Is Basswood a Hardwood? Yes. Here’s Why It Feels So Soft (7 Facts)

Basswood is a hardwood because it comes from a broadleaf (Tilia) tree, even though the wood itself is soft and dents easily. Basswood still dents easily because it has low density and low Janka hardness compared to most furniture hardwoods. Once you separate “hardwood” (tree type) from “hard wood” (dent resistance), the label makes sense and the buying decisions get easier.

Contents Here

- 1 What does “hardwood” mean in woodworking?

- 2 Is basswood a hardwood or a softwood?

- 3 Why does basswood feel soft if it’s a hardwood?

- 4 How hard is basswood compared to other woods?

- 5 What does basswood do well in a shop?

- 6 Where does basswood struggle?

- 7 How do you fasten basswood without splitting or stripping?

- 8 How do you finish basswood so it looks clean?

- 9 When is basswood the right pick?

- 10 Common Questions Woodworkers Ask About Basswood

- 11 Final thoughts

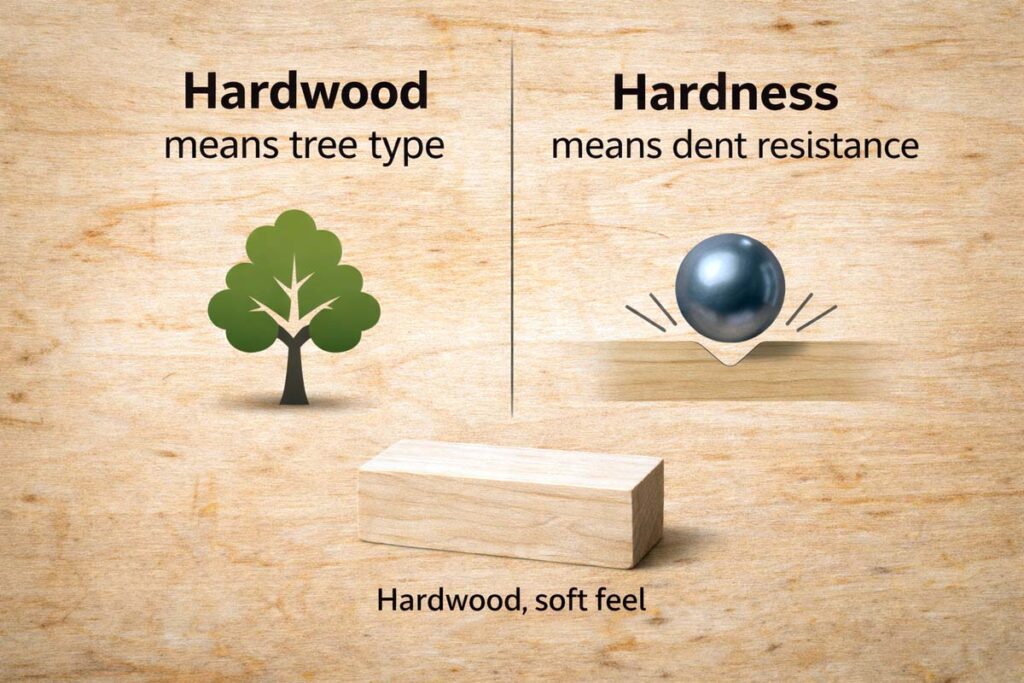

What does “hardwood” mean in woodworking?

Hardwood describes what kind of tree produces the lumber. Hardwood trees are angiosperms, which means they produce flowers and enclose their seeds. Penn State Extension explains this “hardwood vs hard wood” mix-up and notes the terms have little to do with physical hardness.

Softwood describes lumber from gymnosperms, which are cone-bearing trees such as pine, fir, and spruce.

Is basswood a hardwood or a softwood?

Basswood is a hardwood because it comes from Tilia (American basswood is Tilia americana), a broadleaf hardwood forest species. The U.S. Forest Service describes American basswood as a tree of eastern and central hardwood woodlands and calls the wood “soft” and “light,” which is about working properties, not classification.

If you see “linden” or “lime wood,” you’re usually looking at the same general group (Tilia species) sold under different common names.

Why does basswood feel soft if it’s a hardwood?

Basswood feels soft because density drives denting and wear, and basswood is low-density compared to most cabinet woods. The hardwood/softwood label is about tree biology, while “hardness” is a measurable mechanical property.

That’s why woodworkers can truthfully say both of these:

- Basswood is a hardwood (classification).

- Basswood is a soft wood (workability and dent resistance).

How hard is basswood compared to other woods?

The Janka test measures the force required to embed a 0.444″ steel ball halfway into wood.

American basswood lists at 410 lbf on the Janka scale.

That number explains what you feel at the bench:

- A clamp pad, a fingernail, or the corner of a tool can leave marks fast.

- Sharp edges bruise during handling and sanding.

- Screws can strip if you don’t predrill and choose the right fastener.

If you want a quick refresher on screw behavior in wood, this guide on what wood screws are helps you match fastener style to soft stock. (No guessing in the shop saves more time than the “right screw, right pilot hole” habit.)

