Wood Screw Size Chart: 12 Essential Sizes for Trim, Hinges, Jigs

Wood screw size chart entries tell you two things fast: the screw’s diameter (gauge number) and the screw’s length, so you can match the fastener to the wood thickness, pilot hole, and load.

If you’ve ever bought “#8 × 1-1/4 in.” screws and still split a board or stripped a head, the chart wasn’t the problem—the setup was. The fixes are usually a correct pilot hole, a clearance hole in the top piece, and a length that gives real thread engagement.

If you’re building outdoors or in damp shops, these corrosion-resistant fastener options can help—read my guide on stainless steel wood screws before you buy your next box.

Contents Here

- 1 What does a wood screw size like “#8 × 1-1/4 in.” mean?

- 2 What is the most useful wood screw size chart for gauge and diameter?

- 3 What pilot hole size matches each wood screw size?

- 4 Why do clearance holes matter as much as pilot holes?

- 5 How do you choose the right wood screw length?

- 6 Which wood screw gauges work best for common jobs?

- 7 How do metric wood screws relate to U.S. gauge numbers?

- 8 What mistakes ruin results even when the chart is correct?

- 9 FAQs about wood screw size chart

- 10 Final thoughts

What does a wood screw size like “#8 × 1-1/4 in.” mean?

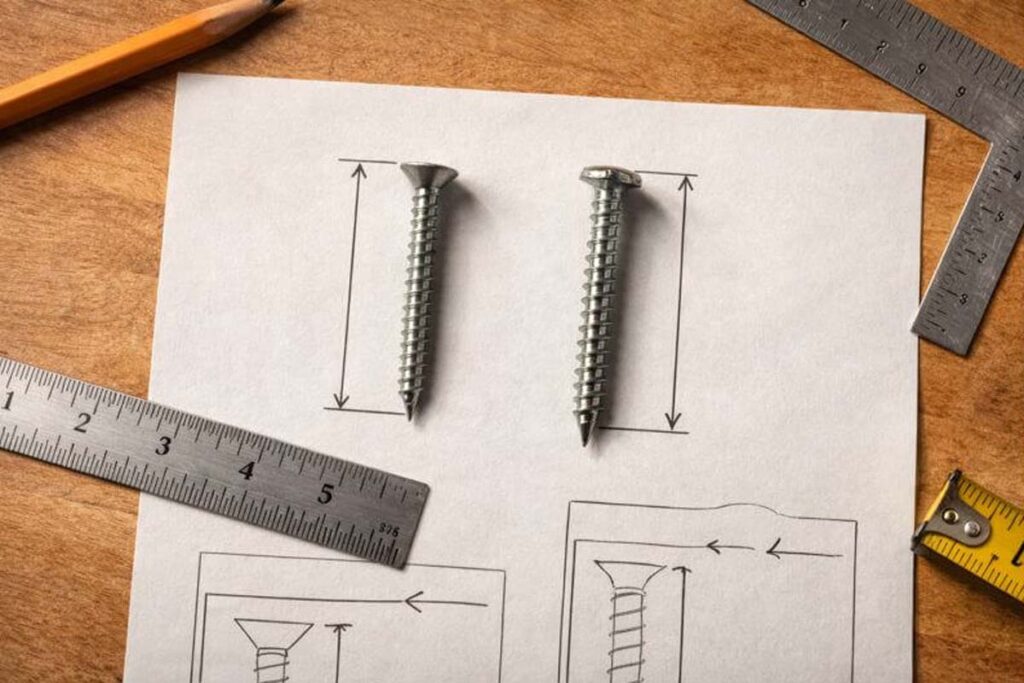

A wood screw size like #8 × 1-1/4 in. means the #8 is the gauge (diameter) and 1-1/4 in. is the length, measured from the tip to the point where the head seats. Engineer Fix notes that countersunk heads (flat/bugle) measure overall length including the head, while pan/round/hex heads measure from the underside of the head to the tip.

