How to Make Wood Glue Dry Faster: 7 Proven, Safe Shop Tricks

To make wood glue dry faster, you want to shorten clamp time safely, not cheat strength. Most “drying” problems come from cold air, high humidity, thick glue lines, or loose joints. I’ll show you what drying and curing really mean, what speeds glue-ups the right way, and what shortcuts quietly weaken your work.

Contents Here

- 1 Drying vs curing: what “faster” actually means

- 2 Factors that control how fast wood glue dries

- 3 Prep for speed before you open the glue

- 4 Safe ways to make wood glue dry faster

- 5 What not to do: common myths and mistakes

- 6 How to tell wood glue is dry enough for the next step

- 7 FAQs on Make Wood Glue Dry Faster

- 8 Final Words

Drying vs curing: what “faster” actually means

Wood glue usually changes in two stages. First it sets enough that clamps can come off. Later it cures to full strength inside the joint. If you rush the second part, the joint may look fine and fail later.

A good rule in my shop is simple. If the joint will see stress, let it cure fully. If you’re just trimming squeeze-out or moving the piece, you’re dealing with set time.

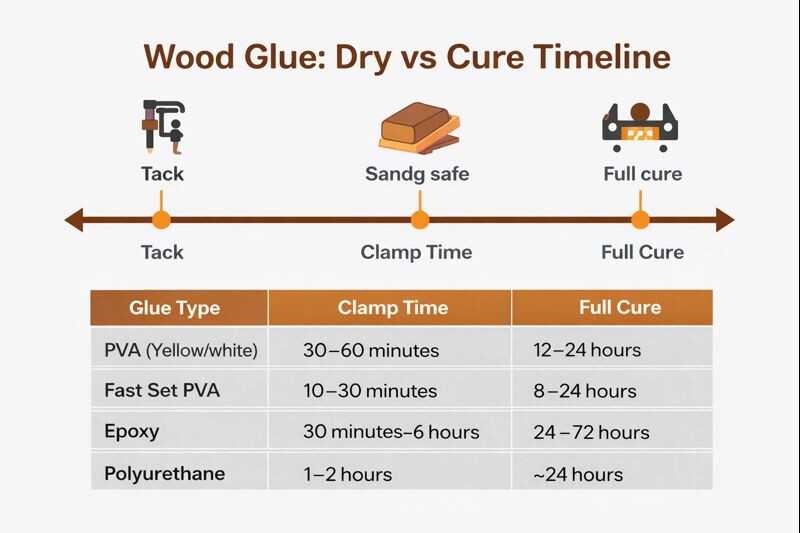

Quick reference chart by glue type

Times vary by brand and conditions, but this keeps expectations realistic.

| Glue type | What it does | Typical clamp/handling time | Full cure time |

|---|---|---|---|

| PVA (yellow/white “carpenter’s glue”) | Water evaporates + polymers bond | 30–60 minutes | 12–24 hours |

| Fast-set PVA | Same idea, shorter open time | 10–30 minutes | 8–24 hours |

| Polyurethane glue | Moisture-cured reaction | 1–2 hours | ~24 hours |

| Epoxy | Chemical cure | 30 min–6 hours (depends) | 24–72 hours |

| CA (super glue) | Rapid chemical set | seconds–minutes | minutes–hours |

If you’re unsure, follow the bottle. Glue labels are written for a reason.

Factors that control how fast wood glue dries

If you understand the levers, you’ll stop guessing. Most wood glues slow down for four reasons: cold temperature, high humidity, poor airflow, or too much glue. Joint fit matters too. A tight joint with a thin glue line sets faster and ends stronger.

Temperature and humidity: the biggest levers

PVA glues dry mostly by water leaving the joint. Cold air slows evaporation. Humid air slows it even more. If your shop feels chilly and damp, your glue will act like it.

Aim for comfortable room conditions. Warm and moderately dry air is the sweet spot. Extremely high heat can skin glue over and trap moisture inside.

