How Long Should Wood Glue Dry Before Removing Clamps: 5 Pro Tips

Removing clamps: how long should wood glue dry before removing clamps comes down to stress, glue type, and shop conditions. In short, for most wood glue joints, leave the clamps on 30–60 minutes for light, unstressed pieces, but wait about 24 hours before stressing or loading the joint.

If you’re staring at a glued joint and itching to move on, the safest mindset is simple—clamps come off when the glue has “set,” but the joint isn’t ready for real stress until it cures. That one distinction prevents most glue-ups from failing later.

Contents Here

- 1 The real answer: clamp time vs full cure (don’t mix them up)

- 2 Drying vs curing: what those words mean in a wood shop

- 3 Clamp-time chart by glue type (quick and practical)

- 4 What changes clamp time in real shops

- 5 Clamping technique that affects results (not just the clock)

- 6 How to tell it’s safe to remove clamps

- 7 After clamps come off: when to sand, machine, finish, or load the joint

- 8 FAQs on how long wood glue should dry before removing clamps

- 9 Conclusion

The real answer: clamp time vs full cure (don’t mix them up)

“Dry enough to remove clamps” is really set time, not full strength. Set time means the joint won’t slide around when you handle it gently. Full cure is when the glue reaches its designed strength and stops being vulnerable to movement, heat, and load.

Here’s the rule I teach in my shop:

- Unstressed joints: clamps often come off in 30–60 minutes in a warm shop.

- Stressed joints: keep clamps on longer, and don’t load the joint for about 24 hours.

- Cold shop, thick glue, or dense wood: add time—sometimes a lot of it.

If you want a deeper baseline for timing, see these typical shop-condition ranges for wood glue dry times and how they shift with temperature and humidity.

Also learn: How Long to Clamp Wood Glue: 10-Minute Guide for Beginners

What counts as an “unstressed” vs “stressed” joint?

An unstressed joint is supported by the parts around it and won’t be flexed much. Think picture frames, small boxes, light trim, and decorative assemblies.

A stressed joint gets leveraged, racked, bounced on, or loaded. Think chairs, stools, table bases, bed rails, shelves carrying weight, and anything that gets dragged or twisted. If the joint will see force, treat it as stressed—even if it looks small.

Drying vs curing: what those words mean in a wood shop

Wood glue feels hard long before it’s fully cured. That’s why people pop clamps, start sanding, and then wonder why a seam telegraphs later or a joint creaks loose.

- Dry / set: the glue grabs and holds alignment.

- Cure: the glue develops strength throughout the glue line.

If you want to work with confidence, it helps to understand set time versus handling time instead of relying on the “feels dry” test.

Know more: How Strong Is Gorilla Wood Glue: 7 Hard Truths for Stronger Joints

Clamp-time chart by glue type (quick and practical)

Most clamp-time questions are really “What glue are you using?” questions. Glue families behave differently, and the label always wins if it’s specific.

PVA / yellow wood glue (most common for woodworking)

For common PVA and aliphatic resin glues, a safe shop baseline is:

- Clamp removal: often 30–60 minutes in a 70°F shop.

- Gentle handling: usually fine after that, if you’re careful.

- Stress/load: wait about 24 hours whenever the joint matters.

If you’re planning a big assembly schedule, it helps to know the full cure timeline for common wood glues so you’re not rushing a table base or chair rung.

Polyurethane glue (foaming types)

Polyurethane glue can need longer clamping than typical yellow glue, especially when the fit isn’t perfect. It also depends heavily on moisture and temperature. Clamp it until the joint is fully stable and the glue has stopped creeping.

My advice: if you’re using polyurethane because the project is tricky, give it extra time and avoid stressing the joint early.

Epoxy and CA (super glue)

- Epoxy: can be very strong, but cure time depends on the formulation. Some epoxies handle in hours, others need overnight.

- CA glue: grabs fast, but it’s not a replacement for wood glue on structural joints.

If you’re repairing furniture and choosing between glues, this breakdown on picking the right glue for a furniture repair helps you match strength, gap-filling, and working time to the job.

What changes clamp time in real shops

Two glue-ups can use the same glue and still behave differently. These factors are why.

Temperature (including cold-garage glue-ups)

Wood glue is happiest around room temperature. In a cold garage, glue sets slowly, and clamping “the usual 30 minutes” can be a mistake.

If your shop is chilly, plan for longer clamp time and longer cure time. Warm parts, warm glue bottles, and warm air make a noticeable difference.

Humidity and wood moisture

High humidity slows evaporation. Damp lumber also fights you, because moisture moves around the glue line and changes how the glue behaves.

If your wood feels cool and clammy, don’t trust a fast clamp schedule. Give the joint more time to stabilize.

