Titebond Wood Glue vs Gorilla Wood Glue: 7 No-Regret Choices

Titebond wood glue vs Gorilla wood glue comes down to your project conditions, not brand loyalty. Both are dependable, water-based woodworking glues. Your pick depends on moisture, working time, and finish quality expectations.

Titebond is a family of glues. Original, II, and III don’t behave the same. This comparison focuses on what changes at the bench: strength, water performance, timing, cleanup, and finishing.

Contents Here

- 1 Key takeaways (the 30-second answer)

- 2 Titebond vs Gorilla Wood Glue comparison table (at-a-glance)

- 3 Glue formula differences (why they behave differently)

- 4 Strength in real joints (not just label claims)

- 5 Water resistance, outdoor use, and temperature limits

- 6 Open time, clamp time, and full cure (what to do on a workbench)

- 7 Application, cleanup, and shelf life (ease-of-use section)

- 8 Sanding, staining, and glue-line appearance

- 9 Versatility and gap-filling (when each glue makes sense)

- 10 Best uses by project (decision guide)

- 11 FAQs on Titebond Wood Glue vs Gorilla Wood Glue

- 12 Final Words

Key takeaways (the 30-second answer)

If you just want the quick answer, start here:

- For most indoor furniture and cabinet work, Titebond Original and Gorilla Wood Glue both work well in tight joints.

- For damp rooms and light outdoor exposure, Titebond II and Gorilla Wood Glue usually make more sense than interior-only glue.

- For outdoor furniture that sees rain and repeated wet-dry cycles, Titebond III is the safer Titebond pick.

- For big glue-ups, Titebond III’s longer working time can keep assembly calm.

Also read: Wood Glue vs Liquid Nails: 12 Quick Checks Before You Glue

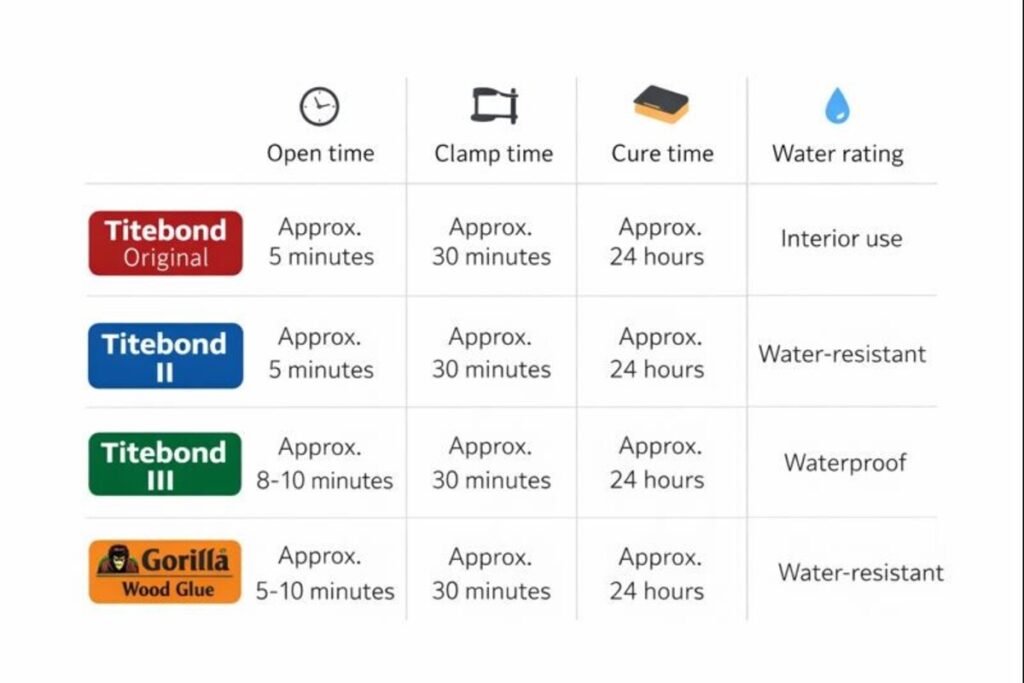

Titebond vs Gorilla Wood Glue comparison table (at-a-glance)

These ranges assume room temperature and moderate humidity. Treat them as a starting point. Wood species, moisture, and glue amount all change timing.

