Thin Birch Plywood: How to Cut, Join, and Finish 1/8 Baltic Birch

Thin birch plywood is a plywood sheet that uses birch face veneers to give you a smooth, paint-ready surface in a slim, stable panel. Most woodworkers buy it for drawer bottoms, cabinet backs, small jigs, laser projects, and tray parts that need to stay flat without the fuzz you get from cheaper underlayment. If you are shopping for 1/8 in wood, you also run into baltic birch 1/8 plywood, which behaves differently because of its core build. This guide breaks down thickness, grade, cutting methods, and finishing so your next project comes off the bench crisp and square.

Contents Here

- 1 What counts as thin birch plywood?

- 2 Thin birch plywood vs Baltic birch plywood

- 3 When baltic birch 1/8 plywood makes sense

- 4 How to pick a good sheet of thin birch plywood

- 5 Best uses for thin birch plywood in tray work

- 6 How to cut thin birch plywood without splintering

- 7 Cutting tips for baltic birch plywood in 1/8 in wood thickness

- 8 How to join thin birch plywood without weak corners

- 9 Sanding and edge prep for thin birch plywood

- 10 Finishing thin birch plywood so it stays flat

- 11 Storage and handling: what keeps 1/8 plywood from warping

- 12 FAQs about Thin Birch Plywood

What counts as thin birch plywood?

Manufacturers sell birch plywood in several thin panel ranges.

- 1/8 in (nominal): common for drawer bottoms, tray bottoms, back panels, and light-duty skins

- 5.2 mm (Baltic birch nominal “1/4”) and 3 mm (Baltic birch “1/8” class in metric lines): common in Baltic birch formats

- 1/4 in (nominal): still “thin” for furniture parts, dividers, and tray sides, with less flex

Woodworkers chasing the thinnest wood for a project often mean “thin sheet goods,” not the thinnest possible veneer. Veneer alone dents and cracks fast. Thin plywood adds cross-banded layers that resist splitting.

Thin birch plywood vs Baltic birch plywood

Birch plywood usually means a birch-faced panel over a mixed core. The face can look good, but the inner plies vary by brand and price.

Baltic birch plywood usually uses more, thinner plies and a void-free core standard that cabinetmakers and jig builders trust. That construction makes routing cleaner and edges more consistent for exposed-ply designs. Example below from Woodpeckers Store:

If your project needs crisp edges, fewer internal voids, and predictable sanding, high quality baltic birch plywood earns its price. If you plan to paint and fully cover edges with trim, a good domestic birch-faced panel can still work.

And, If you want a quick sizing refresher before you buy, see my detailed plywood thickness guide and plywood sheet sizes guide to match nominal labels to what you’ll measure at the bench.

When baltic birch 1/8 plywood makes sense

Baltic birch 1/8 plywood shines when a panel needs to stay flat but still flex a little.

Common shop uses include:

- Tray bottoms and lightweight tray dividers

- Drawer bottoms in small drawers

- Scroll-saw patterns and craft parts

- Templates, router patterns, and story sticks

- Laser-cut parts where a consistent core prevents blowout

For larger spans, 1/8 can “drum” or sag. Add a shallow frame, a center runner, or step up to 1/4 when stiffness matters.

How to pick a good sheet of thin birch plywood

A buyer chooses thin plywood by checking flatness, face quality, and core quality.

Look at the faces

- A clean face shows tight grain, minimal patches, and no raised scarf seams.

- A good face sands without fuzzy fibers or soft spots.

Check the core

- A quality core shows consistent plies and few voids along the edge.

- A poor core shows gaps that blow out during cutting and leave weak glue lines.

Check flatness

- A flat sheet sits with minimal rocking on a known-flat surface.

- A warped sheet fights your clamps and prints a twist into trays and boxes.

If you’re building cabinets or structural casework, it also helps to know what “cabinet grade” implies in your region. My overview of cabinet-grade plywood clarifies what to expect before you pay for a premium label.

Best uses for thin birch plywood in tray work

Thin birch plywood supports tray builds because it stays stable across seasons.

Good matches:

- Tray bottoms that glue into a rabbet or groove

- Sides and rails when you laminate two thin layers for stiffness

- Decorative inlays and painted panels

- Light-duty tiered-tray shelves when you reinforce the underside

If your tray will contact food directly, the finish matters more than the wood species. My guide on sealing a wooden serving tray pairs well with thin birch panels because edges and end-grain-like ply lines drink finish.

