Heat Resistant Wood Glue: 9 Strong Picks for Cabinets and Trays

Heat resistant wood glue matters anytime a joint has to stay tight in warm rooms, sunlit windows, or busy kitchens. Most “strong” glues can still soften and creep when heat and steady load team up. The good news is you can pick the right adhesive quickly once you understand exposure, stress, and cure.

Contents Here

- 1 Quick Checklist: The Top 9 Heat Resistant Wood Glue

- 2 What I mean by “heat resistant” (and what I don’t)

- 3 What “heat resistant” actually means for wood glue

- 4 How heat breaks glue joints (and why “creep” matters)

- 5 Types of glue and how they handle heat

- 5.1 PVA and aliphatic resin (yellow carpenter’s glue)

- 5.2 Cross-linking PVAs and “Type I / Type II” style labels

- 5.3 Polyurethane glue (moisture-cure, gap-filling tendencies)

- 5.4 Epoxy (when you truly need higher heat tolerance)

- 5.5 Hide glue and specialty adhesives (worth knowing, not always the answer)

- 6 Reviews of the 9 Best Heat Resistant Wood Glue

- 6.1 Titebond Instant Bond Heat Resistant Wood Adhesive

- 6.2 KRAFTPROTZ All Purpose Glue

- 6.3 DAP Weldwood Professional Heat Resistant Wood Glue

- 6.4 Everbuild D41 D4 Wood Adhesive

- 6.5 Titebond III Ultimate Heat Resistant Wood Glue

- 6.6 Protado 35g Heavy Duty Clear Wood Glue

- 6.7 Titebond Original Wood Glue 5063

- 6.8 ClenyMagi High Strength Fast Drying Clear Wood Glue

- 6.9 WoldoClean All-Purpose Adhesive

- 7 Buyer’s guide: choosing the right heat resistant wood glue for warm conditions

- 8 Heat-tough glue picks by use case (no reviews yet, just what to look for)

- 9 Application and prep: where heat resistance is actually won

- 10 Troubleshooting: signs heat is winning (and what to do about it)

- 11 Safety notes that matter with warm-condition adhesives

- 12 FAQs on Heat Resistant Wood Glue

- 12.1 Does “waterproof” glue automatically mean better heat resistance?

- 12.2 Can regular carpenter’s glue handle a warm kitchen?

- 12.3 What’s the biggest reason glue joints fail when it’s hot?

- 12.4 How long should I clamp glued wood together?

- 12.5 What’s the difference between using wood glue and using screws?

- 12.6 Is epoxy always the best choice for heat?

- 12.7 Can I use heat to speed up glue curing?

- 13 Final Remarks

Quick Checklist: The Top 9 Heat Resistant Wood Glue

- Titebond Instant Bond Wood Adhesive

- KRAFTPROTZ All Purpose Glue

- DAP Weldwood Professional Wood Glue

- Everbuild D41 D4 Wood Adhesive

- Titebond III Ultimate Wood Glue

- Protado 35g Heavy Duty Clear Wood Glue

- Titebond Original Wood Glue 5063

- ClenyMagi High Strength Fast Drying Clear Wood Glue

- WoldoClean All-Purpose Adhesive

Also read this if you want guidance on choosing a strong adhesive for repairing wooden furniture pieces.

What I mean by “heat resistant” (and what I don’t)

In everyday woodworking, “heat resistant” usually means the glue line stays stable in service heat—think warm cabinets, radiator covers, a tray stand near a sunny window, or a piece that lives above a dishwasher. It does not mean it’s safe for direct flame, stove-side heat, or fireplace surrounds.

If your project will see temperatures that make you nervous to touch the surface, treat that as a different category. In that case, you’ll often be looking beyond typical wood glue and leaning toward specialty epoxies or mechanical joinery.