If you want the quick decoder for the markings on the box, start with this guide on how screw gauge numbers translate to real sizes.

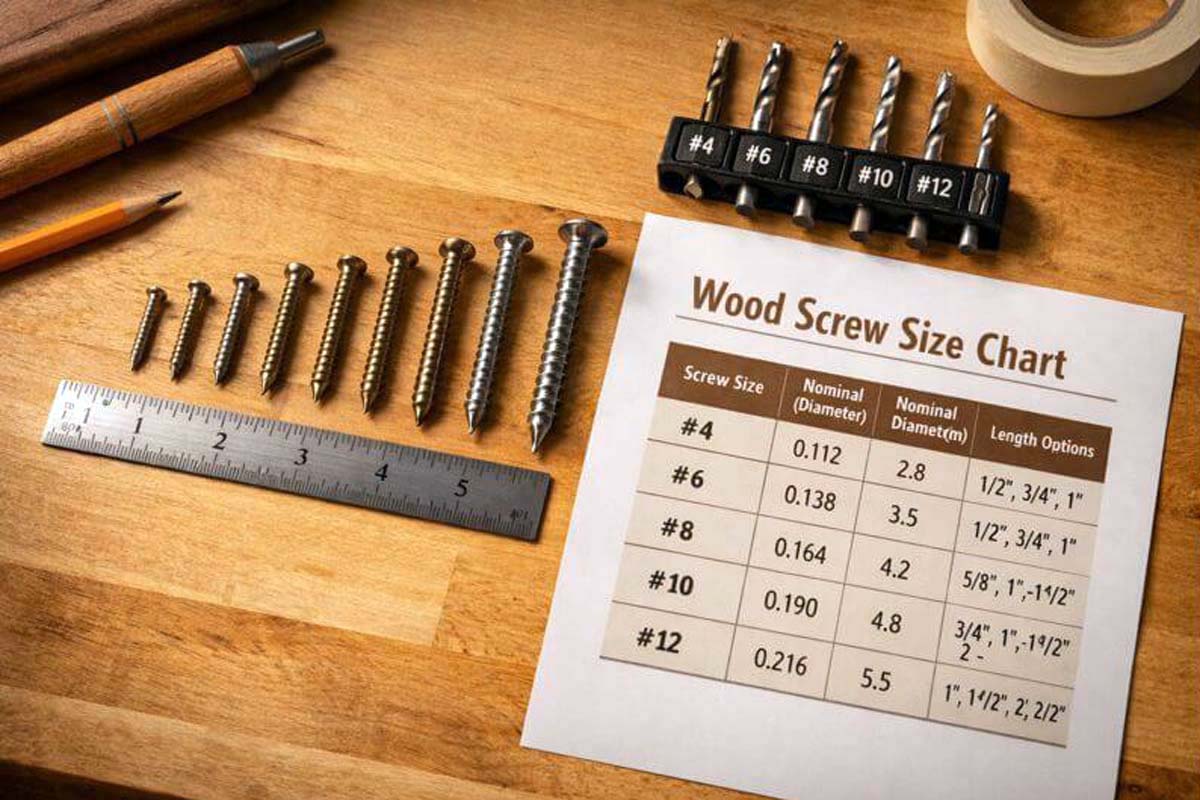

What is the most useful wood screw size chart for gauge and diameter?

