Polyurethane Glue for Wood in 2026: 8 Pro Picks for Tough Joints

Using polyurethane glue for wood pays off when you need a moisture-curing adhesive that grabs hard, bonds mixed materials, and stays rigid after it cures. Polyurethane glue foams as it reacts with moisture, so the technique matters more than the brand.

In this guide, I’ll show you when polyurethane glue makes sense, when it doesn’t, and the exact steps I use to keep joints tight and cleanup painless.

Contents Here

- 1 Quick Checklist: Top 8 Polyurethane Glues for Wood

- 2 What is polyurethane glue for wood?

- 3 When does polyurethane glue work better than regular yellow wood glue?

- 4 When should you avoid polyurethane glue?

- 5 What tools and supplies help polyurethane glue behave?

- 6 Reviews of the 8 Best Polyurethane Glues for Woodworking Projects

- 6.1 Grizzly One Polyurethane Wood Adhesive

- 6.2 Gorilla Original Waterproof Polyurethane Glue

- 6.3 Loctite PL Premium Fast Grab Polyurethane Construction Adhesive

- 6.4 Akfix 360FC Fast Drying Polyurethane Wood Glue

- 6.5 Mitreapel Waterproof Polyurethane Glue

- 6.6 Grizzly One 16 Ounce Polyurethane Adhesive

- 6.7 Titebond Fast Set Polyurethane Construction Adhesive

- 6.8 Kraken Bond D4 Fast Drying Polyurethane Wood Glue

- 7 How do you buy the right polyurethane glue for your woodworking project?

- 8 How do you use polyurethane glue on wood without a foamy mess?

- 9 How long should you clamp polyurethane glue?

- 10 How do you clean up polyurethane glue squeeze-out?

- 11 Does polyurethane glue really fill gaps in wood?

- 12 Will polyurethane glue mess up staining and finishing?

- 13 What are the main safety rules for polyurethane glue?

- 14 FAQs on Polyurethane Glue for Wood

- 15 Final thoughts

Quick Checklist: Top 8 Polyurethane Glues for Wood

- Grizzly One Polyurethane Wood Adhesive

- Gorilla Original Waterproof Polyurethane Glue

- Loctite PL Premium Fast Grab Polyurethane Construction Adhesive

- Akfix 360FC Fast Drying Polyurethane Wood Glue

- Mitreapel Waterproof Polyurethane Glue

- Grizzly One 16 Ounce Polyurethane Adhesive

- Titebond Fast Set Polyurethane Construction Adhesive

- Kraken Bond D4 Fast Drying Polyurethane Wood Glue

Also read: Top 10 Strongest Wood Glues for Furniture Repair

What is polyurethane glue for wood?

