What Thickness Plywood for Cabinets: 7 Proven Sizes That Don’t Sag

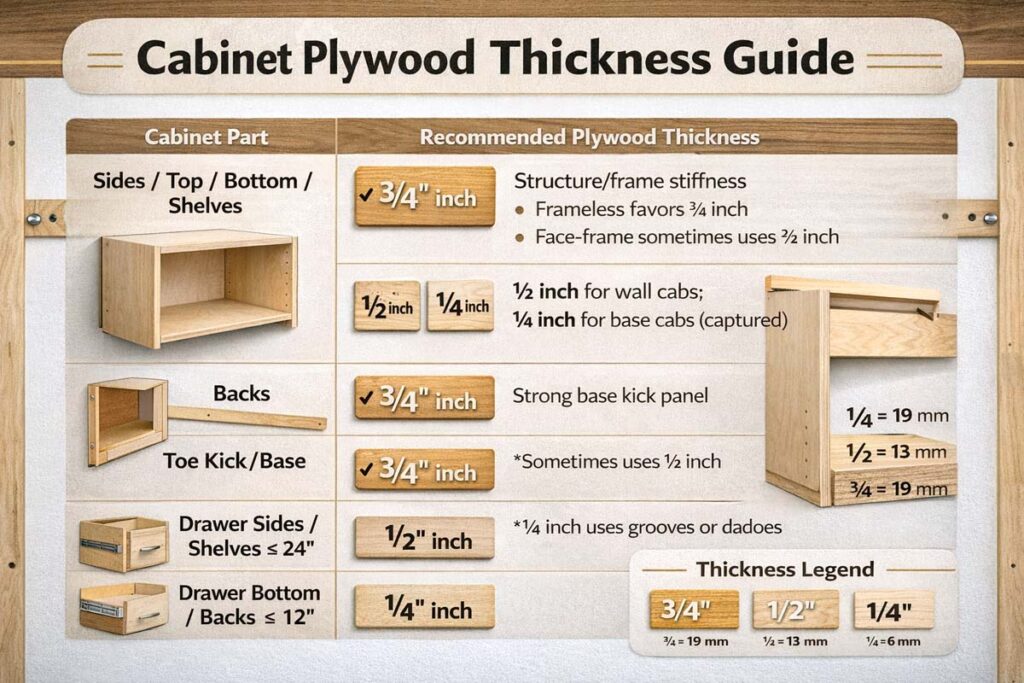

What thickness plywood for cabinets comes down to stiffness, screw-holding, and how much load each part carries. Most cabinet boxes run best on 3/4-inch (19 mm) plywood for sides, tops, bottoms, and shelves, with thinner panels reserved for backs, nailers, and drawer parts.

The “right” thickness also depends on whether you build frameless (Euro) or face-frame, how wide your shelves span, and how you plan to hang wall cabinets. Below is a shop-tested way to pick thicknesses that stay square, hang safely, and resist sag over time.

Contents Here

- 1 What thickness plywood for cabinets is standard?

- 2 Why 3/4-inch plywood is the default for cabinet boxes

- 3 When 1/2-inch plywood works well in cabinets

- 4 When 1/4-inch (or 1/8-inch) panels make sense

- 5 Frameless vs face-frame thickness choices

- 6 Shelf thickness, span, and sag in the real world

- 7 Nominal vs actual thickness: why “3/4” isn’t always 0.750

- 8 Plywood type matters as much as thickness

- 9 A fast way to choose thickness for your cabinet build

- 10 Moisture and abuse zones: where thicker (or different) panels pay off

- 11 FAQs about What Thickness Plywood for Cabinets

- 12 Final shop recommendation

What thickness plywood for cabinets is standard?

For most kitchens, 3/4-inch plywood handles the cabinet “structure,” while 1/2-inch and 1/4-inch handle closures and secondary parts. Commercial casework specs commonly call out 3/4-inch (19 mm) panels for sides and fixed parts, then step down for backs and drawer parts.

A practical breakdown:

- Cabinet sides, bottoms, tops, fixed partitions: 3/4 in (19 mm)

- Adjustable shelves (typical kitchen widths): 3/4 in (19 mm) (go thicker for wide spans or heavy loads)

- Wall-cabinet backs: 1/2 in (13 mm) when the back helps carry hanger loads

- Base-cabinet backs (often captured in a dado): 1/4 in (6 mm) in many spec sets

- Toe-kick/base parts in architectural casework: ≥ 17.5 mm (0.688 in)

Read more: What Is the Thickest Plywood You Can Buy? 7 Powerful Facts

Why 3/4-inch plywood is the default for cabinet boxes

3/4-inch plywood gives you dependable screw purchase for hinges, slides, and assembly fasteners, and it resists racking when the cabinet gets dragged into place. Many architectural casework specs set “standard panels” (top, bottom, side, interior panels) at 3/4 in (19 mm) for that reason.

In a small shop, 3/4 also simplifies joinery. Dadoes and rabbets land cleanly, and edge banding has enough meat to stay flat through sanding and finishing.

When 1/2-inch plywood works well in cabinets

1/2-inch plywood fits best where the panel closes a box or supports lighter loads, not where it defines the cabinet’s shape.

Good 1/2-inch uses:

- Wall-cabinet backs when you want a stronger hanging surface than 1/4-inch provides. Some casework specs call for 1/2 in upper backs.

- Cabinet stretchers/nailers when the cabinet also has a face frame and the stretcher mainly ties the box together.

- Drawer sides in some spec sets (often paired with a thicker front/back).

If you build frameless cabinets, 1/2-inch sides start to feel “springy” unless you add design features that replace stiffness (full backs, fixed partitions, thicker nailers, shorter spans).