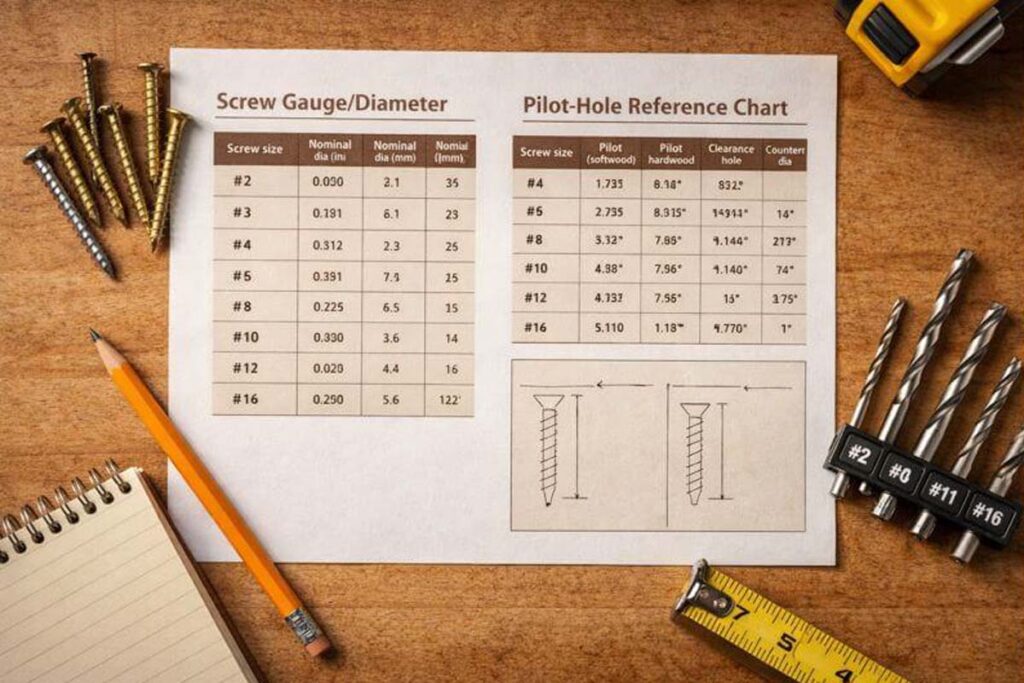

The most useful diameter chart shows gauge → nominal diameter, plus the fact that real screws vary a little by spec and manufacturer. AFT Fasteners publishes wood screw thread/body dimensions tied to ASME B18.6.1, including a nominal (“basic”) diameter and a major diameter range.

| Screw size | Nominal dia (in) | Nominal dia (mm) | Major dia range (in) | Threads/in (TPI) |

|---|---|---|---|---|

| #2 | 0.086 | 2.2 | 0.079–0.090 | 26 |

| #3 | 0.099 | 2.5 | 0.092–0.103 | 24 |

| #4 | 0.112 | 2.8 | 0.105–0.116 | 22 |

| #5 | 0.125 | 3.2 | 0.118–0.129 | 20 |

| #6 | 0.138 | 3.5 | 0.131–0.142 | 18 |

| #7 | 0.151 | 3.8 | 0.144–0.155 | 16 |

| #8 | 0.164 | 4.2 | 0.157–0.168 | 15 |

| #9 | 0.177 | 4.5 | 0.170–0.181 | 14 |

| #10 | 0.190 | 4.8 | 0.183–0.194 | 13 |

| #12 | 0.216 | 5.5 | 0.209–0.220 | 11 |

| #14 | 0.242 | 6.1 | 0.235–0.246 | 10 |

| #16 | 0.268 | 6.8 | 0.261–0.272 | 9 |

Shop note: When you’re matching to a drill bit, use the screw you’re actually holding, not just the printed nominal. That’s where calipers earn their keep.

