How to Cut a Dowel Rod Without a Saw: 5 Fast, Clean Methods

To cut a dowel rod without a saw, clamp it in a V-block so it can’t roll, score a deep ring around the cut line with a sharp utility knife (or chisel), snap it at the score, then sand the end flat.

A sharp utility knife, a chisel, or even a friction cord can produce a usable cut when a handsaw is not on the bench. This guide covers the cleanest no-saw methods, which dowel sizes each method fits, and the quick sanding steps that leave a tight joint and a tidy end.

If you want a quick refresher on dowel basics, see this guide to what a wooden dowel is and how it works in joinery. If you make your own stock, this walkthrough on how to make dowels at home helps you match diameter and grain for cleaner cuts.

Contents Here

- 1 Can you cut a dowel rod without a saw?

- 2 What tools cut a dowel cleanly without a saw?

- 3 Safety setup that reduces slips

- 4 Method 1: Score-and-snap with a utility knife

- 5 Method 2: Score-then-sever with a chisel

- 6 Method 3: Nibble-and-rotate with heavy-duty shears

- 7 Method 4: Friction cord pull-cut

- 8 Method 5: Sandpaper strap cut

- 9 How to get a square cut without a saw

- 10 Common problems and fixes

- 11 Final safety check

Can you cut a dowel rod without a saw?

Yes. Woodworkers cut a dowel without a saw by scoring the circumference with a knife or chisel, then snapping or paring the remaining fibers. That approach keeps the cut line controlled and reduces tear-out. Knife control matters because knives drive a large share of hand lacerations in emergency departments, so set up a stable holding method before cutting.

If you’re deciding between species, read how dowel rods work as alignment pins in joinery so you match the wood to the job.

What tools cut a dowel cleanly without a saw?

A utility knife, a sharp chisel, heavy-duty shears, a friction cord, and sandpaper used as an abrasive “strap” all cut dowels. Each tool fits a different diameter and wood species.

- Utility knife (score-and-snap): clean on 1/8″ to 3/8″ (3 to 10 mm) dowels in softwoods and straight-grain hardwood.

- Chisel (score-then-sever): clean on 3/8″ to 1″ (10 to 25 mm) dowels when the end faces matter.

- Shears (nibble-and-rotate): fast on 1/8″ to 1/4″ (3 to 6 mm) dowels, with more crushing risk.

- Friction cord (pull-cut): works on small dowels when patience beats tool access.

- Sandpaper strap (abrasive cut): slow, controlled, and good for short trims.

Safety setup that reduces slips

Knife injuries often happen when the blade slips and contacts the off-hand. HSE describes that exact pattern as the common mechanism for hand-knife accidents.

Set up like this before any cut:

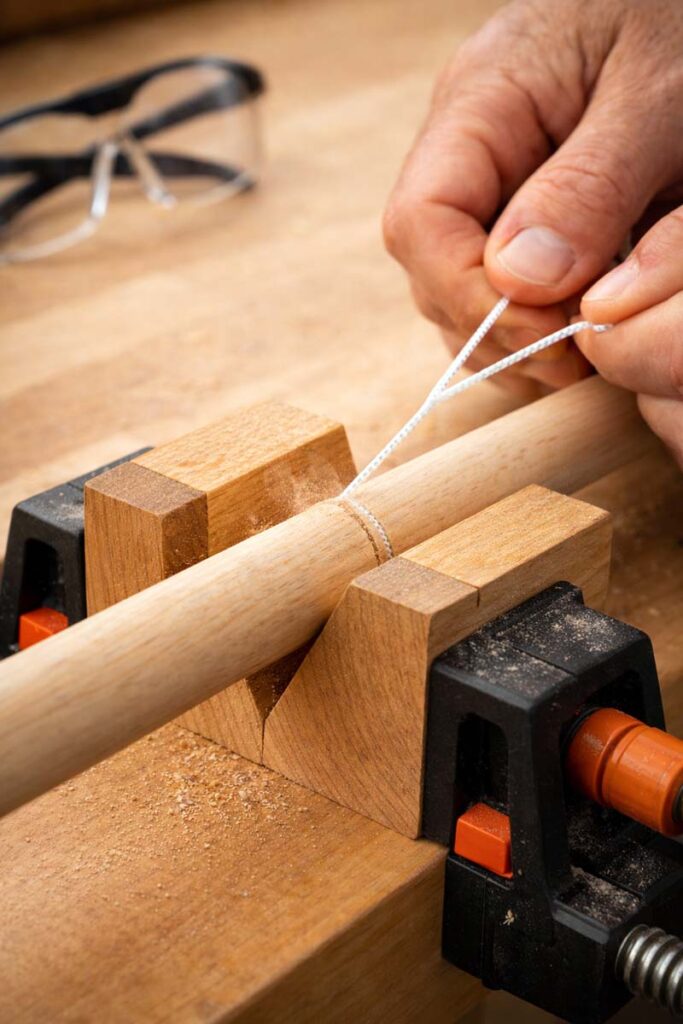

- Clamp the dowel or trap it in a V-block (two scraps forming a “V”) on the bench.

