Wood Glue for Plywood: Top 11 Picks for Rock Solid Joints

Wood glue for plywood is a purpose-made adhesive that wets the veneer fibers and cures into a hard bond between sheets and joints. Because plywood offers lots of flat surface area, the right glue spreads evenly, grips tight under clamps, and helps prevent seam creep and delamination over time. Choose a PVA for dry interiors, or a water-rated formula for damp rooms and outdoor work.

In this guide, you’ll learn which glue types hold best for indoor panels, humid rooms, outdoor builds, and repairs—plus the prep and pressure tricks that prevent weak seams, warps, and glue-starved joints. If you want strong, clean bonds without guessing, start here.

Contents Here

- 1 Top 11 Picks for the Wood Glue for Plywood

- 2 Where plywood glue-ups fail and why plywood acts different

- 3 Quick picker: the best glue choice by project type

- 4 Glue types that work on plywood and when to use them

- 5 Reviews of the 11 Best Wood Glue for Plywood

- 5.1 Titebond 1416 III Ultimate Wood Glue for Plywood

- 5.2 Titebond 5066F Original Wood Glue for Plywood

- 5.3 Gorilla Natural Wood Glue for Plywood

- 5.4 Gorilla Ultimate Waterproof Wood Glue

- 5.5 Grizzly One Wood Glue for Plywood

- 5.6 Loctite PL Premium Polyurethane Construction Adhesive

- 5.7 WEST SYSTEM G/flex Epoxy

- 5.8 System Three Quick Cure 5 Epoxy Adhesive

- 5.9 Elmer’s E7000 Carpenter’s Wood Glue

- 5.10 Liquid Nails Heavy Duty Construction Adhesive

- 5.11 DAP 157 Rapid Fuse Wood Adhesive

- 6 Buying guide: what to compare before you pick a plywood wood glue

- 7 Surface prep for strong plywood bonds

- 8 Step-by-step: gluing plywood to plywood without warps or weak seams

- 9 Reinforcing plywood joints for long-term durability

- 10 Troubleshooting common plywood glue problems

- 11 FAQs on the Wood Glue for Plywood

- 11.1 What’s the strongest adhesive for plywood?

- 11.2 Can I use regular wood glue on plywood?

- 11.3 Is it better to use solvent-based or water-based adhesives for plywood?

- 11.4 How long does it take for glue/adhesive to cure on plywood?

- 11.5 How long should I clamp a plywood glue joint?

- 11.6 Can I use construction adhesive for outdoor plywood projects?

- 11.7 Does plywood grain direction matter when gluing two pieces together?

- 11.8 What’s the best glue for plywood edges or edge banding?

- 11.9 Do I need screws when gluing plywood together?

- 11.10 How do I fix a failed plywood glue joint?

- 12 What You Should Do Next

Top 11 Picks for the Wood Glue for Plywood

- Titebond 1416 III Ultimate Wood Glue

- Titebond 5066F Original Wood Glue

- Gorilla Natural Wood Glue

- Gorilla Ultimate Waterproof Wood Glue

- Grizzly One Wood Glue

- Loctite PL Premium Polyurethane Construction Adhesive

- WEST SYSTEM G/flex Epoxy

- System Three Quick Cure 5 Epoxy Adhesive

- Elmer’s E7000 Carpenter’s Wood Glue

- Liquid Nails Heavy Duty Construction Adhesive

- DAP 157 Rapid Fuse Wood Adhesive

Also read this if you’re looking for a strong wood adhesive to fix furniture.

Where plywood glue-ups fail and why plywood acts different

Plywood isn’t one piece of wood. It’s thin veneers stacked with alternating grain direction and bonded at the factory. That construction makes panels stable, but it also changes how glue behaves.

Most failures come from one of these shop mistakes:

- Dusty faces: sanding dust acts like ball bearings. Wipe it off.

- Finished or sealed surfaces: glue can’t bite into varnish, paint, or wax.

- Glue starvation: too little glue or too much clamp pressure squeezes it dry.

- Uneven pressure: clamps on the edges only can leave a hollow middle.

- Weak edge bonding: plywood edges soak glue fast and need extra care.

If you want a quick refresher on how strong a cured glue line can be, skim this breakdown of what a hardened glue joint can realistically handle: how strong a cured glue line gets.

