What Is Birch Plywood? 7 Hard Truths for Stronger, Flatter Builds

Birch plywood is a hardwood plywood panel that uses birch veneer on the face, the back, or throughout the core to produce a stiff, smooth sheet for cabinetry, furniture, and shop projects. Manufacturers build it by stacking thin wood veneers with alternating grain direction, then bonding those layers under heat and pressure. Woodworkers pick it because it machines cleanly, holds screws well for its weight, and paints or clears nicely when the face veneer is sound. The exact performance depends on the veneer grade, core type, thickness, and whether it is true Baltic birch or a birch-faced panel.

After you understand how the layers and grades work, it gets easier to choose the right sheet for a cabinet box, a drawer, or a tray.

Contents Here

- 1 What is birch plywood made of?

- 2 How is birch plywood different from solid birch lumber?

- 3 What are the common types of birch plywood?

- 4 What do birch plywood grades mean?

- 5 What thicknesses are typical for birch plywood?

- 6 Why do woodworkers use birch plywood?

- 7 Is birch plywood good for cabinets?

- 8 What are the main drawbacks of birch plywood?

- 9 How do you choose the right birch plywood sheet?

- 10 How do you cut and drill birch plywood without tearout?

- 11 What glue works best with birch plywood?

- 12 How do you finish birch plywood for a clean, durable surface?

- 13 Safety notes for cutting and sanding birch plywood

- 14 Birch plywood in one sentence

What is birch plywood made of?

Birch plywood uses three main parts: face veneer, core, and adhesive.

Face veneer is the thin birch layer you see. It sets the look and takes stain or paint. A clean, even face veneer also sands more predictably because you are not fighting patches and voids.

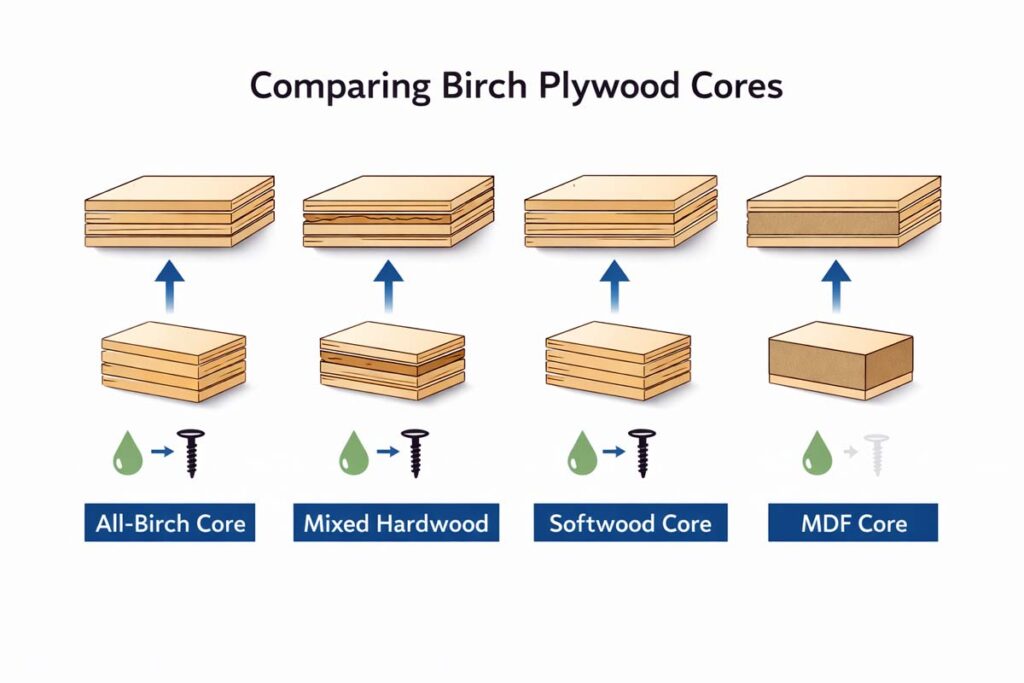

The core is the stack of inner plies. Depending on the product, those plies may be all birch, mixed hardwood, softwood, or composite. More, thinner plies usually mean better screw holding, flatter sheets, and fewer internal gaps.

The adhesive bonds the plies. The glue type and press quality influence delamination resistance. For any panel used around moisture, read the stamp and the manufacturer notes on exposure rating.

If you want a quick foundation on how veneer sheets differ by intended use, see the breakdown of cabinet-grade plywood versus shop-grade sheets.

How is birch plywood different from solid birch lumber?

Birch plywood trades âone thick piece of woodâ for âmany thin layers.â That change affects stability and workholding.

Solid birch expands and contracts across the grain with seasonal humidity. Plywood spreads movement across alternating grain layers, so a cabinet side or drawer panel stays flatter.

