What Wood to Use for Cabinets: 9 Proven Picks for Any Style

What wood to use for cabinets depends on three things: the cabinet part you’re building, the finish you want, and the moisture the cabinet will live with. Cabinet boxes need flat, stable sheet goods. Doors and face frames need solid lumber that machines cleanly and holds joinery. Painted cabinets favor smooth, closed-grain woods and MDF panels, while stained cabinets favor attractive grain like oak, cherry, or walnut. In this guide, I’ll break down the best woods for each cabinet component and give you reliable “buy this, avoid that” picks for kitchens, baths, and utility spaces.

Contents Here

- 1 Start with the cabinet parts that need wood

- 2 Best solid hardwoods for cabinet doors and face frames

- 3 Best “paint-grade” solid woods for cabinets

- 4 Best sheet goods for cabinet boxes

- 5 Wood movement matters more than most people expect

- 6 Match the wood to the finish you want

- 7 Best woods by cabinet “job”

- 8 What to look for when buying cabinet wood

- 9 Shop safety notes for cabinet materials

- 10 Bottom line: the best wood choices for cabinets

Start with the cabinet parts that need wood

Cabinets aren’t one material. A good build mixes materials on purpose.

Cabinet boxes (the carcass) stay square when the panels stay flat. Hardwood plywood stays flatter than solid wood because cross-banded plies resist seasonal movement.

Face frames (on framed cabinets) take screws, hinges, and bumps. Straight-grained hardwood holds fasteners and stays crisp at the edges.

Doors and drawer fronts take the most wear and the most attention. Dent resistance comes from species hardness, and the common yardstick is the Janka hardness test (higher number = more dent resistance).

Drawer boxes need tough corners and stable sides. Many shops use maple for drawer parts because it machines cleanly and resists wear.

Also know: Cabinet Grade Plywood

Best solid hardwoods for cabinet doors and face frames

If you want a “safe” hardwood choice that works in most kitchens, start here.

Hard maple (sugar maple) makes a durable door and frame stock. The Janka rating runs around 1,450 lbf, which helps it resist dents from daily use.

Use maple when you want a smooth, tight grain for clear finish or light stain. It also paints well after proper sanding and priming.

Red oak and white oak give strong grain, high durability, and easy sourcing. Red oak commonly lists around 1,290 lbf on the Janka scale.

Use oak when you want pronounced grain and a traditional look. Choose white oak when you want better moisture resistance than red oak in damp environments.

Cherry builds classic, warm cabinets with a smooth texture. Cherry’s Janka value is commonly listed around 950 lbf.

Use cherry when you want a furniture look and you accept that it darkens with UV exposure over time.

Black walnut delivers a high-end look with deep color and strong figure. Walnut is often listed around 1,010 lbf on the Janka scale.

Use walnut for stained or clear-finished doors and drawer fronts where the wood is the feature.

Birch (yellow birch) sits in the practical middle: strong, fine-grained, and affordable in many areas. Birch is commonly listed around 1,260 lbf Janka.

Use birch when you want a smooth cabinet face with better dent resistance than many “budget” hardwoods.

Alder is easy to machine and takes paint well. It’s softer; Janka values often list in the 500–600 lbf range, which dents easier than maple or oak.

Use alder when you want a lower-cost solid wood door, or when you plan a painted finish and accept lower dent resistance.

Best “paint-grade” solid woods for cabinets

Paint hides grain, so the goal shifts: straight lumber, low movement, and easy prep.

Poplar is a top paint-grade choice for face frames and door rails/stiles because it machines cleanly and stays stable when it’s dry. It’s soft, so it dents more than maple. Many Janka tables list poplar around the 500–600 lbf range.

Use poplar for painted face frames and trim. Avoid it for exposed shelves that take heavy wear.

Pine and fir work for utility cabinets, shop cabinets, and rustic looks. Expect knots, pitch, and more movement than hardwoods.

Use clear, straight stock (fewer knots) for face frames. For doors, pine needs careful sealing to prevent knot bleed through paint.

Read next: Shop Grade Plywood

Best sheet goods for cabinet boxes

Cabinet boxes win or lose on panel quality. Flat panels keep doors aligned and drawers running smooth.

Hardwood plywood is the standard for long-life cabinet boxes. It gives good screw holding, decent moisture tolerance, and strong stiffness at common cabinet spans.

