, mortise-and-tenon, and well-fit dowels.

If you want a quick refresher on what this category is, here’s my plain-language breakdown of what PVA wood glue really is and when it excels.

Polyurethane for mixed materials and stubborn repairs

Polyurethane glues cure with moisture and often foam as they set. That foaming can help fill tiny voids, but it’s not structural foam. You still need solid clamping pressure to bring wood fibers into contact. This category is handy when you’re bonding wood to non-wood surfaces or dealing with slightly less-than-perfect fits.

If you’re comparing brands in this lane, you’ll like this Titebond vs Gorilla comparison for everyday shop work.

Epoxy and resorcinol for marine-level exposure

When the job involves real gaps, oily woods, or constant wet exposure, epoxy-style systems make sense. They’re two-part, they cure by chemical reaction, and they can be incredibly reliable when mixed and applied correctly. Resorcinol is an old-school, proven option in marine work, but it’s fussier about joint fit and clamping.

If you’re on the fence, read wood glue versus epoxy for wet-area repairs before you commit.

Construction adhesives and marine sealants

Construction adhesives and marine sealants can be great for outdoor assemblies, especially where movement and flexibility matter. They’re not always the best choice for fine joinery, though, because they’re thicker and can prevent tight wood-to-wood contact.

This helps clarify the tradeoffs: when a construction adhesive makes more sense than wood glue.

The scorecard I use when comparing waterproof adhesives

When people ask me “what’s the best,” I don’t start with a brand. I start with a short scorecard that matches how projects fail in real life.

- Water rating: Type I / Type II or D3 / D4, where applicable.

- Glue family: PVA, polyurethane, epoxy/resorcinol, or construction adhesive.

- Open time: Can you assemble without rushing and starving the joint?

- Clamp time and full cure: When can clamps come off, and when is it truly ready?

- Gap behavior: Tight-joint glue or true gap filler?

- Cleanup and finishing: Will squeeze-out ruin stain or paint?

- Temperature tolerance: Cold shop performance matters more than people think.

- Safety and odor: Ventilation needs, skin contact, and food-contact concerns.

If you want the timing details in one place, these two guides save a lot of guesswork: how long to clamp wood glue for a strong bond and how long wood glue takes to fully cure.

Which waterproof wood glue fits your project

This is the section where I’ll add product reviews next, once you send your product names and details. For now, use these as “project lanes” so you pick the right glue type before you pick a bottle.

Outdoor furniture and patio builds

For chairs, benches, planters, and outdoor trays, you want a glue that’s rated for exterior exposure and works well on tight-fitting joinery. Most of the time that points to a Type I / D4-style wood glue in the cross-linking PVA category, unless you have gaps or mixed materials.

Also remember: glue is only one layer of defense outdoors. A good finish matters too, especially on end grain. If you’re building serving pieces or trays, this guide helps: how to seal a wooden serving tray so it stays protected.

Kitchen and bathroom woodwork

Cabinet repairs, vanity trim, and humid-room shelving often do fine with water-resistant options if the joint is protected and you’re not dealing with standing water. The big wins here are clean glue lines, decent open time, and a glue that won’t fight your finish.

If staining is part of the plan, don’t skip this: is wood glue stainable without leaving light patches?

Boats, docks, and constant wet exposure

If the project could see prolonged soaking, repeated heavy wetting, or true marine conditions, this is where epoxy/resorcinol-style systems earn their keep. The goal becomes reliable bonding even when wood movement and moisture are working against you.

Quick repairs, odd materials, and imperfect joints

When you’re repairing something that’s already cracked, slightly warped, or has paint you can’t fully remove, polyurethane glues or construction adhesives may be practical. The tradeoff is cleanup, squeeze-out, and finishing.

If the surface is painted, you’ll want this context first: does wood glue work on painted wood or do you need a different approach?

Reviews of the 8 Best Waterproof Wood Glue

Grizzly One Waterproof Wood Glue

Waterproof polyurethane wood glue for oily woods

Grizzly One is a ready-to-use polyurethane that shines when wood glue usually struggles—oily/exotic species and even wet stone (as long as one surface is porous). The long working time is handy for complex assemblies, but expect typical polyurethane behavior: expansion, squeeze-out, and more cleanup attention.

