What Size Plywood for Cabinets: 5 Simple Sizes That Work Every Time

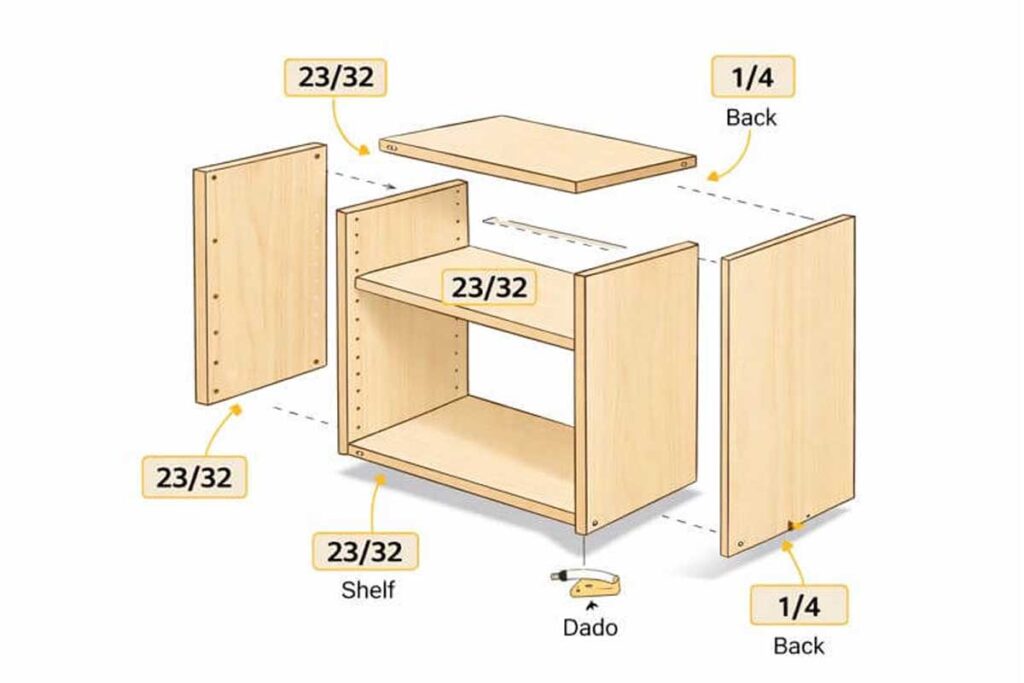

Choosing what size plywood for cabinets comes down to two decisions: thickness for strength and sheet size for efficient cutting. Most cabinet shops default to 3/4-inch (often sold as 23/32) for cabinet boxes and shelves, then step down to 1/2-inch for drawer parts and 1/4-inch for backs and drawer bottoms. APA’s panel “Performance Category” system is one reason you’ll see 23/32, 15/32, and 19/32 on tags instead of the nominal fractions.

Contents Here

- 1 What does “plywood size” mean when you’re building cabinets?

- 2 What plywood thickness should you use for each cabinet part?

- 3 What thickness plywood should you use for cabinet boxes?

- 4 What thickness plywood should you use for cabinet shelves so they don’t sag?

- 5 What thickness plywood should you use for cabinet backs?

- 6 What sheet size plywood should you buy for cabinets?

- 7 What type and grade of plywood belongs in cabinets?

- 8 How do you match joinery and hardware to plywood thickness?

- 9 How do you prevent racking and wobble in plywood cabinets?

- 10 Common mistakes when choosing plywood for cabinets

- 11 FAQs about what size plywood for cabinets

- 12 Final thoughts

What does “plywood size” mean when you’re building cabinets?

“Plywood size” for cabinets means thickness first, then length × width (sheet size). Thickness controls screw holding, shelf sag, and how stiff the box stays when you move it around. Sheet size controls waste, grain direction, and whether you can break sheets down safely in a small shop.

Why doesn’t “3/4-inch plywood” measure 3/4 inch?