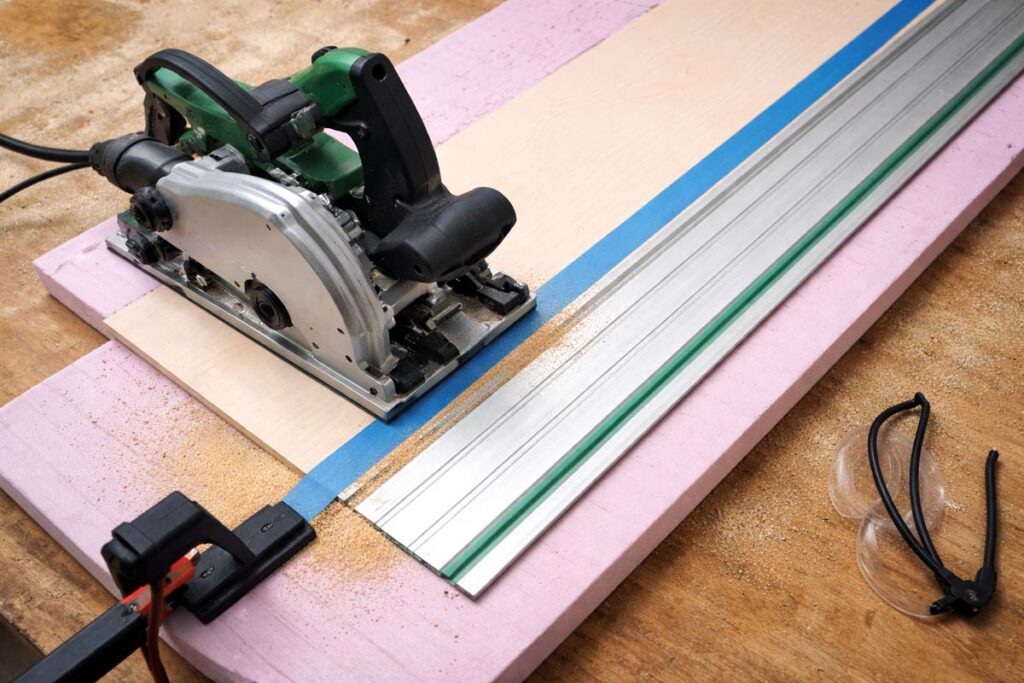

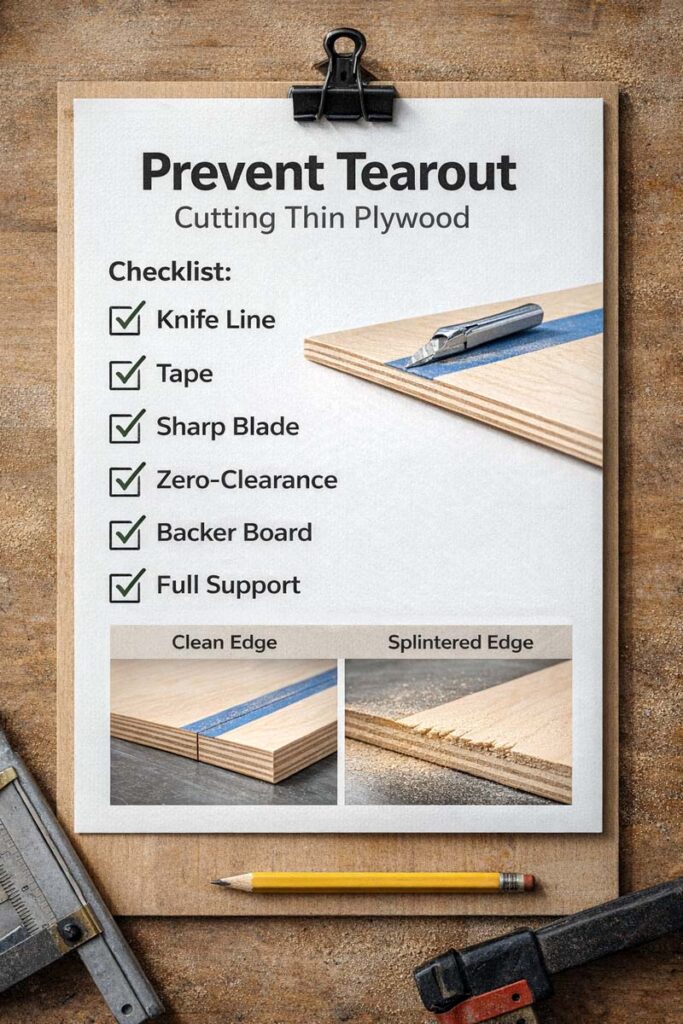

How to cut thin birch plywood without splintering

Thin plywood splinters because the top veneer and the bottom veneer tear in opposite directions. A clean cut comes from supporting fibers and controlling the exit side.

Tools that cut thin birch plywood cleanly

- Track saw or circular saw with a fine-tooth plywood blade

- Table saw with a sharp combination or plywood blade and a zero-clearance insert

- Jigsaw with a down-cut blade for visible top faces

- Utility knife for short straight scores on 1/8 panels

- Blue painter’s tape for delicate veneers

A reliable cutting sequence that reduces tearout

- Mark the cut line with a sharp pencil and a knife line on the show face.

- Support the sheet fully with foam insulation, a sacrificial board, or a spoil panel.

- Use a sharp, fine-tooth blade and keep feed steady to prevent chatter.

- Put the best face where your tool cuts cleanest: show face down on most circular saws, show face up on most table saws.

