Can You Use Wood Glue on Plastic? 9 Mistakes to Avoid Today

You can use wood glue on plastic, but standard PVA wood glue rarely bonds well and usually peels off unless the plastic is rough and the joint is low-stress—epoxy or polyurethane is a better choice.

If you’ve ever tried gluing a plastic insert onto a wooden tray, you’ve probably seen the problem: the joint looks fine, then peels off later. That’s not you doing it “wrong.” It’s usually the glue choice, the plastic type, or both. In this article, I’ll show you when wood glue can work, when it can’t, and what to use instead so the bond survives real use.

Contents Here

- 1 Can you use wood glue on plastic? A straight answer you can plan around

- 2 Why wood glue struggles on plastic (and why sanding alone isn’t magic)

- 3 Wood glue types and what actually happens on plastic

- 4 Plastic type matters more than most people think

- 5 Best alternatives to wood glue for bonding plastic to wood

- 6 Surface prep that actually moves the needle

- 7 Step-by-step: How to glue plastic to wood so it stays put

- 8 Durability tips: moisture, heat, flex, and wood movement

- 9 Food-contact and serving pieces: a quick, sensible caution

- 10 Conclusion

Can you use wood glue on plastic? A straight answer you can plan around

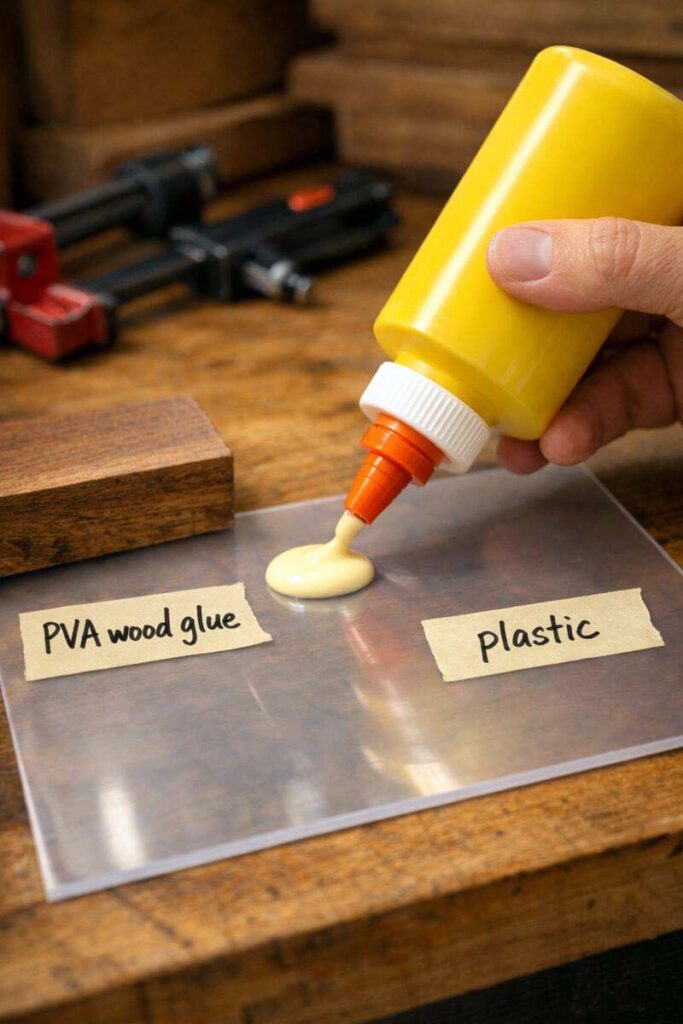

Most “wood glue” is PVA (yellow or white carpenter’s glue). PVA is built for porous materials, especially wood fibers. Plastic isn’t porous, and many plastics are slick by design. So yes, you can smear wood glue on plastic, but you usually won’t get a dependable bond for anything that’s bumped, flexed, or pulled.