$125 at AmazonSpecifications

- Type: Polyurethane (liquid), waterproof

- Working time: 25–35 min

- Clamp time: 2–5 hrs

- Full cure: ~12 hrs

- Viscosity: 7500 cps

Pros

- Bonds oily woods well

- Strong for interior/exterior

- Stainable and sands easily

Cons

- Expands as it cures

- Longer clamp time than PVAs

West System 105A Epoxy Resin + 206

Marine-grade waterproof epoxy for repairs

This bundle is built for serious water exposure—boat work, structural repairs, and bonding where gaps or tricky fibers show up. The calibrated pumps reduce mixing mistakes, while the slow hardener gives you breathing room in warm shops. Plan ahead: it reaches max strength over days, not hours.

$104.47 at AmazonSpecifications

- Type: 2-part epoxy (5:1 mix)

- Pot life (72°F): 20–25 min

- Solid state: 10–15 hrs

- Max strength: 1–4 days (full cure up to 4 days)

- Tensile strength: 7318.6 psi

Pros

- Excellent wet-out on wood fiber

- Great for marine and bonding jobs

- Pumps simplify accurate mixing

Cons

- Longer cure window

- Mixing required every time

System Three T-88 Epoxy Adhesive

Structural waterproof epoxy adhesive for woodworking

T-88 is a structural epoxy that’s at home in joinery, repairs, and mixed-material bonds (wood, metal, composites). It cures to a clear amber look and stays dependable in wet conditions. The biggest success factor is clamping technique—too much pressure can starve the joint.

$34.95 at AmazonSpecifications

- Type: 2-part epoxy, waterproof

- Cure (good properties): ~16 hrs at 70°F

- Full cure: ~72 hrs

- Viscosity: Moderate

- Tensile strength: 7000 psi

Pros

- Strong structural bond

- Works on multiple materials

- Good for small gaps and repairs

Cons

- Slower full cure

- Requires careful mixing/clamping

Titebond 1416 III Ultimate Waterproof Wood Glue

Type I waterproof PVA for outdoor furniture

This is the classic “grab it and build” choice for tight-fitting outdoor joinery. It cleans with water, sands cleanly, and meets ANSI/HPVA Type I for water resistance. It’s also approved for indirect food contact, which is handy for cutting boards—just remember it’s not for continuous submersion.

$35.89 at AmazonSpecifications

- Type: PVA wood glue, waterproof

- Standard: ANSI/HPVA Type I

- Full cure: 24 hrs

- Viscosity: 4,200 cps

- Tensile strength: 1,750 psi

Pros

- Easy cleanup and sanding

- Great open time and tack

- Food-contact friendly (indirect)

Cons

- Not for below-waterline use

- Needs temps above 47°F

Franklin International 1412 Titebond-3 Glue

Small-bottle waterproof wood glue for quick jobs

If you want the Titebond III performance in a smaller size, this one fits the bill for repairs, trim, and occasional woodworking. You still get Type I water resistance, strong tack, and water cleanup. Best results come from tight joints and proper clamping—don’t rely on glue alone to fix bad fit.

$5.68 at AmazonSpecifications

- Type: PVA wood glue, waterproof

- Standard: ANSI/HPVA Type I

- Full cure: 24 hrs

- Color: Tan

- Size noted: 4 oz (small format)

Pros

- Easy for small projects

- Strong, sandable bond

- Works indoors/outdoors

Cons

- Not ideal for big glue-ups

- Not for continuous submersion

Gorilla Ultimate Waterproof Wood Glue

Outdoor-safe waterproof PVA with longer working time

This is a waterproof PVA aimed at indoor/outdoor work where you want a clean bond line and a bit more working time. It dries a natural tan, stays sandable/paintable, and doesn’t foam like polyurethane. It’s a good fit for furniture, edging, and general repairs in changing weather.

$11.32 at AmazonSpecifications

- Type: PVA, waterproof

- Standard: ANSI/HPVA Type I

- Working time: ~15 min

- Full cure: 24 hrs

- Viscosity: Low

Pros

- No foaming, cleaner finish

- Handles sun and temperature swings

- Easy soap-and-water cleanup

Cons

- Not a true gap-filler

- Needs solid clamping on joints

Loctite 1451588 Tan PL Premium Polyurethane Tube

Waterproof polyurethane construction adhesive for tough materials

PL Premium is more “construction adhesive” than fine-joinery glue. It’s built for grab power and bonding wood to tough surfaces like masonry, stone, PVC trim, and metal—indoors or out. Use it when precision joinery isn’t the goal and you need a thick, durable adhesive line.

