Plywood Thickness Guide: 9 Must-Know Sizes (Nominal vs Actual)

Plywood thickness trips up good woodworkers every week because the label on the rack is not the number your calipers see. Nominal isn’t always actual. Mills and standards use “named” thicknesses to simplify buying and stocking, while sanding, veneer layup, and product category shift the final measurement. This guide shows what common labels usually measure, what 19/32 means in plain shop terms, and how to pick a thickness that fits your joinery, shelves, and cabinet parts without surprises.

Contents Here

- 1 Nominal vs actual thickness

- 2 Nominal label → typical actual thickness range (by category)

- 3 Plywood thickness chart

- 4 What is 1/2-inch plywood?

- 5 What is 19/32 plywood?

- 6 What is 3/4-inch plywood

- 7 What is the thinnest plywood?

- 8 Thickest plywood panels and where people use them

- 9 What’s the thickest plywood you can buy?

- 10 How to measure plywood thickness correctly

- 11 Project guidance: where thickness differences cause problems

- 12 Checklist: before you cut joinery, measure thickness

- 13 FAQs about Plywood Thickness

- 14 Concluding Notes

Nominal vs actual thickness

Nominal thickness is the name printed on the sheet. Actual thickness is the measured thickness after the panel gets pressed, cured, and sanded. Plywood manufacturers sand faces to hit flatness and appearance targets, and that sanding removes material. Product category also changes targets: structural sheathing, underlayment, and cabinet plywood often land in different “typical” ranges even when the shelf tag says the same nominal size.

The practical result is simple: a sheet marked 1/2 in. often measures a little under 0.500 in., and that difference shows up fast in dados, rabbets, and hardware fits.

After you get the basics here, you can follow my previously written guides on cabinet-grade plywood basics and how to choose plywood thickness for cabinets to dial in sheet selection for cabinet work.

Nominal label → typical actual thickness range (by category)

These ranges reflect common retail sheet goods in the U.S. market. Your calipers win every argument at the bench.

| Nominal label | Common category | Typical actual thickness range |

|---|---|---|

| 1/8 in. | craft / door skin panels | ~0.090–0.125 in. |

| 1/4 in. | underlayment / utility | ~0.200–0.250 in. |

| 3/8 in. | underlayment / sheathing | ~0.320–0.375 in. |

| 1/2 in. | sheathing / underlayment / cabinet panels | ~0.450–0.500 in. |

| 19/32 in. | rated sheathing (often “5/8 class”) | ~0.580–0.610 in. |

| 5/8 in. | subfloor / underlayment | ~0.590–0.625 in. |

| 3/4 in. | cabinet panels / shop panels / subfloor | ~0.700–0.750 in. |

Use these as planning numbers, then confirm with a measurement on your actual sheet.

Again I added below a clear list of plywood thickness chart, just follow.

