Where can I get plywood cut to size: 7 Accurate Cuts Without a Truck

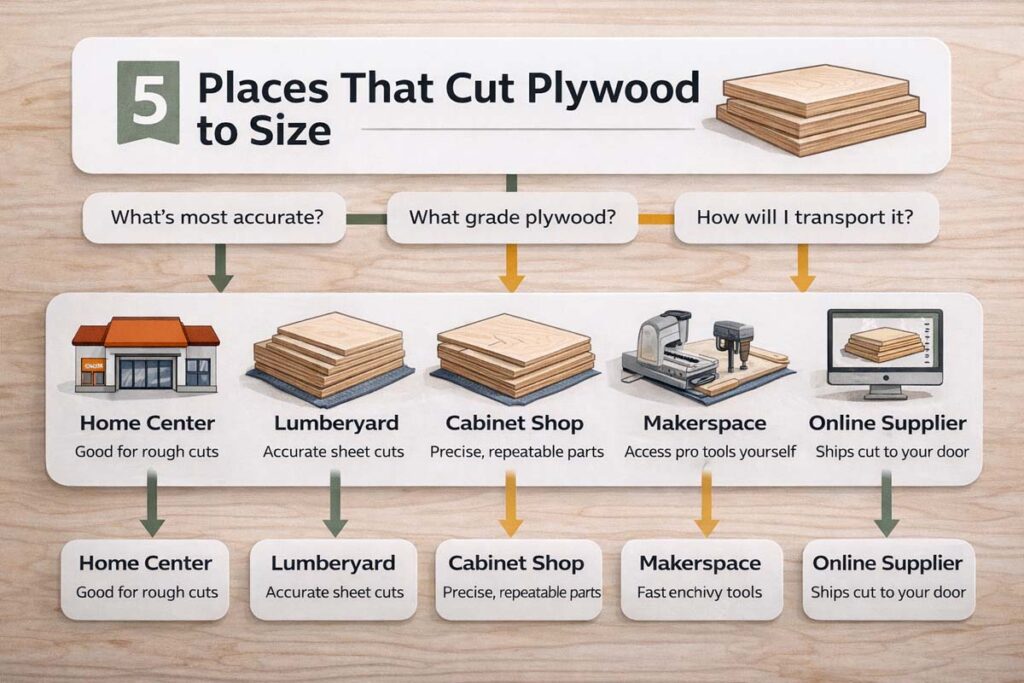

Where can I get plywood cut to size? You can get plywood cut to size at big-box home centers (like Home Depot or Lowe’s), local lumberyards, cabinet shops, makerspaces, or online plywood retailers that offer cut-to-size services.

The best place depends on the cut accuracy you need, the plywood grade you want, and how you plan to transport the pieces. A good cut list and clear tolerances keep the job clean and reduce surprises when you start building.

Contents Here

- 1 What are the best places to get plywood cut to size?

- 2 How do I choose the right place for my project?

- 3 What information should I bring when I order plywood cuts?

- 4 What cut tolerance should I ask for?

- 5 How do I avoid tear-out and chipped veneer on cut edges?

- 6 What should I measure and mark before I leave the store?

- 7 What is the safest way to transport pre-cut plywood parts?

- 8 Can I get plywood cut to size for small projects like trays and organizers?

- 9 Quick ordering checklist for cut-to-size plywood

- 10 Final Remarks

What are the best places to get plywood cut to size?

A plywood supplier solves two problems at once: they sell sheet goods and they cut them with shop-grade saws. Your best options fall into five groups.

Big-box home centers

Home centers cut plywood on a vertical panel saw. That saw handles full sheets well and keeps you from wrestling a 4×8 onto your own table saw.

Home centers fit best when:

- You need rough breakdown cuts for transport.

- You plan to trim to final size at home.

- You want common plywood, like construction-grade or sanded panels.

Watch-outs:

- Panel saw fences drift with heavy use.

- Staff often aims for “close,” not cabinet tolerance.

- Tear-out happens when blades get dull.

If you need cleaner faces for painted or finished work, learn what “cabinet-grade” means before you order. This guide helps you speak their language: what cabinet-grade plywood means in plain terms.

Local lumberyards and hardwood dealers

A lumberyard sells better sheet goods and usually runs a well-tuned panel saw or sliding table saw. The operator cuts plywood every day, so the process is steadier.