Plywood also gives you wide panels without glue-ups. That saves time on parts like case sides, shelves, and bottoms.

The downside is the edges. Solid birch has continuous grain on an edge. Birch plywood shows plies, so you either feature the layers, cover them with edge banding, or design around them.

What are the common types of birch plywood?

“Birch plywood” shows up on labels for a few different products. The name alone does not tell you what core you are buying.

Birch-faced plywood

Birch-faced plywood uses birch veneer on the face and back, but the core may be mixed hardwood or softwood. You often see this in big-box sheet goods. It can be a good value for painted work or parts that get edge banding, but inspect for core voids.

All-birch plywood

All-birch panels use birch veneers in the face and in the core. This usually increases ply count and improves edge strength and screw bite. It also tends to weigh more than a mixed-core sheet of the same thickness.

Baltic birch

Baltic birch is a specific style of all-birch plywood that is typically built with many thin plies and clean edges. It is popular for drawers, jigs, shop cabinets, and small furniture because it holds fasteners well and stays flat when stored properly. Sizes and standards vary by region and supplier, so confirm sheet dimensions before you design parts. If you need a refresher on common formats, use this guide to plywood sheet sizes chart.

Pre-finished birch plywood

Pre-finished panels come with a factory-applied clear coat. They save finishing time for cabinet interiors, drawer boxes, and utility furniture. The tradeoff is glue and finish compatibility. You usually need to scuff-sand bonding areas and keep glue off finished faces.

What do birch plywood grades mean?

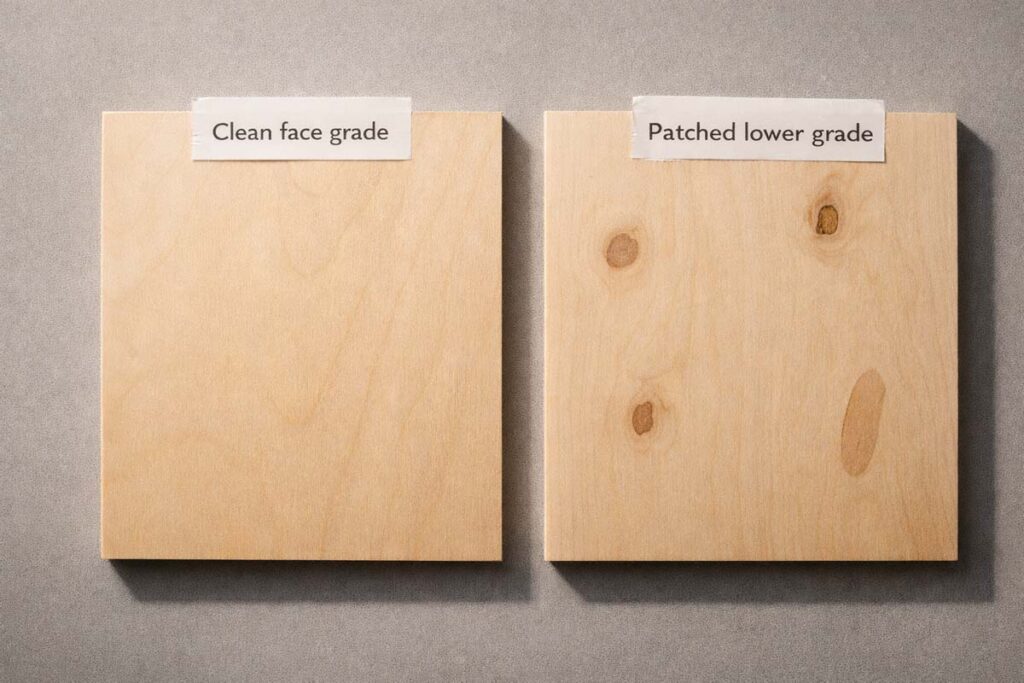

Grades describe the quality of the face and back veneers, not just the core.

In plain terms:

- A better face grade has fewer patches, tighter repairs, and fewer visible defects.

- A lower face grade allows more knots, mineral streaks, open repairs, or discoloration.

- The back grade is often lower than the face on “one good side” panels.

Because grading systems vary by supplier and standard, treat the stamp as a starting point, then judge the sheet in front of you. In the shop, I look for three things before I buy: face uniformity, core voids on the edges, and flatness across the sheet.

What thicknesses are typical for birch plywood?

Birch plywood comes in the same general thickness range as other sheet goods, but the “nominal” label does not always match the real measurement. A “3/4 in” sheet often measures a bit under 3/4 in, and that matters for dados and hardware. Before you cut joinery, measure your sheet with calipers or a reliable rule.

For a practical reference that matches how woodworkers plan joinery, keep this plywood thickness guide chart handy.

Why do woodworkers use birch plywood?

