Wood Glue vs Liquid Nails: 12 Quick Checks Before You Glue

Wood glue vs Liquid Nails usually comes down to one simple question: are you joining wood fibers to wood fibers, or are you sticking “stuff” to “stuff”? If you’re building furniture, tight joinery, or anything you plan to sand and finish clean, wood glue is hard to beat.

If you’re hanging trim, bonding uneven surfaces, or working with mixed materials, construction adhesive (including many Liquid Nails formulas) often makes life easier.

Contents Here

- 1 Wood glue vs Liquid Nails at a glance (quick decision guide)

- 2 Understanding wood glue (what it is and why it excels on wood)

- 3 Understanding Liquid Nails / construction adhesive (what it is and why builders use it)

- 4 Head-to-head comparison: Wood Glue vs Liquid Nails

- 4.1 Strength (shear vs tensile) — what “stronger” really means

- 4.2 Flexibility and gap-filling (tight joinery vs imperfect surfaces)

- 4.3 Drying time vs full cure (what you can do when)

- 4.4 Water/heat resistance (indoor vs outdoor reality)

- 4.5 Safety, odor, and ventilation (VOCs matter)

- 4.6 Cleanup, removal, and storage (the real-life factor)

- 4.7 Finish quality (sanding, staining, painting, and visible glue lines)

- 4.8 Cost and tools required (caulk gun vs squeeze bottle)

- 5 Best uses by project (match the adhesive to the job)

- 6 How to get the strongest bond (application tips that actually help)

- 7 Mistakes to avoid (the common failure points)

- 8 FAQs on Wood Glue vs Liquid Nails

- 9 Final Words

Wood glue vs Liquid Nails at a glance (quick decision guide)

If you want the fastest, most practical rule:

- Choose wood glue when the parts fit well, you can clamp, and you care about a clean, sandable seam.

- Choose Liquid Nails / construction adhesive when surfaces are a little wonky, you’re bonding dissimilar materials, or you need strong grab without perfect joinery.

Here are a few real examples.

Wood glue is usually the better pick for:

- Edge-gluing panels, table tops, and shelves

- Mortise-and-tenon, dowels, biscuits, and tight dado joints

- Furniture repairs where you need a neat glue line (this is where a purpose-built option matters—see my notes on choosing the right glue for furniture repairs)

Liquid Nails / construction adhesive is usually better for:

- Baseboards, door casing, wall panels, and other trim work

- Subfloor squeaks and remodel jobs where you can’t clamp well

- Wood-to-drywall, wood-to-masonry, or wood-to-metal bonds

What Liquid Nails actually is (brand vs product type)

“Liquid Nails” is a brand name, not one single adhesive. One tube might be latex-based for interior trim. Another might be solvent-heavy and meant for tougher bonding jobs. Before you commit, read the tube for surface compatibility, indoor/outdoor rating, and cure time. That one habit prevents most “it didn’t stick” headaches.

Read next: Wood Glue vs Epoxy: 7 Clear Tests for a Stronger Bond

Understanding wood glue (what it is and why it excels on wood)

Wood glue is made to soak slightly into wood fibers and lock them together as it cures. When your joint fits properly, wood glue can produce a bond that’s stronger than the surrounding wood—especially in shear loads, like a panel glue-up.

If you want a quick refresher on what you’re actually buying, my breakdown of PVA-based carpenter’s glue labels clears up a lot of confusion.

Common wood glue types readers actually see in stores

Most folks run into these in the aisle:

- PVA / aliphatic resin (yellow “carpenter’s” glue): the everyday workhorse for indoor joinery.

- Water-resistant PVA variants: better when moisture is a real concern, like mudroom benches or outdoor items that won’t live in standing water.

- Polyurethane and epoxy: less common for basic woodworking, but useful when you need gap filling or non-wood bonding (and you’re ready for messier cleanup).

Understanding Liquid Nails / construction adhesive (what it is and why builders use it)

Construction adhesive is thicker and stickier by design. It’s built for jobs where the surfaces aren’t perfectly flat, where materials move a bit, or where you’re bonding across different substrates. In remodeling work, that “grab” is a big deal.