- Clean the edge with a light sanding block pass, not heavy belt sanding.

Safety matters more with thin stock because it can chatter and kick. If you’re still setting up your kit, my checklist for essential safety gear for tray stand builds covers the basics that prevent eye and lung problems in plywood work.

Cutting tips for baltic birch plywood in 1/8 in wood thickness

Baltic birch cuts cleaner than voidy panels, but it still needs support.

Practical shop tips that help:

- Use a fresh blade. A dull blade crushes plies and leaves “fuzz” on the edge.

- Clamp a backer board behind the cut when using a jigsaw or router.

- Use a zero-clearance setup on the table saw to support the bottom veneer.

- For tiny parts, stick the panel to a sacrificial board with double-sided tape to keep fingers away from the blade.

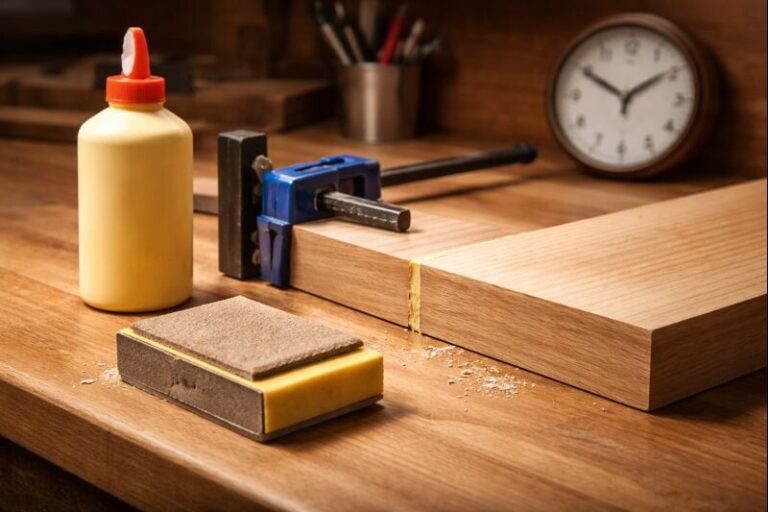

How to join thin birch plywood without weak corners

Thin plywood does not give screws much bite at the edge. A join that spreads load across long grain holds better.

Good options for thin panels:

- Rabbets and dados for tray frames and shallow boxes

- Grooves to capture a 1/8 bottom panel like a drawer bottom

- Lamination: glue two 1/8 layers with the grain aligned for a stiffer 1/4 blank

- Pin nails or brads as clamps, not as the main strength

If you do use screws, pilot holes prevent splitting and reduce “mushrooming” around the head. These two guides help dial in fasteners: guide to screw into wood and a detailed guide to stop wood splitting when screwing.

Sanding and edge prep for thin birch plywood

Thin veneer sands through fast. A careful approach keeps the face intact.

- Use a sanding block and light pressure on faces.

- Start with a finer grit than you would on solid wood when the face looks thin.

- Break edges with one or two passes to prevent splinters.

If you struggle with rough edges on plywood or tray parts, my method for sanding end grain smooth translates well to ply edges because the ply lines behave like alternating end grain.

Finishing thin birch plywood so it stays flat

Thin panels move less than solid wood, but moisture still causes warp when one side gets sealed more than the other.

A finishing routine that prevents most warp:

- Seal both faces in the same session.

- Seal edges early because ply edges soak finish fast.

- Let panels dry flat with stickers or spacers so air hits both sides.

For serving trays, cured film finishes matter. If polyurethane is on your list, my explainer on whether polyurethane is food-safe when cured helps you choose a finish with realistic expectations.

Storage and handling: what keeps 1/8 plywood from warping

Thin sheets warp from uneven humidity and poor support.

- Store sheets flat, fully supported, with weight on top.

- Avoid leaning thin panels against a wall for long periods.

- Bring panels into the shop area so they acclimate before cutting.

FAQs about Thin Birch Plywood

How to cut thin birch plywood?

Use a sharp fine-tooth blade, fully support the sheet, and cut with a steady feed so it doesn’t chatter. Score the cut line with a knife on the show face to reduce tearout.

What is the best blade for 1/8 in wood plywood cuts?

A carbide, fine-tooth plywood blade gives the cleanest edges in 1/8 stock. More teeth means less splintering, especially if the blade is sharp and you use a zero-clearance insert.

What is baltic birch 1/8 plywood used for?

It’s commonly used for tray bottoms, small drawer bottoms, dividers, craft parts, templates, and shop jigs. People like it because the core is consistent and the edges look cleaner.

How do you stop thin plywood from splintering on a jigsaw?

Use a down-cut jigsaw blade for the show face, tape the cut line, and clamp a sacrificial backer underneath. Keep the shoe flat and slow down through curves to prevent chatter.

What finish works best on thin birch plywood for trays?

For trays, a durable film finish like water-based polyurethane or a cured wipe-on poly resists moisture and stains. Seal both faces and the edges in the same session to help prevent warping.