Birch plywood earns its reputation because it performs well across several common shop tasks.

- Cabinet boxes and shelves: It stays flatter than many solid-wood panels at the same width.

- Drawer boxes: Multi-ply cores resist splitting at screws and staples better than coarse-core panels.

- Paint-grade furniture: A stable panel reduces seasonal seam telegraphing.

- Jigs and fixtures: Consistent thickness and stiffness improve repeatability.

If your project is specifically cabinetry, it helps to compare options across species and constructions. This roundup on how to choose plywood for cabinets gives you useful context on where birch fits.

Is birch plywood good for cabinets?

Birch plywood works well for cabinets when the sheet has a sound core, a consistent thickness, and a face grade that matches your finish plan. For paint, a clean birch face sands quickly and supports a smooth topcoat. For clear finish, you want fewer patches and tighter veneer.

The real deciding factor is the specific panel in your cart. Two “birch” sheets from different suppliers can behave like different materials.

If you are weighing it for casework, this focused guide on using birch plywood in cabinets is worth a read.

What are the main drawbacks of birch plywood?

Birch plywood has a few predictable pain points. None are deal breakers if you plan for them.

Face veneer can be thin. Sanding through the veneer is easy if you lean on a random-orbit sander. Use light pressure, fresh discs, and stop as soon as the surface is uniform.

Core voids can show up. Voids weaken edges and can ruin dado strength. Check the edge of the sheet before you buy. If you see gaps, choose a different sheet or plan to avoid exposed edges.

Edges need a strategy. If the layers are part of the look, break the edge with a small chamfer and finish it cleanly. If not, apply edge banding or a solid wood strip.

Moisture exposure varies. Some birch plywood is intended for interior dry use. Some is rated for higher exposure. Read the stamp and store panels flat and dry.

How do you choose the right birch plywood sheet?

I treat sheet selection like tool selection. Match the material to the job, not the label.

Here is an order that works in a lumberyard aisle:

- Pick the thickness based on the part. Shelves, sides, and structural panels need stiffness. Drawer parts may not.

- Decide on your edge plan. Exposed plies, edge banding, or solid edging change what core quality you need.

- Match the face grade to the finish. Clear finish needs a better face than paint.

- Inspect for flatness and voids. Sight down the sheet and check the edges.

- Buy the cleanest sheets from the stack. Consistency saves time later.

If you need sheets cut down before you bring them home, this guide on getting plywood cut to size can help you plan the cleanest approach.

How do you cut and drill birch plywood without tearout?

Birch veneer chips when the cutting edge lifts fibers. You control that by supporting the veneer and keeping blades sharp.

- Use a sharp, high-tooth-count blade for plywood.

- Use a zero-clearance insert on a table saw or a track saw splinter guard.

- Score cut lines with a knife for critical show edges.

- Put painter’s tape over the cut line when you need extra insurance.

- Drill clean holes with brad-point bits and back up the exit side with scrap.

When you cut exposed edges that will stay visible, a light chamfer or roundover reduces splintering and makes the finish look intentional.

What glue works best with birch plywood?

Most interior birch plywood bonds well with quality wood glue when the surfaces fit and clamps apply even pressure. The biggest mistakes I see are glue starvation on end-grain edges and trying to glue over dust or finish.

For plywood-to-plywood joints:

- Scuff-sand glossy factory faces where the glue will land.

- Remove dust before glue-up.

- Use enough glue to wet the surface, then clamp to a thin squeeze-out line.

- Keep clamping pressure even to avoid bowing panels.

If you want brand and application specifics, this article on best glue for plywood gives targeted advice for sheet-good joints.

How do you finish birch plywood for a clean, durable surface?

Birch takes finish well, but it rewards good surface prep.

For paint: sand lightly, fill defects that matter, prime, then topcoat. A primer that sands nicely makes the job easier.

For clear finish: sand lightly and evenly. Keep your grit progression controlled. A thin face veneer does not forgive aggressive sanding.

For projects that need a wipe-clean protective coat, a clear topcoat matters. If you are finishing something handled often, like a serving piece, this tutorial on sealing a wooden serving tray shows a practical path.

Safety notes for cutting and sanding birch plywood

Plywood machining produces fine dust and can irritate lungs fast in a closed shop. Protect yourself every time you cut or sand sheet goods.

- Wear a properly fitted respirator or dust mask rated for fine particles.

- Use dust collection at the tool and a shop air filter if you have one.

- Support sheets to prevent binding and kickback.

- Keep hands clear and use push tools on small parts.

Finishes and adhesives also have label directions for ventilation and PPE. Follow the product instructions and the SDS when you are unsure.

Birch plywood in one sentence

Birch plywood is a layered hardwood panel that uses birch veneer and cross-laminated plies to deliver a flat, strong sheet for cabinets, furniture, and shop builds.