What “heat resistant” actually means for wood glue

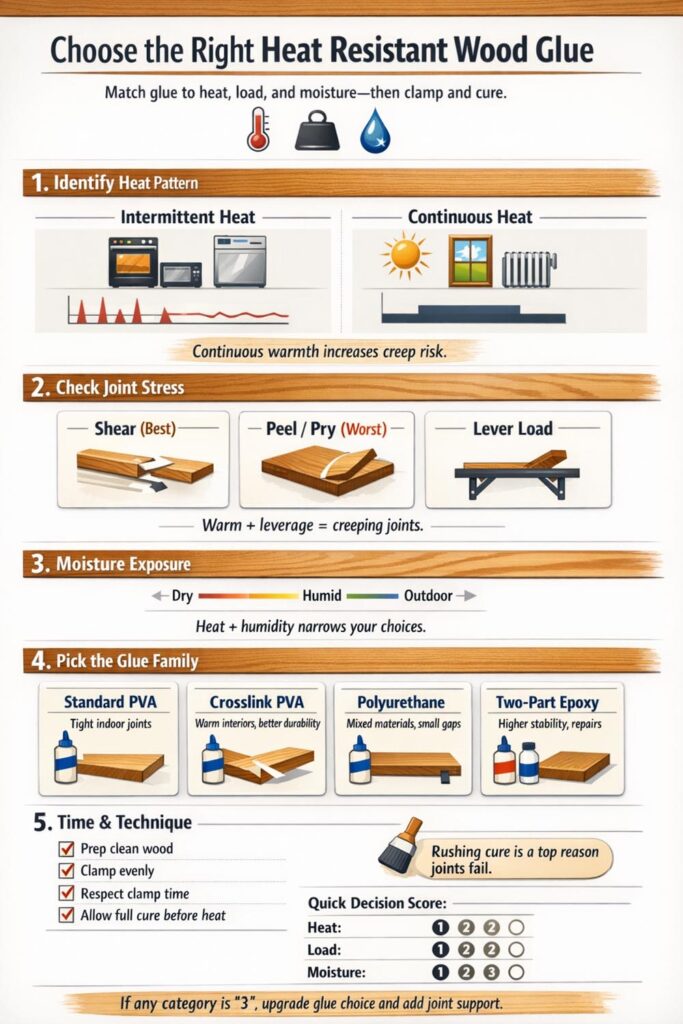

Heat resistance isn’t a single magic number on a label. It’s a mix of how the adhesive behaves when warm, how the joint is designed, and whether the glue reached full strength before it ever saw heat.

A glue can test strong in a lab pull test, then creep slowly on your wall shelf at home. That’s why it helps to think in two simple buckets: continuous heat and intermittent heat.

Continuous vs intermittent heat (the rating trap)

Continuous heat is the all-day kind: sun through glass, a warm kitchen corner, a cabinet above an appliance. Intermittent heat is the short burst: a warm dish set down briefly, a quick spike when the oven runs, or a heater turning on and off.

Many glues handle spikes fine, but creep under steady warmth—especially if the joint is under load. If you want your glue choice to hold up, assume continuous heat is the real test unless you’re certain it’s only occasional.

How heat breaks glue joints (and why “creep” matters)