Where it sometimes works:

- Decorative, low-stress parts that never get pried or flexed

- Rough, textured plastics with lots of mechanical “tooth”

- Large surface areas that are clamped well and never see moisture

Where it usually fails:

- Smooth plastic (most household plastics)

- Any joint under tension, peel, vibration, or twisting

- Outdoor or wet areas

If the part matters, treat wood glue as a “maybe” and choose an adhesive meant for plastic.

Also learn: Does Gorilla Wood Glue Work on Plastic? Avoid 9 Mistakes Today

Why wood glue struggles on plastic (and why sanding alone isn’t magic)

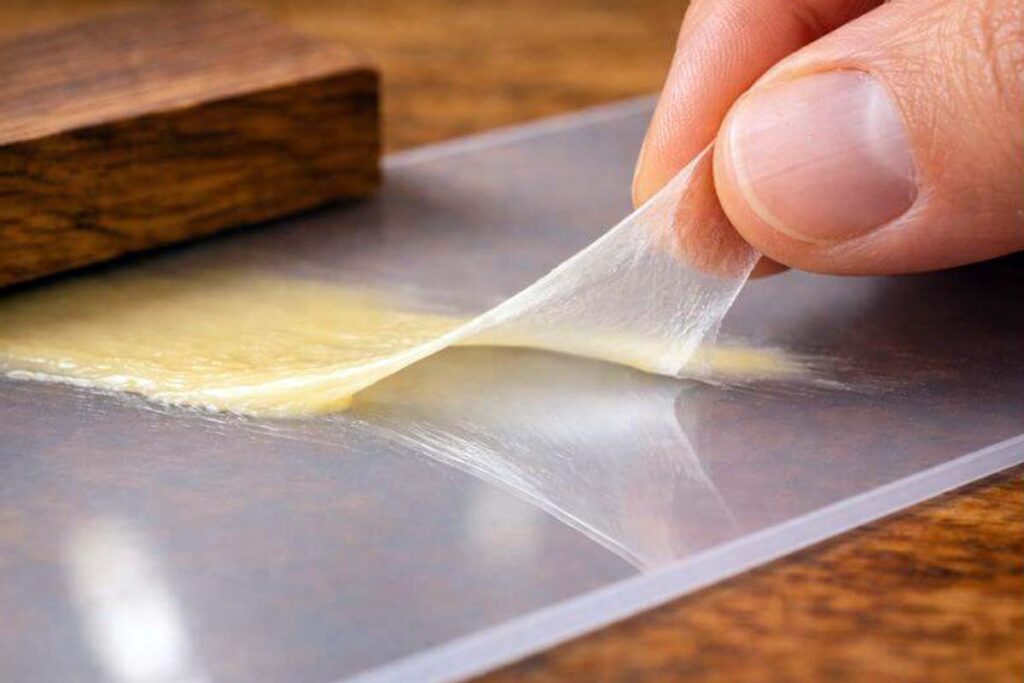

Wood glue wins by soaking into wood fibers and locking in as it cures. Plastic gives it nothing to soak into. On top of that, many plastics have low surface energy, meaning glue doesn’t wet the surface well. You can clamp hard and still end up with a thin skin of dried glue that lifts like tape.

Sanding helps, but it doesn’t change the chemistry. You’re mostly creating scratches so the adhesive can grip mechanically. That’s a good step, but it can’t turn PVA into a plastic-bonding adhesive.

Wood glue types and what actually happens on plastic

PVA (yellow/white carpenter’s glue)

This is the classic bottle of wood glue: Titebond-style yellow glue or white school-style glue. On plastic, PVA typically dries into a flexible film that peels away under stress. If you want a feel for what PVA can realistically do on wood, check the breakdown on how much weight a glued joint can really carry in practice. Plastic usually performs worse than those wood-to-wood numbers.

“Water-resistant” PVA

Some PVAs are rated for moisture resistance, but they’re still PVAs. Moisture rating doesn’t automatically mean “sticks to plastic.” It means it holds up better on wood once cured.