“3/4 inch” is usually a nominal label, while the stamp or tag often lists a Performance Category such as 23/32. APA documents and labeling commonly use categories like 15/32, 19/32, and 23/32.

Some retailers also sell panels that come out closer to 21/32, especially in certain product lines, which is why cabinet joinery works better when you measure your sheet before you cut dados.

Shop move that prevents headaches: Set your dado/slot off the actual panel with a test cut, not the sticker.

Learn more at: What Wood Is Better for Kitchen Cabinets: 5 Pro Picks for Paint or Stain

What plywood thickness should you use for each cabinet part?

Use this chart as a starting point, then adjust for span length, hardware, and whether the cabinet is face-frame or frameless.

| Cabinet part | Typical plywood thickness | Why it works |

|---|---|---|

| Box sides / top / bottom | 3/4 (23/32) | Stiff box, better fastener bite, stable for frameless builds |

| Shelves | 3/4 (23/32) | Better sag resistance; reinforce or add supports on long spans |

| Back panel (captured in dado/rabbet) | 1/4 | Standard for keeping the case square with less weight |

| Back panel (full structural back) | 1/2 | Stiffer nailing surface; helpful when you want a stronger back |

| Drawer sides / backs | 1/2 (15/32) | Strong enough, lighter than 3/4; common for plywood drawers |

| Drawer bottoms | 1/4 (or thicker for wide drawers) | Common for captured bottoms; go thicker if the drawer is wide/heavily loaded (measure and design for it) |

| Doors (slab) | 3/4 | Resists warping better than thin panels on large doors (design-dependent) |

| Shaker door panel (in frame) | 1/4–1/2 | Panel floats in grooves; thickness depends on groove depth and look |

What thickness plywood should you use for cabinet boxes?

Most frameless (European-style) cabinet boxes use 3/4-inch-class material because it holds screws and hardware well and keeps the case rigid. Builders discussing cabinet cases often favor 3/4 for sides with 1/4 backs, especially for ease of fastening and overall stiffness.

When does 1/2-inch plywood work for cabinet boxes?

1/2-inch plywood works best in face-frame cabinets where the face frame adds stiffness and helps keep the box square. eHow specifically notes that 1/2 can be used for cabinet sides (especially with face frames) to save weight and cost, while thicker material supports certain hinge styles.

Use 1/2 for boxes when:

- The cabinet is face-frame and the frame is well-joined.

- Boxes are narrow (think pull-outs, small uppers).

- You add solid hanging rails/stretchers and don’t rely on a flimsy back.

What thickness plywood should you use for cabinet shelves so they don’t sag?

Start with 3/4-inch-class plywood for shelves, then control sag with span length and reinforcement. The Sagulator exists for a reason: sag depends on material, load, and span, and edging strips can improve stiffness.

Cabinetmakers commonly treat ~32 inches as an upper limit for 3/4 plywood shelves depending on load, and they add dividers or supports for longer runs.

Better Homes & Gardens also recommends stiffening shelves with a front cleat/molding or additional support when spans get longer and loads get heavier.

Practical shelf rule: If the shelf is long, add a front stiffener (solid strip) or add a vertical divider to cut the span.

Also know: What Type of Plywood for Cabinets: 8 Essential Buying Checks

What thickness plywood should you use for cabinet backs?

1/4-inch plywood is the common choice for cabinet backs when the back is captured in a dado/rabbet and you’re using the box and face/frame structure to handle loads. A cabinet-industry discussion specifically centers on 1/4 vs 1/2 vs 3/4 backs and how builders choose based on strength and installation needs.

Some suppliers also recommend 1/4 for backs and 1/2 when you need more strength or fastening area.

Use 1/2 backs when:

- You want a stiffer cabinet (tall pantry, utility cabinet).

- You’re hanging heavy loads and want more screw bite into the back.

- You’re building a cabinet that needs to handle rougher handling (garage/shop).

What sheet size plywood should you buy for cabinets?

Most cabinet layouts assume 4×8 sheets, because that’s the common standard size for plywood.

For drawer boxes and smaller parts, some builders prefer 5×5 Baltic birch because it’s easier to handle and commonly sold in that format by plywood suppliers.