Lumberyards fit best when:

- You want Baltic birch, maple, walnut-veneered panels, or true cabinet plywood.

- You need more consistent thickness and flatter sheets.

- You want fewer voids on plywood edges.

Ask for:

- Cut accuracy in writing, even if it is informal.

- Blade type, if your veneer is prone to chipping.

- Whether they label each part to your cut list.

If your project is cabinetry, you’ll also get value from knowing which plywood type belongs in boxes, shelves, and doors. Here’s a solid starting point: which plywood works best for cabinets.

Cabinet shops and millwork shops

A cabinet shop cuts plywood on a sliding saw or a CNC router. That setup produces repeatable parts and square edges.

Cabinet shops fit best when:

- You need tight sizing for joinery, like dados and rabbets.

- You want multiple identical parts, like shelves or tray blanks.

- You want edge banding, drilling, or CNC cutouts.

Watch-outs:

- Shops prioritize their own jobs.

- Minimum fees are common for small cut lists.

- Lead times change week to week.

A cabinet shop also helps when you want “parts cut, ready to assemble.” Bring a drawing, bring a cut list, and keep the conversation about dimensions and grain direction.

Makerspaces and community woodshops

A makerspace gives you access to a panel saw, track saw, or table saw, plus room to break down sheets safely. You do the cutting, but you avoid buying tools you only need once.

Makerspaces fit best when:

- You want control over final dimensions.

- You need to test-fit parts as you go.

- You want guidance from shop staff.

This route works well if you already build small projects and want a safer setup for sheet goods.

Online plywood suppliers with cut-to-size services

Some online retailers sell plywood panels cut to your dimensions. You send a cut list, then they ship flat-packed parts.

Online cutting fits best when:

- You do not have a vehicle for full sheets.

- You want a specific veneer or core, like marine, Baltic birch, or bamboo panels.

- You want parts delivered to the door.

Watch-outs:

- Shipping damage happens without good packaging.

- Returns get expensive for custom-cut orders.

- Some vendors limit small strips due to breakage risk.

Before you buy, read the cut tolerance and kerf rules. A seller’s “exact” still has a tolerance range.

How do I choose the right place for my project?

Choose based on accuracy, plywood grade, and your next step in the shop.

- Pick a home center when you need rough cuts for transport and you plan to trim later.

- Pick a lumberyard when you need better plywood, flatter sheets, and cleaner cuts.

- Pick a cabinet shop when the pieces need to fit together without cleanup.

- Pick a makerspace when you want control and shop-grade tools without buying them.

- Pick online cut-to-size when delivery and convenience matter more than seeing the sheet before it is cut.

If your project is a finished piece, also match the plywood type to the finish. Veneer faces and soft cores behave differently under stain and clear coats. This overview can help you decide before you order: how to choose the best plywood for cabinets and furniture-style builds.