Polyurethane “wood” glues

Polyurethane glues (the expanding, foaming types) can bond to more materials than PVA, including some plastics. They’re not perfect, but they’re often more forgiving than carpenter’s glue for mixed-material joints. They also expand, which can fill gaps, but that expansion can push parts out of alignment if you don’t clamp well.

If you’re comparing glue strength on wood to set expectations, the notes on strength differences between common carpenter’s glues help put the baseline in your head.

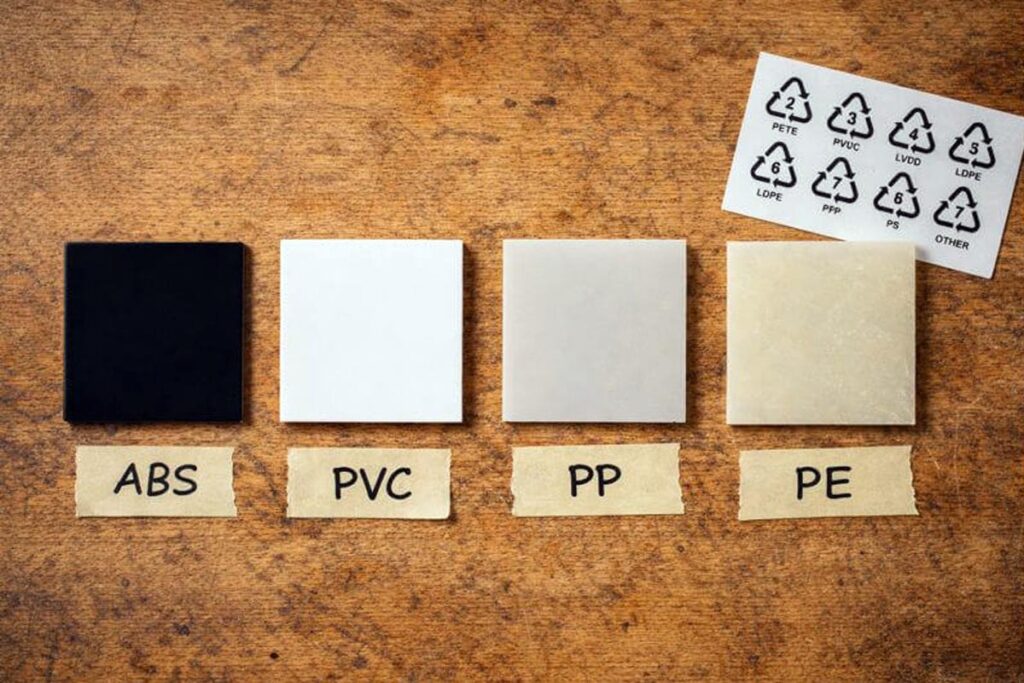

Plastic type matters more than most people think

Not all plastic is the same. If you don’t know what plastic you have, you’re guessing—and guessing is why these repairs fail.

More glue-friendly plastics:

- ABS (often used in tool housings and some rigid parts)

- PVC (common in pipe and trim)

- Acrylic / PMMA (clear rigid sheets and displays)

Hard-to-bond plastics:

- PP (polypropylene) and PE (polyethylene)

These are common in kitchen containers, bins, and many “flexy” molded items. They resist adhesives unless you use special primers or specialty products.

Quick ways to identify plastic:

- Look for a recycling mark and letters like PP, PE, HDPE, PVC, ABS

- Notice flexibility: PP/PE often feels waxy and slightly springy

- Try a water droplet test: if water beads tightly, adhesion is harder

If it’s PP or PE and the bond is important, plan on epoxy plus serious surface prep, or skip glue entirely and use mechanical fasteners.

Best alternatives to wood glue for bonding plastic to wood

You’ve got a few good options. The “best” one depends on the job.

