Wood Glue vs Construction Adhesive: 7 Picks for Stronger Builds

Wood glue vs construction adhesive comes down to fit, surface, and how you’ll use the piece. Wood glue is built to fuse wood fibers in tight joinery, where clamps can pull parts snug. Construction adhesive is made to grab uneven or mixed surfaces, and it’s happier bridging small gaps.

If you’re building furniture, trays, cabinets, or anything you’ll sand and finish, the “right” choice often depends on how clean the joint fits. If you’re attaching wood to concrete, metal, painted surfaces, or rough framing, the better choice usually depends on tack and gap tolerance.

In the next few minutes, you’ll get a quick side-by-side comparison, simple project rules, and the prep steps that prevent failures. I’ll also keep cure time realistic, because rushing is what ruins most bonds—especially the full cure time for common wood glues.

Contents Here

- 1 Wood glue vs construction adhesive at a glance

- 2 What wood glue is and why it shines on joinery

- 3 What construction adhesive is and when it’s the better tool

- 4 The differences that actually change results

- 5 Best use cases with real project examples

- 6 Common mistakes that lead to weak bonds

- 7 FAQs on Wood Glue vs Construction Adhesive

- 8 Conclusion

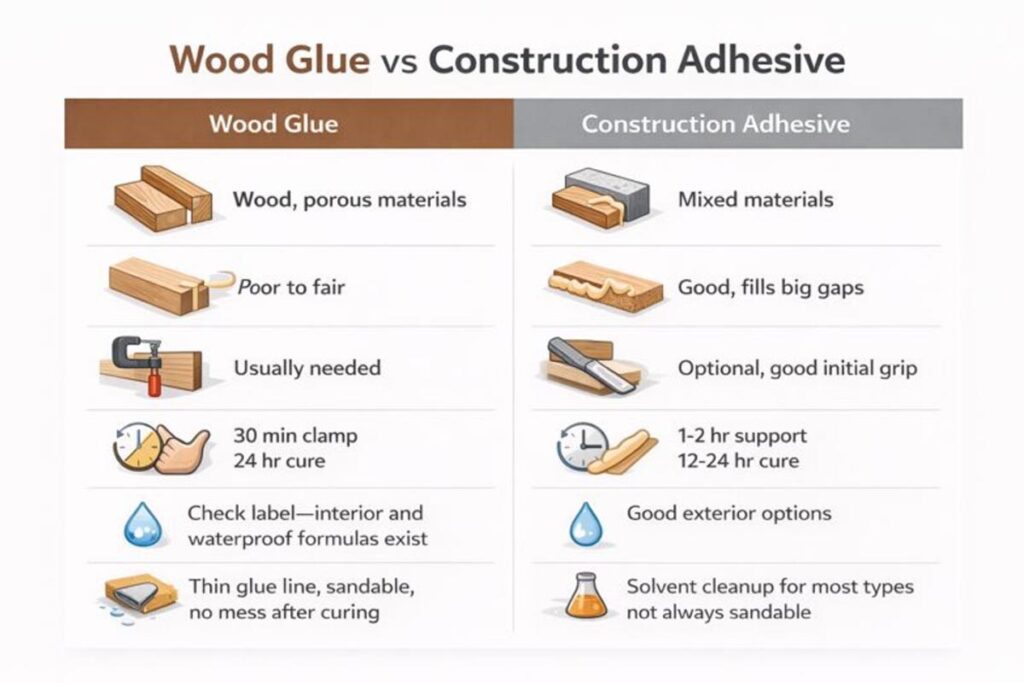

Wood glue vs construction adhesive at a glance

If you want the short version, here it is.

| Factor | Wood Glue | Construction Adhesive |

|---|---|---|

| Best for | Tight wood-to-wood joints | Mixed materials and jobsite bonding |

| Gap filling | Poor to fair (depends on type) | Good (thicker, bridges uneven surfaces) |

| Clamping/support | Usually needed for best strength | Often “grabs,” but support still matters |

| Finish quality | Clean glue lines, sands well | Can be rubbery, messy, harder to sand |

| Moisture options | Indoor and waterproof ratings exist | Many exterior-rated options exist |

| Cleanup | Water cleanup for common PVA | Often solvent cleanup; label-dependent |

Fast rule-of-thumb you can trust

Use these rules when you’re standing in the aisle:

- Fine woodworking and tight joints: choose wood glue.

