What Is Polyurethane Glue? 7 Powerful Uses Woodworkers Trust

Polyurethane glue is a moisture-activated adhesive that cures into a hard, durable plastic-like bond and expands slightly as it sets. Many “original” polyurethane glues also foam and expand while curing, which helps them bond uneven surfaces but can make a mess if you use too much.

Polyurethane glue earns its keep when you need one glue to grab a mix of materials (wood + metal, wood + stone, etc.) and you can clamp the joint tight while it cures.

Contents Here

What is polyurethane glue made of?

Polyurethane glue is typically made from isocyanate-terminated polyurethane prepolymers (often based on aromatic polyisocyanates and MDI isomers), plus small amounts of additives that control flow, shelf life, and cure behavior. Safety Data Sheets commonly list aromatic polyisocyanate prepolymer and MDI (methylene diphenyl diisocyanate) variants as key components.

What that means at the bench

- The bottle contains reactive resin, not a “drying” glue. It cures by chemistry, not evaporation.

- Moisture triggers the reaction. Humidity, damp wood fibers, or a misted surface starts cure.

- Isocyanates drive performance—and safety rules. Isocyanates can irritate skin and airways and can cause sensitization/asthma in some exposures. Gloves and ventilation aren’t optional.

If you’re comparing glue families (PVA vs PU vs epoxy), this is a useful companion read: wood glue vs epoxy for repairs.

How does polyurethane glue work when it cures?

Polyurethane glue cures when isocyanate-ended resin reacts with moisture, creating a hardened polymer and releasing gas that causes foaming/expansion.

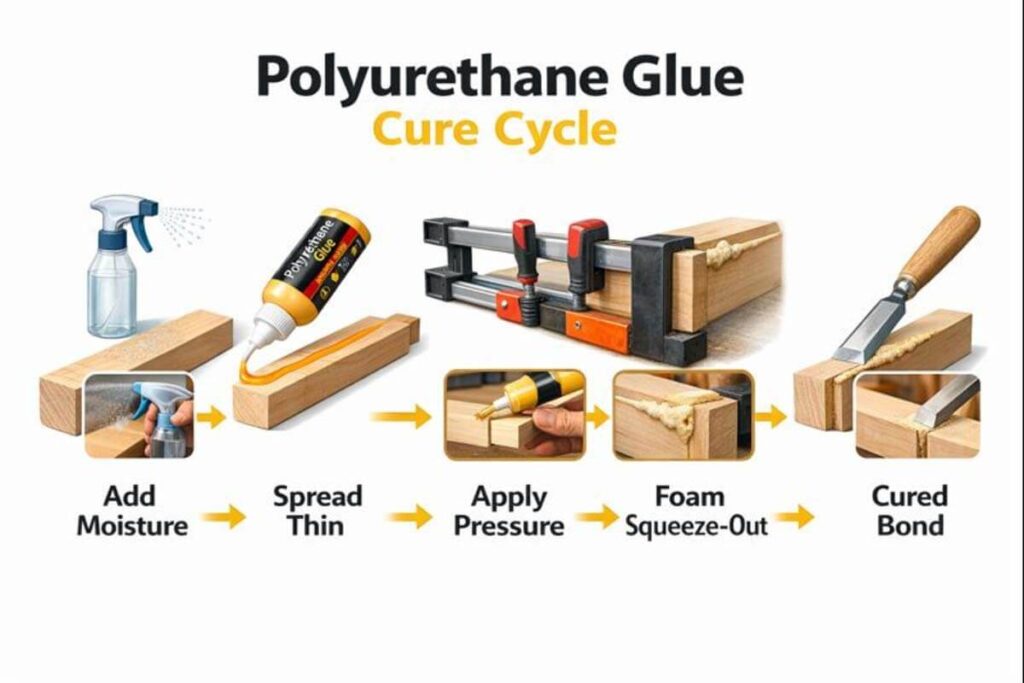

Here’s the cure cycle in plain shop terms:

- You add (or rely on) moisture. A light mist on one surface kick-starts the reaction on dry stock.

- The glue wets the surfaces. It creeps into pores and scratches better than many water-based glues.