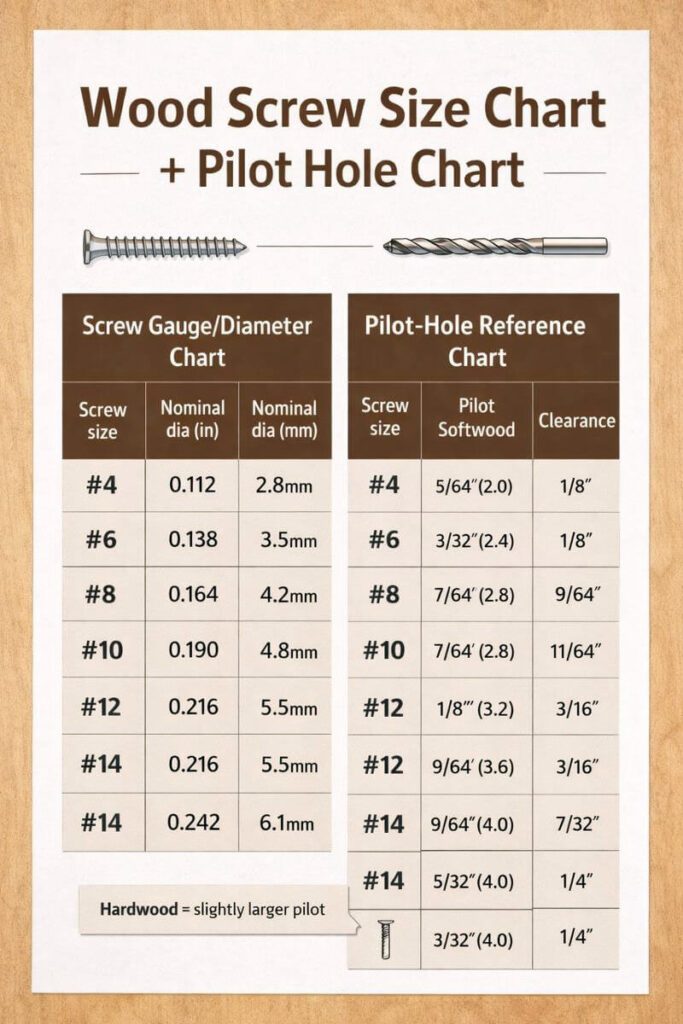

What pilot hole size matches each wood screw size?

A pilot hole chart works best when it separates pilot hole (for the threads) from clearance hole (for the shank through the top board) and includes a countersink diameter for flat heads. Albany County Fasteners’ pilot-hole guide lists all three.

| Screw size | Pilot (softwood) | Pilot (hardwood) | Clearance hole | Countersink dia |

|---|---|---|---|---|

| #2 | 1/16 in (1.5 mm) | 5/64 in (2.0 mm) | 3/32 in | 3/32 in |

| #3 | 1/16 in (1.5 mm) | 5/64 in (2.0 mm) | 7/64 in | 7/64 in |

| #4 | 5/64 in (2.0 mm) | 3/32 in (2.4 mm) | 1/8 in | 1/8 in |

| #5 | 5/64 in (2.0 mm) | 3/32 in (2.4 mm) | 9/64 in | 9/64 in |

| #6 | 3/32 in (2.4 mm) | 7/64 in (2.8 mm) | 9/64 in | 5/32 in |

| #7 | 3/32 in (2.4 mm) | 7/64 in (2.8 mm) | 5/32 in | 5/32 in |

| #8 | 7/64 in (2.8 mm) | 1/8 in (3.2 mm) | 11/64 in | 11/64 in |

| #9 | 7/64 in (2.8 mm) | 1/8 in (3.2 mm) | 3/16 in | 3/16 in |

| #10 | 1/8 in (3.2 mm) | 9/64 in (3.6 mm) | 3/16 in | 3/16 in |

| #12 | 9/64 in (3.6 mm) | 5/32 in (4.0 mm) | 7/32 in | 7/32 in |

| #14 | 5/32 in (4.0 mm) | 3/16 in (4.8 mm) | 1/4 in | 1/4 in |

Albany’s best-practice notes also call out two habits that prevent most headaches: drill the pilot slightly shorter than the screw length and keep the bit perpendicular.

If you’re getting splits near edges, my step-by-step on preventing splits when driving screws pairs well with the chart.

Why do clearance holes matter as much as pilot holes?

Clearance holes matter because they let the top piece slide and clamp tight instead of “riding up” on the threads. DIYData explains that since the upper shank of many wood screws is unthreaded, drilling a clearance hole in the top piece helps the screw pull the boards tight.