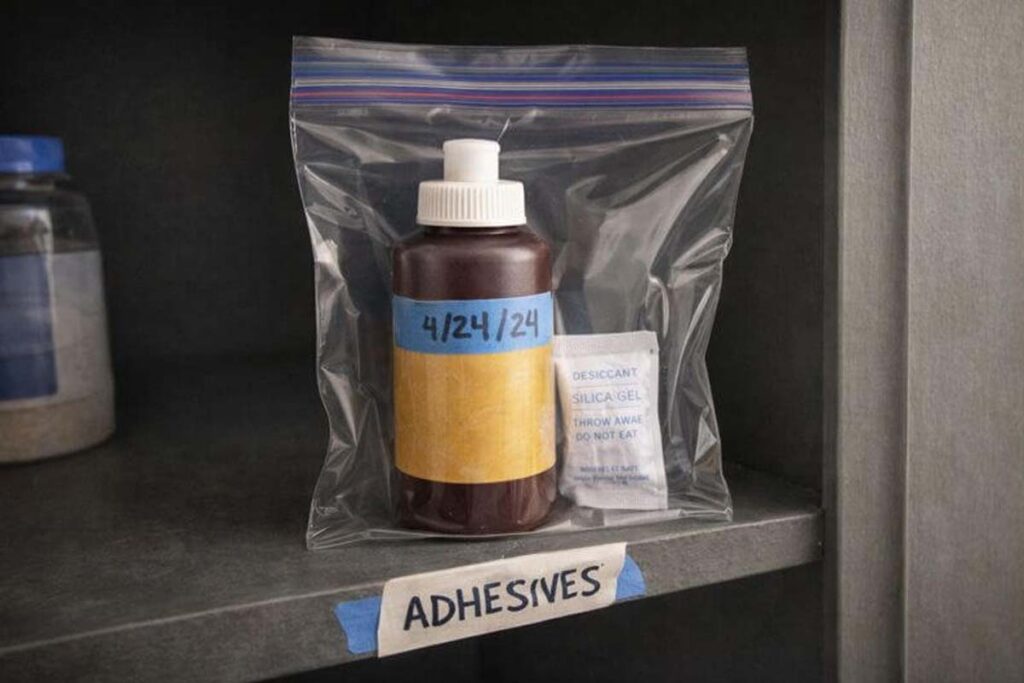

Polyurethane glue for wood is a one-part adhesive that cures by reacting with moisture in the wood, the air, or a lightly dampened surface. Example of a polyurethane wood glue from Grizzly brand below:

That moisture-triggered cure causes foaming squeeze-out, which looks like gap filling—but the foam itself is weak compared to the thin glue line inside a tight joint.

When does polyurethane glue work better than regular yellow wood glue?

Polyurethane glue works better than PVA wood glue when the job needs water tolerance, mixed-material bonding, or extra open time.

Use it when you’re doing any of the following:

- Bonding dissimilar materials (wood to metal, ceramic, some plastics) where PVA won’t hold well

- Gluing oily or dense woods where you want a moisture-cure option (think tricky exotics)

- Longer, fussy glue-ups because polyurethane glue can give a minimum ~20 minutes open assembly time under typical conditions

- Outdoor projects that see humidity and wetting (with the reminder that “water-resistant” is not the same as “submersible”)

If your project is a serving tray, match the glue choice to your finish plan—see my guide on food-safe finish decisions for serving pieces.

When should you avoid polyurethane glue?

You avoid polyurethane glue when you need clean glue lines, easy squeeze-out cleanup, or tight-fitting joinery that already glues perfectly with PVA.

Skip it for:

- Show surfaces where any glue line might telegraph through stain

- Fast assembly work where PVA’s simple wipe-up saves time

- Loose joints you’re “hoping” the foam will fix (it won’t add strength where wood-to-wood contact is missing)

What tools and supplies help polyurethane glue behave?

A few simple items keep polyurethane glue under control:

- Nitrile gloves and eye protection (polyurethane products commonly contain isocyanates and can irritate skin/eyes or trigger sensitization)

- Small spray bottle or damp rag (for controlled moisture)

- Clamps and cauls (to keep joints tight while the glue expands)