- Keep the off-hand behind the cutting path, not “pinching” near the cut line.

- Expose only the blade length needed and cut away from your body, as utility-knife safety training recommends.

- Put on eye protection and consider cut-resistant gloves for the off-hand. For a quick PPE rundown, see essential safety gear for small woodworking builds.

Method 1: Score-and-snap with a utility knife

This method produces a surprisingly square break when the score line goes deep and even.

- Mark the cut. Wrap painter’s tape around the dowel with the tape edge on the cut line. Use the tape edge as a visual guide.

- Build a V-block. Set the dowel in the V so it cannot roll. Clamp the V-block to the bench.

- Score the circumference. Hold the knife steady and rotate the dowel, letting the blade cut a shallow groove all the way around.

- Deepen the score. Repeat rotations until the groove reaches roughly 1/3 of the dowel diameter. On a 3/8″ dowel, that groove lands near 1/8″ deep.

- Snap on a hard edge. Place the score line on the corner of a scrap block. Press down in one controlled motion.

- Dress the end. Sand the end grain flat and break the sharp corner with a light chamfer.

For a smooth end face that glues well, follow this guide to sanding end grain smooth without fuzz.

Why it works: the score line acts like a controlled weak point. The break follows the circle you cut, not the random grain.

Method 2: Score-then-sever with a chisel

A chisel gives more leverage and less hand strain on thicker dowels.

- Mark the cut. Use a square and pencil, then wrap tape as a clean reference line.

- Trap the dowel. Clamp it in a V-block or between two scraps.

- Knife-score first. Make a light knife score around the line to reduce splintering.

- Seat the chisel in the score. Set the bevel facing the waste side for a cleaner shoulder.

- Tap to sever fibers. Use light mallet taps while rotating the dowel a quarter turn at a time.

- Pare the last fibers. Finish with controlled paring cuts, then sand.

Best use: dowels that show, like tray handles, stand columns, or exposed pins.

Method 3: Nibble-and-rotate with heavy-duty shears

Shears cut fast, but they crush fibers on hardwood and larger diameters. Keep expectations realistic.

- Mark the line. Tape helps here.

- Take small bites. Cut only 1/8 of the diameter per bite.

- Rotate between bites. Walk around the dowel until the fibers let go.

- Sand the end flat. Plan on extra sanding to remove crush marks.

Best use: softwood dowels, bamboo skewers, and temporary jigs.

Method 4: Friction cord pull-cut

A strong cord plus friction can cut through a small dowel. It runs slow, but it works when your kit is thin.

- Clamp the dowel hard. Any movement wastes effort.

- Wrap the cord once. Set it on the cut line like a belt.

- Pull with short strokes. Keep tension and saw the cord back and forth.

- Refresh the line. If the cord wanders, re-seat it in a shallow knife score.

- Finish with sanding. The cut face usually needs flattening.

Tip: thin braided nylon grips better than slick paracord.

Method 5: Sandpaper strap cut

This is the cleanest “no blade” option for small trims.

- Clamp the dowel.

- Wrap coarse sandpaper (60 to 80 grit) around the line.

- Pull like shining shoes. Keep the paper tight and centered.

- Switch to 120 grit to true the face.

Best use: shaving off 1/16″ to 1/8″ (1.5 to 3 mm) when a dowel runs long in a drilled hole.

How to get a square cut without a saw

Square cuts come from a stable reference and even removal around the circumference.

- Use a tape wrap to “self-square” the line.

- Trap the dowel in a V-block to stop rolling.

- Rotate the dowel instead of swinging your hand around it.

- Flatten the end on sandpaper laid on a flat surface (glass, tile, or a cast-iron top).

Common problems and fixes

The dowel splinters at the edge: Deepen the score line and knife-score first before snapping. Tape reduces surface tear-out.

The cut ends up angled: Your score line varies in depth. Re-score the high side and snap again, or sand the end square on a flat sanding surface.

Shears crush the fibers: Switch to the knife or chisel method, or take smaller bites and rotate more often.

The dowel refuses to snap: The score depth stays shallow. Increase score depth to about 1/3 diameter, then snap over a sharper corner.

Final safety check

Hand and finger lacerations generate large numbers of emergency department visits, and knives link to a major share of those product-related injuries. Treat every “quick cut” like a real operation.

Keep these habits on the bench:

- Clamp the work and use a V-block.

- Cut away from your body and keep blade exposure short.

- Keep the off-hand out of the cutting path.

- Sand and chamfer the end so the dowel seats without shaving fibers.