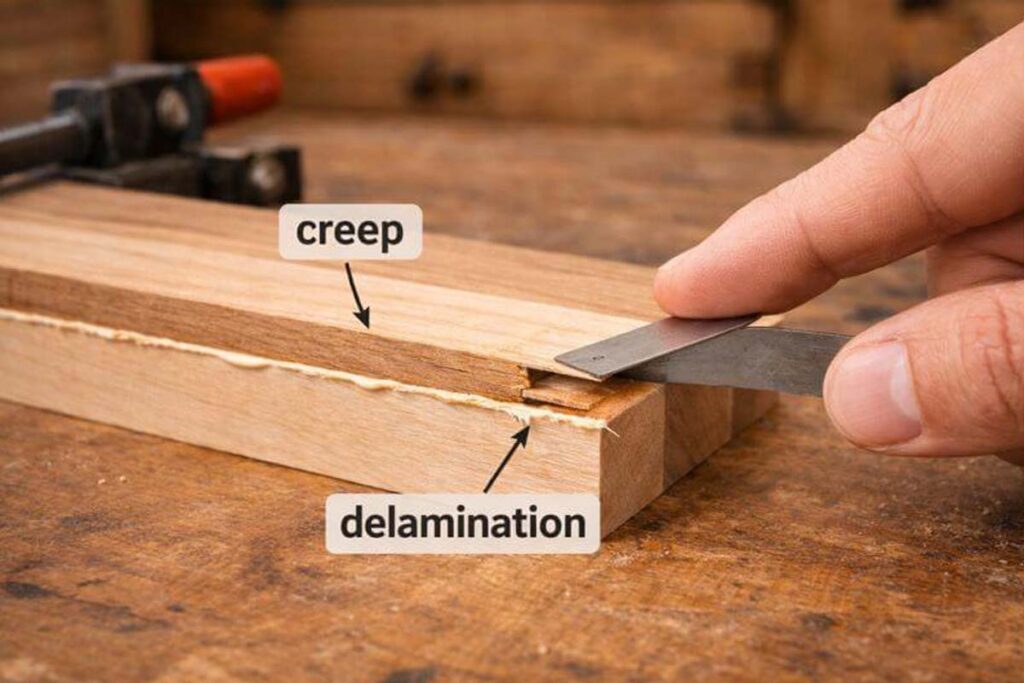

Most glue failures from heat aren’t dramatic. The joint doesn’t liquefy and fall apart. It moves—slowly.

That movement is called creep. Under warmth and steady stress, a glue line can relax just enough that a tight joint turns into a hairline gap. Laminations start to lift. Trim slides. A handle feels loose again.

If you’ve ever wondered why a glued part held perfectly in winter but shifted by late summer, creep is usually the culprit.

Real-world heat sources that cause failures

Here are the usual troublemakers I see in real homes and shops:

- Sun through a window heating a dark-stained surface daily

- Upper kitchen cabinets that live in warm, greasy air

- Above-dishwasher panels that cycle warm and humid

- Radiator covers and nearby shelves

- Attics, garages, sheds where heat builds and lingers

- Outdoor furniture where sun and moisture work together

If any of those match your project, your glue choice and your clamping discipline matter more than usual.

Types of glue and how they handle heat

There’s no single “best” adhesive for every hot-ish situation. What works for a tight mortise-and-tenon inside the house might be a poor choice for a laminated panel that sits in a sunny window.

Below is the practical way to think about common glue families.

PVA and aliphatic resin (yellow carpenter’s glue)

Standard yellow carpenter’s glue (PVA/aliphatic resin) is the workhorse for tight-fitting wood joints. It’s easy, affordable, and strong in a well-made joint.

Where it can struggle is warm, loaded joints. Under heat and steady stress, many PVAs are more prone to creep than people expect. That doesn’t make them “bad.” It just means you don’t want to rely on them for a joint that’s fighting gravity while warm.

If you want a quick refresher on the glue family itself, this breakdown of what PVA glue is and why it behaves the way it does helps you connect the label to the performance.

Cross-linking PVAs and “Type I / Type II” style labels

Some PVAs are formulated to resist moisture better and hold up in harsher conditions. You’ll often see water-resistance classifications (commonly discussed as Type I/II in the U.S.) or European-style durability classes like D3/D4 on certain products.

Don’t treat those labels as “heat proof.” Treat them as a sign the adhesive is built for tougher service conditions overall. In warm, humid spaces—like kitchens and laundry rooms—those tougher formulations can be a smarter baseline than basic school-bottle PVA.

Polyurethane glue (moisture-cure, gap-filling tendencies)

Polyurethane glue gets picked when people want “gap filling,” but it’s not a cure-all. It can bond a variety of materials and can tolerate imperfect joinery better than some PVAs.

The catch is the foaming action can push parts apart if clamping is sloppy. It also isn’t the neatest glue to sand and finish. I use it when the project benefits from its material compatibility, not because I’m trying to brute-force a bad joint.

Epoxy (when you truly need higher heat tolerance)

Epoxy is often where you land when you need more stability under heat than typical wood glue provides. It can bond well, handle mixed materials, and resist creep better in many situations.

