Hide Glue vs Wood Glue: 11 Quick Tests to Pick the Right Glue

Hide glue vs wood glue is one of those choices that sounds minor until you’re fixing a chair or gluing up a panel. Both can make strong joints, but they behave differently when you clamp, sand, finish, and repair later. I’ll walk you through the practical differences so you can pick confidently.

Contents Here

- 1 Hide glue vs wood glue at a glance

- 2 What is hide glue (and why it behaves differently)

- 3 What is wood glue (PVA) and the common “wood glue” types people mix up

- 4 Pros and cons of hide glue

- 5 Pros and cons of wood glue (PVA) for most projects

- 6 Key differences that matter

- 7 When to use hide glue (best-fit project list)

- 8 How to use hide glue vs wood glue (basic workflow + best practices)

- 9 Troubleshooting (what to do when things go wrong)

- 10 FAQs on Hide Glue vs Wood Glue

- 10.1 Is wood glue safe for cutting boards?

- 10.2 Which glue is better for antique furniture?

- 10.3 Is hide glue as strong as wood glue?

- 10.4 Is hide glue waterproof or water resistant?

- 10.5 How do you reverse or remove hide glue from a joint?

- 10.6 Why does hide glue have a shorter shelf life than wood glue?

- 11 Final Words

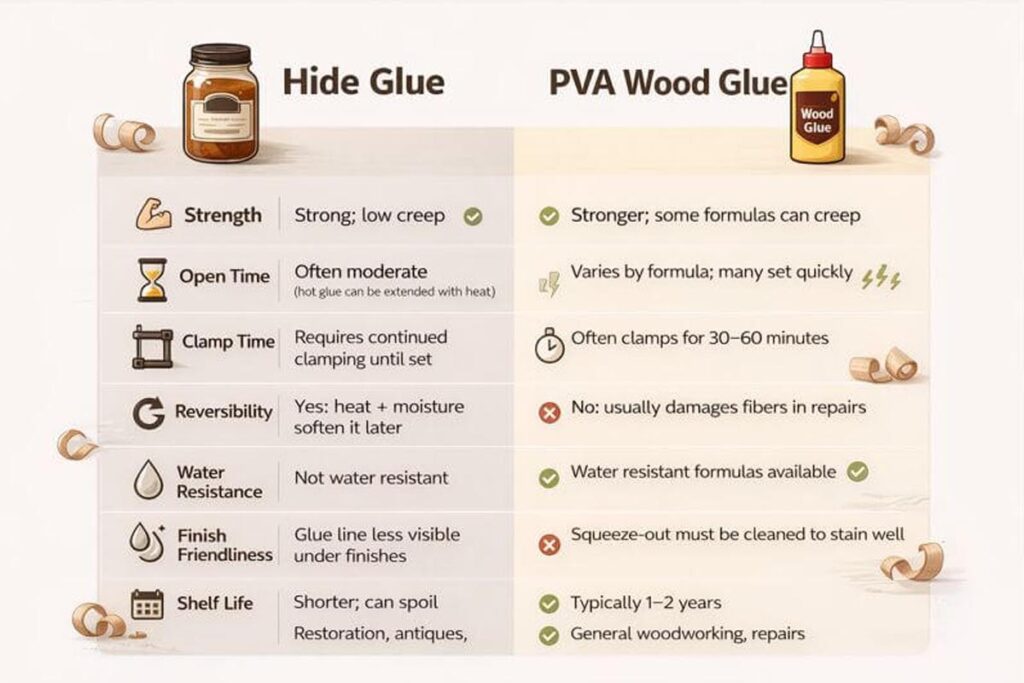

Hide glue vs wood glue at a glance

If you want the short version, here it is: hide glue shines when you care about future repairs and a clean finish line. Standard wood glue (usually PVA) wins for speed, convenience, and moisture-resistant options.