Two-part epoxy (my first pick for most wood-to-plastic bonds)

Epoxy bonds well to wood and many plastics, and it’s excellent when the fit isn’t perfect. It also handles shock and vibration better than brittle glues.

Use epoxy when:

- The joint carries weight

- The part gets bumped or handled often

- You need gap-filling strength

Helpful habit: don’t stress the joint early. Even when epoxy feels hard, full cure takes time. The same “don’t rush it” rule applies to wood glue too—this timeline guide on full cure time before you hang weight on it is a good mindset reference.

Cyanoacrylate (super glue) for small, tight-fitting parts

Super glue is great for small repairs and tight joints where the parts fit cleanly. It grabs fast, but it can be brittle. If the plastic flexes, the bond can crack.

Use CA when:

- The part is small

- The fit is tight

- The joint won’t flex much

Pro tip: scuff-sanding the plastic and wood makes CA far more consistent.

Polyurethane adhesive for gap-filling and moisture resistance

Polyurethane adhesive can be a strong choice when the joint might see humidity, or when the surfaces aren’t perfect. It also bonds to wood well.

Use polyurethane when:

- You need water resistance

- The joint has small gaps

- You can clamp firmly

Clamping matters here. If you’re unsure how long to keep pressure on a joint, this quick reference on how long to keep clamps on a glue-up helps you build good habits across adhesives.

Contact cement for large surface areas

If you’re laminating a plastic sheet to a wooden face with lots of surface area, contact cement can work well. It’s less ideal for small parts or high-peel edges, but it’s handy for “skin-on” style bonds.

Specialty plastic adhesives (and when you actually need them)

For difficult plastics like PP/PE, you may need:

- Adhesion promoters/primers made for low-energy plastics

- Plastic-specific systems (like MMA adhesives) designed for structural bonds

These can be excellent, but they’re not always worth buying for a one-off craft project unless the joint must not fail.

Surface prep that actually moves the needle

Most glue failures on plastic come down to oils, smoothness, or not enough clamp pressure. Here’s what works reliably.

Clean and degrease first

Plastics often carry mold-release residue from manufacturing. Even fingerprints can hurt adhesion.

- Wash with dish soap and warm water

- Dry completely

- Wipe with isopropyl alcohol on a lint-free rag

Avoid harsh solvents unless you know the plastic type. Some plastics haze or soften.

Scuff-sand the plastic (and the wood if it’s glossy)

For most adhesives, sanding makes a big difference.

- Use 120–220 grit to create visible scratch patterns

- Sand only what will be glued

- Wipe away dust after sanding

If you’ll be sanding the glue line later, remember that timing matters. Here’s a practical guide on when it’s safe to sand after gluing so you don’t gum up paper or tear a half-cured bond.

Consider primers for PP/PE

If the plastic is polypropylene or polyethylene, sanding alone may not be enough. An adhesion promoter can help the adhesive wet and bite. If you don’t want to mess with primers, your best “simple” option is usually mechanical fastening.