The tradeoff is real: mixing, careful ratios, longer cure schedules, and more attention to surface prep. If you’re on the fence between families, this comparison of wood glue versus epoxy for demanding joints can help you decide without guessing.

Hide glue and specialty adhesives (worth knowing, not always the answer)

Hide glue earns points for reversibility and tradition. In some fine woodworking contexts, that matters. For heat-heavy service conditions, though, you generally want to be cautious unless you already know the full performance profile you need.

Reviews of the 9 Best Heat Resistant Wood Glue

Titebond Instant Bond Heat Resistant Wood Adhesive

Fast-Set, Temperature-Tough Spot Repairs

This thick cyanoacrylate gel is built for quick fixes where clamping is awkward. It grabs fast, fills larger gaps than runny super glues, and stays steady around heat and solvents—handy on MDF edges, trim returns, and small parts.

$11.99 at AmazonIf you’re comparing CA to traditional glue, see this quick explainer on wood glue vs super glue for repairs.

Specifications

- Type: Cyanoacrylate (gel), thick/thin options

- Set/cure: listed 18 seconds

- Size: 2 oz bottle; water resistant

Pros

- Reduces or eliminates clamp time

- Bonds wood and many plastics/stone

Cons

- Short working time; practice helps

- Not ideal for large structural joints

KRAFTPROTZ All Purpose Glue

Heat-Ready Universal Super Glue for Mixed Materials

A thin-to-medium CA that’s made for fast household repairs across wood, plastic, metal, glass, and rubber. It dries clear for visible fixes and includes a precision tip to control mess. For warm areas, its heat resistance helps, but keep joints tight—super glue isn’t forgiving on loose fits.

$9.49 at AmazonIf you’ve ever wondered why some bottles fail early, read does wood glue expire and how to store it.

Specifications

- Type: Cyanoacrylate (liquid), medium viscosity

- Full cure: 3 hours; waterproof

- Size: 1.75 oz tube; tensile strength listed 25 lb

Pros

- Bonds in seconds, minimal pressure

- Clear finish, large tube

Cons

- Brittle on flexing parts

- Limited reposition time

DAP Weldwood Professional Heat Resistant Wood Glue

Warm-Zone PVA for Clean Sanding and Finishing

This professional PVA is a solid choice when you need a traditional wood-glue workflow but want extra resistance to heat, oils, grease, and common solvents. Once cured, it sands, stains, and paints well, making it practical for cabinetry and furniture touch-ups.

$7.27 at AmazonIf finish compatibility is your concern, here’s a helpful note on whether wood glue is stainable after cure.

Specifications

- Type: PVA (liquid), ~5500 cps

- Full cure: 24 hours; water resistant

- FDA compliant for indirect food contact

Pros

- Strong, finish-friendly glue line

- Good resistance to shock when cured

Cons

- Needs full cure before heat/load

- Not a gap-filler for loose joints

Everbuild D41 D4 Wood Adhesive

Waterproof D4-Grade Glue for Hot, Wet Service

This hybrid-resin D4 adhesive is designed for internal and external joinery where moisture and temperature swings are common. It sets in about 10 minutes, dries clear, and conforms to EN 204 D4 and WATT 91 (per listing). Give it patience—its highest water resistance is stated to arrive after 7 days.

$46.26 at AmazonFor clamp timing basics, use how long to clamp wood glue without rushing.

Specifications

- Type: Hybrid resin (liquid), high viscosity

- Full cure: 7 days; waterproof

- Notes: don’t use below 10°C; water cleanup

Pros

- D4 waterproof rating; temperature resistant

- Clear dry, strong bond for joinery

Cons

- Not suitable for load bearing

Titebond III Ultimate Heat Resistant Wood Glue

Durable Waterproof Glue for Warm Kitchens and Shop Builds

Titebond III is built for demanding interior/exterior work where heat, humidity, and handling add up. It offers strong initial tack, sands cleanly, and is described as ANSI/HPVA Type I waterproof.