- Wood to concrete, metal, drywall, or plastic: choose construction adhesive.

- Big gaps or wavy surfaces: construction adhesive, plus fasteners when needed.

- Outdoor exposure: pick a product rated for water and temperature swings.

- Clean stain-grade work: wood glue keeps your glue line easier to hide.

If you’re still unsure, pick based on surface fit. Tight fit favors wood glue. Poor fit favors construction adhesive.

Read more: Titebond Wood Glue vs Gorilla Wood Glue: 7 No-Regret Choices

What wood glue is and why it shines on joinery

Wood glue is built for woodworking because it bonds into wood fibers. With a well-fit joint, the glue line is thin and strong. That’s why you see it in furniture, cabinets, picture frames, and most indoor repairs.

Most hobby and shop work uses PVA (carpenter’s glue). If you want a plain-English explanation of what that means, read this guide on what “PVA” actually refers to in common carpenter’s glue. It helps when you’re comparing bottles that look similar.

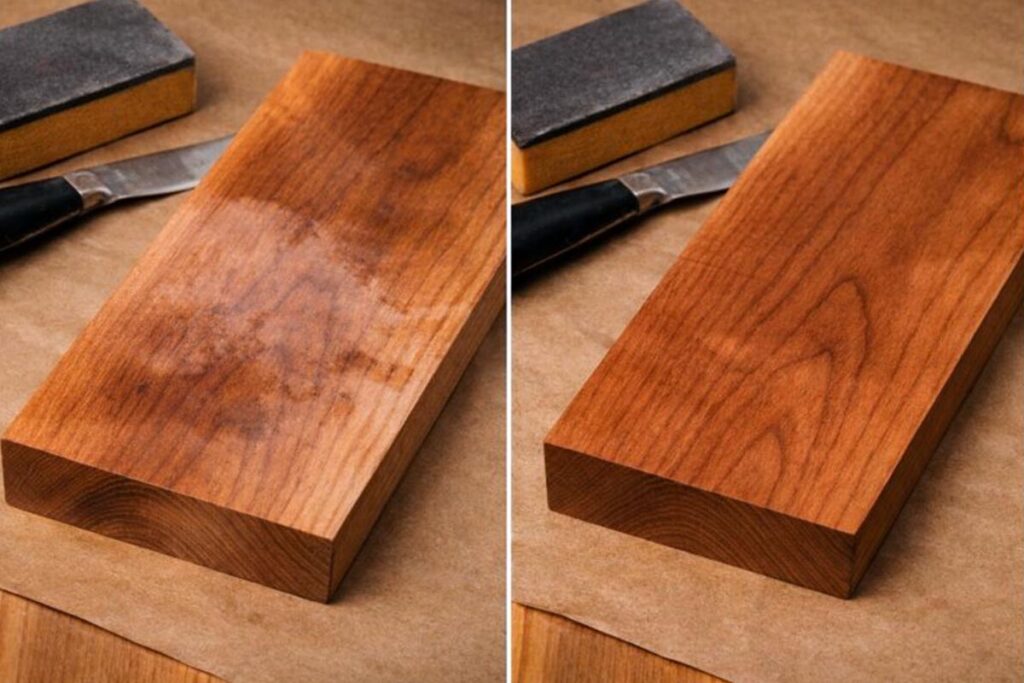

Wood glue also plays nicely with sanding and finishing. When you clean squeeze-out correctly, you’ll avoid those pale blotches that show up under stain. If you’ve fought that problem before, this walkthrough on getting rid of dried squeeze-out without scarring the wood is worth keeping bookmarked.

Types of wood glue worth knowing

You don’t need a chemistry degree here. You just need to know what each type is good at.