Quick picking guide

- 4×8: Best when you’re building a full kitchen run and want long rips for sides and stretchers.

- 5×5: Handy for drawers, small cabinets, and shops without a panel saw; often used for Baltic birch.

Safety note: Breaking down full sheets is where kickback and awkward handling happen. Use support, keep the offcut from pinching the blade, and don’t “catch” a falling sheet with your hands near the cut line.

What type and grade of plywood belongs in cabinets?

Cabinets build easier and finish cleaner with cabinet-grade hardwood plywood, not construction sheathing. APA specifically warns that “Exposure 1” sheathing is often mistaken for “Exterior” and gets used where it doesn’t belong.

For cabinets, you typically want:

- Flat panels (less warp)

- Better faces (for paint or clear finish)

- More consistent cores (fewer void surprises at dadoes and edges)

Baltic birch gets used a lot for drawers and modern exposed edges; suppliers commonly sell it in multiple thicknesses and 5×5 sheets.

When you’re bonding plywood parts, match the glue to the job—this guide on choosing wood glue that works well on plywood layers can help: wood glue selection for plywood laminations.

How do you match joinery and hardware to plywood thickness?

You match joinery to thickness by cutting to the real panel and choosing fasteners that don’t blow out the veneer.

- Dados/rabbets: Cut dado width from a test piece of your plywood so parts slide in without slop (labels vary).

- Shelf pins: Thicker sides give you more margin for error and better holding power.

- Screws: Pre-drill near edges; plywood veneers split when you force fasteners.

How do you prevent racking and wobble in plywood cabinets?

You prevent racking by making the cabinet behave like a box beam: square it, lock it, and tie the corners together.

- A captured back (in a dado/rabbet) helps hold the cabinet square during install.

- Wider cabinets stay straighter with stretchers/hanging rails and a back that fits tight.

- Shelves sag less when you add a front stiffener or center divider.

Common mistakes when choosing plywood for cabinets

- Buying by the label, not the caliper. “3/4” can vary, so measure before you cut joinery.

- Using sheathing-grade panels for finished cabinetry. They’re built for structure, not clean faces and stable cabinet parts.

- Over-spanning shelves. Long spans sag unless you reinforce or support.

- Skipping a real back. Thin, stapled-on backs without capture don’t resist racking the same way.

FAQs about what size plywood for cabinets

Can I build kitchen cabinets out of 1/2-inch plywood?

Yes—1/2-inch plywood works best for face-frame cabinets where the frame adds stiffness and you design your joinery and hanging rails accordingly. eHow notes 1/2-inch sides can save weight and cost in face-frame builds.

Is 23/32 the same as 3/4 for cabinet work?

For most cabinet work, 23/32 is the common “3/4 class” thickness you’ll see in panel performance categories, and builders design around it. APA lists 23/32 as a standard performance category. Still, measure your sheet before cutting dados because retail panels can vary.

What thickness plywood should I use for drawer boxes?

1/2-inch-class plywood (often 15/32 actual) is a common drawer-box choice because it balances strength and weight. APA lists 15/32 as a standard performance category, and many cabinet guides recommend 1/2 for drawer sides/backs.

What thickness plywood should I use for cabinet doors?

Slab doors commonly use 3/4-inch-class material, while framed doors (like shaker) can use thinner panels because the frame carries stiffness. The right pick depends on door size, hinge type, and whether you’re painting or finishing clear.

hould I buy 4×8 or 5×5 sheets for cabinets?

Buy 4×8 for full cabinet runs and long cabinet sides, and consider 5×5 for Baltic birch drawers and smaller parts because it’s easier to handle and commonly sold in that size.

Final thoughts

What size plywood for cabinets gets simple when you assign thickness by function: 3/4-class for boxes and shelves, 1/2-class for drawers, 1/4 for backs and bottoms, then reinforce anything that spans wide. Measure the real panel before you cut joinery, and let the cabinet’s design—not just the material—carry the load. Good luck.