What Is PVA Wood Glue? 5 Essential Uses, Limits, and Best Practices

PVA wood glue is a water-based polyvinyl acetate adhesive that bonds wood by soaking into the fibers and drying into a strong, durable glue line. It’s the common “carpenter’s glue” you see in white or yellow bottles, and it works by soaking into wood fibers and drying into a tough plastic film. Pick the right type, use good clamping, and it’s hard to beat.

Contents Here

- 1 What is PVA wood glue?

- 2 How PVA wood glue bonds wood

- 3 Types of PVA wood glue you’ll see on shelves

- 4 Best uses for PVA wood glue in woodworking

- 5 When NOT to use PVA wood glue

- 6 How to use PVA wood glue correctly

- 7 Safety, toxicity, and food-contact questions

- 8 Storage, shelf life, and troubleshooting

- 9 PVA glue vs other common woodworking adhesives

- 10 FAQs on PVA wood glue

- 10.1 Is PVA wood glue waterproof or just water-resistant?

- 10.2 What’s the difference between white glue and yellow carpenter’s glue?

- 10.3 How long should I clamp a PVA glue joint?

- 10.4 Can I use PVA on MDF, plywood, veneer, or particleboard?

- 10.5 Can I thin PVA glue with water?

- 10.6 Will PVA glue work on metal or plastic?

- 10.7 Is PVA wood glue safe for cutting boards?

- 11 Conclusion

What is PVA wood glue?

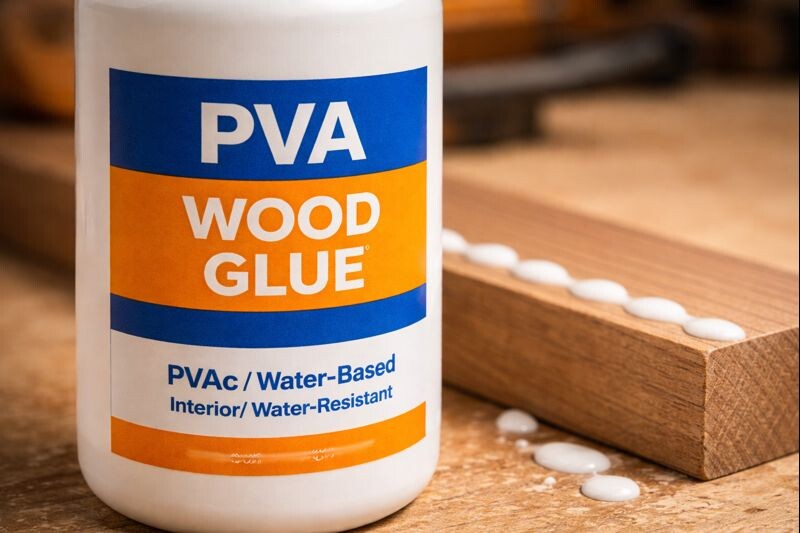

PVA wood glue (eg,Gorilla Ultimate Waterproof PVA Wood Glue) is typically made from polyvinyl acetate (often shortened as PVAc), suspended in water as an emulsion. When you spread it on wood, the water begins to leave the glue line, and the remaining polymer forms a strong bond inside the surface fibers.

In everyday terms, PVA is the family of glues most people mean when they say “wood glue.” It’s popular because it’s easy to use, cleans up with water while wet, and gives strong joints when the wood fits well.

What does PVA stand for, and why PVAc shows up on labels?

You’ll see “PVA” used casually, but the polymer behind many wood glues is PVAc (polyvinyl acetate). Some labels use the chemical name, some use “PVA,” and plenty just say “wood glue.”

Here’s the practical takeaway: if the bottle says carpenter’s glue, wood glue, or PVA, you’re almost always dealing with a PVAc/PVA-style adhesive meant for porous materials like wood, paper, and some fabrics.

How PVA wood glue bonds wood

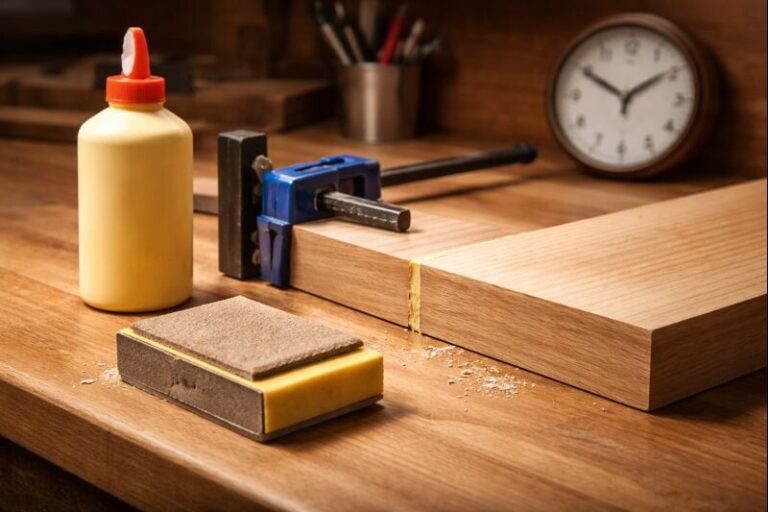

PVA works best when two things are true: the wood surfaces meet tightly, and the glue has time under pressure.