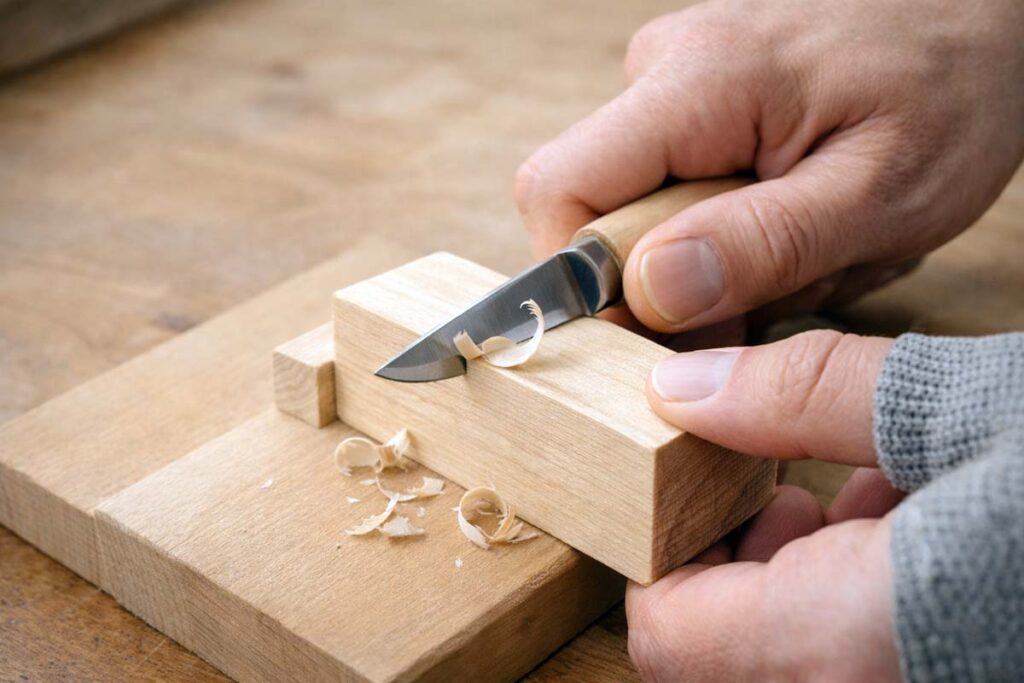

What does basswood do well in a shop?

Basswood earns its reputation because it cuts and carves cleanly with sharp edges. It also stays fairly stable when dried, and its grain doesn’t fight you like ring-porous hardwoods can.

Basswood tends to work best for:

- Relief carving and small figures

- Pyrography (wood burning) and painted crafts

- Mock-ups, templates, and test fits

- Lightweight tray accents and small decorative parts

If you build small tray décor pieces, you’ll also get mileage out of cleaner prep work. This walkthrough on how to sand end grain smooth applies directly to basswood edges that fuzz up when abrasives get dull.

Where does basswood struggle?

Basswood struggles when a project needs dent resistance, crisp corners that stay crisp, or strong screw holding.

Avoid basswood for:

- High-wear serving surfaces that get stacked, scraped, or banged around

- Thin parts that depend on screw threads for strength

- Long spans that carry weight (shelves, tray uprights, stand arms)

If your goal is a sturdy build, start with a wood selection guide built for structural needs. This article on best wood types for sturdy tiered tray stands gives you a safer baseline when strength matters more than easy cutting.

How do you fasten basswood without splitting or stripping?

Basswood rewards careful fastener prep.

Use these habits when screws matter:

- Drill a pilot hole sized for the screw’s root diameter.

- Add a countersink to reduce surface bruising.

- Drive by hand for the last few turns to prevent stripping.

- Use washers under hardware heads when the part is thin.

If you want a step-by-step screw workflow, keep this on hand: how to screw into wood without tearing up the fibers. For split prevention, this companion guide stays focused: how to stop wood splitting when screwing.

How do you finish basswood so it looks clean?

Basswood takes paint well because the grain stays subtle, but it can blotch with some stains and it can raise grain with water-based products.

A practical finishing approach:

For paint: sand to a consistent scratch pattern, remove dust, then use a primer or sanding sealer before topcoat. If brush marks bug you on flat parts, this guide on getting a smooth painted finish without brush marks helps you dial in technique.

For clear coat: basswood can look pale and a bit “flat” under a clear finish, so the goal is often protection, not dramatic figure. On trays that touch food or utensils, finish choice matters. This article covers a common question clearly: is polyurethane food safe when cured.

For sealing a tray surface: use a finish that cures hard and cleans easily. This guide fits that exact use case: how to seal a wooden serving tray.

When is basswood the right pick?

Basswood fits best when your project priorities match its strengths:

You want basswood when you need easy shaping, clean carving, and predictable cutting more than you need toughness. It’s a smart choice for learning tool control because it shows mistakes without punishing your hands or your blades.

Common Questions Woodworkers Ask About Basswood

Is basswood a hardwood or softwood?

Basswood is a hardwood because it comes from a broadleaf (Tilia) tree, but it works like a soft wood because it’s low-density and dents easily. That’s why both terms show up.

Is a basswood tree a hardwood?

Yes. A basswood tree is a hardwood species (Tilia) in the botanical sense, meaning it’s a flowering, broadleaf tree—not a cone-bearing softwood like pine or fir.

Is basswood the same as balsa?

No. Basswood and balsa are different woods from different trees. Balsa is much lighter and softer; basswood is still soft, but it’s denser and usually carves cleaner.

Is basswood good for furniture?

It depends. Basswood works well for painted parts, trim, and interior components, but it dents easily. I wouldn’t use it for tabletops, chair seats, or other high-wear surfaces.

Does basswood hold screws?

Basswood can hold screws, but it strips easier than denser woods. Predrill pilot holes, don’t overtighten, and use longer screws or reinforced joints when the part needs real strength.

Final thoughts

Basswood is a hardwood by tree type, even though it dents like a soft wood. Use it when you want easy carving, clean machining, and a smooth painted finish. Pick a tougher hardwood if the part needs to resist dings, wear, or heavy screw holding. Good luck and enjoy.