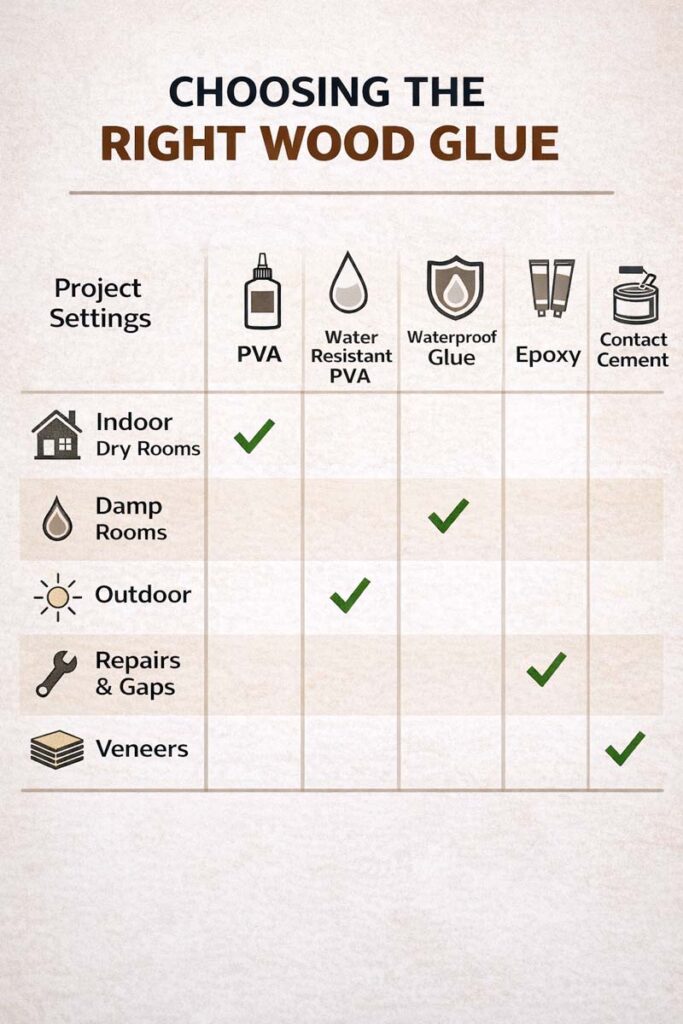

Quick picker: the best glue choice by project type

When folks search “wood glue for plywood,” they’re usually trying to answer one question: Which glue should I use for my situation? Here’s a straight shop-friendly picker.

- Indoor furniture, cabinets, shelves (dry rooms): standard PVA wood glue

- Kitchens, bathrooms, garages (humidity and occasional damp): water-resistant PVA

- Outdoor or repeated wet/dry exposure: waterproof-rated glue or epoxy

- Gaps, busted edges, repairs, ugly fits: epoxy (or polyurethane if you know its quirks)

- Veneers and laminate skins: contact cement (used correctly)

If “PVA” still feels like a mystery label, this explains it in plain terms: what PVA on a glue bottle actually means.

Indoor furniture and cabinetry

For tight-fitting plywood joints indoors, a basic carpenter’s wood glue is usually the best move. It spreads easily, cleans up with water, and sands without leaving a rubbery mess. It also gives you enough working time to get parts aligned.

Moisture-prone spaces like kitchens and baths

In damp areas, use a glue that’s rated for water resistance. This is where the label matters more than the brand name. If the joint will see humidity, wet mopping, or condensation, don’t gamble with a basic interior glue.

Outdoor plywood and weather exposure

Outdoor work needs more than “pretty strong.” It needs a bond that survives expansion, contraction, and occasional soaking. Waterproof-rated glue is the common pick for well-fitted joints. For messy repairs and gaps, epoxy often outlasts everything else.

Gaps, damaged edges, and imperfect fits

If you can’t get clean wood-to-wood contact, don’t expect a thin glue line to perform miracles. Epoxy can bridge voids and rebuild strength where plywood edges are torn up. Polyurethane glue can work too, but it expands and can push joints out of alignment if you overdo it.

If you’re deciding between those two, this comparison helps: when epoxy makes more sense than standard glue.