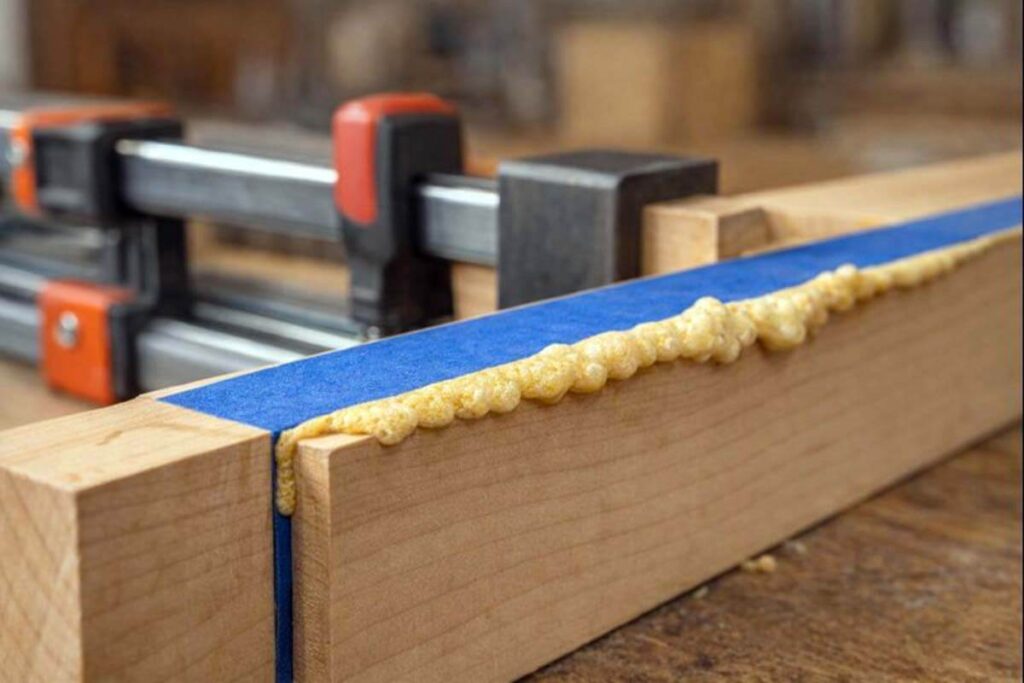

- It releases carbon dioxide. That gas creates the familiar foam expansion.

- The polymer hardens into a plastic-like solid. The bond reaches handling strength after a clamp window, then continues curing to full strength.

- The foam isn’t “magic gap fill.” The expanding foam can bridge small irregularities, but tight joinery still produces the strongest bond.

Practical takeaway: Treat PU glue like a “thin-film” adhesive that needs pressure—not like spray foam that replaces joinery.

What is polyurethane glue used for?

Polyurethane glue is used for bonding wood to dissimilar materials and for assemblies that need water resistance—especially when you can clamp the joint well. Manufacturers commonly market it for wood plus materials like stone, metal, ceramic, glass, and some plastics (with exceptions).

Common shop uses

- Wood-to-metal hardware repairs

- Scuff sand metal, degrease, and clamp hard until cure.

- Example: tray handles, brackets, hanger tabs (avoid food-contact surfaces).

- Outdoor and damp-location assemblies

- Use it on projects exposed to splashes or humidity swings.

- If your main goal is “waterproof wood glue,” compare options here: best waterproof wood glue for woodworking.

- Bonding irregular or porous-to-nonporous pairs

- Stone/wood, ceramic/wood, wood/painted surfaces (prep matters).

- Repairs where a little expansion helps coverage

- The foam can help contact uneven fibers, but it still needs clamping pressure to avoid pushing parts apart.

Materials you should not assume it bonds

Some polyurethane glues do not recommend use on polyethylene (PE), polypropylene (PP), or oily/rubbery materials with plasticizers. Test first, especially on mystery plastics.

If you’re gluing painted parts, this may help your decision: does wood glue stick to paint?

When should you use polyurethane glue?

You should use polyurethane glue when the job needs moisture-activated cure, good grip on mixed materials, and you can apply strong clamping pressure for the full clamp window.

My “reach for PU glue” checklist

- Ask: is this a mixed-material bond?

- If it’s wood-to-wood with tight joinery, I usually reach for PVA first. (PU works, but it’s rarely the easiest.)

- Ask: will the project see water or temperature swings?

- PU glues are often marketed as waterproof and indoor/outdoor capable.

- Ask: can I clamp it firmly without the parts creeping?

- PU glue expands while curing, so weak clamping invites misalignment.

- Ask: do I need easy cleanup?

- PU glue does not clean up like PVA. Wipe squeeze-out early, protect surfaces, and plan your cleanup.

- Ask: is there any chance of food contact?

- Many PU glue brands do not recommend food contact even after cure. For serving trays, keep glue lines away from food zones and choose finishes carefully.

Related: is polyurethane food safe when cured? and is wood glue food safe?