$7.97 at AmazonI still treat cure time seriously on warm-service projects—this guide on how long for wood glue to fully cure before loading keeps you out of trouble.

Specifications

- Type: Advanced PVA (liquid), medium viscosity

- Clamp time: listed 30 minutes; tensile strength 4000 psi

- Notes: indirect food contact; don’t use below 47°F

Pros

- Waterproof rating; easy sanding

- Longer open time for bigger glue-ups

Cons

- Not for continuous submersion

- Not for structural/load bearing

Protado 35g Heavy Duty Clear Wood Glue

Clear-Drying CA Gel for Tight, Fast Repairs

Protado’s gel-style cyanoacrylate is aimed at clean, nearly invisible repairs on wood, MDF, plywood, and small assemblies. It grabs in 10–30 seconds, then builds strength as it cures (listed 24 hours). The precision nozzle helps on seams, trim, and edge chips.

$7.99 at AmazonIf you end up with glue on fingers, keep this handy: how to get wood glue off skin safely.

Specifications

- Type: Cyanoacrylate (gel), high viscosity

- Set: 10–30 seconds; full cure 24 hours

- Waterproof; heat resistant; 35g bottle

Pros

- Clear drying for neat repairs

- Good control on vertical surfaces

Cons

- Short working time

- Not ideal for wide joints with movement

Titebond Original Wood Glue 5063

Classic Carpenter’s Glue With Solid Heat Resistance

This aliphatic-resin wood glue is the old reliable for tight-fitting interior joints. It sets quickly, sands well, and is described as resistant to heat, solvents, and mildew—useful in warm rooms where moisture isn’t the main threat.

$3.68 at AmazonFor strength expectations, this quick reference on how strong wood glue really is helps you match glue to the job.

Specifications

- Type: Aliphatic resin/PVA (liquid), ~3,200 cps

- Fast set; short clamp time; water cleanup

- Water resistance: not water resistant; 8 oz bottle

Pros

- Excellent sandability; finish-friendly

- Great for hardwoods/softwoods, porous materials

Cons

- Needs tight joinery (not gap filling)

ClenyMagi High Strength Fast Drying Clear Wood Glue

Quick-Bond Waterproof Glue for Small Parts and Trim

ClenyMagi is positioned as a fast-bonding clear adhesive that works on wood plus mixed materials like ceramic and stone. It sets in 10–15 seconds and fully cures in 24 hours (per listing), with a precision tip that’s helpful for seams, edging, and vertical repairs.

$6.99 at AmazonIf squeeze-out happens, this guide on how to remove dried wood glue cleanly saves your finish.

Specifications

- Form: gel/liquid; medium viscosity

- Set: 10–15 seconds; full cure 24 hours

- Waterproof; clear finish; bottle

Pros

- Clear drying for visible fixes

- Easy application with fine tip

Cons

- Limited reposition time

- Best on tight, well-mated surfaces

WoldoClean All-Purpose Adhesive

Heat-And-Humidity Repair Glue With a Fine-Tip Cap

This medium-viscosity CA flows smoothly for controlled, clean repairs on wood, metal, plastic, ceramic, and glass. It bonds in about 10–45 seconds and cures in 24 hours (per listing), making it useful for quick household and garage fixes that still need decent heat and humidity tolerance.

$6.99 at AmazonIf you’re deciding between this and construction adhesive for a project, compare them here: wood glue vs construction adhesive for real jobs.

Specifications

- Type: Cyanoacrylate (liquid), medium viscosity

- Bond: 10–45 seconds; full cure 24 hours

- Water resistant; clear finish; anti-clog cap

Pros

- Precise applicator, clean results

- Works across many materials

Cons

- Not for flexible, bending joints

- Short working time on larger assemblies

Buyer’s guide: choosing the right heat resistant wood glue for warm conditions

Picking heat resistant wood glue gets simple when you stop shopping by label and start shopping by exposure + stress + moisture. The glue that holds a picture frame perfectly can still creep on a loaded shelf in a warm kitchen. Use the steps below and you’ll land on a reliable choice without guesswork.