When you clamp a properly fitted joint, the glue spreads into a thin film and penetrates the wood’s surface fibers. As it dries, that film locks into the grain structure. That’s why a well-made PVA joint often fails in the wood next to the glue line, not in the glue itself.

One important limitation: PVA is not a gap filler. If you’re trying to bridge a sloppy joint, you may get a weak, rubbery glue line that breaks later.

Types of PVA wood glue you’ll see on shelves

Most confusion comes from seeing different colors and claims on bottles. The core idea is simple: there’s basic interior PVA, and there are modified versions designed for moisture resistance, longer working time, or faster grab.

White PVA vs yellow “carpenter’s” glue

White PVA is the classic school-and-craft glue style. It’s useful for light woodworking, crafts, and porous materials. Many woodworkers still use it for smaller jobs where ultimate water resistance isn’t needed.

Yellow carpenter’s glue is usually an “aliphatic resin” or modified PVA formulation designed for woodworking. It tends to grab a little faster, sand more cleanly, and is commonly chosen for furniture and cabinet work.

Neither color automatically means “stronger.” Joint fit, clamping, and correct drying time matter more than the shade of the glue.

Water resistance ratings, and what “indoor vs outdoor” really means

You’ll see bottles marketed as interior, water-resistant, or waterproof. Some woodworking glues are also sold using Type ratings (often Type I, II, or III), depending on testing standards and formulation.

Instead of memorizing ratings, use this rule that keeps you out of trouble:

- Interior builds (dry rooms, decor, shelving): standard PVA is usually fine.

- Occasional moisture (kitchen items, bathrooms, utility spaces): look for a glue specifically labeled water-resistant.

- Outdoor exposure (rain, sun, seasonal swings): don’t assume a “stronger” PVA makes it an exterior miracle. Outdoor furniture does better when the design sheds water and you protect it with a proper finish.

If your project will live around spills or humidity, it also helps to seal it correctly. A quick reference is this article on how to seal a wooden serving tray for everyday use.

Best uses for PVA wood glue in woodworking

PVA shines when the joint surfaces match and you can clamp them firmly. These are the sweet spots:

- Edge-glued panels (table tops, tray bottoms, wide boards made from strips)

- Tight joinery like dados, rabbets, tongues, and grooves

- Furniture and cabinet assembly where parts seat cleanly

- General repairs when broken parts mate back together without gaps

- Some veneering and laminations, when you choose a glue with suitable open time and you press evenly

If you’re choosing glue for a chair, stool, or anything that takes racking stress, it’s worth reading this comparison of glue options that hold up in real furniture repairs.

When NOT to use PVA wood glue

PVA is a workhorse, but it isn’t the answer for every job.

Avoid it when you have:

- Big gaps or poorly fitted joints (it doesn’t build strength in thick glue lines)

- Non-porous surfaces like metal, glass, many plastics, or oily woods without prep

- Constant water exposure (think submerged use or long-term saturation)

- High heat situations where the glue line can soften over time

- Places where creep matters, like parts under steady load that might slowly shift

If you’re trying to bond unlike materials or fill voids, epoxy is usually the better category to consider.

How to use PVA wood glue correctly

This is the process I follow when I want a glue-up to stay put for years.

- Dry-fit the joint first. If it doesn’t seat cleanly without glue, fix the fit.

- Prep the surfaces. Freshly cut or sanded surfaces bond best. Remove dust.

- Apply a thin, even coat. A small bead spread out beats a thick blob.

- Coat both sides when needed. End grain and thirsty woods often benefit from a light sizing coat.

- Assemble and “rub” the joint. A small wiggle helps wet both surfaces fully.

- Clamp with steady pressure. You want a tight joint, not crushed wood fibers.

- Clean squeeze-out at the right time. See the cleanup notes below.

- Wait for full strength before stressing the joint. “Feels dry” is not “fully cured.”

Clamping, open time, dry time, and full cure

Woodworkers use a few different timing terms, and they’re not interchangeable:

- Open time is how long you can work before the glue starts to skin over.

- Clamp time is how long the joint should stay under pressure.

- Full cure is when the glue reaches its maximum strength.

If you want a clear breakdown for planning a project timeline, these two references help a lot:

- How long does it take for wood glue to dry under normal shop conditions

- How long for wood glue to fully cure before heavy use

Temperature and humidity matter. Cold shops slow drying. Very dry air can shorten open time and make rushed glue-ups harder.

Cleanup and squeeze-out control

Squeeze-out is normal. What matters is how you handle it.

- While wet: a lightly damp rag can wipe it, but don’t smear glue into the grain. Smearing can cause blotchy stain later.