Look for plywood sold as “hardwood plywood” with veneer faces (maple, birch, oak, walnut). Pay attention to the core:

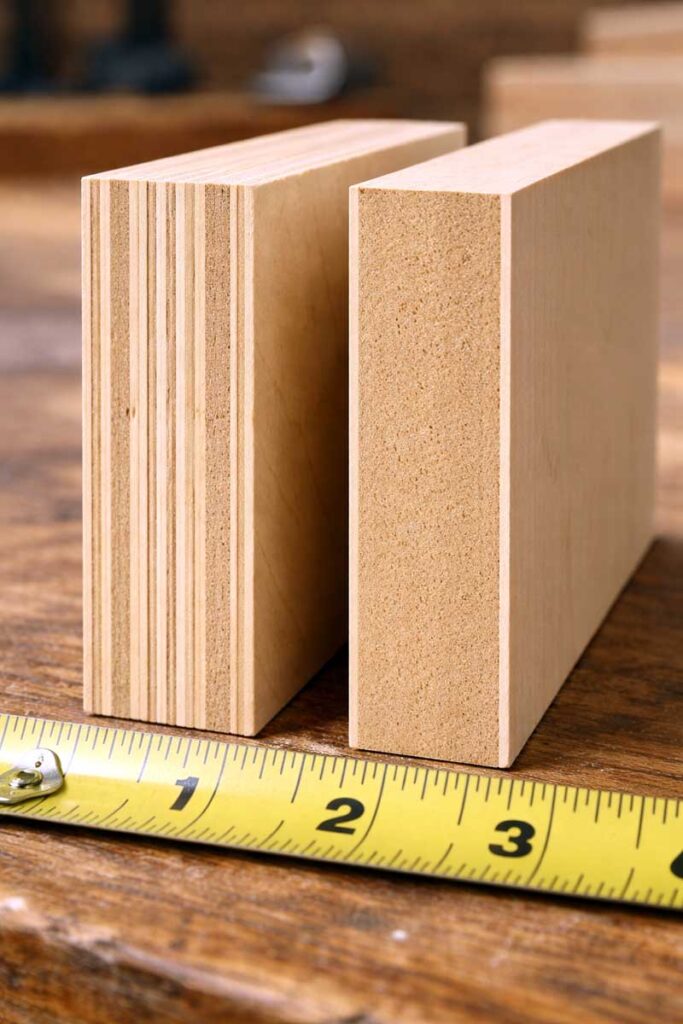

- Veneer-core plywood is lighter and often holds screws well, but some panels contain internal voids.

- MDF-core plywood stays flatter and gives a smoother face, but it’s heavier and edges need careful fastening.

Woodworking industry discussions often point out MDF/particle cores offer strong dimensional consistency, while veneer-core panels can include voids.

Baltic birch-style plywood (many thin plies) often comes flatter and more void-resistant than standard big-box plywood. It’s a strong choice for drawer boxes and shop-built organizers. In many markets, “Baltic birch” labeling varies, so inspect edges for consistent plies.

MDF (medium-density fiberboard) produces dead-flat panels and a smooth painted surface. It’s common for painted door panels and for flat end panels. It swells when it soaks up water, so it fits better in dry areas or well-protected installs.

Particleboard and melamine appear in many factory cabinets because they’re flat and cost-effective. They hold screws less reliably than plywood, so hardware choice and fastening method matter. Many frameless systems use confirmat screws or specialized hardware designed for particleboard.

A quick health and compliance checkpoint

In the U.S., regulated composite wood products (hardwood plywood, MDF, particleboard) must meet TSCA Title VI labeling and emissions requirements.

If you’re buying sheet goods for indoor cabinets, choose panels labeled TSCA Title VI (and/or CARB Phase 2). CARB publishes comparison materials and updates when requirements change.

Wood movement matters more than most people expect

Solid wood moves across the grain as humidity changes. Plywood moves far less because plies cross each other and balance the panel.

Two details help you predict trouble:

First, tangential shrinkage (around the growth rings) exceeds radial shrinkage (across the rings), and that imbalance drives cupping. Extension resources tie cupping to differential shrinkage across the grain and reference USDA Wood Handbook shrinkage values.

Second, longitudinal shrinkage (along the length) stays small, often around 0.1%–0.2%, so most cabinet movement problems show up in width, not length.

Practical takeaway in the shop: use plywood for wide cabinet sides and bottoms, and use solid wood where you need strong edges and joinery. When you build slab doors or wide panels from solid wood, use frame-and-panel construction so the panel can float.

Match the wood to the finish you want

For stained or clear-finished cabinets, pick woods with attractive grain and predictable color:

Oak gives bold grain lines. Cherry and walnut give richer natural color. Maple and birch give a cleaner, tighter look but can stain blotchy without good prep.

If you stain maple or birch, use a consistent sanding schedule and a proven conditioner or sealer coat. Blotch happens when earlywood and latewood absorb finish at different rates.

For painted cabinets, choose woods and sheet goods that sand smooth and stay stable:

Poplar face frames + MDF door panels is a common paint recipe because it reduces grain telegraphing. Use hardwood for door frames if you want stronger edges and hinge screws.

A paint job fails fast when the substrate moves. Put the money into flat panels and dry lumber before you spend it on premium paint.