Glue types that work on plywood and when to use them

PVA wood glue

PVA is the common yellow or white woodworking glue. It’s ideal when parts fit well and the joint can be clamped evenly. On plywood, it shines for cabinetry, furniture panels, drawer boxes, and shop fixtures that stay dry.

For best results, don’t guess at coverage. A thin, complete film beats thick blobs every time. This helps you get the spread right: how much adhesive to actually apply.

Water-resistant and waterproof PVAs

These look like standard wood glue, but they’re formulated to resist moisture. Some are water-resistant (good for humid interiors), while others are closer to waterproof (better for outdoor exposure). Your project environment matters more than the label claims.

A kitchen cabinet in a dry home is one thing. A porch stool in the rain is another.

Polyurethane glue

Polyurethane glue cures with moisture and can bond some mixed materials. The catch is that it foams and expands. That foam isn’t stronger than a tight glue line, so don’t treat it as a gap filler you can rely on.

Use it when:

- You need some water resistance

- The parts aren’t perfectly uniform

- You can clamp hard and keep things from shifting

Avoid it when:

- You need a clean glue line for fine joinery

- You can’t control squeeze-out cleanup

Epoxy

Epoxy is the “get out of jail” option when plywood is damaged, gappy, or destined for abuse. It’s gap-filling, tough, and reliable when mixed correctly. It’s also less forgiving: you need accurate mixing and decent shop temperature.

Use it for:

- Repairing blown-out plywood edges

- Reinforcing screw holes and stripped areas

- Bonding panels when fit isn’t perfect

Safety note: epoxy can irritate skin fast. Wear gloves and keep ventilation moving.

Contact cement

Contact cement is for veneers, laminate sheets, and skins where you want an instant bond across a wide surface. It’s not the same workflow as wood glue. You coat both surfaces, let them tack up, then commit.

This is not the place for “adjustments after clamping.” Plan your alignment before the pieces touch.

Construction adhesive

Construction adhesive is common in building work, not fine woodworking. It can be useful for subfloors, rough framing, and areas where you’re fastening with screws or nails anyway. For tight plywood joinery, it’s usually the wrong feel and the wrong finish.

If you’re weighing it against traditional wood glue, this side-by-side helps: wood glue compared with construction adhesives.

Reviews of the 11 Best Wood Glue for Plywood

Titebond 1416 III Ultimate Wood Glue for Plywood

Waterproof Choice for Exterior Plywood Builds

Titebond III is a top pick when plywood needs a water-proof bond without switching to epoxy. It’s a water-based PVA that sands clean and doesn’t get weird under most finishes, so it works well for outdoor furniture, shop fixtures, and plywood laminations that may see weather.

$35.89 at AmazonSpecifications

- Water resistance: Waterproof (ANSI/HPVA Type I)

- Full cure: 24 hours

- Tensile strength: 1,750 PSI

Pros

- Water cleanup, strong initial tack

- Longer open time helps bigger glue-ups

- FDA indirect food contact approval

Cons

- Not for continuous submersion

- Use above 47°F; not structural/load-bearing

Titebond 5066F Original Wood Glue for Plywood

Reliable Interior Glue for Plywood Cabinets

Titebond Original is an interior-only workhorse for plywood cabinetry, drawer boxes, and shelves that live in dry spaces. It grabs fast, clamps quickly, and sands nicely, which makes it friendly for paint- or clear-finish work where glue lines can ruin your day.

$21.99 at AmazonSpecifications

- Water resistance: Not water resistant

- Full cure: 24 hours

- Use temp: Above 50°F

Pros

- Fast set and short clamp time

- Strong bond and easy water cleanup

- Finish-friendly and sands clean

Cons

- Avoid damp areas and exterior work

- Not for structural/load-bearing joints

Gorilla Natural Wood Glue for Plywood

Water-Resistant PVA for Plywood in Humid Rooms

This Gorilla PVA is a solid middle ground when plywood might see humidity or light moisture but you still want easy spread and easy cleanup. It cures to a natural tan line and stays non-foaming, which is helpful for clean plywood-to-plywood glue-ups and edge banding.