$20.03 at AmazonSpecifications

- Type: 100% polyurethane, waterproof

- Format: 4 oz tube (pack of 2)

- Viscosity: Medium to high

- Compatible: wood, concrete, stone, brick, PVC trim, more

- Noted: VOC compliant, repositionable

Pros

- Bonds many materials well

- Strong grab for installs/repairs

- Works inside and outside

Cons

- Thicker bead can hurt tight joinery

- Cleanup is tougher than PVAs

Boncart Super Strong Waterproof Wood Glue

Clear-drying waterproof wood glue for crafts and repairs

Boncart targets clean-looking results—dries clear, includes precision applicators, and clamps fast enough for small furniture fixes and crafts. It’s a practical option for hobby work and indoor projects, plus light outdoor use. For heavy exterior joints, confirm real-world performance on a test piece first.

$9.99 at AmazonSpecifications

- Type: PVA, waterproof

- Clamp time: 20–30 min

- Full cure: 24 hrs

- Viscosity: Low

- Features: Precision nozzle + brushes, non-toxic claim

Pros

- Clear glue line looks neat

- Easy, controlled application

- Quick clamp window for small jobs

Cons

- No Type I/D4 rating listed

- Not a gap-filling adhesive

Buying guide: choose fast with these checks

Water exposure, UV, and temperature swings

Ask one blunt question: “Will this joint see rain, standing water, or freeze-thaw cycles?” If yes, you need a higher water rating and a glue family that matches the stress. UV doesn’t usually destroy the glue line directly, but UV and heat destroy finishes, and water gets in after that.

Open time, clamp time, and full cure

Open time is how long you can work before the glue starts grabbing. Clamp time is when it can hold shape. Full cure is when it’s ready for real stress.

If you’ve ever sanded too soon and watched a glue line sink later, you’ve felt this mistake. Here’s the timing you need: how long wood glue should dry before sanding.

Joint fit and real gap filling

Most traditional wood glues are happiest when the joint fits well. If your joint has gaps, you’re often better off fixing the fit first. When that’s not possible, move toward a true gap-filling system instead of hoping foaming glue will “build structure.”

This also ties into glue quantity. Too little starves the bond, and too much makes finishing miserable. Use this as a sanity check: how much wood glue to use without weakening the joint.

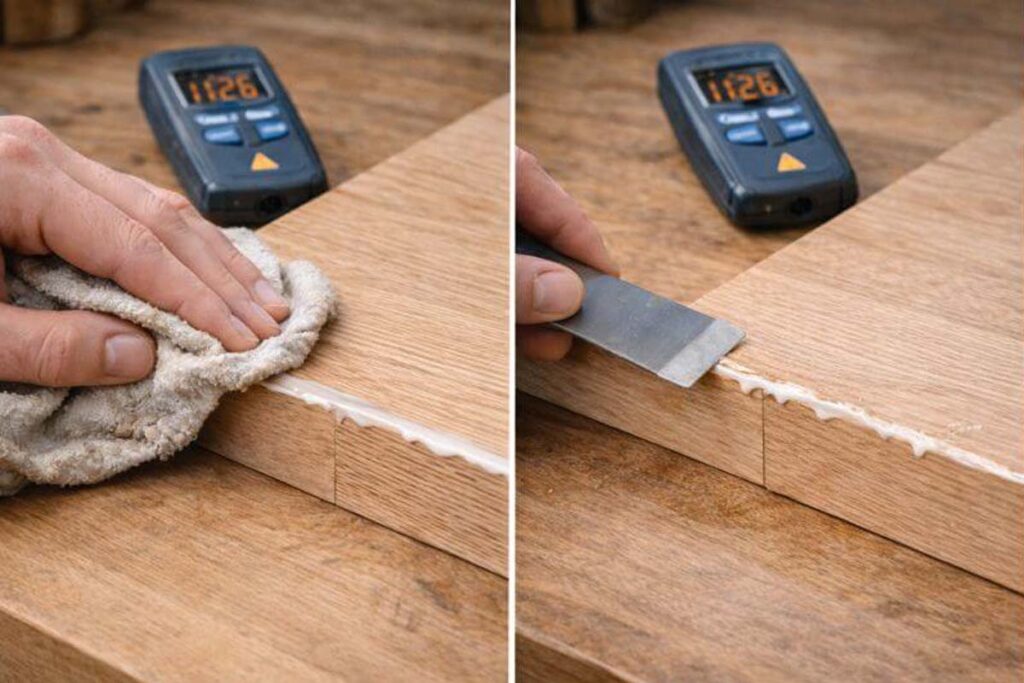

Cleanup and finishing: stain, paint, and sanding

Squeeze-out that dries on the surface will block stain and telegraph through paint. The best habit is wiping while wet (when the glue allows it) or waiting until it gels, then scraping clean.