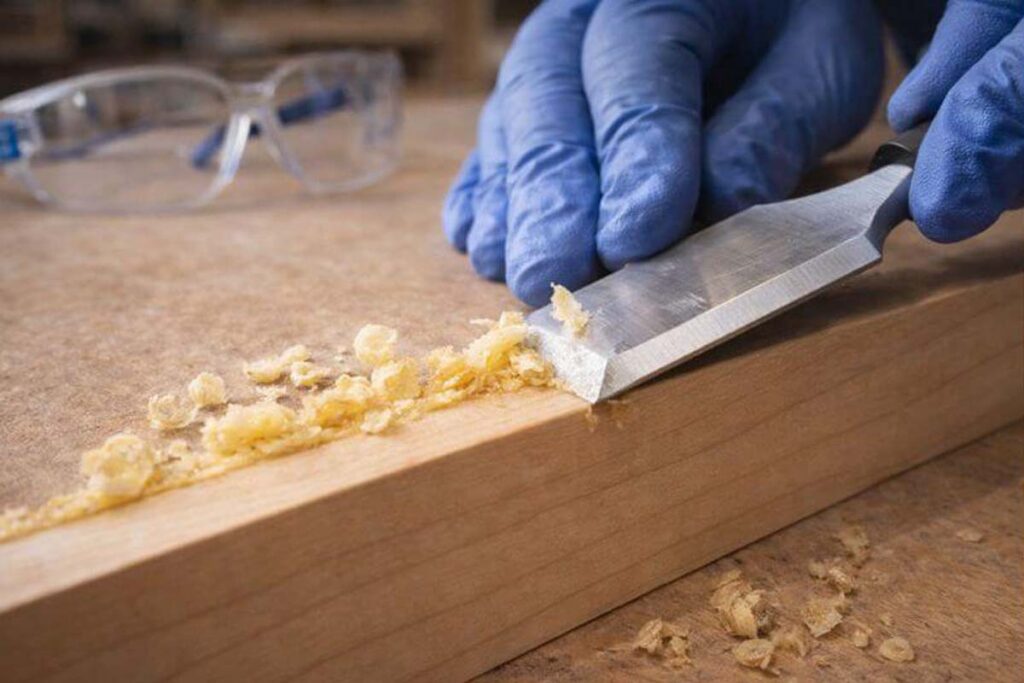

- Sharp chisel or scraper (best tool for cured foam)

If you’re still building your kit, my checklist for basic shop protection and PPE belongs on your wall.

Reviews of the 8 Best Polyurethane Glues for Woodworking Projects

Grizzly One Polyurethane Wood Adhesive

Moisture-cure wood adhesive for oily hardwood joints

Grizzly One suits furniture and exterior assemblies where you want a rigid, no-creep bond and enough open time to position clamps calmly. The liquid spreads easily, then expands as it cures, so tight joinery and firm clamping matter more than “gap filling.” I like it for exotic hardwoods and mixed-material repairs (wood to stone) when PVA glue struggles.

$125 at AmazonSpecifications

- Form: viscous liquid; 7,500 cps

- Working time: 25–35 min

- Clamp: 2–5 hrs; full cure: ~12 hrs

- Water resistance: waterproof

Pros

- Long open time for complex clamping

- Stainable; sands/scrapes cleanly

Cons

- Foams; plan a scrape step

Gorilla Original Waterproof Polyurethane Glue

Expanding polyurethane glue for wood and mixed materials

Gorilla Original works best for repairs and outdoor builds where you need one glue that bonds wood plus metal, stone, ceramic, glass, foam, and some plastics. The water-activated formula expands as it cures, so I treat it like a precision adhesive: thin coat, light moisture, and solid clamping. Use it on tight-fitting joints; the foam is not structural strength.

$23.99 at AmazonSpecifications

- Form: liquid resin

- Expansion: claims up to 3×

- Full cure: ~24 hrs

- Waterproof

Pros

- Bonds wood, metal, ceramic, glass, stone, foam

- Outdoor-friendly after cure

Cons

- Slower than most PVAs

Loctite PL Premium Fast Grab Polyurethane Construction Adhesive

Fast-grab urethane for wood panels and vertical installs

PL Premium Fast Grab fits subfloor, panel, and vertical bonding where high initial tack reduces bracing. The moisture-curing formula gives some repositioning time and can expand during cure, so keep parts aligned with clamps or temporary blocks. I reach for it when a caulk-gun bead is the practical choice, not a fine

$10.98 at AmazonSpecifications

- Form: cartridge; high viscosity

- Feature: fast grab/high tack

- Full cure: ~24 hrs

- Low VOC: <2% (claim); water resistant

Pros

- Bonds OSB/MDF, masonry, stone, foam

- Indoor/outdoor, weather resistant

Cons

- Less precise than brush-on glue lines

Akfix 360FC Fast Drying Polyurethane Wood Glue

D4 Waterproof Polyurethane Glue for Quick Wood Joinery

Akfix 360FC suits fast assemblies when you can dry-fit first and clamp without delay. The directions call for joining parts within 2 minutes, then pressing 15–20 minutes, with tack-free time in 5–15 minutes. I’d use it for exterior furniture parts and wood-to-metal or wood-to-foam bonding when you want a D4/EN 204 option.