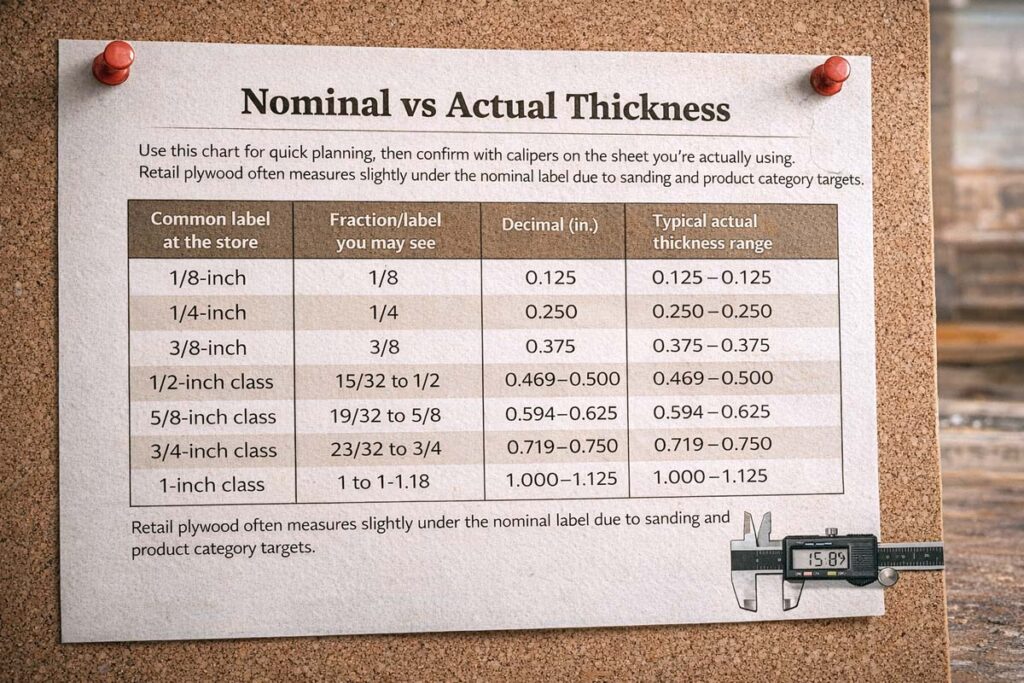

Plywood thickness chart

Use this chart for quick planning, then confirm with calipers on the sheet you’re actually using. Retail plywood often measures slightly under the nominal label due to sanding and product category targets.

| Common label at the store | Fraction/label you may see | Decimal (in.) | What it’s commonly used for |

|---|---|---|---|

| 1/8-inch | 1/8 | 0.125 | skins, curved work, drawer bottoms (light duty) |

| 1/4-inch | 1/4 | 0.250 | drawer bottoms, backs, underlayment (light duty) |

| 3/8-inch | 3/8 | 0.375 | underlayment, light panels, utility builds |

| 1/2-inch class | 15/32 to 1/2 | 0.469–0.500 | cabinet parts, underlayment, shop projects |

| 5/8-inch class | 19/32 to 5/8 | 0.594–0.625 | rated sheathing, subfloor/underlayment |

| 3/4-inch class | 23/32 to 3/4 | 0.719–0.750 | cabinets, shelving, subfloor (stiffer) |

| 1-inch class | 1 to 1-1/8 | 1.000–1.125 | heavy-duty floors, stout bench tops, specialty |

See more at: Plywood Sheet Sizes, Standard Dimensions, and Square Footage

What is 1/2-inch plywood?

1/2-inch plywood is a nominal thickness category used for cabinets, underlayment, and shop builds. The actual thickness is often around 15/32 inch (0.469″), but it can vary by product line.

1/2-inch plywood is a nominal panel class used for cabinet parts, drawer boxes, underlayment, and general shop builds where a mid-thickness sheet balances stiffness and weight. Most “1/2” plywood measures under 0.500 in. because face sanding and category targets land closer to the mid-0.4s to high-0.4s on many sheets.

What is actual thickness of 1/2 plywood?

The actual thickness of 1/2 plywood often falls around 15/32 in. (0.469 in.) to 1/2 in. (0.500 in.), depending on grade and category. Cabinet and hardwood-veneered panels often measure near the mid-to-high 0.4s, while some specialty panels land closer to a true half.

How thick is 1/2 inch plywood?

Most “1/2-inch” plywood measures roughly 0.45 to 0.50 inches. Some sheets land near 15/32 (common), while others are closer to a true 0.500 inch, so measure your sheet.

What is 19/32 plywood?

19/32 plywood is a nominal panel thickness equal to 0.594 inches. You’ll often see it in rated sheathing and subfloor panels, and it’s noticeably thicker than anything sold as “1/2 inch.”

Retail racks most often use it on rated sheathing and subfloor-style panels where the product line targets a “5/8 class” panel with predictable span ratings and stiffness.

Is 19/32 half inch plywood?

No. 19/32 plywood is thicker than 1/2. In shop terms, it behaves closer to a light 5/8 panel than anything called “half inch.” If you route a dado sized for your 1/2 sheet, 19/32 will not fit without widening the groove.

Where it shows up and how it compares to “1/2”

Builders buy 19/32 for floors and roofs because that thickness hits common structural layouts. Woodworkers run into it when the home center stocks “1/2” in one aisle and rated panels nearby. The label looks close, but the joinery fit is not close.

What is 3/4-inch plywood

3/4-inch plywood is the workhorse thickness for cabinet boxes, furniture carcasses, and shelves because it provides stiffness, screw holding, and edge durability in one sheet. Many sheets marked 3/4 measure a bit under the full 0.750 in. due to sanding and category targets.