How do you use polyurethane glue correctly?

You use polyurethane glue correctly by prepping the surfaces, adding light moisture, applying a thin film, and clamping long enough to prevent foam from forcing the joint open.

Step-by-step application (shop method)

- Dry fit the joint. The best bonds come from tight contact, even with PU glue.

- Prep both surfaces. Remove dust, oils, wax, and loose fibers. Scuff-sand smooth metal/plastic for tooth.

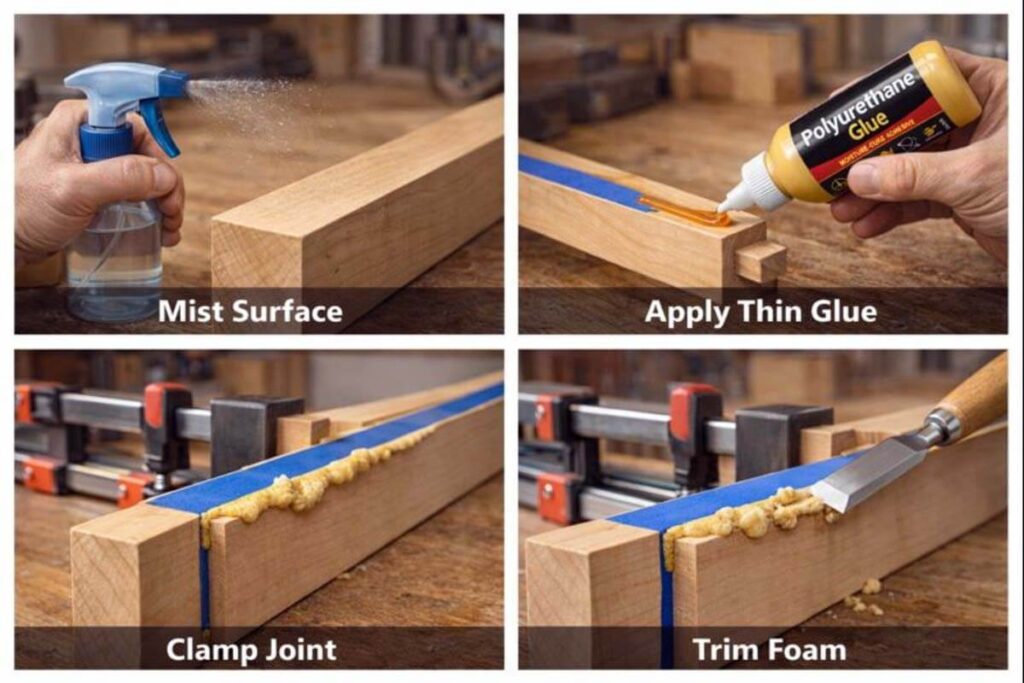

- Lightly dampen one surface. Mist—don’t soak. Moisture starts the cure.

- Spread a thin layer of glue. Thin beats thick with PU. Over-application guarantees foam cleanup.

- Clamp firmly. Example guidance from one major brand: clamp/grip 1–2 hours with full cure in ~24 hours.

- Deal with squeeze-out at the right time.

- Wipe wet squeeze-out promptly (per label guidance) or let it cure and trim/sand.

Clamp-time note: Different PU formulations vary. For example, Titebond’s polyurethane glue literature lists a longer working time and a shorter clamp time than many foaming PU glues.

What are the downsides of polyurethane glue?

Polyurethane glue’s main downsides are foaming expansion, messy squeeze-out, and higher safety demands compared with common PVA wood glues.

- Foam can weaken a sloppy joint. Expansion looks like “gap filling,” but tight joints still win for strength.

- It stains skin and can irritate. Many labels warn to wear gloves, and isocyanates can cause dermatitis or respiratory sensitization in some exposures.

- Cleanup is less forgiving. Urethane-based adhesives generally clean up with mineral spirits when uncured, not water.

If you want a simpler everyday glue for clean wood joints, start with: what is PVA wood glue?

FAQs about Polyurethane Glue

Does polyurethane glue expand?

Polyurethane glue expands because its moisture-cure reaction releases carbon dioxide, which creates foam while the adhesive hardens.

Is polyurethane glue waterproof?

Many polyurethane glues are marketed as waterproof and suitable for indoor/outdoor exposure, but you still need good surface prep and clamping for a durable joint.

Is polyurethane glue safe for serving trays?

Many brands do not recommend food contact with cured or uncured polyurethane glue, so keep it away from food-contact surfaces and follow the manufacturer’s guidance for your specific product.