- PVA (yellow/white carpenter’s glue): Great for tight-fitting indoor joints. Some formulas are water-resistant or waterproof-rated.

- Polyurethane wood glue: Handles moisture better and can bond some non-wood materials. It foams as it cures, so it’s messier and needs careful clamping.

- Epoxy: Good for repairs and imperfect fits when you need gap tolerance. It’s also handy when the joint can’t be clamped easily.

For most trays, shelves, and furniture work, PVA covers a lot of ground. If you’re repairing a chair rung or a wobbly frame, this roundup on choosing a glue that’s proven for furniture repair can save time and frustration.

What construction adhesive is and when it’s the better tool

Construction adhesive is a thick, high-grab adhesive made for jobsite conditions. It’s designed to bond dissimilar materials and tolerate uneven surfaces. Think subfloors, paneling, trim to drywall, stair treads, and wood-to-masonry connections.

It’s also more forgiving when parts don’t fit perfectly. That gap-bridging ability is why a lot of builders reach for it first. The tradeoff is cleanup and finish quality. Many construction adhesives stay a bit rubbery, and some don’t sand cleanly. On stain-grade woodwork, that can bite you later.

Types of construction adhesive you’ll see most often

Again, keep it practical.

- Latex/acrylic construction adhesive: Often lower odor and easier cleanup. Common for interior projects.

- Polyurethane construction adhesive: Strong and durable, often exterior-rated. Usually messy and sticks to everything.

- Hybrid/reactive formulas: Built for strong “grab” and faster curing in many conditions. Label details matter a lot.

Don’t assume one tube works everywhere. Read what materials the product approves, especially for plastics, foam, or treated lumber.

The differences that actually change results

This is the section that decides your outcome. If you remember nothing else, remember these points.

Material compatibility and surface prep

Wood glue works best on porous materials, especially wood-to-wood. Construction adhesive often works across porous and non-porous surfaces. That includes drywall, concrete, metal, and some plastics.

No matter what you use, prep matters. Dust, oil, and glossy paint reduce bond strength. When in doubt, scuff-sand and wipe clean. If your project includes end grain, it helps to prep it properly so it doesn’t drink the adhesive. This guide on sanding end grain until it feels truly smooth pairs well with any glue-up.

Strength: what “stronger” really means

People love asking which is stronger, but strength depends on the joint and the load.

A well-fit wood joint glued with wood glue can be extremely strong. If you’ve ever wondered what that looks like in real terms, here’s a straight answer on how strong wood glue can be in typical joints, plus a practical breakdown of how much weight a glued joint may hold in real projects.

Construction adhesive can be very strong too, especially in shear loads and mixed-material bonds. It’s often chosen because it grabs quickly and tolerates imperfect surfaces. That doesn’t automatically make it “stronger” for fine joinery. Tight joinery still favors wood glue.

Gap filling, movement, and flexibility

Wood glue prefers tight contact. If there’s a gap, you’re depending on dried glue as a filler, and that’s not the same as wood. Some glues handle small gaps better than others, but snug joints always perform best.

Construction adhesive is built to bridge gaps and stay flexible. That flexibility helps when materials move with temperature and humidity. It’s one reason it’s common for subfloors and trim.

Here’s the honest shop rule: if the gap is big, don’t “fix” it with more adhesive. Improve the fit, add a backer, or reinforce with fasteners.

If screws are part of your plan, use corrosion-resistant hardware where moisture is possible. This guide on choosing stainless steel screws for wood projects that see humidity covers the basics without the fluff.

Dry time, clamp time, and full cure

Drying isn’t the same as curing, and that misunderstanding causes a lot of failures.

Wood glue usually needs clamping pressure and time. If you want clear, practical numbers, start with how long wood glue takes to set enough to handle and then read how long it takes to fully cure for maximum strength. Clamp time matters too, and this is the reference I point friends to when they ask how long a glued joint should stay clamped.

Construction adhesive often “grabs” faster, but full cure can still take a while. Many projects need temporary bracing or fasteners while it cures. Temperature and humidity affect both products, so read the label and adjust your schedule.