$72.99 at AmazonSpecifications

- Liquid; viscosity: 5,000–15,000 cps

- Join: within 2 min; press: 15–20 min

- Tack-free: 5–15 min; full cure: 24 hours

- Waterproof; D4/EN 204 (claim)

Pros

- Fast handling on small glue-ups

- Good moisture and weather resistance

- Brush-on application for control

Cons

- Short join window limits complex clamps

Mitreapel Waterproof Polyurethane Glue

Clear moisture-cure glue for repairs and small gaps

Mitreapel targets repair work: picture frames, crafts, toys, and mixed-material fixes where you want a clear glue that dries stainable, paintable, and sandable. It handles heat, cold, and water exposure per the product description, which makes it a practical option for indoor/outdoor touch-ups. Prep matters: roughen shiny metal, glass, or some plastics, then clean and lightly moisten the surface to start the cure.

$17.99 at AmazonSpecifications

- Liquid; clear; viscosity: medium

- Full cure: 1 day

- Waterproof

- Compatible: wood, metal, glass, ceramic, concrete, foam

Pros

- Finishes cleanly after cure (sand/paint/stain)

- Useful on vertical surfaces (no runs claim)

- Broad compatibility for household repairs

Cons

- Foaming squeeze-out needs scraping

- “Gap fill” is limited for strength

Grizzly One 16 Ounce Polyurethane Adhesive

Small-bottle polyurethane glue for wood and outdoor repairs

This 16-ounce Grizzly One fits smaller shops that want long working time without storing a big container. The liquid spreads easily, expands as it cures, and leaves a rigid bond that sands or scrapes cleanly. Use it on tight-fitting joints, and tape off show faces to keep foamed squeeze-out from staining.

$25 at AmazonSpecifications

- 16 oz; liquid; viscosity: 7,500 cps

- Working time: 25–35 minutes

- Clamp: 2–5 hours; full cure: 12 hours

- Waterproof

Pros

- Easier to finish before it ages

- Long open time supports careful alignment

- Stainable after cure

Cons

- Foams; cleanup is a scrape step

- Needs at least one porous surface

Titebond Fast Set Polyurethane Construction Adhesive

Fast-setting urethane for treated and engineered lumber

Titebond Fast Set is built for jobsite conditions: wet, frozen, treated, and engineered lumber, plus near-freezing temperatures where some adhesives get stubborn. It extrudes as a smooth bead from a cartridge, so it shines on framing, panels, and repairs—not fine joinery. I like it when you need strength on non-porous-to-non-porous contact and you want a waterproof bond after cure.

$13.19 at AmazonSpecifications

- Cartridge; viscosity: 150,000

- Full cure: 24 hours

- Waterproof

- VOC-compliant; works near freezing (claims)

Pros

- Handles tough lumber and cold weather

- Strong, durable bond for construction tasks

- Easy bead application and positioning

Cons

- Too thick for delicate glue lines

- Cured squeeze-out requires scraping

Kraken Bond D4 Fast Drying Polyurethane Wood Glue

Marine-style polyurethane glue for wood repairs and wet areas

Kraken Bond targets outdoor and marine work where moisture and weather swings punish weak glue lines. The gel body gives decent control on edges and end grain, and the product positions itself as transparent and low odor. The tradeoff is cure schedule: the listed full cure time is 7 days, so plan clamps and avoid early stress.

$99.99 at AmazonSpecifications

- Gel; viscosity: 5,000–15,000 cP

- Full cure: 7 days

- Waterproof; D4 certified (claim)

- Compatible: wood, metal, concrete, polystyrene foam

Pros

- Suits wet-area and exterior repairs

- Clear look supports tidy finish work

- Bonds multiple materials for mixed fixes

Cons

- Long cure slows turnaround

- Expansion can shift parts if unclamped

How do you buy the right polyurethane glue for your woodworking project?