| Glue | Water resistance (practical view) | Open/working time (typical) | Clamp time (typical) | Full cure (typical) | Dried color | Best fit |

|---|---|---|---|---|---|---|

| Titebond Original | Interior use | ~5 minutes | ~30 minutes for many joints | ~24 hours | Yellow/tan | Tight joinery, fast assembly |

| Titebond II | Water-resistant (Type II class) | Similar to Original for most work | Often ~30–60 minutes | ~24 hours | Light yellow | Indoor/outdoor projects, kitchens |

| Titebond III | Waterproof-class (Type I spec) | ~8–10 minutes | ~30–60 minutes | ~24 hours | Light brown | Outdoor builds, longer glue-ups |

| Gorilla Wood Glue | Water-resistant (often sold as indoor/outdoor) | Often a bit more forgiving than fast PVAs | ~20–30 minutes | ~24 hours | Natural/tan | Fast clamping, clean bond line |

What products are included in this comparison

This compares Titebond Original, Titebond II Premium, and Titebond III Ultimate against Gorilla Wood Glue (the PVA wood glue). Gorilla also sells other adhesives, including the foaming polyurethane “classic” Gorilla Glue. Make sure you’re holding the wood glue bottle if you want water cleanup and a non-foaming bond line.

If you want a quick refresher on how these glues work, read what PVA wood glue actually is.

Glue formula differences (why they behave differently)

Woodworkers usually care about outcomes. Does it grab fast? Does it creep? Does it sand clean? Formula is why those differences show up.

Titebond Original is an aliphatic resin wood glue that sets quickly and sands well for interior work. Titebond II and Gorilla Wood Glue are both water-based PVA glues aimed at better moisture performance than interior-only formulas. Titebond III uses a different polymer blend in the one-part, water-cleanup, waterproof-class category. That’s why it typically offers more open time and stronger water performance than standard PVAs.

If your joints are snug and clamped right, all of these can outlast the wood. The bigger difference is forgiveness in cold shops and large glue-ups. It also matters when the piece lives outside.

Strength in real joints (not just label claims)

In good joinery, wood glue often fails by tearing wood fibers. It doesn’t usually peel clean off the glue line. That’s the reason “stronger than wood” can be true in practice.

Two habits matter more than brand:

- Dry-fit so parts pull together without force.

- Clamp enough to close the joint without starving it.

If you want numbers and examples, see how strong wood glue is in real projects and how much weight a glued joint can hold. For Gorilla-specific expectations, we also covered how strong Gorilla’s wood glue bond can be.

Water resistance, outdoor use, and temperature limits

This is where most people pick the wrong bottle.

Titebond Original is for interior use. It doesn’t belong on outdoor furniture. Titebond II targets water resistance in the “Type II” category. It’s often fine for outdoor pieces that don’t stay soaked. Titebond III is designed for the higher “Type I” water-resistance class. It’s where I lean for patio work.

Gorilla Wood Glue is sold as water-resistant and indoor/outdoor friendly. In the shop, that usually means it handles dampness better than interior-only glue. Still, protect outdoor joints with smart design and a finish that sheds water.

If a project will see standing water, plan for drainage. Glue is only part of the weather plan.

Open time, clamp time, and full cure (what to do on a workbench)

Working time is your window to spread glue and assemble parts. Clamp time is how long the joint needs pressure before it stops shifting. Full cure is when the bond reaches total strength.

For many PVA wood glues:

- You can often unclamp after 20–60 minutes for an unstressed joint.

- You still want close to a full day before heavy load or machining.

If you’re planning your workflow, these help:

- How long wood glue takes to set

- How long it takes for wood glue to dry

- How long for wood glue to fully cure

- How long you should wait before removing clamps

If you’re in a hurry, don’t rush clamp time first. Adjust your schedule instead. Here are practical options on how to make wood glue dry faster without weakening joints.

Application, cleanup, and shelf life (ease-of-use section)

These glues like the same basics: clean wood, fresh glue, and even pressure.

Here’s the routine that prevents most failures:

- Spread a thin, even coat on one face for most joints.

- Add a little more for end grain, because it drinks glue.

- Clamp until you see a small bead of squeeze-out along the seam.

If you’re unsure how much is enough, this quick reference on how much wood glue to use for common joints clears up the guesswork.