If you’re tempted to rush, don’t heat-blast a glue-up without thinking. There are safer ways. This article on speeding up glue drying without wrecking the bond lays out what helps and what backfires.

Finish quality, sanding, and cleanup

If you care about a clean finish, wood glue is usually easier to live with. It sands well once cured, and it doesn’t stay rubbery. The biggest problem is squeeze-out that gets into the grain. Clean it while it’s fresh, or remove it carefully once it gels.

Construction adhesive can be tough to sand and may smear. It can also print through paint if it stays flexible under a thin finish. If your project will be painted, take your time with prep so the surface stays flat. This guide on getting a smooth painted finish without brush marks helps you avoid the “lumpy trim” look that shows every mistake.

Also, if your build will be stained, be careful with any adhesive that might resist stain. This quick guide on whether glue residue can affect stain absorption is a good reminder before you commit.

Safety and ventilation

Most PVA wood glues are low odor and easy to handle. Construction adhesives vary widely. Some have strong odors and require ventilation. Gloves are a smart habit either way, and eye protection matters when you’re scraping or sanding cured adhesive.

If you’re making items that could touch food, be cautious about assumptions. Different products cure differently. This article on when cured glue is considered food-safe in typical shop use gives a solid starting point.

Best use cases with real project examples

Here’s how I’d choose in the shop, without overthinking it.

Choose wood glue for:

- Edge-gluing boards for trays, shelves, and panels

- Tight joinery like dados, rabbets, and mortise-and-tenon

- Furniture repairs where a clean glue line matters

- Projects that will be stained and need invisible bonds

If you’re timing a build, this matters: don’t sand too soon. Follow this guide on how long glue should dry before you start sanding so you don’t clog paper or smear a soft glue line.

Choose construction adhesive for:

- Wood to concrete, drywall, brick, or metal

- Subfloor squeaks and stair tread bonding

- Trim and paneling where surfaces aren’t perfectly flat

- Outdoor assemblies where flex and weather exposure matter

Even here, think about support. Adhesive is not a clamp. Use bracing, fasteners, or both when gravity is working against you.

Common mistakes that lead to weak bonds

Most failures aren’t “bad glue.” They’re avoidable habits.

- Skipping surface prep: Dust, oil, and glossy paint kill adhesion.

- Using adhesive as a filler: Big gaps need better fit or reinforcement.

- Not clamping or supporting: Wood glue needs pressure; construction adhesive needs support.

- Rushing cure time: Set time isn’t full strength time.

- Over-applying: Excess squeeze-out creates finish problems and waste.

If you’re wondering about quantity, this guide on how much glue is enough without overdoing it keeps it simple.

One more practical note: check shelf life. Old glue can act fine and still fail. If you’ve got a bottle that’s been sitting for years, read this on how to tell if glue has expired or thickened past usefulness.

FAQs on Wood Glue vs Construction Adhesive

Is construction adhesive stronger than wood glue?

It can be stronger in mixed-material bonds and gap situations. In tight wood joinery, wood glue often equals or beats it.

Can I use construction adhesive on wood-to-wood joints?

You can, but it’s usually messier and less friendly for fine finishes. For tight joints, wood glue is the cleaner choice.

Do I need to clamp construction adhesive like wood glue?

Clamping is less common, but support still matters. If the parts can move, brace or fasten them until cured.

Can I paint over construction adhesive?

Sometimes, but check the label. Some adhesives remain flexible and can print through paint if the coat is thin.

How do I clean up squeeze-out without ruining the finish?

Wipe fresh squeeze-out carefully and avoid smearing into the grain. For cured residue, remove it gently before sanding and finishing.

Conclusion

Wood glue vs construction adhesive comes down to fit, materials, and finish expectations. For tight wood joints and clean results, wood glue is usually the right pick.

For mixed materials, uneven surfaces, and jobsite conditions, construction adhesive often performs better. Choose based on the project’s demands, then follow the label for cure time and surface prep.