$26.99 at AmazonSpecifications

- Water resistance: ANSI/HPVA Type II (water resistant)

- Clamp time: 20–30 minutes

- Full cure: 24 hours

Pros

- Sandable and paintable with a clean bond line

- Works on hardwoods, softwoods, composites

- Soap-and-water cleanup

Cons

- Not fully waterproof for constant weather

- Tan glue line may show on very light wood

Gorilla Ultimate Waterproof Wood Glue

Type I Waterproof for Outdoor Plywood Panels

Gorilla Ultimate is aimed at tougher moisture exposure, with a Type I waterproof rating and a workable open time for assembly. It stays non-foaming and finishes well, which makes it a good fit for plywood outdoor projects where you still want a clean, sandable glue line.

$11.32 at AmazonSpecifications

- Water resistance: Waterproof (ANSI/HPVA Type I)

- Working time: ~15 minutes

- Full cure: 24 hours

Pros

- Handles water, sun, and temperature swings better

- Sandable/paintable with natural tan bond line

- Easy water-based cleanup

Cons

- Large laminations may need fast clamping teamwork

- Still needs good surface contact (not a true gap filler)

Grizzly One Wood Glue for Plywood

Polyurethane Option for Oily Woods and Mixed Plywood Jobs

Grizzly One is a ready-to-use polyurethane adhesive built for tough situations—oily woods, imperfect surfaces, even wet stone—so it can help when plywood projects involve tricky materials. It expands as it cures and claims no creep, which can be useful where parts see movement.

$125 at AmazonSpecifications

- Chemistry: Polyurethane

- Full cure: ~12 hours

- Working time: 25–35 minutes; clamp: 2–5 hours

Pros

- 100% waterproof, no mixing

- Bonds oily/exotic woods well

- Sands/scrapes; stainable and tintable

Cons

- Expansion can push joints if clamped poorly

Loctite PL Premium Polyurethane Construction Adhesive

Subfloor-Grade Bonding for Plywood

PL Premium is built for construction bonding, not fine joinery. It’s great for plywood subfloors, sheathing, and installs where you want strong grab, gap-filling behavior, and weather resistance—especially when you’re also using fasteners.

$6.48 at AmazonSpecifications

- Format: Cartridge (caulk gun)

- Set time: ~30 minutes; full cure: 24 hours

- Water resistance: Waterproof; works on wet/frozen surfaces

Pros

- Bonds many materials beyond wood

- Good for imperfect framing surfaces

- Paintable with low solvent odor

Cons

- Not ideal for tight furniture seams

- Squeeze-out is harder to sand clean than PVA

WEST SYSTEM G/flex Epoxy

Repair-Grade Epoxy for Plywood Delamination and Edge Rebuilds

G/flex is made for the ugly stuff: damp wood, stressed joints, shock, vibration, and difficult-to-bond materials. For plywood, it’s excellent for repairing delamination, rebuilding blown-out edges, and bonding dissimilar materials where PVA would struggle.

$35.12 at AmazonSpecifications

- Mix ratio: 1:1

- Full cure: ~2 days

- Water resistance: Waterproof (wet-surface capable with technique)

Pros

- Strong, toughened bond that resists peel and vibration

- Works on damp wood and hard-to-glue species

- Gap-filling behavior for repairs

Cons

- Longer cure time than wood glue

- Requires accurate mixing and careful cleanup

System Three Quick Cure 5 Epoxy Adhesive

Fast-Setting Epoxy for Small Plywood Fixes

Quick Cure-5 is for quick repairs and small glue jobs where speed matters more than long open time. It’s handy for plywood chips, small cracks, and knot/void filling, especially when you want a clear cure in thin films.

$37.95 at AmazonSpecifications

- Set time: ~5 minutes

- Full properties: up to 72 hours (best strength)

- Water resistance: Water resistant

Pros

- Very fast set for small shop fixes

- 1:1 mix ratio; bonds wood and composites

- Fills small defects cleanly

Cons

- Too little working time for big panels

- Clamp pressure must be moderate to avoid squeeze-out starvation

Elmer’s E7000 Carpenter’s Wood Glue

Quick Clamp Interior Glue for Plywood Repairs

Elmer’s E7000 is a familiar, easy PVA for small plywood repairs and indoor builds where you want fast clamp time and simple cleanup. It’s non-toxic and finishes well, so it fits hobby projects and household fixes.