Buying polyurethane glue for wood goes smoothly when you match the bottle’s specs to your joint type, moisture exposure, and clamp setup.

- What are you bonding? Choose polyurethane when you need wood-to-wood plus “mixed-material” bonding (wood to metal/stone/foam). Pick standard PVA wood glue instead for clean interior cabinet joints.

- Is it indoor or outdoor? Buy a glue that states exterior/water-resistant use if the piece will see rain, wet hands, or a damp garage. Don’t trust “gap filling” as a strength rating.

- Check open time on the label. Buy the longest open time you realistically need for your assembly (big panels and complicated clamping benefit most). If you’re doing quick joinery, shorter open time is fine.

- Check clamp time and full cure time. Buy the glue whose clamp time matches your workflow. Longer clamp times aren’t “worse”—they’re just slower.

- Pick the right bottle size. Buy smaller bottles if you glue occasionally. Polyurethane cures with moisture, so big bottles can harden in storage before you use them up.

- Look for a controllable nozzle. Buy a bottle with a narrow tip or a cap that seals well. Polyurethane expands, so precision application saves cleanup.

- Read cleanup directions before you commit. Buy polyurethane only if you’re okay with scraping cured foam. If you want easy wipe-up, switch to PVA.

- Respect safety labeling. Buy a product you can use with gloves, eye protection, and ventilation—then store it sealed and upright.

How do you use polyurethane glue on wood without a foamy mess?

You use polyurethane glue on wood by prepping clean surfaces, adding light moisture, applying a thin coat, and clamping firmly while it cures.

1) Fit the joint first

A tight joint creates strength because the real bond happens in a thin glue line, not in the foam.

2) Clean and (lightly) dampen

Remove dust and oil, then lightly dampen one surface with a mist or damp cloth—do not soak it. For dense hardwoods, dampen both faces lightly.

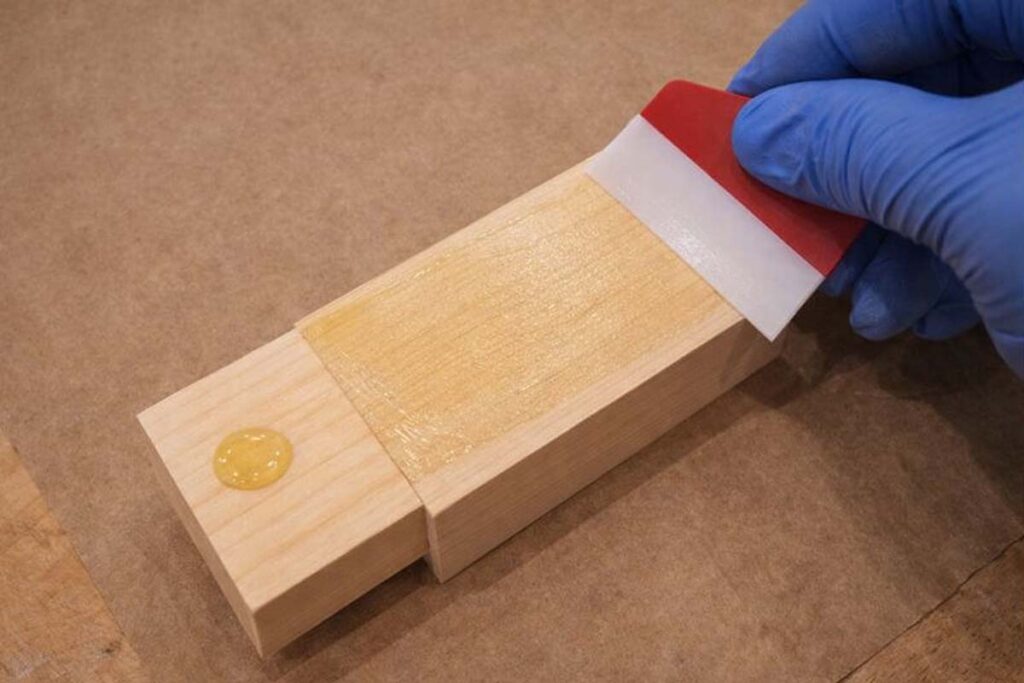

3) Apply glue to the dry side—thin and even

Spread a thin coat on the dry surface and avoid overapplying, because expansion will push glue out of the joint.