- After it gels: this is my favorite moment. The glue turns rubbery, and you can slice it off cleanly with a chisel.

- After it cures: scraping works, but it takes more care to avoid gouging.

A simple habit that prevents finishing headaches is to use a bright light at a low angle and inspect the surface before stain or clear coat. Glue you can’t see now will show up later.

Safety, toxicity, and food-contact questions

Most PVA woodworking glues are water-based and low in odor. Basic common-sense shop habits still apply: avoid getting it in your eyes, don’t eat it, and wash it off skin before it dries.

Food-contact is where people get tripped up. Some glues are marketed as non-toxic after curing, but formulas and certifications vary by brand and product line. If you’re making a cutting board, utensil, or serving item, check the manufacturer’s wording for that specific bottle.

It can also help to think about the finish you’re putting on top. If you’re comparing finishing choices, this piece on whether cured polyurethane is food safe for common household projects is a useful companion read.

Storage, shelf life, and troubleshooting

PVA glue lasts longer when you treat it like a product that hates extremes.

- Store it with the cap tight.

- Keep it from freezing. Freeze-thaw cycles can ruin the emulsion.

- Don’t leave it baking in a hot car or unheated shed.

If the glue turns chunky, stringy, or smells off, don’t trust it on a project you care about.

Common problems and what usually caused them

The joint snapped clean on the glue line: Often a fit issue, not enough clamping, oily/dusty surfaces, or glue that skinned over before assembly.

The joint slid around during clamping: Too much glue, clamps tightening unevenly, or not enough friction in the joint. Lightly snug clamps first, then tighten evenly.

The glue line shows under stain or paint: Glue residue was left on the surface. Scrape squeeze-out instead of smearing it, and do a final inspection before finishing.

How to remove dried PVA glue from wood

For cured glue blobs, start with a sharp scraper or chisel and work carefully with the grain. If the glue is stubborn, gentle heat can soften it slightly, but go slow and avoid scorching the wood. Sanding is fine after scraping, but sanding alone can spread glue into pores and make finishing worse.

If you’re in a hurry for a glue-up to stop feeling tacky, this guide on ways to make glue dry faster without ruining the joint is the safer approach than blasting everything with high heat.

PVA glue vs other common woodworking adhesives

PVA is the “daily driver,” but other glues earn their place.

Epoxy: Best when you need gap filling, bonding odd materials, or working around less-than-perfect fits. It’s slower and messier, but strong in thick sections.

Polyurethane glue: Moisture-cures and can foam as it reacts. It can bond some materials PVA won’t, but the foaming isn’t structural by itself. Clamp well.

Hide glue: Traditional, reversible with heat and moisture, and helpful for repairs where you might want to take the joint apart later.

CA (super glue): Fast and handy for small fixes, but it’s usually brittle compared to a proper wood glue joint.

If your project is classic wood-to-wood joinery with tight parts, PVA stays hard to beat.

FAQs on PVA wood glue

Is PVA wood glue waterproof or just water-resistant?

Many PVA-based glues are water-resistant rather than truly waterproof, and “waterproof” claims depend on the product and standard used. If the project is outdoors or regularly wet, pick a glue labeled for that use and design the build to shed water.

What’s the difference between white glue and yellow carpenter’s glue?

White glue is a basic PVA commonly used for crafts and light duty. Yellow carpenter’s glue is typically a modified formulation aimed at woodworking, often with a bit faster grab and better sanding behavior. Both can be strong when the joint fits well.

How long should I clamp a PVA glue joint?

Clamp time varies by product, temperature, and joint type, but the joint should stay clamped until it’s stable and the glue has set. For planning, check how long wood glue takes to set before you move the clamps, then allow full cure time before heavy stress.

Can I use PVA on MDF, plywood, veneer, or particleboard?

Yes, PVA is commonly used on wood composites because they’re porous. The key is even pressure and good surface contact, especially with veneer and laminations where uneven clamping can cause bubbles or dry spots.

Can I thin PVA glue with water?

Sometimes, but it depends on the job. Light thinning can help for sizing end grain or certain craft uses, but too much water can weaken the glue line. When in doubt, use the glue as intended and focus on spreading a thinner, even coat instead.

Will PVA glue work on metal or plastic?

Usually not well. PVA prefers porous materials. For metal, glass, or many plastics, you’ll typically get better results with epoxy or a specialty adhesive designed for those surfaces.

Is PVA wood glue safe for cutting boards?

Some products are considered non-toxic after curing, but you should rely on the manufacturer’s statement for that exact glue. If it’s a gift or something you’ll use daily, it’s worth choosing a glue and finish that clearly match food-contact expectations.

Conclusion

PVA wood glue is a dependable, wood-friendly adhesive that works best with tight joints and good clamping. Choose the bottle that matches your environment, give it the time it needs to set and cure, and keep squeeze-out from spoiling your finish. When the fit is right, a simple PVA glue-up can outlast the piece itself.