If you’ve already got a mess, this helps you fix it without gouging the project: remove dried glue without damaging wood fibers.

Safety, odor, and food-contact projects

Most wood glues are unpleasant on skin and worse in your lungs when you’re working in a closed room. Wear gloves when it makes sense, ventilate, and read the label for cleanup directions.

For cutting boards and serving pieces, people ask about safety constantly. This covers the “when cured” reality: is wood glue food safe once it’s fully cured?

If you’re also finishing with polyurethane, this matters too: is polyurethane food safe when cured.

How to get a waterproof wood glue joint step by step

A good glue joint is boring. That’s the goal.

Prep the wood

- Let the wood acclimate to the space you’re building in.

- Dry-fit the joint so clamps go on without panic.

- Remove dust and oils from the bond surfaces.

- For oily woods, a quick solvent wipe can help, then glue promptly.

If the wood is soaking wet, pause. Even moisture-curing glues don’t solve bad conditions.

Apply glue and clamp correctly

- Spread an even film that covers the full surface.

- Bring parts together and clamp until you see a thin, consistent squeeze-out.

- Use enough pressure to close the joint, not crush the wood.

- Leave clamps on for the time that matches your glue category and shop temperature.

If you want a clean standard to follow, use the clamp-time guide here: how long should wood glue dry before removing clamps.

Cure, scrape, sand, and finish

- Let the glue reach full strength before heavy stress.

- Scrape squeeze-out clean, then sand once the bond is ready.

- Apply an appropriate finish for the environment.

On outdoor builds, finishing is part of the waterproof plan, not an optional step.

Common waterproof-glue mistakes I see

- Using the wrong rating for the environment: A damp basement shelf and a rain-soaked bench aren’t the same job.

- Gluing cold: Many glues struggle in low temperatures. Warm the shop or choose a system suited to it.

- Thinking foam equals strength: Foaming glues can be useful, but the foam itself isn’t a structural substitute.

- Rushing sanding and finishing: If you sand too early, glue lines can shift and telegraph through finish.

- Assuming old glue is “probably fine”: Expired glue can look normal and still bond poorly. If you’re unsure, check this: does wood glue expire in the bottle.

Storage and shelf life: keep your glue working

Store glue where it won’t freeze or bake. Keep the cap clean so it seals tight. If a bottle has been frozen, separated badly, or smells off, don’t play on it for an outdoor build.

If you’re running a small shop shelf, rotate bottles like you rotate finish. Buy what you’ll use in a reasonable window, and label the purchase month with a marker.

FAQs on Waterproof Wood Glue

What’s the difference between waterproof and water-resistant wood glue?

Water-resistant glue handles humidity, spills, and occasional wetting. Waterproof-rated glue is designed to survive harsher soak-and-heat cycles without the bond line failing, which matters most for outdoor projects.

What does ANSI/HPVA Type I mean, and is it truly waterproof?

ANSI/HPVA Type I is a performance rating tied to tougher water-and-heat testing than Type II. It’s “waterproof” in testing terms, but real-world success still depends on tight joinery, clamping, and proper cure time.

How long should I clamp wood when using waterproof wood glue?

Clamp time depends on the glue type, temperature, and joint fit. As a practical rule, most exterior PVAs need at least 30–60 minutes clamped, while polyurethane and epoxy often need longer to set.

How long does waterproof wood glue take to fully cure before outdoor use?

Most waterproof PVAs reach workable strength in a few hours but need about 24 hours for a full cure. Polyurethane and epoxy can take 24–72 hours, especially in cooler or humid conditions.

Can I glue damp wood, or does the wood need to be completely dry?

Aim for dry, stable wood for best strength. Slight surface dampness can be okay with some glues, but wet wood risks weak bonds and joint movement as it dries, especially outdoors.

Which glue works best for oily woods like teak or ipe—PVA, polyurethane, or epoxy?

Epoxy is usually the safest bet on oily woods because it bonds well when surfaces are cleaned properly. PVAs can struggle, and polyurethane can work, but it’s less forgiving if the fit is poor.

Can I stain or paint over waterproof wood glue without blotching?

Yes—if you prevent dried squeeze-out from sealing the grain. Wipe fresh glue carefully or let it gel and scrape clean, then sand lightly. Always test stain on a scrap joint first.

Final Reflections

The best waterproof wood glue for your project depends on water exposure, joint fit, and how you work. Tight joinery usually favors a high-rated exterior wood glue in the PVA family. Mixed materials and tricky repairs may steer you to polyurethane or construction adhesive. Constant wet exposure is where epoxy-style systems shine. Pick the glue, then glue it right.