A quick rule I use in the shop:

- Restoration, instruments, or “I might need to take this apart later” → hide glue.

- Most everyday furniture builds and general repairs → PVA wood glue.

Side-by-side comparison table

| Factor you’ll notice in the shop | Hide glue (hot or liquid) | Wood glue (PVA / carpenter’s glue) |

|---|---|---|

| Typical use | Restoration, instruments, traditional joinery | Most woodworking and home repairs |

| Open time | Often moderate; can be extended with heat | Varies by formula; many are fast |

| Clamp time | Usually needs steady clamping until set | Often 30–60 minutes clamp, then cure |

| Full cure | Depends on thickness and humidity | Often 24 hours for full strength |

| Reversibility | Yes, with heat and moisture | Not really; joint removal is destructive |

| Creep under load | Low | Can creep in warm, stressed joints |

| Finish friendliness | Glue line can be less obvious | Squeeze-out can block stain/finish |

| Water resistance | Poor | Available in water-resistant formulas |

| Shelf life | Shorter, especially liquid | Longer if stored well |

| Cleanup | Warm water when fresh | Water when fresh; harder when cured |

Also see: Wood Glue vs Super Glue: 5 Fast Tests to Choose the Right One

What is hide glue (and why it behaves differently)

Hide glue is a collagen-based adhesive made from animal hide and bone. In woodworking terms, that means it “grabs” wood fibers well and can be softened again later with heat and moisture. That reversibility is why restorers and instrument makers still rely on it.

Hide glue also has a nice habit: fresh hide glue will bond to old hide glue. That matters when you’re repairing an older joint and don’t want to scrape every last trace away.

Liquid hide glue vs hot hide glue (what changes in the shop)

You’ll run into two common forms:

Hot hide glue comes as granules or flakes. You mix it with water and warm it in a glue pot. It sets as it cools, so your timing and shop temperature matter.

Liquid hide glue comes in a bottle. It’s modified (often with urea) to stay liquid at room temperature. That makes it easier for small jobs, but it usually has a shorter shelf life and can be weaker if it’s old.

If you do occasional repairs, liquid hide glue is the simple entry point. If you’re doing serious restoration work, hot hide glue gives you more control.

What is wood glue (PVA) and the common “wood glue” types people mix up

When most folks say “wood glue,” they mean PVA (polyvinyl acetate) or aliphatic resin carpenter’s glue. It’s the stuff that spreads easily, cleans up with water while wet, and is forgiving for general joinery.

If you want a quick refresher on the basics, start with what PVA wood glue actually is. It’ll make the comparisons below much clearer.

People also call polyurethane and epoxy “wood glue,” but those are different adhesives with different strengths. For the hide glue vs wood glue decision, you’re usually comparing hide glue to PVA.

When polyurethane or epoxy is the better call (brief but useful)

If the joint sees steady moisture, big temperature swings, or mixed materials, switch adhesives. Polyurethane and epoxy handle gaps and weather better than hide glue, and often better than standard PVA.

That said, most indoor wood-to-wood joints don’t need anything exotic. A well-fit joint with the right glue will outlast the furniture.

Pros and cons of hide glue

Hide glue has a reputation for “old-school,” but the advantages are practical.

Pros

- Reversible for repairs. Heat and moisture can release a joint without shredding the wood.

- Great for restoration. It bonds to existing hide glue in older pieces.

- Friendly under finishes. Glue lines can be less obvious when you’re careful.

- Low creep. Helpful for joints that stay under load for years.

Cons

- Poor water resistance. Not the best choice for outdoor projects or damp spaces.

- Temperature sensitive. Heat can soften it, especially in stressed joints.

- Shorter shelf life. Bottled hide glue can fail if it’s old.

- More setup. Hot hide glue needs warming and a bit of routine.

If you’re unsure whether your bottle is still good, compare it to how you’d judge shelf life for other adhesives. This article on whether wood glue expires in the bottle gives you a simple checklist you can adapt.