4) Clamp right away

Clamp the joint so pressure is even across the entire glue line, and keep parts from drifting as the glue expands.

5) Leave it alone until it earns it

Follow the bottle’s clamp-time guidance, then give the joint an overnight rest before you stress it.

Strong glue-ups start with good surface prep—especially on end grain. Here’s how I sand end grain smooth without rounding edges.

How long should you clamp polyurethane glue?

You clamp polyurethane glue for wood based on the product label, but general shop guidance puts minimum clamp time around 2 hours for many polyurethane adhesives, with best results from leaving the assembly clamped longer (often overnight).

Some formulations advertise faster clamp times (for example, certain polyurethane products list ~45 minutes clamp time and ~30 minutes working time), so always treat the label as the final word.

How much pressure is “enough”?

Moderate clamping pressure lands around 30–60 psi at the contact area; overclamping can starve the joint by squeezing too much glue out.

How do you clean up polyurethane glue squeeze-out?

You clean up polyurethane glue by wiping uncured glue quickly, then scraping cured foam after it hardens.

- While wet: wipe squeeze-out with a dry cloth; some guides allow paint thinner for wet cleanup, used carefully with gloves and ventilation

- After cure: remove foam mechanically by scraping or chiseling, because the foam has no strength and pops off cleanly when you hit it at the right time

Shop timing tip: I let the foam fully harden, then pare it flush with a sharp chisel held flat to the surface.

Does polyurethane glue really fill gaps in wood?

Polyurethane glue fills gaps visually, but the foamy squeeze-out does not add strength, so the joint still needs wood-to-wood contact.

If your joint has real gaps, switch to a method that actually restores structure (better joinery, a patch, or an adhesive designed for gap-filling strength).

Will polyurethane glue mess up staining and finishing?

Polyurethane glue takes stain better than many adhesives, but you still need clean surfaces because excess glue can block absorption—especially with some water-based dyes.

The practical fix is simple: prevent squeeze-out where the finish must look perfect, then scrape cured glue clean before sanding.

If you’re chasing even color on pine, glue cleanup matters—my walkthrough on reducing blotching before stain helps a lot.

What are the main safety rules for polyurethane glue?

Polyurethane glue safety comes down to skin/eye protection, ventilation, and avoiding repeated exposure.

Many polyurethane adhesives include isocyanates and carry hazard warnings such as skin irritation, allergic skin reaction, and respiratory sensitization risk. Wear gloves, protect your eyes, and work where fresh air moves through the shop—then wash up after the glue-up.

FAQs on Polyurethane Glue for Wood

Is polyurethane glue waterproof for outdoor wood projects?

Polyurethane glue handles wetting and high humidity well, but “water-resistant” products are not all rated for continuous submersion.

Do I need to mist the wood first?

Polyurethane glue cures with moisture, so a light spritz helps in dry conditions or on low-moisture stock. A damp surface speeds cure; a soaked surface weakens control and increases foam.

How do I remove cured polyurethane glue from wood?

Cured polyurethane glue comes off best with mechanical removal—scrape, chisel, or sand it off after it hardens. Don’t gouge the wood chasing the last haze; scrape flush, then sand flat.

Final thoughts

Polyurethane glue for wood rewards careful prep, light moisture, thin application, and steady clamping. The glue earns its reputation when you use it for the right jobs—mixed materials, longer assemblies, and damp conditions—then clean the foam after it cures instead of smearing it around. Good luck, and keep your glue-ups tight.