Airflow and ventilation

Moving air helps moisture leave the glue line. Still air lets humidity build around the joint. A small fan across the workbench often beats a stronger clamp, especially on wide glue-ups.

Keep airflow gentle. You don’t want a dust storm landing in wet squeeze-out.

Glue amount, joint fit, and clamp pressure

More glue does not mean faster results. Thick glue lines take longer to dry because there’s more moisture trapped. A well-fitted joint should need a thin, even coat, then firm clamping.

Look for light squeeze-out along the seam. That’s usually the sign you used enough.

If you’re doing repairs where hardware holes are involved, tight wood-to-wood contact matters even more. The same principle shows up when you’re reinforcing a damaged fastener hole the right way instead of trying to “fill” the problem with adhesive.

See more: How Long for Wood Glue to Fully Cure: 7 Crucial Dry vs Cure Facts

Prep for speed before you open the glue

This is the part most people skip. It’s also the part that makes glue-ups feel effortless.

Dry-fit everything first. Stage your clamps, cauls, and a damp rag. Make sure parts slide together smoothly without fighting. If you’re scrambling with clamps after glue is on, you’ll lose time and open strength.

Use fresh glue and store it right

Old glue can get stringy or thick. That changes how it wets the wood and how it sets. Keep glue sealed tight and stored cool. If it smells off, has chunks, or pours like jelly, it’s time to replace it.

Good habits with adhesives go hand-in-hand with tool habits. If you’re building routines, my best advice is to start with simple shop care like beginner-friendly tool maintenance practices so your clamps and cutters stay reliable.

Also learn: How Long Does Wood Glue Take to Set? 5 Glue Types, Real Times

Safe ways to make wood glue dry faster

If you only remember one thing, remember this. Improve the environment first, then adjust your technique, and only then reach for “faster” products.

Improve the room first: warm and dry wins

Bring the project indoors if your shop is cold. Even a spare room can cut drying time dramatically. In sticky seasons, a dehumidifier in the workspace can be a game-changer.

Don’t set a wet glue-up in direct, blasting heat. Warm is good. Hot and uneven is trouble.

Add airflow: small fan, big payoff

Set a fan so air passes over the work, not directly into the glue line. You’re drying the air around the joint, not trying to “blow” the glue dry. If you see glue rippling, the fan is too close.

This is especially helpful on wide panels and tray bottoms where squeeze-out holds moisture.

Apply gentle heat: hair dryer or space heater

A hair dryer on low can help, but treat it like finishing work. Keep it moving. Keep it back. Heat a broad area, not one spot. If the wood feels hot to your hand, you’re overdoing it.

A small space heater nearby is often safer than a focused blast. A heat gun is easy to misuse and can cause weak, brittle glue behavior.

Apply the right amount of glue, not “extra”

Use a thin coat on both surfaces when possible. Spread it with a brush or a scrap of wood. You want full coverage without puddles. Thick beads take longer and encourage sloppy squeeze-out cleanup.

If you’re tempted to use glue as a gap filler, fix the fit instead. A better fit saves time and improves strength.

Choose faster products when speed truly matters

Sometimes the best way to speed the job is picking a glue designed for it. Fast-set PVA is made for shorter clamp time. It’s great for small parts, quick assemblies, and repeat projects.

For tiny repairs, CA glue with an accelerator can be useful. I don’t use it for structural joints, but it’s handy for quick trim fixes and small chips.

Glue-type notes you shouldn’t ignore

Polyurethane glue cures with moisture. Bone-dry conditions can slow it down, but too much water causes foaming and weak glue lines. A light mist is plenty when the label calls for it.

Epoxy cures by chemistry, not evaporation. Heat can speed it up, but only within safe ranges. Mixing ratio matters more than anything else.

What not to do: common myths and mistakes

There are a few “tips” that spread because they sound smart. They also cause weak joints.

- Don’t dilute wood glue with water to “help it dry.”