Too much glue and heavy squeeze-out

A thick glue layer doesn’t automatically mean a stronger joint. It usually means a longer dry time, more squeeze-out, and more cleanup risk.

Aim for a thin, even coat that wets both surfaces. When squeeze-out appears, it’s telling you the joint is seated, not that you need more pressure.

Wood species and density

Porous woods can “grab” quickly, while dense hardwoods may need more patience. The bigger issue is usually fit and pressure, but species can change how consistent your timing feels.

Clamping technique that affects results (not just the clock)

Clamps don’t create strength—they create contact. Your goal is full contact along the joint line, without distorting parts.

- Use enough pressure to close the joint.

- Don’t crank clamps until boards bow or joints starve for glue.

- Use cauls when needed to keep panels flat and seams aligned.

If your assembly feels rushed, you’re likely bumping into open-time limits. That’s when joints slide, parts drift, and clamp time doesn’t matter because alignment is already compromised.

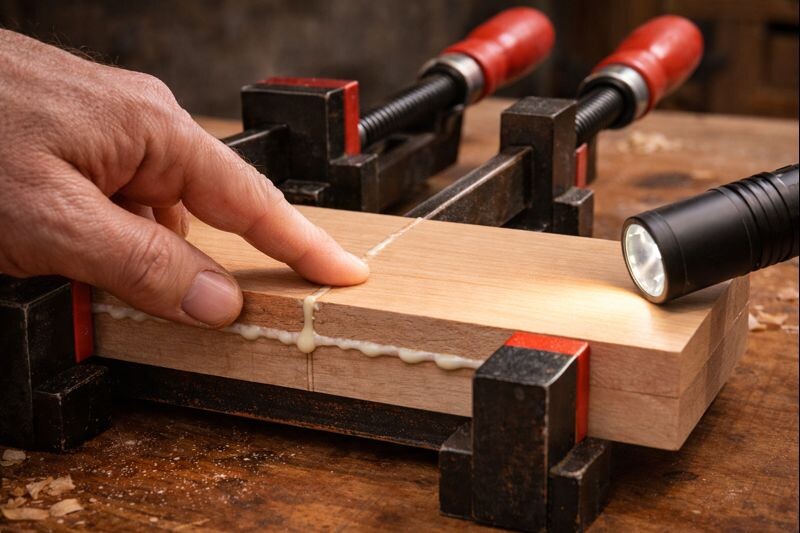

How to tell it’s safe to remove clamps

I like practical checkpoints more than guessing by minutes.

You can usually remove clamps when:

- The joint stays aligned when you lightly press near the seam.

- The parts don’t shift when you remove one clamp and re-check.

- The glue squeeze-out has turned rubbery, not liquid.

If you’re unsure, leave clamps on longer. Waiting rarely hurts; removing early can ruin a joint quietly, and you won’t notice until later.

After clamps come off: when to sand, machine, finish, or load the joint

This is where most beginners get burned. A joint can be “clamp-off ready” and still be cure-soft.

- Light handling: usually okay once the joint is stable.

- Sanding/planing: better when glue has firmed up, so you don’t smear it.

- Heavy machining or stress: wait until the glue has had real time to cure.

If you’re trying to move faster without gambling on strength, use controlled shop conditions. This guide on speeding up glue drying without weakening the joint walks through safe ways to warm the workspace and improve airflow.

FAQs on how long wood glue should dry before removing clamps

Can I remove clamps after 20 minutes if the joint feels solid?

Sometimes it feels solid, but that doesn’t mean it’s stable. If the joint matters, give it more time. Early removal is a common cause of tiny shifts that weaken the glue line.

How long should clamps stay on for a table, chair, or shelf?

Those are stressed joints. Keep clamps on longer, and don’t load the joint for roughly 24 hours. When in doubt, wait overnight before putting weight on it.

Does wiping glue squeeze-out change drying or clamp time?

Not much, as long as you don’t flood the joint with water. Wipe carefully or let squeeze-out gel and scrape it. Your clamp schedule should be based on joint stress and conditions, not cleanup timing.

How long after gluing can I sand or apply finish?

Sanding too soon can smear glue into the grain and show up under finish. Wait until glue is firm, then sand. For best results, give the joint adequate cure time before final surfacing and finishing.

Is more clamp pressure better for a stronger bond?

No. Too much pressure can bow parts or squeeze out too much glue. Use enough pressure to close gaps and hold alignment, then let the glue do its job.

Conclusion

The safest answer to clamp removal is: remove clamps after the glue sets, then avoid stressing the joint until it cures. For most yellow wood glues in a warm shop, that’s often 30–60 minutes for gentle handling, and about a day before real load. When it’s cold, humid, or structural, add time and sleep better.