1) Map your heat exposure

Ask: how hot, and for how long?

- Intermittent heat: short spikes from an oven cycle or a warm dish.

- Continuous heat: hours of sun through glass, radiator warmth, or hot cabinet zones.

Continuous heat is tougher because it encourages slow movement over time.

2) Judge load and failure direction

Heat usually shows up as creep under load.

- Tight long-grain joints handle warmth better than you’d think.

- Peel/pry joints (trim, handles, brackets) loosen sooner when warm.

If the joint is levered or carrying weight, add joinery support or discreet fasteners.

3) Don’t ignore humidity

Warm plus moisture is rough on glue lines. Kitchens, laundry rooms, and outdoor pieces need more durability than a dry bookshelf. If the project sees steam, splashes, or dew, plan for it from the start.

4) Match the glue family to the situation

- Standard carpenter’s glue (PVA/aliphatic): best for tight-fitting indoor wood joints. Here’s a plain explanation of how PVA glue behaves in real joinery.

- Upgraded PVAs: good when you want easy cleanup but need better durability in warm interiors.

- Polyurethane glue: useful for mixed materials or small gaps, but clamping must be firm.

- Epoxy: the safer pick for higher heat stability, repairs, and mixed substrates. This guide on when epoxy makes more sense than wood glue lays out the tradeoffs.

For big glue-ups, choose a formula with enough open time to align parts calmly before clamping, without rushing anything.

5) Treat time as a performance feature

Warm-service joints punish rushed cures. Follow the label minimums, then give yourself margin. Use this reference on how long to keep clamps on a glue joint and this breakdown of full cure timing before you load the project as your baseline.

6) Run a quick scrap test for high-stakes builds

Glue two scraps using the same wood and joint style. Let it fully cure, then warm it in sunlight and try to flex it. If it creeps, switch adhesive or improve the joint.

Tip: If you need speed, use safer methods from these practical ways to help glue dry faster instead of overheating the joint.

Heat-tough glue picks by use case (no reviews yet, just what to look for)

This is where most competitor articles list specific bottles and do quick pros/cons. I’ll keep this section focused on selection rules, and we’ll drop your product reviews in right after you send details.

Warm interior zones: kitchens, sunny windows, radiator-adjacent shelves

Look for adhesives that prioritize:

- Lower creep under load

- Better durability in warm, humid air

- Reasonable working time for careful assembly

If the joint will be stressed while warm, give joinery extra support and don’t skimp on clamp time.

Exterior sun plus moisture: outdoor trays, patio serving pieces, garden décor

Outdoor projects are rough because heat and moisture cycle together. Even a “hot day” glue choice has to survive damp nights and morning dew.

Prioritize:

- High moisture resistance

- A glue line that won’t soften and shift when warm

- Finishing steps that protect the wood from swelling

If you’re finishing an outdoor serving piece, don’t ignore sealing. This walkthrough on how to seal a wooden serving tray so moisture stays out pairs well with a durability-minded glue choice.

When standard wood glue isn’t enough: higher-heat areas

If your project sits near sustained high heat, treat glue as only one part of the solution.

- Consider epoxy systems that are designed for higher service temperatures.

- Add mechanical fasteners or joinery that carries the load independently.

- Re-think placement or add heat shielding if possible.

I’m careful here for a reason: “heat resistant” gets used loosely online. Your project deserves a safer, more conservative approach.

Application and prep: where heat resistance is actually won

I can’t tell you how many glue failures I’ve repaired that weren’t caused by the product. They were caused by dust, poor clamping, cold shops, or rushing.

Here’s the shop-simple process that gives you the best odds.

Surface prep that holds up under warmth

- Sand fresh on mating surfaces and dry-fit first.

- Remove oils and finishes completely. Glue bonds wood, not varnish.

- Blow or brush off dust so it doesn’t weaken the glue line.

- Use the right amount—too little starves the joint, too much makes a mess.

If you tend to guess on quantity, this guide on using the right amount of glue without starving the joint will tighten up your results quickly.

