What Type of Plywood for Cabinets: 8 Essential Buying Checks

The type of plywood for cabinets comes down to core type, face grade, and thickness. For most kitchens and built-ins, cabinetmakers use 3/4-inch hardwood plywood with a stable core for the box, and a cleaner face veneer for anything you’ll see. That choice keeps panels flatter, holds screws better, and finishes more predictably than construction plywood. Below I’ll walk you through picking plywood by cabinet part (boxes, shelves, backs, doors), then narrow it to a few “buy this and build” recipes.

Contents Here

- 1 Start with the cabinet parts, not the sheet

- 2 Use cabinet-grade hardwood plywood, not sheathing plywood

- 3 Pick the core that matches your build

- 4 Choose a face grade that fits what people will see

- 5 Use the thickness that matches spans and joinery

- 6 Match the glue/bond rating to the room

- 7 Buy panels that meet low-emission standards

- 8 Four “grab-and-build” plywood recipes that work

- 9 What I check at the lumberyard before a sheet goes in the truck

- 10 FAQs about Type of Plywood for Cabinets

- 11 Bottom line

Start with the cabinet parts, not the sheet

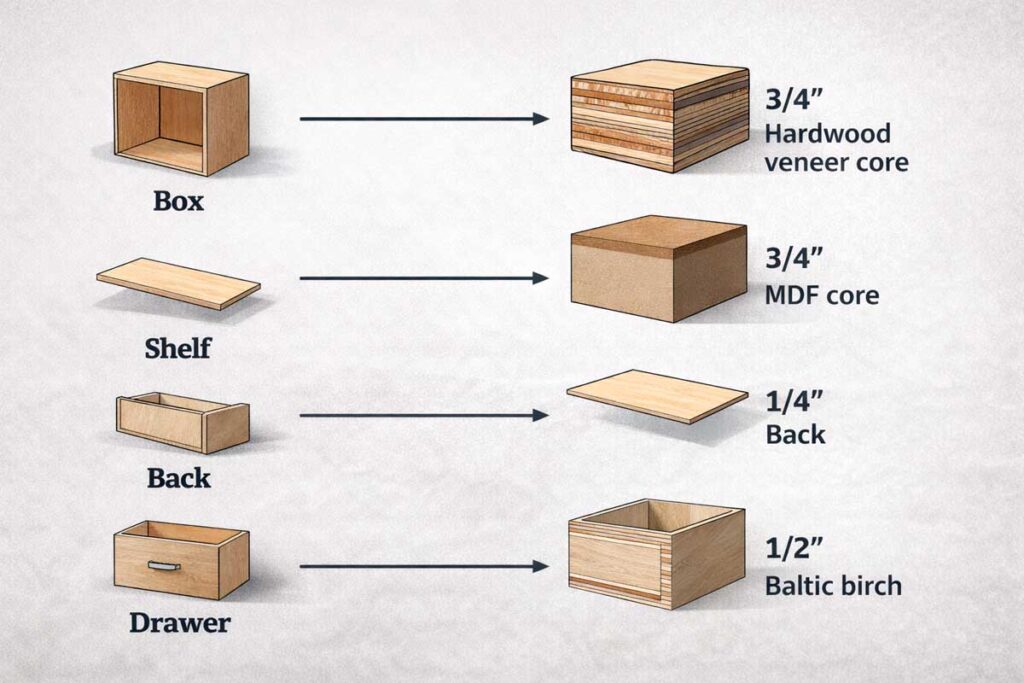

Cabinets fail in a few predictable ways: shelves sag, sides rack out of square, and fasteners loosen. Each part asks for a different strength.

Cabinet boxes (sides, bottoms, tops) need stiffness and fastener holding. Frameless boxes also rely on panel stiffness to stay square because the box acts like the frame.

Shelves need stiffness first, then a clean edge strategy. Long spans punish low-density cores.

Back panels need racking resistance. A thin back in a proper dado can lock a box square better than a thicker back stapled on.

Doors and drawer fronts need a clean face veneer that matches your finish plan. The core matters less than veneer quality for looks, but it still affects flatness.

Learn more on: Are Plywood Cabinets Good? 7 Tough Checks Before You Buy

Use cabinet-grade hardwood plywood, not sheathing plywood

Hardwood plywood is built and sold for appearance and interior woodworking. The industry grades it by veneer quality and intended use, which helps you buy predictably instead of gambling by the stack. The hardwood and decorative plywood standard (ANSI/HPVA HP-1) defines marketing classifications, quality criteria, and how panels are marked.