Pros and cons of wood glue (PVA) for most projects

PVA is popular for a reason. It’s reliable, easy, and widely available.

Pros

- Strong wood-to-wood bonds. Especially in tight-fitting joints.

- Easy cleanup while wet. Water and a rag handle most messes.

- Many formulas. Fast-set, extended open time, and water-resistant versions exist.

- Easy to find. Any hardware store will have several options.

Cons

- Hard to reverse. Taking a joint apart later usually damages the wood.

- Finish problems from squeeze-out. Dried glue can block stain and make pale patches.

- Creep can happen. In warm conditions with constant load, some joints shift.

Want a realistic strength baseline? See how strong a glued joint can really be.

Key differences that matter

This is where the decision becomes simple. Think about the joint, the environment, and whether you’ll ever want to undo it.

Strength, creep, and long-term durability

In a well-made joint, both glues can be very strong. The bigger difference is what happens over time under load. Hide glue tends to resist creep, so it can hold alignment better in stressed joints.

PVA is still plenty strong, but some formulas can slowly move when warm and loaded. That shows up in long shelves, bent laminations, and chairs that live near heat.

Open time, clamp time, and full cure

Open time is how long you have to assemble the joint after spreading glue. Clamp time is how long it needs pressure. Cure time is when it reaches full strength.

PVA varies a lot by brand and formula, and people often rush the cure. If you want the safe timing, here’s a clear guide on how long wood glue takes to fully cure.

Hide glue sets differently. Hot hide glue “gels” as it cools, so you work efficiently and clamp promptly. Liquid hide glue is slower and feels more like PVA, just less water-resistant.

Reversibility and repair work

This is the big one. Hide glue can be re-softened with heat and moisture, which means you can fix a loose joint without wrecking the surrounding wood.

PVA doesn’t give you that option. If you force a PVA joint apart, you usually tear wood fibers and change the fit. For antiques, that’s a problem you can’t undo.

Finish/appearance (glue line, stain, clear coat)

Both glues can ruin a finish if you leave squeeze-out where stain or topcoat needs to bite. The difference is how obvious it gets and how you manage cleanup.

My habit is to avoid wiping wet glue across open grain. I let squeeze-out gel, then slice it off with a sharp chisel. If you’ve already got dried glue on a surface, don’t panic. This method for removing dried glue without damaging wood can save the finish.

If your build will be stained, it also helps to know whether glue will take stain cleanly and what to do when it won’t.

Water and heat exposure (indoor vs outdoor reality)

Hide glue and water don’t mix. Occasional humidity is fine for indoor furniture, but steady moisture, outdoor exposure, or wet-cleaned surfaces are asking for trouble.

PVA gives you more options. Standard PVA is for interior work, while water-resistant versions are better for kitchens, bathrooms, and some outdoor pieces. If the job is truly outdoors year-round, consider exterior-rated adhesives and finishes together.

Cost, availability, storage, and shelf life

PVA is cheap, easy to find, and stores well when the cap stays clean. Hide glue can cost a bit more, and hot hide glue requires a small setup.

Shelf life matters more than most people think. A half-used bottle that froze in the garage can fail even if it looks normal. With hide glue, I’m stricter: if it smells off, strings oddly, or never really sets hard, I toss it.

When to use hide glue (best-fit project list)

Hide glue earns its spot in the shop when repairability and clean work matter.

Use hide glue for:

- Antique furniture repairs where joints may need future service.

- Musical instruments where reversible joints are part of the craft.

- Traditional joinery with tight fits, like dovetails and mortise-and-tenon.

- Veneer work and delicate glue-ups where you want predictable grab.

Hide glue also suits “rub joints” on small parts, where you press and rub the pieces until the glue grabs. It’s a neat trick, and it works best with practice.

When to use wood glue (best-fit project list)

For most furniture builds, PVA is the dependable choice.