Clamping rules that prevent heat creep later

Clamping isn’t about crushing the wood. It’s about holding perfect contact while the adhesive sets.

- Use enough pressure to close the joint evenly end-to-end.

- Clamp with cauls if you’re prone to bowing panels.

- Keep parts from skating by using light tack or alignment aids.

- Leave clamps on for the full recommended time, even if it “feels set.”

For most common PVAs, this reference on how long to keep clamps on before you move the piece is a good baseline. Then add extra patience if the shop is cool or the joint is heavy.

Don’t sand, stress, or heat the joint too early

A joint can feel solid long before it’s truly cured. If you sand aggressively, route edges, or put the piece into a warm spot too soon, you can weaken the bond or lock in creep.

If timing is your struggle point, this note on how long to wait before sanding a glued joint keeps you from undoing good work.

Troubleshooting: signs heat is winning (and what to do about it)

When heat is the problem, the symptoms look a little different than a simple bad glue-up.

Common signs

- A tight seam becomes a hairline gap over time

- Laminated strips start to lift at the edges

- Trim pieces slide slightly out of position

- A handle or bracket feels firm cold, then loose when warm

What fixes actually work

If the joint has shifted, you usually can’t “re-glue” over old adhesive and expect a reliable repair. Old glue blocks penetration and weakens the bond.

Do this instead:

- Disassemble if possible, using gentle heat only if appropriate.

- Remove old adhesive thoroughly.

- Refit the joint so it closes cleanly again.

- Choose a more suitable adhesive family for the service conditions.

- Clamp properly and let it reach full cure before returning to heat.

If you need help cleaning up without chewing up your work, this method for removing dried glue without damaging wood fibers is the safest starting point.

Safety notes that matter with warm-condition adhesives

- Ventilate well, especially with epoxy and polyurethane products.

- Wear gloves if you’re sensitive or doing repeated glue-ups.

- Keep heat tools away from solvents and uncured adhesive.

- If a project is near true high heat, don’t “test it” casually indoors.

For a general shop setup refresher, I like pointing beginners to essential safety gear that actually gets used. It’s not fancy, but it prevents dumb injuries.

FAQs on Heat Resistant Wood Glue

Does “waterproof” glue automatically mean better heat resistance?

Not always. Waterproof ratings focus on moisture performance, not how the glue line behaves when warm and loaded. Some tough waterproof formulas resist creep better, but you still need to check heat exposure and joint stress.

Can regular carpenter’s glue handle a warm kitchen?

Often, yes—if the joint is tight, mostly long-grain, and not heavily loaded. Regular carpenter’s glue can creep in warm zones like above appliances, so give it full cure time and avoid high-leverage joints.

What’s the biggest reason glue joints fail when it’s hot?

Creep under load is the big one. Heat softens many adhesives slightly, and a stressed joint can slowly slip instead of snapping. Over time, that creates hairline gaps, delamination, or loose parts.

How long should I clamp glued wood together?

Follow the bottle’s clamp-time minimum, then add a little margin for thicker parts, cooler shops, or big glue-ups. A joint can feel set quickly but still needs hours (or longer) to reach real strength.

What’s the difference between using wood glue and using screws?

Wood glue spreads strength across the whole joint and can be stronger than the wood when fitted well. Screws add instant holding power and handle pull-out forces, but can split wood and don’t replace good joint fit.

Is epoxy always the best choice for heat?

No. Epoxy can be great for heat stability and mixed materials, but it’s slower, fussier, and needs careful mixing and prep. For tight indoor joinery, a good wood glue is often easier and plenty strong.

Can I use heat to speed up glue curing?

A little warmth can help, but too much can weaken the bond by skinning the glue, causing uneven cure, or increasing creep later. It’s safer to improve airflow, clamp properly, and let the joint cure fully.

Final Remarks

Heat resistant wood glue is less about chasing a miracle bottle and more about matching adhesive to heat exposure, joint stress, and moisture. Build joints that support themselves, prep clean surfaces, clamp with purpose, and respect full cure time. When heat becomes sustained and serious, step up to specialty systems and stronger joinery.