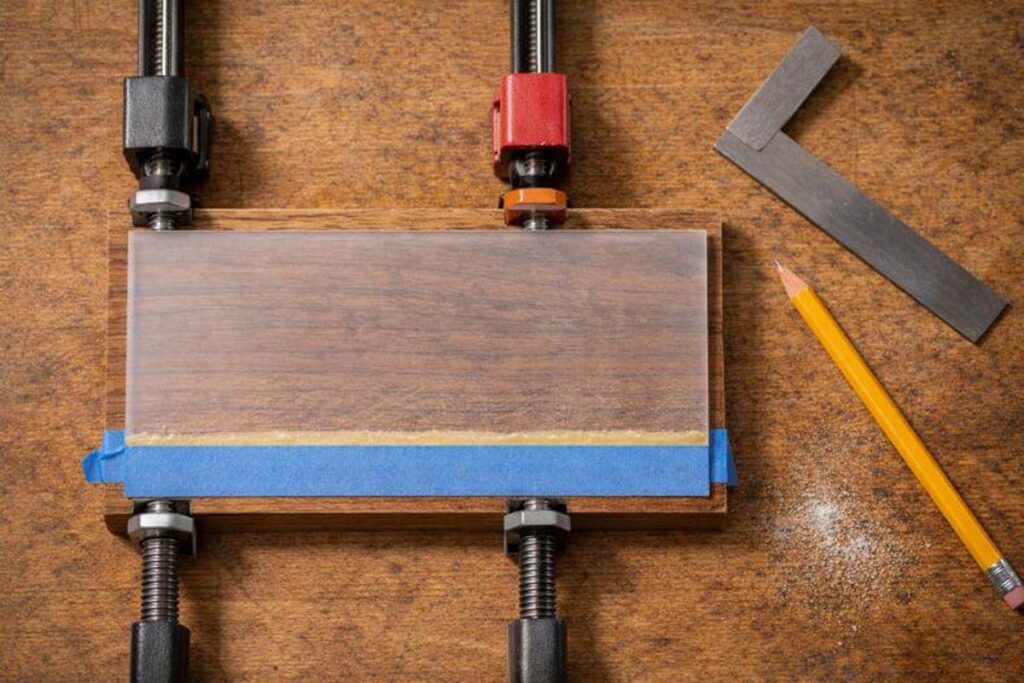

Step-by-step: How to glue plastic to wood so it stays put

This is the process I use when I need a dependable bond.

Tools and supplies

- Sandpaper (120–220 grit)

- Isopropyl alcohol + lint-free rag

- Clamps (or firm weights for flat laminations)

- Chosen adhesive (epoxy, polyurethane, or CA)

- Optional: painter’s tape for squeeze-out control

Steps

- Test fit first. Make sure everything sits flat and aligned.

- Clean both surfaces. Soap and water, then alcohol wipe.

- Scuff-sand the plastic. Create a uniform scratch pattern.

- Prep the wood. Bare wood bonds best; scuff glossy finishes.

- Apply adhesive correctly.

- Epoxy: mix thoroughly, spread a thin, even layer

- Polyurethane: thin layer; expect slight expansion

- CA: tiny amount; press parts together quickly

- Clamp with steady pressure. Don’t crush parts, just hold firmly.

- Control squeeze-out. Tape edges or wipe carefully as appropriate.

- Let it cure fully. “Dry” isn’t the same as “ready for stress.”

If you’re working with classic wood glue anywhere else in the project, it helps to know its timing. This quick read on how long wood glue takes to set before it stops shifting keeps your workflow smoother.

Durability tips: moisture, heat, flex, and wood movement

A bond that survives the first day can still fail a month later if the joint sees movement.

- Flex kills brittle glues. If the plastic bends, avoid CA alone.

- Peel force is worse than shear. Design joints to resist peeling.

- Wood moves with humidity. Plastic mostly doesn’t. Wider parts can stress the glue line as seasons change.

- Heat can soften some adhesives. Hot cars and sunny windows matter.

For outdoor or damp areas, epoxy or polyurethane usually beats PVA. And if the joint is structural, consider backing up the bond with screws.

If you go the mechanical route, it helps to know the basics so you don’t split the wood. This walkthrough on keeping wood from cracking when driving fasteners is worth a look before you commit to screws.

Food-contact and serving pieces: a quick, sensible caution

If the plastic is part of a serving tray or kitchen piece, keep adhesives away from direct food-contact zones. Many adhesives are safe once cured in certain uses, but it depends on the product and the application. For finishing the wood side of a serving project, you may also want to understand whether cured finishes are food-contact friendly and how to protect the surface without leaving it gummy.

Conclusion

Wood glue can stick to plastic in a limited, low-stress way, but it’s rarely dependable for real use. For most wood-to-plastic bonds, epoxy is the safest bet, polyurethane adhesive is a strong runner-up, and super glue works for small, tight repairs. Clean, scuff-sand, clamp well, and give the joint full cure time before stressing it.