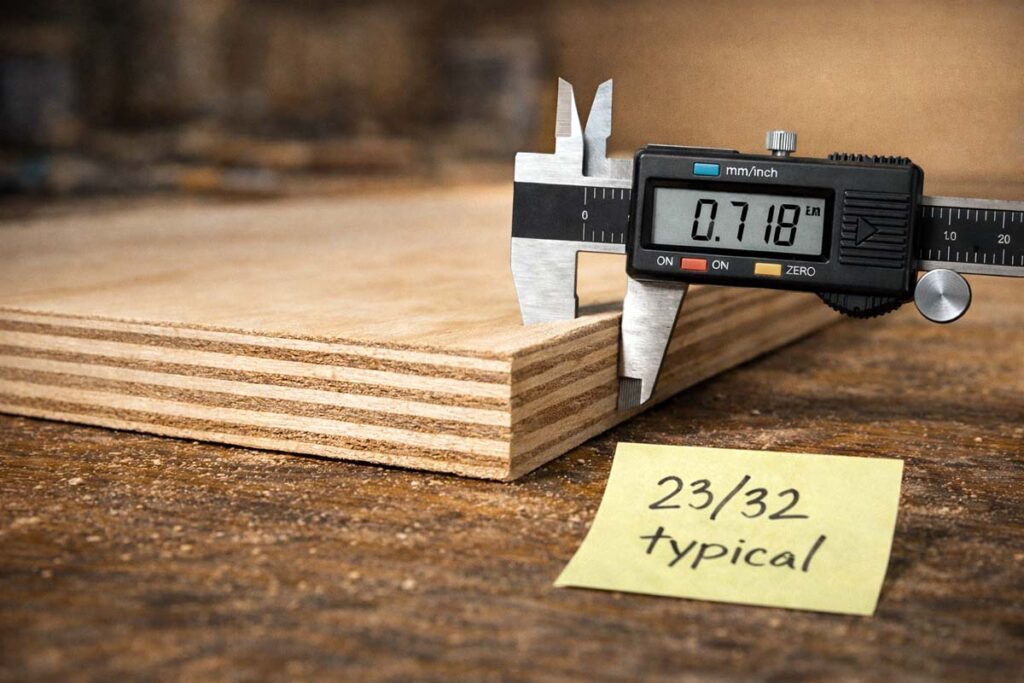

How thick is 3/4 inch plywood?

3/4 plywood often measures around 0.70–0.75 in. The most common “shop reality” number is near 23/32 in. (0.71875 in.) on many panels, but some cabinet-grade sheets land closer to a true 0.750 in. Measure first if you cut joinery or use Euro-style hardware.

If you build cabinets often, you can use my guides on what size plywood to buy for cabinets and what thickness plywood works best for cabinets to match thickness to parts, spans, and hardware.

What is the thinnest plywood?

The thinnest plywood sold widely in home centers is often 1/8 in. nominal, commonly used as door skins, curved skins, drawer bottoms, and lightweight paneling. Specialty suppliers sell thinner veneer-core panels and aircraft-style plywood, but those are niche products with different handling needs.

Thin panels earn their keep when the part needs a skin, not a structure. A thin sheet also telegraphs bumps and voids, so it rewards flat substrates and full support.

Thickest plywood panels and where people use them

Thicker plywood is less universal than thin stock because weight, cost, and handling climb fast. Many retailers carry up to 3/4 in. nominal as a standard shelf item, and thicker panels show up through lumberyards, cabinet suppliers, and specialty sheet-good dealers.

Woodworkers use thicker panels for:

- benchtops and assembly tables

- stair treads and landings

- thick jigs that hold shape

- built-ups where a single thick slab reduces glue lines

For a quick buying snapshot, you can follow my guide on the thickest plywood you can buy.

What’s the thickest plywood you can buy?

The thickest plywood you can buy depends on where you shop and what product line you accept. Most big-box stores top out around 3/4 in. nominal. Lumberyards and specialty suppliers often stock thicker structural panels and industrial sheet goods in select sizes, sometimes as special order.

If you need a thick panel for a flat surface, consider a stable build-up: two thinner sheets laminated with full glue coverage often stay flatter than a single heavy sheet from an unknown stack.

How to measure plywood thickness correctly

Accurate measuring prevents loose joinery and fit issues.

Use this order in the shop:

- Use calipers for a direct reading at multiple points on the sheet.

- Measure away from corners where handling damage rounds edges.

- Check both long edges and one spot near the center.

- Avoid chipped plies and crushed edges that read thin.

- Write the measurement on painter’s tape and stick it to the sheet before you cut joinery.

A tape measure works for rough sizing, but it does not read the last few hundredths cleanly on a frayed plywood edge.