Construction plywood (like CDX) is engineered for structural work and tolerates knots, patches, and thicker glue lines. Those panels work for shop cabinets, but they fight you on finishing and edge quality.

If you want cabinets that look clean and stay tight for years, start in the hardwood plywood rack.

Pick the core that matches your build

“Hardwood plywood” describes the face and grading system. The core is what decides weight, flatness, edge quality, and screw holding. The three common cores are veneer core, MDF core, and particleboard core.

Veneer core (classic cabinet plywood)

Veneer core uses cross-banded wood plies through the thickness. It’s lighter than MDF-core panels and generally holds screws well in the face and edges when you use proper pilot holes.

Use veneer core when:

- You hang boxes on a wall and want less weight.

- You build face-frame cabinets and rely on screws into the box sides.

- You want better edge fastener holding than particleboard-core panels.

Watch-outs: some veneer-core sheets have interior voids. Voids don’t ruin a cabinet, but they can wreck a dado, a shelf pin line, or a clean edge band.

MDF core (flat and paint-friendly)

MDF core uses a dense fiberboard center with thin crossbands and face veneers. And MDF core stays very flat, which helps with long cabinet sides and big door panels.

Use MDF core when:

- You plan a painted finish and want a dead-smooth face.

- You need flat panels for frameless boxes and wide gables.

- You intend to edge-band every exposed edge.

Watch-outs: MDF edges don’t hold screws like veneer core. Fine-thread confirmat screws or euro screws help, and a pilot hole matters every time. MDF dust is also nasty—cut it with dust collection and a respirator.

Particleboard core (common in euro-style production)

Particleboard core uses compressed wood particles. Many commercial frameless cabinet systems use it because it machines consistently and stays flat.

Use particleboard core when:

- You build frameless cabinets with confirmat screws and edgebanding.

- You want stable sheet goods at a lower cost than veneer core.

- You plan to cover edges and avoid edge screws where possible.

Watch-outs: edge screw holding is the weak point. Design around that with joinery that puts fasteners into faces, not raw edges.

Choose a face grade that fits what people will see

Hardwood plywood grades describe veneer appearance on the face and back. In the U.S., you’ll often see combinations like A1, A2, B2, B3, and so on. The letter typically describes the better “face” and the number describes the back. Suppliers use these grades to sell panels meant for two visible sides versus one visible side.

Here’s the practical shop translation:

- An A1 or A2 panel fits exposed ends, door panels, and finished interiors where you want a clean, consistent face.

- A B2 panel fits cabinet sides and bottoms when the inside gets painted or covered, and the outside gets a face frame or end panel.

- A B3 or A3 panel fits carcase parts where one side stays hidden or faces a wall.

If you build stained cabinets, buy your visible components from the same lift if you can. Veneer color varies across runs.

Use the thickness that matches spans and joinery

Thickness is both strength and “meat” for joinery. The cabinet world standardizes around a few sizes.

- 3/4-inch (often 23/32 in) is the workhorse for cabinet sides, bottoms, tops, and most adjustable shelves.

- 1/2-inch (often 15/32 in) fits drawer boxes, some fixed shelves, and lightweight uppers when designed carefully.

- 1/4-inch fits backs and drawer bottoms when captured in grooves.

Baltic birch is its own category. It’s commonly sold in metric thicknesses like 12 mm (~1/2″) and 18 mm (~3/4″), and suppliers often list ply counts (for example, 18 mm with about 13 plies). The uniform plies make it excellent for drawer boxes and clean edges.

Quick selection table

| Cabinet part | Best “default” plywood | Notes |

|---|---|---|

| Box sides/bottom/top | 3/4″ hardwood plywood, veneer core | Lighter, strong screw holding |

| Frameless boxes | 3/4″ hardwood plywood, MDF or particleboard core | Flat panels, plan for edgebanding |

| Adjustable shelves | 3/4″ veneer core or Baltic birch | Add a front edge stiffener on long spans |

| Back panel | 1/4″ plywood in a dado | Dadoed back adds racking strength |

| Drawer boxes | 1/2″ Baltic birch | Great machining and edge durability |

| Exposed end panels | A-grade face hardwood plywood | Match species and veneer cut |

Match the glue/bond rating to the room

Plywood labels often include bond classifications like Exterior or Exposure 1. These ratings describe adhesive durability and intended moisture exposure. APA-trademarked panels commonly list these bond classes.

For cabinets:

- For a typical living space, an interior-rated hardwood plywood works fine.

- For kitchens, baths, laundry rooms, or mudrooms, a panel rated Exposure 1 or Exterior adds moisture tolerance in the glue line.