It’s also why many formulas smell stronger and demand better ventilation. If you’re sensitive to fumes, treat that seriously.

“Versatility + gap filling” is the real selling point

Standard wood glue wants tight contact. Construction adhesive tolerates small gaps and imperfect surfaces much better. So if your baseboard has a bowed section, or your wall panel isn’t dead-flat, a bead of construction adhesive can keep things snug where clamps can’t reach.

Head-to-head comparison: Wood Glue vs Liquid Nails

This isn’t just “which is stronger.” The better question is which adhesive fits the stresses, surfaces, and finish requirements of your project.

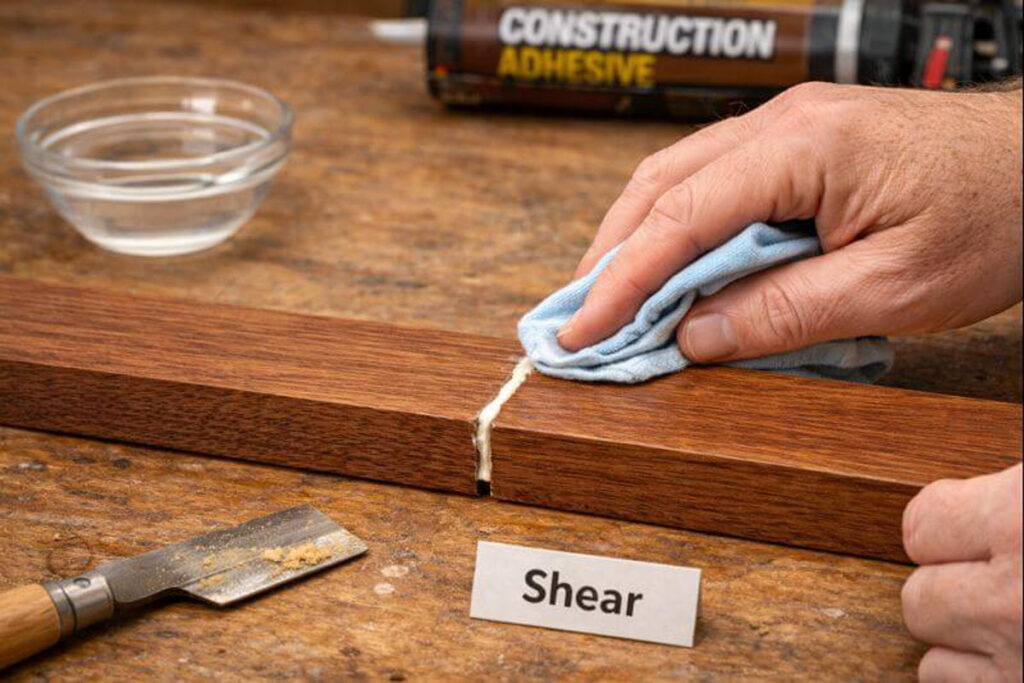

Strength (shear vs tensile) — what “stronger” really means

Wood glue shines when you’ve got a well-fit wood joint that will see shear loads—think edge-glued panels or joinery where the pieces can’t peel apart easily. If you’re curious how strong that can get in normal shop conditions, see my notes on what makes a glued joint strong in the first place.

Construction adhesive often feels stronger early because of its initial tack, and it can do better in situations where the load tries to pull or peel materials apart—especially when the surfaces aren’t a perfect match.

Flexibility and gap-filling (tight joinery vs imperfect surfaces)

Wood glue rewards good woodworking. If you’ve got gaps, you’re asking it to bridge air, and that’s not where it’s happiest. Construction adhesive is much more forgiving when reality shows up—crooked framing, textured surfaces, and small voids.

If your parts don’t mate cleanly, fix the fit first when you can. When you can’t, that’s when construction adhesive earns its keep.