Project guidance: where thickness differences cause problems

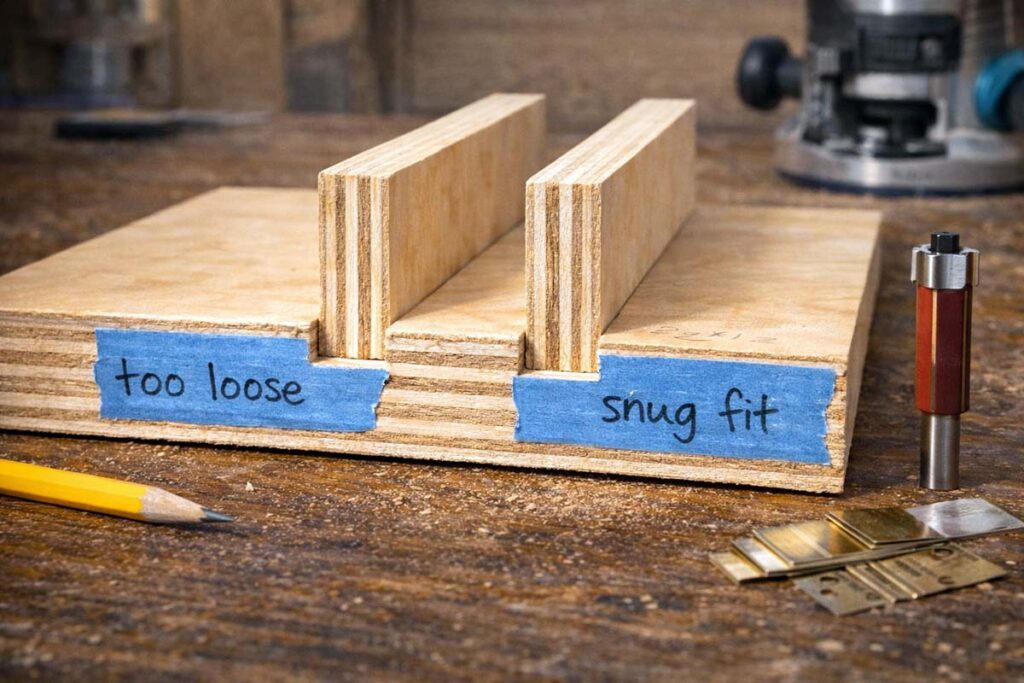

Thickness drift hurts projects when a cut relies on a tight fit.

Dados and rabbets: A dado stack set to “1/2” cuts a groove that matches 0.500 in., not 0.465–0.485 in. The joint ends up sloppy. Plywood-ready router bits, test cuts, or shims fix this.

Shelves and spans: A shelf cut from thin-measuring “3/4” stock flexes more than expected, especially with heavy loads. The label does not carry stiffness; thickness and core quality do.

Cabinet parts and hardware: European hinges, drawer slides, and confirmat screws expect consistent material. A panel that measures 0.70 in. behaves differently than one at 0.75 in. Layout stays cleaner when you confirm thickness before drilling.

If you glue plywood parts, match the adhesive to the job and clamp time to your workflow. For glue selection, you can follow my guide on wood glue for plywood assemblies.

Checklist: before you cut joinery, measure thickness

- Measure thickness with calipers in at least three spots.

- Cut a test dado or rabbet in scrap from the same sheet.

- Adjust the cutter to the measured thickness, not the nominal label.

- Keep the measured thickness written on the sheet for the whole build.

- Re-check thickness if you switch to a new sheet from the stack.

FAQs about Plywood Thickness

How thick should plywood subfloor be in a garage loft?

For a garage loft, most builders use 23/32-inch (about 3/4-inch class) tongue-and-groove subfloor for stiffness, especially at 16-inch joist spacing. Go thicker or add blocking for heavier storage loads.

How thick is plywood?

Plywood thickness ranges from very thin panels around 1/8 inch for skins and backs up to about 1-1/8 inch for heavy-duty subfloor panels. What you need depends on span, load, and fastening.

What thickness plywood for roof?

Roof sheathing is commonly 7/16 inch OSB or 1/2-inch class plywood for many standard rafter spacings, but requirements vary by span and local code. Use rated panels and match thickness to your framing layout.

How thick is 15/32 plywood?

15/32 plywood is 0.46875 inches thick, which is a common actual thickness for many sheets sold as “1/2-inch.” It’s often used for cabinet parts, underlayment, and general shop projects.

How thick is 23/32 plywood?

23/32 plywood is 0.71875 inches thick, and it’s a very common actual thickness for panels sold as “3/4-inch.” You’ll see it in cabinet boxes, shelving, and tongue-and-groove subfloor sheets.

Concluding Notes

Plywood thickness works best when you treat the rack label as a category name and your calipers as the final authority. Measure the sheet, set joinery to the measured number, and plan around the panel class you actually bought. That habit prevents loose dados, wobbly shelves, and hardware surprises, and it keeps your builds consistent from one stack of plywood to the next.