Use wood glue for:

- Panel glue-ups like table tops and cabinet sides.

- General joinery for indoor furniture and shelving.

- Fast repairs where you need a strong bond with simple steps.

- Projects needing water resistance when you choose the right formula.

If you’re fixing furniture and want a safe all-around pick, use this guide to choosing glue for repairs.

How to use hide glue vs wood glue (basic workflow + best practices)

Good glue work starts before you open the bottle.

- Dry-fit first. Make sure the joint closes fully without heroic clamping.

- Prep the surfaces. Freshly cut or lightly sanded wood bonds best.

- Use the right amount. You want coverage, not puddles.

- Clamp smart. Even pressure and good alignment beat brute force.

- Clean up at the right time. Let squeeze-out gel, then remove cleanly.

If you’re unsure about volume, use this guide to applying the right amount of glue.

Hide glue best practices (temperature, timing, cleanup)

- Warm the parts when you can. Cold wood shortens working time.

- Work in a steady rhythm. Hot hide glue rewards good preparation.

- Clamp promptly, then leave it alone. Don’t “test” the joint early.

- Clean with warm water while fresh. After it hardens, you’ll scrape.

With hot hide glue, temperature control matters. You’re aiming for warm and brushable, not boiling.

Wood glue best practices (clamps, squeeze-out, cure)

- Spread a thin, even film. Starved joints fail; puddles just squeeze out.

- Clamp long enough. If you pop clamps too soon, joints can slip.

- Let it cure before stressing. Strength keeps rising after it feels “dry.”

If you want a simple clamp schedule, this article on how long to keep clamps on a glued joint is a handy reference.

Troubleshooting (what to do when things go wrong)

- The joint feels weak or pops apart: Usually it’s poor fit, oily wood, or end grain soaking up glue. Size end grain with a thin coat first, then glue normally.

- You see light patches after staining: That’s almost always glue contamination. Scrape the surface back, clean the pores, and test stain again on a hidden spot.

- The glue skinned over before assembly: Your open time was too short. Dry-fit faster, switch to a longer-open-time formula, or glue in stages.

- Clamps left dents: Use pads—cork, scrap wood, or cardboard—and don’t over-tighten. Pressure should close the joint, not crush fibers.

- Old hide glue won’t set: Don’t fight it. Old liquid hide glue can fail quietly. Replace it and reglue.

FAQs on Hide Glue vs Wood Glue

Is wood glue safe for cutting boards?

Many cured PVAs are considered safe for indirect food contact, but check the exact product and intended use. Here’s a deeper look at whether cured wood glue is appropriate for kitchen projects.

Which glue is better for antique furniture?

Hide glue is usually the safer choice for antiques because it can be reversed and repaired later without destroying original joinery. PVA can make future restoration harder.

Is hide glue as strong as wood glue?

In tight-fitting joints, hide glue can be very strong. PVA is also strong and more forgiving for everyday builds. Strength differences matter less than joint fit, clamping, and the environment the piece will live in.

Is hide glue waterproof or water resistant?

No. Hide glue doesn’t like steady moisture. It can soften with humidity, heat, or water exposure, so it’s best for interior work and restoration.

How do you reverse or remove hide glue from a joint?

Gentle heat and moisture will soften hide glue. People often use a warm iron, steam, or carefully applied hot water, then work the joint apart slowly. Go easy—forced separation can split wood.

Why does hide glue have a shorter shelf life than wood glue?

Liquid hide glue is organic and can degrade faster, especially with heat swings. PVA is more stable in storage. Always date your bottle and avoid freezing either glue.

Final Words

Hide glue vs wood glue comes down to how you want the project to live. If future repairs and clean restoration work matter, hide glue is hard to beat.

If you want a strong, simple, everyday adhesive with plenty of water-resistant options, PVA is the usual pick. Choose based on environment, joint fit, and whether you’ll ever need to undo your work.