Cleanup is easiest while wet. A damp rag works, but avoid smearing glue into open grain if you plan to stain. When the squeeze-out turns rubbery, a scraper usually removes it cleanly. If you’ve got dried squeeze-out, follow these steps for how to remove wood glue without damaging wood.

Shelf life matters more than people admit. Old glue can get stringy, thick, or lumpy, and strength can drop. If you’re not sure about a bottle, check whether wood glue expires and what “bad glue” looks like.

Safety and non-toxicity notes

These are generally low-odor, water-based woodworking glues, but common sense still matters. Keep glue out of your eyes, wash up after use, and give joints time to cure before food-contact situations.

If you’re building serving trays or anything near food, read whether cured wood glue is food-safe for kitchen projects. It’ll help you choose safe habits, even when the label says “non-toxic.”

Sanding, staining, and glue-line appearance

Most glue complaints aren’t about strength. They’re about finish.

Any PVA glue can block stain if residue stays on the surface. That’s why wiping squeeze-out with a wet rag can backfire on open-grain woods. A better plan is to keep squeeze-out minimal, let it gel, and then scrape it clean.

For finishing timing and stain behavior, these two are worth your time:

- How long to let wood glue dry before sanding

- Whether wood glue is stainable and how to avoid blotches

Gorilla Wood Glue often dries a natural tan color. Titebond Original dries more yellow. In tight joints, you rarely see either. In gaps or smeared areas, both can show, especially under light stains. If you’re curious about appearance, see whether Gorilla’s wood glue dries clear or stays visible.

Versatility and gap-filling (when each glue makes sense)

Wood glue is at its best when wood touches wood. None of these are true gap fillers. A thin glue line is usually a strong glue line.

If you’ve got gaps you can’t close with clamping, fix the joint first. Plane the edge, tune the fit, or remake the part. When you can’t, that’s when epoxy becomes the better choice. Using extra PVA to “fill” a gap often leaves a weak line that telegraphs through finish.

Also remember that “Gorilla” can mean different products. Gorilla Wood Glue is water cleanup and does not foam like polyurethane Gorilla Glue.

Best uses by project (decision guide)

Here’s how I’d pick at the bench.

Indoor furniture, cabinets, and trim

Use the glue that matches your pace. Titebond Original is a solid default when moisture isn’t a factor. Gorilla Wood Glue is also a good choice if you want fast clamping and a clean-looking bond line. For repairs, this roundup on choosing the best glue for furniture repair jobs helps match glue to the break.

Kitchen, bathroom, and utility projects

Moisture happens. Titebond II and Gorilla Wood Glue usually make more sense than interior-only glue for small items that might get damp. Keep standing water off joints with good finish and design.

Outdoor furniture, planters, birdhouses, and patio pieces

If it will live outdoors and you want fewer regrets, Titebond III is the safer Titebond pick. Pair it with joinery that sheds water and a finish that protects end grain.

Large glue-ups like table tops

Open time matters. When you’re gluing up wide panels, Titebond III’s longer working window can help. Dry-fit, stage your clamps, and work steadily.

FAQs on Titebond Wood Glue vs Gorilla Wood Glue

Is one brand actually stronger than the other?

In tight joints with proper clamping, both can exceed the wood’s strength. Differences show up more in open time, water resistance, and how forgiving the glue is during assembly.

Is Gorilla Wood Glue waterproof?

Gorilla Wood Glue is typically described as water-resistant and sold for indoor/outdoor use. Gorilla also sells “Ultimate” formulas that are marketed as waterproof, so check the exact bottle.

What’s the difference between Titebond Original, II, and III?

Original is aimed at interior woodworking. II is designed for better water resistance. III is the waterproof-class option and usually gives a longer working window.

Does Gorilla Wood Glue foam like classic Gorilla Glue?

No. Gorilla Wood Glue is a PVA wood glue and does not foam like polyurethane Gorilla Glue.

How do I know if my wood glue has gone bad?

If it’s lumpy, stringy, separated, or smells off, skip it. Don’t trust it on a critical joint. Store glue sealed at room temperature and avoid freezing.

Final Words

Titebond wood glue vs Gorilla wood glue is an easy decision when you focus on conditions. For indoor furniture, both brands work well in tight joints with proper clamping. For damp use, step up to a water-resistant option. For true outdoor exposure, choose the waterproof-class glue and build in water-shedding details.