What Is Baltic Birch Plywood? 9 Powerful Facts Woodworkers Trust

Baltic birch plywood is a birch-veneer plywood panel that uses many thin plies, usually with a birch core, to create a stiff, stable sheet with clean-looking edges. Woodworkers use it for cabinet parts, drawer boxes, jigs, and painted builds because it machines predictably and stays flatter than many soft-core panels. The catch is that stores often label several products as âÂÂBaltic birch,â even when the core and glue rating differ. This guide explains what it is, how itâÂÂs made, how to spot it at the rack, and when to choose something else.

Contents Here

- 1 What makes Baltic birch plywood different from regular birch plywood?

- 2 How is Baltic birch plywood made?

- 3 Why do woodworkers choose Baltic birch for cabinets, drawers, and jigs?

- 4 How can you tell if a sheet is real Baltic birch plywood?

- 5 What grades should you expect when buying Baltic birch?

- 6 Is Baltic birch plywood a good choice for serving trays?

- 7 How does Baltic birch cut, rout, and sand?

- 8 What are the downsides of Baltic birch plywood?

- 9 When should you choose something else?

What makes Baltic birch plywood different from regular birch plywood?

Baltic birch plywood uses a multi-ply construction with thin, uniform layers, while many âÂÂbirch plywoodâ sheets use a softwood or mixed core with birch faces.

That core difference shows up fast in real work.

Baltic birch panels usually rout cleaner on the edge because the plies are consistent. Dados and rabbets tend to land in solid material instead of surprise voids. Screws also bite more reliably when the core is hardwood instead of soft core bands.

If you want a quick baseline for how panel labels get used in cabinet stock, read TrayEditâÂÂs breakdown of cabinet-grade plywood and what the term usually signals.

How is Baltic birch plywood made?

Baltic birch plywood stacks thin birch veneers with alternating grain direction, then bonds the stack under heat and pressure.

Three parts matter when you buy it:

Face veneers: Manufacturers press birch face veneers onto the front and back. Higher face grades look cleaner and need less patching work.

Core plies: True Baltic birch often uses birch plies through the core. The edge shows many thin layers with fewer large gaps.

Adhesive system: Panels can use different glue ratings. The sheet stamp or the supplier spec tells you more than the product nickname.

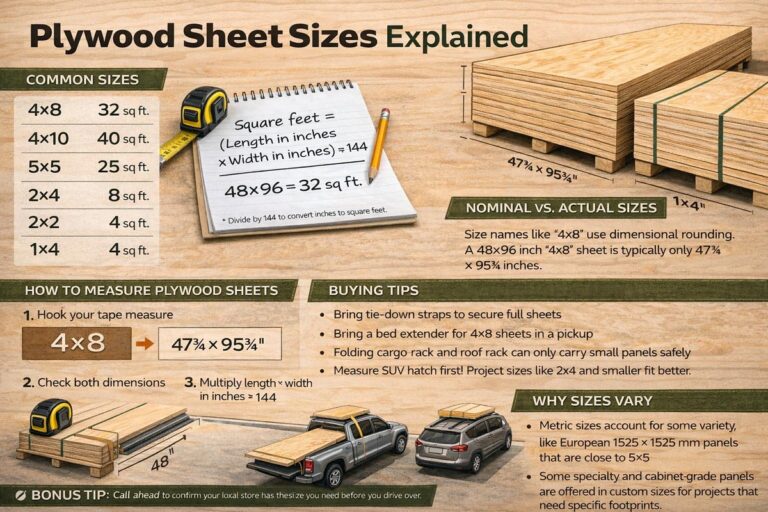

If your build depends on tight joinery, sheet thickness matters. These references help you choose thickness and plan layout: the plywood thickness chart guide and a quick refresher on plywood sheet sizes guide.

Why do woodworkers choose Baltic birch for cabinets, drawers, and jigs?

Baltic birch plywood gives predictable machining and good edge strength, which makes joinery and assembly feel consistent.