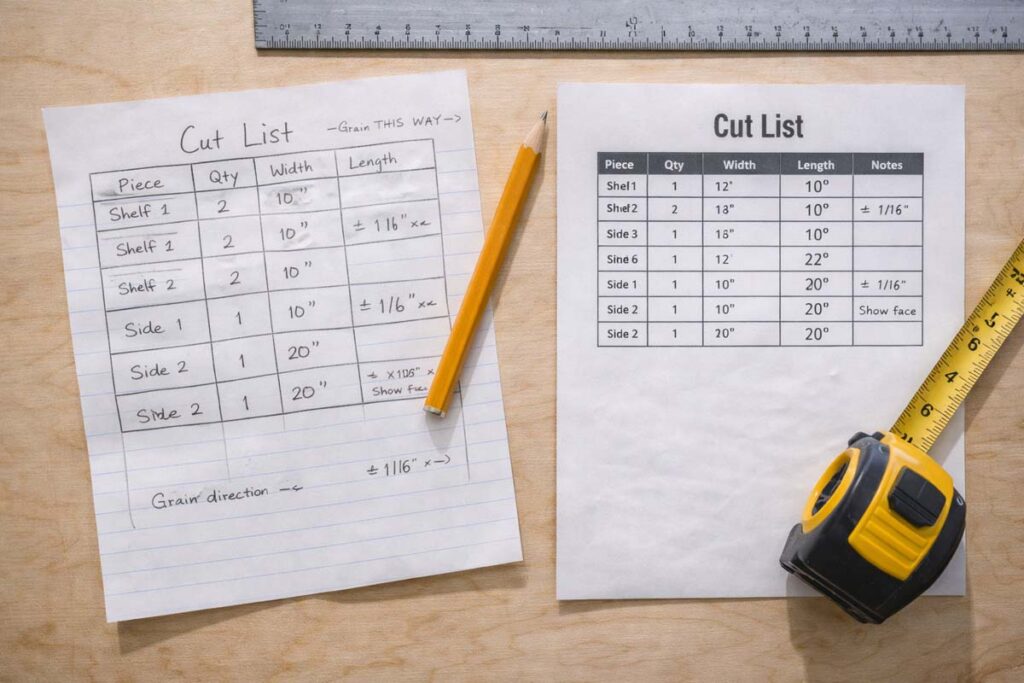

What information should I bring when I order plywood cuts?

A clear cut list keeps your parts consistent and lowers the risk of a wrong cut.

Bring:

- Sheet thickness and plywood type (birch, maple veneer, cabinet-grade, shop-grade).

- Grain direction for each part.

- Final part size and whether the size is “net” or “rough.”

- Quantity of each part.

- Notes for any faces that must stay clean.

If you are new to cut lists, start with rectangles and label them by use, like “tray base” or “shelf.” A cutter reads that faster than a pile of numbers.

What cut tolerance should I ask for?

Cut tolerance is the allowed variation from your listed size. Tolerance matters more when parts need to fit joinery or sit flush.

Use this as a practical shop standard:

- Rough breakdown for transport: “within 1/8 inch” works.

- General building parts you will trim later: “within 1/16 inch” works.

- Joinery-ready parts: ask what their saw holds and whether they can hit “within 1/32 inch.”

A home center panel saw often targets rough work. A cabinet shop usually targets joinery-ready work.

How do I avoid tear-out and chipped veneer on cut edges?

Veneer chips when the blade exits the face. A good cutter reduces chip-out with blade choice, feed rate, and support.

Ask for:

- A sharp plywood blade or a fine-tooth blade.

- The best face orientation for their saw.

- Blue tape on the cut line for fragile veneers.

- A scoring pass, if they use a sliding saw or CNC.

If you still expect to clean edges at home, sand lightly and keep the face veneer intact. This sanding guide helps you avoid ugly edge rounding and fuzzy fibers: how to sand end grain smooth without wrecking edges.

What should I measure and mark before I leave the store?

Measure once before the sheet gets cut. Measure again before you load the parts.

Check:

- Length and width of each part.

- Square corners on at least one large piece.

- Labeling, so parts do not get mixed up.

- Face quality, especially if one face is your “show face.”

If a dimension is off, fix it on the spot. A wrong cut rarely improves after the drive home.

What is the safest way to transport pre-cut plywood parts?

Plywood bends and cracks when it rides unsupported. Transport is a handling problem, not a driving problem.

Do:

- Support long parts with a flat base, like a van floor or truck bed.

- Use a moving blanket between layers to reduce face scratches.

- Strap snug, not crushing tight, to avoid corner damage.

- Keep small strips on top so they do not snap under heavier panels.

If you drive a small car, ask for fewer, larger breakdown pieces. Then trim to final size at home.

Can I get plywood cut to size for small projects like trays and organizers?

Yes. Sheet-goods cutting works well for tray bottoms, risers, and simple boxes. The key is choosing plywood that finishes clean and stays flat.

For small builds, focus on:

- Flat sheets with consistent thickness.

- Cleaner faces that accept paint or clear coat.

- Edges that take sanding without voids.

If you plan to glue plywood parts, choose an adhesive that bonds well to plywood cores and veneers. This guide stays focused on plywood-specific bonding: wood glue options that work on plywood.

Quick ordering checklist for cut-to-size plywood

Use this short checklist at the counter:

- Correct plywood type and thickness

- Good face picked as “show face”

- Grain direction stated on each part

- Cut list labeled by part name and quantity

- Tolerance stated in plain terms

- Parts measured and marked before loading

Final Remarks

You can get plywood cut to size at home centers, lumberyards, cabinet shops, makerspaces, and online cut-to-size suppliers. The right choice depends on how accurate the cuts need to be and how clean the faces must stay. Bring a clear cut list, state grain direction, and set a realistic tolerance. Then measure your parts before you leave. That one habit saves the most time and the most plywood.