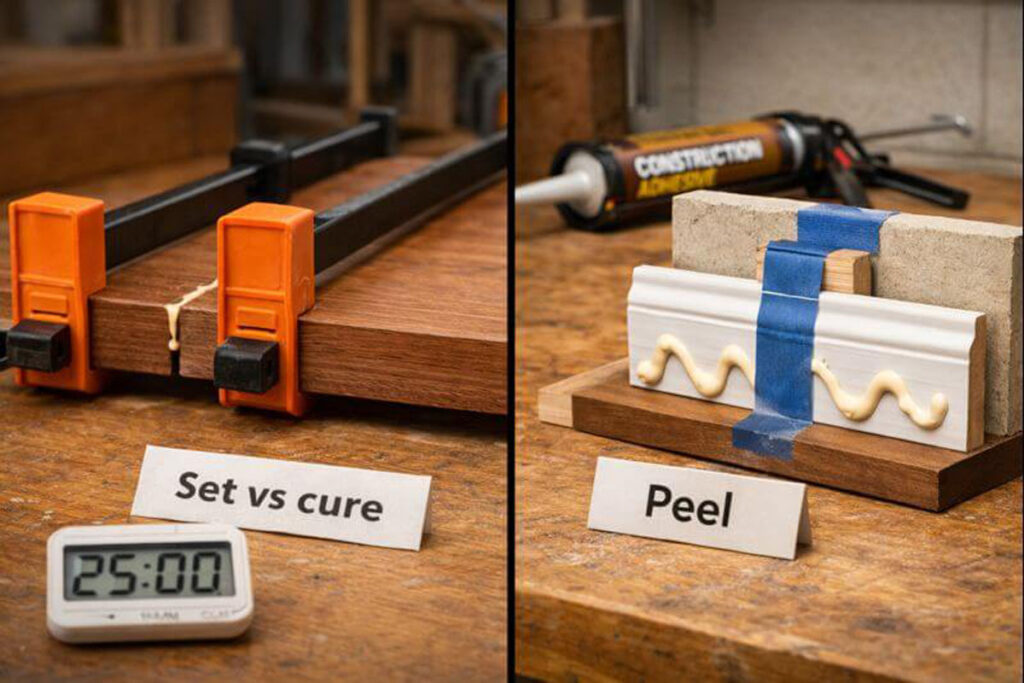

Drying time vs full cure (what you can do when)

A lot of DIY trouble comes from mixing up “set time” and “full cure.”

- Wood glue often grabs fast enough to clamp within a reasonable window, but it still needs time to reach full strength. If timing matters, check how long it takes to set and how long full cure really takes.

- Construction adhesive can have strong early tack, but many formulas still take a while to cure fully—especially in cool or humid conditions.

If the joint will be stressed, give it the full cure time. That patience beats redoing work later.

Water/heat resistance (indoor vs outdoor reality)

Neither product is “magic outdoor glue” by default. Wood glue performance depends on the specific type and rating. Construction adhesive varies wildly by formula too. For outdoor or damp-area work, pick an adhesive explicitly made for those conditions and protect the project with a proper finish.

Safety, odor, and ventilation (VOCs matter)

Wood glue is generally easier to live with indoors. Many construction adhesives contain solvents or stronger chemicals. Use gloves, keep airflow moving, and don’t linger over an open tube while you work. If you’re in a tight room, crack windows and run a fan.

Cleanup, removal, and storage (the real-life factor)

Wood glue is usually forgiving while it’s wet. Construction adhesive is often the opposite.

- For cleaner glue lines, learn how much glue is actually enough so you’re not scraping a mess later.

- If you do get squeeze-out where you don’t want it, here’s a safe approach for removing dried glue without chewing up the wood.

- Pay attention to shelf life too. A lot of “mystery failures” come from old product—especially if it froze or sat open. I keep a note on how to tell when glue has gone bad.

Finish quality (sanding, staining, painting, and visible glue lines)

If your project will be stained or clear-coated, wood glue is usually easier to hide because it belongs in thin, tight seams. Construction adhesive can leave a thicker line and may not sand as cleanly.

If stain is part of your plan, it’s worth understanding whether glue blocks stain and how to prevent blotchy spots. And if sanding timing matters, don’t guess—check how long to wait before sanding a glued joint.

Cost and tools required (caulk gun vs squeeze bottle)

Wood glue is simple: bottle, brush or nozzle, clamps. Construction adhesive usually means a tube and a caulk gun, and you’ll sometimes waste a bit at the tip as it skins over. Cost isn’t always the deal-breaker—workflow is.