It earns its keep in a few common jobs.

Drawer boxes and cabinet parts: A uniform core supports dado joinery and hardware mounting with fewer weak spots.

Jigs and fixtures: Flat jigs stay accurate longer. A stable panel also holds screws and clamping pressure better than low-grade cores.

Painted panels and clean modern work: Birch faces sand smooth and take primer well when you avoid sanding through the veneer.

If you are comparing it to budget panels, check my guide to shop-grade plywood and what youâÂÂre trading off helps you decide when âÂÂgood enoughâ is actually good enough.

How can you tell if a sheet is real Baltic birch plywood?

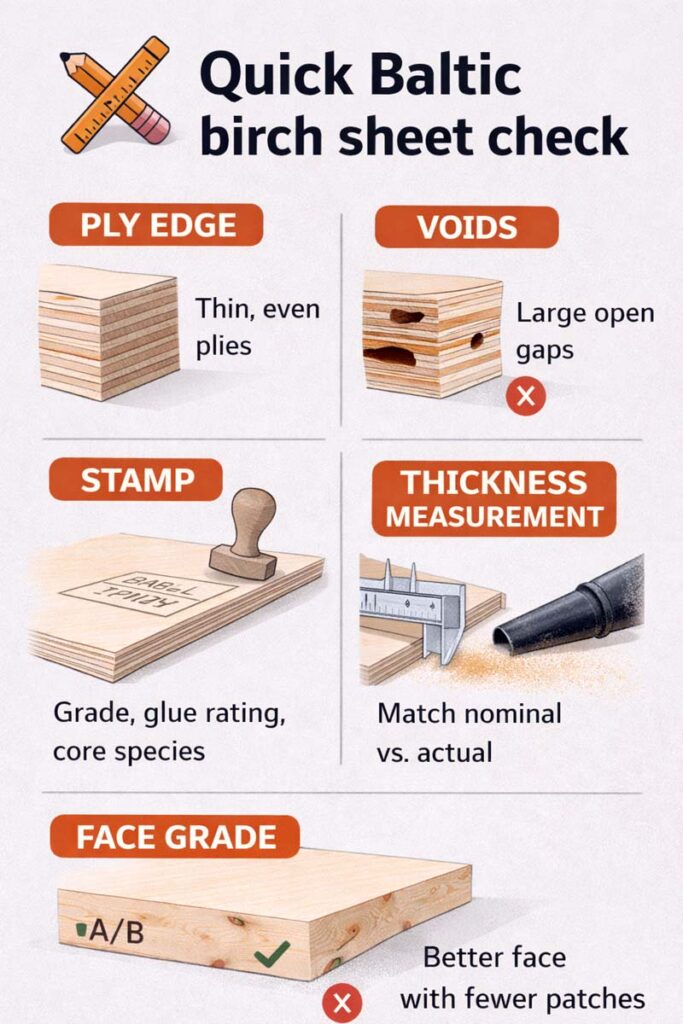

You identify Baltic birch plywood by checking the edge, the core consistency, and the panel markings.

Use this simple shop check in order:

- Inspect the edge. A Baltic birch-style core shows many thin plies and a more uniform look.

- Look for voids. Large gaps and patches in the edge usually mean rougher routing and weaker joinery.

- Confirm what âÂÂbirchâ refers to. Some panels are birch-faced only. A birch face does not guarantee a birch core.

- Check the stamp or the supplier sheet. Glue rating and grade vary by product line and region.

- Measure actual thickness. Nominal thickness and actual thickness can differ, which affects dados and hardware.

When you glue Baltic birch joinery, match the adhesive to your assembly time and shop conditions. Check out my guide on choose wood glue for plywood is a practical fit here.

What grades should you expect when buying Baltic birch?

Baltic birch plywood is sold in face grades that mainly control appearance, not the basic idea of strength.

Higher face grades usually mean fewer patches, fewer dark streaks, and a cleaner look for visible work. Lower grades often make sense for shop cabinets, jig parts, or anything that gets painted.