$8.00 at AmazonSpecifications

- Clamp time: 20–30 minutes

- Full cure: 24 hours

- Size: 4 oz; color: yellow

Pros

- Easy soap-and-water cleanup while wet

- Sandable and paintable

- Strong bond for general carpentry

Cons

- Best treated as indoor-use glue per product positioning

- Small bottle isn’t ideal for large plywood laminations

Liquid Nails Heavy Duty Construction Adhesive

Gap-Filling Tube Adhesive for Plywood Installs

LN903 is geared toward heavy-duty construction bonding, where plywood is one of many materials in the stack. It’s useful for plywood panel installs, rough assemblies, and jobs needing gap filling and impact resistance—especially when paired with mechanical fasteners.

$3.58 at AmazonSpecifications

- Working time: ~10 minutes

- Coverage: ~30 linear feet (1/4″ bead, 10 oz tube)

- Water resistance: Listed as waterproof/weatherproof

Pros

- Strong holding power for heavier materials

- Durable and flexible; fills gaps well

- Indoor/outdoor use

Cons

- Check label limits for specialty installs (tileboard, certain substrates)

DAP 157 Rapid Fuse Wood Adhesive

Fast Handling for Plywood Trim and Quick Fixes

Rapid Fuse is a fast-curing wood adhesive that’s great when you need handling strength almost immediately, like small plywood trim, edge chips, or quick shop repairs. It’s repositionable briefly, then sets up fast enough to sand or stain soon after.

$22.10 at AmazonSpecifications

- Handling strength: ~30 seconds

- Ready for sanding/stain: ~30 minutes

- Water resistance: Water resistant; cures clear

Pros

- Minimal clamp time for small parts

- Clear bond line is finish-friendly

- Repositionable window helps alignment

Cons

- Short open time limits large glue-ups

- Water resistant, not a best-bet for long outdoor exposure

Buying guide: what to compare before you pick a plywood wood glue

If you’re staring at a shelf of bottles, compare these things before you buy:

Water rating and real-world exposure

Don’t buy “waterproof” because it sounds tough. Buy it because your project will actually face water. A sheltered indoor cabinet doesn’t need an outdoor-rated formula. A patio piece does.

Working time, clamp time, and full cure

Working time is how long you can adjust parts before glue grabs. Clamp time is when the joint can come out of clamps. Full cure is when it reaches final strength.

Use these as your shop references:

- How long to keep clamps on a glue-up

- When a joint reaches full strength

- How long to wait before sanding a glued panel

Creep resistance, sanding, and finish work

Some glues can slowly move under heat and constant load. That matters on shelves, bent laminations, and stressed joints. Also, not every glue sands the same. If you hate gummy sanding marks, pick a glue known to sand clean.

Surface prep for strong plywood bonds

Good glue on dirty plywood is still a weak joint. Prep doesn’t need to be fancy, just consistent.

- Scuff sand glossy faces with fine grit if needed.

- Remove dust with a vacuum and a clean rag.

- Avoid bonding over paint or finish unless the adhesive is made for it.

- Treat plywood edges carefully because they absorb glue quickly.

A handy trick for thirsty edges is a light “sizing coat.” Wipe on a thin film, let it soak briefly, then apply normal glue and assemble. It helps prevent a dry, starved glue line.

Step-by-step: gluing plywood to plywood without warps or weak seams

- Dry fit everything first. Mark alignment so you don’t chase parts later.

- Spread glue evenly. Use a roller, card, or brush for full coverage.

- Assemble and slide slightly. That small movement wets both surfaces.

- Clamp with cauls when panels are wide. Cauls spread pressure and keep things flat.

- Use enough clamps to hold contact everywhere. Don’t clamp only the corners.

- Clean squeeze-out at the right time. Wipe while wet, or scrape when rubbery.

- Respect clamp time, then wait for cure. Don’t rush heavy loads.

If you need help with timing, this is a practical reference: how long clamps should stay on before you remove them.

Even glue spread and coverage

On plywood faces, you want a thin film that covers the whole area. Too little glue leaves dry patches. Too much glue creates mess without adding strength. That “even film” is the sweet spot.

Clamping technique and pressure control

Clamps don’t “make it stronger.” They hold surfaces in contact while glue cures. Too little pressure leaves gaps. Too much pressure can squeeze glue out and starve the joint. When in doubt, add cauls and moderate pressure instead of cranking harder.