That rating doesn’t make plywood waterproof. It means the adhesive bond survives moisture better, which matters when a sink cabinet gets wet or a dishwasher steams the box.

Buy panels that meet low-emission standards

Composite wood products in the U.S. fall under formaldehyde rules (TSCA Title VI). EPA lists hardwood plywood, MDF, and particleboard as regulated product categories under the rule.

In plain terms: look for panels labeled as TSCA Title VI compliant (often paired with CARB Phase 2 language). It’s not marketing fluff—those labels tie to testing, certification, and sale requirements.

Shop note: if you cut a lot of sheet goods, use a respirator and dust collection. Your lungs don’t care whether it’s “natural wood dust” or MDF fiber.

Four “grab-and-build” plywood recipes that work

These are the combinations I reach for most often because they build clean and stay stable.

1) Stain-grade kitchen cabinets (solid look, reasonable cost)

Use 3/4″ veneer-core hardwood plywood for boxes, with an A-grade face on exposed ends and any visible interior panels. Use edge banding or hardwood face frames to cover edges.

Why it works: veneer core holds screws well, stays lighter on the wall, and finishes naturally with stains and clears.

2) Paint-grade built-ins (flat panels, easy finishing)

Use 3/4″ MDF-core hardwood plywood for the visible carcase faces and end panels, and veneer-core for internal structural parts if you want better fastener holding.

Why it works: MDF core stays flatter and paints smoother, which reduces telegraphing and face ripples.

3) Frameless “Euro” boxes (production-style)

Use 3/4″ particleboard-core or MDF-core panels with factory-applied melamine or a consistent veneer. Use confirmat screws, dowels, or cam hardware, plus edge banding.

Why it works: the system is designed around those cores and their machining behavior.

4) Tough drawer boxes (daily abuse, clean edges)

Use 1/2″ Baltic birch for sides and backs, and 1/4″ Baltic birch for bottoms captured in a groove.

Why it works: Baltic birch’s uniform plies machine cleanly and resist edge blowout, and suppliers commonly sell it in 12 mm and 18 mm thicknesses with multi-ply construction.

Read more: What Wood to Use for Cabinets: 9 Proven Picks for Any Style

What I check at the lumberyard before a sheet goes in the truck

A 30-second inspection prevents hours of cussing later.

- Sight down the long edge for bow and twist.

- Check both faces for patches, open knots, and mineral streaks where your finish will land.

- Tap along the edges and listen for hollow voids in veneer-core sheets.

- Look at the label for core type, thickness, and bond class (Exposure 1 / Exterior).

- Confirm TSCA Title VI (and often CARB Phase 2 language) if the panel is a composite product.

- If you plan to edge-band, check the veneer thickness. Some bargain panels sand through fast.

FAQs about Type of Plywood for Cabinets

Is Baltic birch good for cabinets?

Baltic birch works great for cabinet parts that benefit from uniform plies—drawer boxes, shelves, and interiors. Many suppliers sell it in metric thicknesses like 12 mm and 18 mm, and they often list ply counts (for example, 18 mm with about 13 plies). Use it where the edge shows or takes abuse, and cover the edge when you want a furniture-grade look.

Can I use MDF for cabinet boxes?

MDF-core plywood builds flat, square boxes and paints cleanly. The weak point is edge screw holding, so design joinery that avoids relying on edge screws alone and use correct pilots and fasteners. MDF also produces fine dust, so cut it with good extraction and a respirator. For sink bases and wet zones, combine it with careful sealing and smart layout.

What about “marine plywood” for kitchen cabinets?

Marine plywood usually focuses on higher-quality veneers and fewer voids, plus durable glue lines. It costs more, and it doesn’t replace good finishing or smart moisture design. For a kitchen, a cabinet-grade hardwood plywood with an Exposure 1 or Exterior bond class plus sealed edges and a proper sink-base layout delivers the practical durability most homes need.

Is CDX plywood okay for shop cabinets?

CDX works for shop cabinets and garage storage when you don’t care about a furniture finish. It’s built for construction tolerance, not visual quality, and it often carries visible defects and rough veneers. If you want painted shop cabinets that wipe clean, step up toa skin panel where it shows.

Bottom line

For most cabinet builds, 3/4-inch cabinet-grade hardwood plywood is the clean, reliable starting point. Pick veneer core for lighter weight and stronger screw holding, pick MDF core for flat paint-ready panels, and pick particleboard core when you build a frameless system designed around it. Match face grade to what people see, buy panels with appropriate bond ratings for the room, and look for TSCA Title VI compliance for indoor air quality.