Do not buy by grade label alone. Flip the sheet, check both faces in good light, and decide which face you want showing.

Is Baltic birch plywood a good choice for serving trays?

Baltic birch plywood works for serving trays when you seal every surface and keep the tray away from standing water.

The faces finish easily, but the exposed edge plies absorb finish faster than the face. That edge needs extra attention if the tray will see spills or frequent wiping.

For tray-specific sealing steps, follow my guide on way to seal a wooden serving tray.

How does Baltic birch cut, rout, and sand?

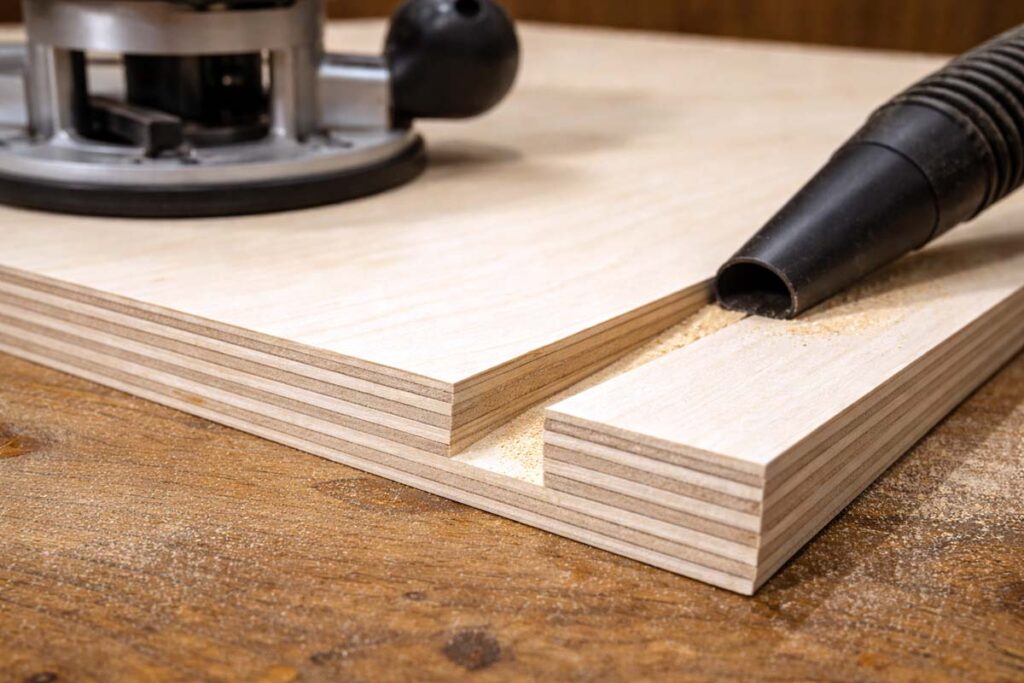

Baltic birch plywood machines cleanly when you use sharp cutters and support the fibers at the cut line.

Use a sharp blade for crosscuts to reduce splintering on the face veneer. A zero-clearance insert helps on the table saw. On the router, take lighter passes to avoid chipping the outer plies.

Sand the faces lightly because face veneers can be thin. If you are cleaning up exposed edges, a sanding block keeps the layers crisp and avoids rounding them over too much.

What are the downsides of Baltic birch plywood?

Baltic birch plywood costs more and it is not the best answer for every environment.

Availability varies, and the label gets used loosely. Some âÂÂBaltic birchâ on a shelf is birch-faced with a different core. Not every sheet uses the same glue rating, so moisture resistance depends on the exact product.

It can also be heavier than soft-core panels. That matters for large doors, wall cabinets, and portable projects.

When should you choose something else?

You pick a different panel when cost, moisture exposure, or surface needs matter more than a uniform birch core.

For kitchen and cabinet projects, it helps to compare options side by side using the best plywood for cabinets and the focused guide on whether birch plywood is good for cabinets.