- Don’t remove clamps early because squeeze-out feels dry.

- Don’t bake glue-ups in an oven or set them on radiators.

- Don’t drown the joint and hope pressure fixes it.

- Don’t glue in cold, damp air and expect quick results.

Don’t dilute the glue

Adding water changes the glue’s formulation and can reduce strength. It also encourages swelling and uneven squeeze-out. If you need better spread, use a brush and apply a thinner layer instead.

How to tell wood glue is dry enough for the next step

I like simple checks that don’t damage the joint.

First, check the clock and conditions. If it’s cold or humid, add time. Next, look at squeeze-out. If it’s rubbery and skins over, you’re approaching safe handling. If it’s still white and wet, leave it alone.

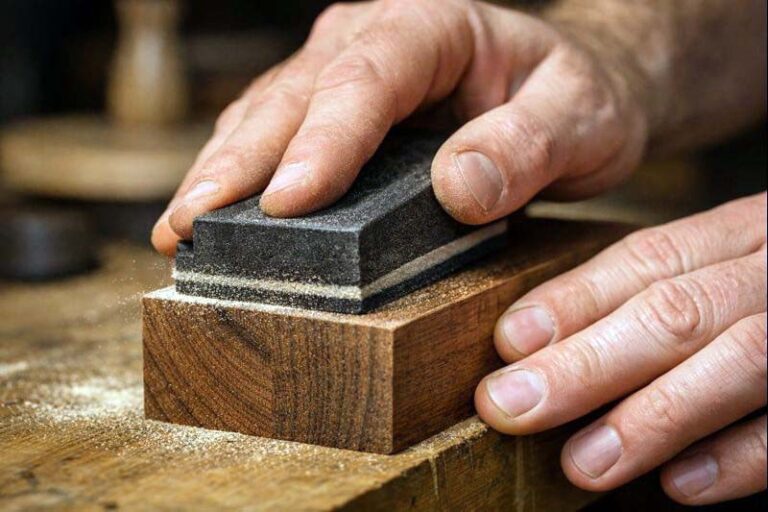

Use the fingernail test on squeeze-out only. Press the squeeze-out lightly. If it dents and stays gummy, it’s too soon. If it flakes or powders, you’re closer to safe trimming and light sanding.

If you plan to paint or seal right after assembly, patience matters even more. Finishes can trap moisture and keep spots tacky. When you’re getting to the finishing stage, it helps to follow a proven process like sealing a wooden serving tray for long-lasting protection rather than rushing into topcoats.

FAQs on Make Wood Glue Dry Faster

How long should clamps stay on wood glue?

Most PVA glue-ups need at least 30–60 minutes in decent conditions. Small joints may set sooner, large panels often need longer. When it’s cold or humid, add time.

What’s the difference between “dry” and “cured” glue?

Dry usually means it’s set enough to handle and unclamp. Cured means the adhesive has reached full strength in the joint. Many failures happen when people stress joints before cure.

Should I use less glue if I want it to dry faster?

Use less in the sense of a thinner, even layer, not starved joints. You still need full coverage. The goal is a thin glue line with a tight fit, not a dry joint.

Is fast-set wood glue as strong as regular glue?

For most indoor woodworking, fast-set PVA is plenty strong when used correctly. It typically has shorter open time, so dry-fit and clamp fast. For high-stress joints, follow the label and let it cure fully.

Why does glue stay tacky under paint or sealer?

Moisture trapped in the glue line can slow finishing. That’s why I wait for full cure before topcoats. If you’re painting, it also helps to avoid common causes of tackiness like heavy coats and trapped moisture, similar to what you see when sealing craft paint so it doesn’t stay sticky.

Final Words

Speeding up wood glue is mostly about better conditions and cleaner technique. Warm, moderately dry air plus gentle airflow shortens clamp time reliably.

Thin, even glue lines in tight joints set faster and stay stronger. Use gentle heat carefully, and let full cure time happen before heavy stress.