Also know: Is Birch Plywood Good for Cabinets? 7 Fast Ways to Avoid Voids

When 1/4-inch (or 1/8-inch) panels make sense

Thin panels belong where they act like a “skin,” not a beam.

Common applications:

- Captured backs in a groove/dado, especially on base cabinets where the countertop and toe-kick structure help control racking. Some architectural specs list 1/4 in lower backs.

- Drawer bottoms (often 1/4-inch plywood, set in a groove). KCMA testing includes drawer-bottom and shelf/bottom loading to check deflection and joint separation.

A thin back gains most of its strength from how you install it. A back stapled to the rear edges works, but a back captured in dados locks the cabinet square and keeps it square.

Frameless vs face-frame thickness choices

Frameless (Euro) cabinets rely on the box for stiffness. That pushes you toward 3/4-inch sides, bottoms, tops, and partitions, plus a back that contributes to squareness and hanging strength.

Face-frame cabinets spread loads into the frame. That sometimes lets you use thinner parts without the cabinet feeling flimsy, but the savings disappear fast if shelves sag or hardware strips out.

If you plan to use European 32 mm hardware patterns, keep your material consistent so your shelf pins and hinge plates land with clean spacing. AWI limits adjustable-shelf hole spacing to 64 mm (2.520 in) on center for its casework requirements.

Shelf thickness, span, and sag in the real world

Shelves sag from load, span, and time under stress (creep). Thickness is the lever you control fastest.

Two useful reference points from industry standards:

- KCMA’s A161.1 program loads shelves and bottoms at 15 lb/ft² for seven days and checks for excessive deflection and joint failure.

- AWI allows a calculated shelf deflection of 6.4 mm (0.250 in) and ties allowable loading to the shelf material’s modulus of elasticity (MOE).

In plain shop terms: a 3/4-inch shelf covers most kitchen cabinet spans comfortably, especially with a solid front edge band. As shelves get wider, specs often jump thickness. One common spec set calls for 3/4-inch shelves up to 30 inches wide and 1-inch shelves from 30–42 inches.

Nominal vs actual thickness: why “3/4” isn’t always 0.750

Sheet goods get sold by nominal thickness, but standards allow a range.

For structural panels, PS 2-18 lists thickness ranges by “Performance Category.” For example:

- 23/32 PERF CAT: 17.46–19.05 mm (0.688–0.750 in)

- 3/4 PERF CAT: 18.26–19.84 mm (0.719–0.781 in)

APA also notes thickness tolerances and explains that panel thickness changes with moisture conditions.

Shop takeaway: measure your plywood before you cut dadoes and before you set your router bit for hinge plates or edge banding flush-trim.

Plywood type matters as much as thickness

“3/4-inch plywood” describes a size, not a quality level. The core and veneer build decide how it machines and how it holds hardware.

What changes your results:

- Veneer-core hardwood plywood cuts cleanly and stays lighter than MDF-core.

- MDF-core plywood gives a flatter face for paint-grade doors and panels, but it holds screws differently and hates leaks.

- Baltic birch-style plywood (all-birch, many plies) stays stiff and machines crisp for drawers and shop cabinets.

If you buy hardwood plywood by grade, HPVA’s HP-1 standard is the common language for face/back grades and construction.

A fast way to choose thickness for your cabinet build

Use this sequence when you’re designing a cabinet set or ordering material:

- Pick the cabinet system. Frameless favors 3/4-inch structure; face-frame gives more flexibility.

- Set shelf spans and loads. Pantry shelves and wide bases drive thickness up faster than sink bases.

- Decide how the back works. A 1/2-inch back can share hanging loads; a 1/4-inch back works best captured in dados.

- Match joinery to thickness. Dados and rabbets support thinner panels better than butt joints.

- Confirm actual thickness with calipers. Cut joinery to the sheet you have, not the label.

Moisture and abuse zones: where thicker (or different) panels pay off

Sink bases, trash pull-outs, and laundry cabinets see more water and impact. Thickness helps, but material choice matters more.

Smart upgrades that hold up:

- 3/4-inch prefinished plywood for cabinet interiors that see cleaners and spills.

- A thicker toe-kick/base build in casework that takes kicks and mops; AWI calls out ≥ 17.5 mm material for toe kicks/bases in its architectural casework material rules.

- Better edge sealing (banding plus finish) on exposed plywood edges, because water enters from edges first.

FAQs about What Thickness Plywood for Cabinets

What kind of plywood for cabinets?

Hardwood plywood (birch, maple, oak) with a solid core works best for cabinets because it stays flatter, machines cleaner, and holds screws better than low-grade sheathing. Choose prefinished for easy wipe-clean interiors.

Is 1/2-inch plywood strong enough for cabinet sides?

1/2-inch plywood works for small, light-duty cabinets or face-frame builds where the frame adds stiffness. For frameless boxes, 3/4-inch sides resist racking better and hold hinges and slides more reliably.

What thickness plywood is best for cabinet shelves?

3/4-inch plywood is the go-to for cabinet shelves because it fights sag across typical spans. If a shelf runs wide or carries heavy dishes, add a thicker shelf or stiffen the front edge.

What thickness plywood is best for cabinet backs?

Use 1/2-inch plywood for wall-cabinet backs when the back helps carry hanging loads into studs. Use 1/4-inch backs when they’re captured in dados and the box gets strength from joinery.

Final shop recommendation

If you want cabinets that assemble square and stay that way, build your carcasses from 3/4-inch plywood, use 3/4-inch shelves by default, and choose the back thickness based on whether it shares structural work. Then measure the actual sheet thickness and cut your joinery to match the plywood you bought, not the stamp on the rack.