Best woods by cabinet “job”

Here are mixes that work because each material plays to its strengths.

Everyday kitchen, high wear (family use): Hard maple doors and face frames + hardwood plywood boxes. Maple’s higher Janka rating helps resist dents at the door edges.

Stained, furniture-style kitchen: Cherry or walnut doors/drawer fronts + maple or birch interiors + hardwood plywood boxes. Cherry and walnut deliver the look; stable sheet goods keep the cabinet geometry tight.

Budget rental or utility kitchen (paint): Poplar face frames + MDF doors (or poplar frames with MDF panels) + TSCA Title VI-labeled melamine or plywood boxes. TSCA Title VI labeling applies to regulated composite panels used in finished goods.

Bathroom vanity (higher moisture): Hardwood plywood box and ends + hardwood face frame. Use a finish system that seals end grain and edges. White oak, sealed well, performs better than many open-pored woods in damp rooms.

What to look for when buying cabinet wood

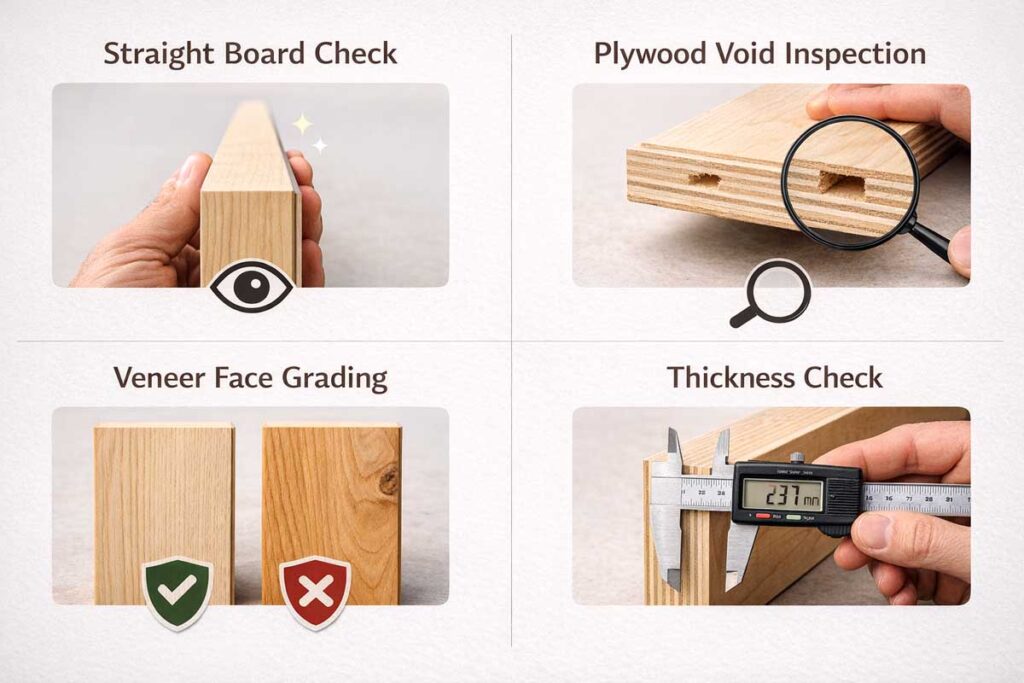

At the yard or supplier, panel quality and straightness matter more than the species name on the sticker.

For solid lumber:

- Buy flatter boards than you think you need. Sight down length and edge.

- Favor straight grain for face frames and door parts.

- Choose kiln-dried stock suited for interior work.

For plywood:

- Inspect edges for voids and patchy cores.

- Check that faces match your finish plan (paint-grade vs stain-grade veneer).

- Buy consistent thickness for joinery. Many “3/4 in” panels run closer to 23/32 in.

For MDF and particleboard:

- Confirm TSCA Title VI / CARB Phase 2 compliance labeling for indoor use.

- Plan your edge treatment (edge banding, solid edging, or a face frame) because raw edges drink finish.

Shop safety notes for cabinet materials

Cabinet work creates a lot of fine dust, and MDF creates the finest dust in the pile. Cut sheet goods with good extraction and a respirator rated for fine particulates. Keep blades sharp to reduce burning and airborne dust.

If you’re sensitive to odors or building for a tight indoor space, lean toward low-emitting panels and ventilate during finishing. EPA guidance explains which composite wood products fall under formaldehyde emissions standards and labeling.

Bottom line: the best wood choices for cabinets

Cabinet boxes stay reliable when you build them from quality hardwood plywood or compliant melamine panels. Doors and face frames look and wear better when you build them from stable hardwood like maple, oak, cherry, or walnut. Painted builds run smoother with poplar for frames and MDF where a dead-flat surface matters. If you pick materials by cabinet part—not by one “perfect” wood—you get straighter installs, better finishes, and fewer call-backs years later.