Reinforcing plywood joints for long-term durability

Glue is excellent when there’s surface area and good fit. For joints that take abuse, add mechanical help.

Good reinforcement options include:

- Dados and rabbets for shelves and cabinet parts

- Biscuits or dowels for alignment and extra glue surface

- Screws used like clamps, especially in shop builds

- Hardwood edging to protect plywood edges from impacts

If you’re wondering what a glued joint can take when loaded, this gives realistic expectations: how much weight a glue joint can hold.

Troubleshooting common plywood glue problems

The joint popped apart cleanly

That usually means poor surface contact, dust, or glue starvation. Sand to fresh wood, remove dust, and re-glue with full coverage. Don’t rely on “extra clamp force” to fix a bad fit.

The plywood face is peeling or delaminating

If the veneer itself is failing, you’re fighting the plywood, not the glue. Epoxy is often the better repair choice here, especially for voids and soft spots. Clamp gently with cauls to avoid crushing the face veneer.

Glue won’t cure or stays rubbery

Cold shops, damp wood, and wrong adhesive for the conditions are common causes. Warm the space, follow the label for temperature range, and give it time. For big assemblies, plan around cure, not hope.

Dried squeeze-out is ruining your finish

Don’t sand dried blobs across bare wood. Scrape it clean, then sand. If you need removal help, this is a safe method: remove dried glue without tearing up the wood surface.

FAQs on the Wood Glue for Plywood

What’s the strongest adhesive for plywood?

For tight, well-fit joints, a good PVA wood glue can be stronger than the wood itself. If the joint has gaps, damage, or will see hard moisture exposure, epoxy is usually the strongest and most reliable option.

Can I use regular wood glue on plywood?

Yes—regular carpenter’s wood glue works great for most indoor plywood projects, especially cabinets and furniture, as long as the surfaces are clean and the parts fit tight. For damp areas or outdoors, step up to a water-rated glue.

Is it better to use solvent-based or water-based adhesives for plywood?

Water-based PVA is the go-to for most plywood joinery because it’s easy to spread, clamps well, and sands clean. Solvent-based adhesives shine for veneers and laminates, where fast grab and wide-area bonding matter more than clamp time.

How long does it take for glue/adhesive to cure on plywood?

It depends on the glue type, temperature, and how tight the joint fits. Many wood glues set in under an hour, but full cure often takes 24 hours or longer—especially in cool shops or thick glue-ups. This explains the difference clearly: when a joint reaches full strength.

How long should I clamp a plywood glue joint?

Most PVA glue joints need at least 30–60 minutes in clamps, but longer is safer for big panels or cool conditions. The joint can feel firm early, yet it still needs time before it’s ready for heavy stress.

Can I use construction adhesive for outdoor plywood projects?

You can, but it’s usually better for construction-style jobs where screws or nails do most of the holding. For outdoor plywood joinery that needs a clean, tight bond, a waterproof wood glue or epoxy is typically a better fit.

Does plywood grain direction matter when gluing two pieces together?

It matters more for stability than for bonding. Plywood already alternates grain layers, but wide laminations can still warp if pressure isn’t even. Keep panels flat with cauls and balanced clamping, especially on larger glue surfaces.

What’s the best glue for plywood edges or edge banding?

For hardwood edging with a tight fit, PVA wood glue is usually perfect. If the plywood edge is porous, torn up, or has voids, epoxy often holds better because it fills gaps and reinforces weak fibers.

Do I need screws when gluing plywood together?

Not always. For clean woodworking joints, glue and clamps are enough when the fit is good. Screws help in shop builds, subfloors, or large assemblies where they act like extra clamps while the glue cures.

How do I fix a failed plywood glue joint?

First, break or separate the joint cleanly, then remove old glue by scraping and sanding back to fresh wood. Refit the parts, apply an even glue layer, and clamp with steady pressure. If gaps caused the failure, switch to epoxy.

What You Should Do Next

Wood glue for plywood isn’t complicated once you match the glue to the job. Use a solid PVA for tight indoor joints, step up to water-resistant formulas for damp spaces, and reach for epoxy when gaps or repairs demand it. Clean prep, even spread, and smart clamping do the heavy lifting.