Practical setup (two-board joint):

- Clearance hole through the top board (matches shank).

- Pilot hole into the bottom board (matches root/shank-between-threads).

- Countersink if you want a flush head.

If you’re building joinery with fasteners, this walkthrough on joining two pieces cleanly with screws shows the same sequence with real shop examples.

How do you choose the right wood screw length?

Choose screw length by giving the receiving piece enough thread engagement without punching through the show face. A common guideline is to drive the screw so it penetrates the base material by about two-thirds of the screw’s length, adjusted for the actual thicknesses you’re joining.

A simple shop method:

- Measure the top piece thickness.

- Pick a screw that goes through the top piece and leaves solid bite in the bottom piece.

- If you’re close to a visible back side, step down 1/4 in. and rely on more screws or better layout instead of risking a blowout.

For a deeper strength-focused rule set, use this guide on embedment depth.

Which wood screw gauges work best for common jobs?

Common gauges work because they balance strength, head size, and how likely the wood is to split.

- #4–#5: small hardware, light trim, thin stock.

- #6: hinges, drawer slides, jigs, light-duty fixtures.

- #8: general cabinet/furniture fastening and light construction.

- #10: heavier fastening and more load, including many outdoor furniture builds.

- #12–#14: thicker stock and higher load where you also have room for a bigger pilot and head.

When the driver starts camming out, stop and reset—don’t “muscle it.” My guide on driving screws into wood without stripping covers the hand pressure and bit-fit tricks that keep heads intact.

How do metric wood screws relate to U.S. gauge numbers?

Metric screws relate to U.S. gauges by diameter, but you’ll see rounding and brand variation. Metalsheets’ gauge table lists common “imperial-to-metric” equivalents like 6 gauge ≈ 3.5 mm, 8 gauge ≈ 4.0 mm, and 10 gauge ≈ 5.0 mm.

If you’re mixing systems, treat the chart as a starting point and confirm with calipers against the major diameter numbers in the table above.

What mistakes ruin results even when the chart is correct?

Mistakes ruin results when the setup ignores wood movement, grain direction, and the screw’s real geometry.

- Skipping the pilot near an edge increases splitting and wandering.

- No clearance hole in the top piece leaves a joint with a gap you can’t tighten.

- Wrong driver bit rounds the recess and chews the head.

- Overdriving strips the hole and kills holding power.

If you already stripped something, use this repair for a stripped screw hole in wood and get the joint back to solid.

FAQs about wood screw size chart

What size drill bit works for a #8 wood screw pilot hole?

A #8 pilot hole usually starts at 7/64 in. for softwood and 1/8 in. for hardwood on a straight-bit chart. If the screw feels tight or squeals in dense hardwood, step up one bit size and retest in scrap.

Do I always need a pilot hole for wood screws?

Pilot holes reduce splitting risk, especially in hardwood, dry stock, and edge fastening, but some situations tolerate skipping. The Spruce Crafts notes that wood type, forces, and pilot holes all affect fastener choice and performance. When you’re close to an edge, drilling wins more often than it loses.

Do I measure screw length including the head or not?

You measure length including the head on screws meant to countersink (flat/bugle), and you measure length from the underside of the head on pan/round/hex heads. That difference explains why two “1-1/4 in.” screws can bury to different depths.

How can I sanity-check a pilot hole size when charts disagree?

You can match the bit to the shank between the threads as a quick check, then go slightly smaller for softwood and slightly larger for hardwood. McFeely’s describes this “hold the bit to the shank” method as a safe starting point when you’re unsure.

Final thoughts

Wood screw size chart use gets easier when you treat the chart as the baseline and then tune for the wood in your hands: drill a pilot that fits the shank, add a clearance hole so parts clamp tight, and pick a length that bites without blowing out the back. If you set up those three steps, the screw size on the box starts working for you instead of against you—good luck.