Best uses by project (match the adhesive to the job)

This is the section I’d print and hang near the glue shelf.

When wood glue is the better choice

Reach for wood glue when:

- You can make tight-fitting joints

- You can clamp the work

- You need a clean seam that sands well

- You’re building furniture, trays, boxes, frames, or cabinetry

For heavy loads, wood glue can still be surprisingly capable when the joint is designed right. If you’re wondering what “capable” means in pounds, here’s a practical look at how much weight a glued joint can support.

When Liquid Nails is the better choice

Choose construction adhesive when:

- Surfaces aren’t perfectly flat

- Clamping isn’t realistic

- You’re bonding wood to drywall, masonry, or metal

- You want strong grab for trim and remodel work

For trim, you’ll often still use fasteners. The adhesive reduces squeaks and movement, while the nails or screws provide immediate mechanical security.

How to get the strongest bond (application tips that actually help)

Great adhesives still fail with poor prep.

- Dry fit first. If the parts rock, fix that before reaching for a stronger tube.

- Prep the surface. Dust, oil, and old finish weaken any bond.

- Use the right amount. Too little starves the joint. Too much makes cleanup harder.

- Hold it still. That means clamps for wood glue and bracing for many construction-adhesive jobs.

- Respect cure time. Don’t stress the joint early.

If you need cleaner, flatter wood surfaces for gluing, getting end grain right helps more than most people expect. My walkthrough on sanding end grain until it feels glassy is a good starting point.

Clamping vs bracing — what each adhesive needs

With wood glue, clamping pressure pulls the joint tight and squeezes the glue into a thin, strong film. If you’re unsure how long to leave clamps on, don’t wing it—use a reliable baseline like realistic clamp times for common shop conditions.

With construction adhesive, “pressure” often means bracing or weighting the piece so it can’t slide while the bead sets. The adhesive may grab quickly, but it still needs stability to cure strong.

Mistakes to avoid (the common failure points)

- Using wood glue to fill big gaps. It’s not spackle, and the joint will be weak.

- Using construction adhesive where you need a thin, invisible seam. It can telegraph through finishes.

- Skipping ventilation with solvent-heavy tubes. Headaches and dizziness aren’t part of the project.

- Stressing the joint early. Set time isn’t full cure time.

- Assuming all Liquid Nails tubes behave the same. Always match the formula to the surfaces.

If your project uses screws alongside adhesive (trim, cleats, wall-mounted work), corrosion resistance matters more than most DIY guides admit. I keep stainless guidance here: picking wood screws that won’t rust and stain your work.

FAQs on Wood Glue vs Liquid Nails

Is Liquid Nails stronger than wood glue?

It depends on the joint. Wood glue can be extremely strong in tight wood joints. Construction adhesive can win on uneven surfaces, mixed materials, and peel-type stresses.

Can I use Liquid Nails instead of wood glue for furniture?

For most furniture joinery, I wouldn’t. You usually want a thin, clean, sandable glue line. Construction adhesive can be messy and harder to hide under stain or clear finish.

Can you use Liquid Nails on wood-to-wood joints?

Yes, but it’s not always the best choice. If the joint fits well and you can clamp, wood glue normally gives a cleaner, more predictable result.

How long does Liquid Nails take to dry and fully cure?

It varies by formula and conditions. Many products feel firm early but need a longer cure to reach full strength. Always follow the tube’s directions for dry time, cure time, and temperature range.

Is Liquid Nails toxic?

Some formulas can have strong solvents and higher VOCs. Use ventilation, avoid skin contact, and keep it away from kids and pets while curing. Read the safety label on the tube.

Can wood glue replace nails or screws?

In woodworking joinery, glue can be stronger than fasteners alone. In construction and trim, fasteners still provide immediate mechanical hold, while adhesive helps reduce movement and squeaks.

Final Words

Wood glue vs Liquid Nails isn’t a fight—it’s a match-up. Use wood glue for tight, sandable, wood-to-wood joinery where clamps can do their job. Use construction adhesive when surfaces aren’t perfect, materials are mixed, or bracing beats clamping. When in doubt, choose the adhesive that fits the surfaces and the finish.