What Size Is a #8 Screw: Exact Size Guide (Diameter, Pitch, Bits)

A standard #8 screw is about 0.164 in (≈4.166 mm) in outside thread diameter, with the length listed separately (for example, #8 × 1-1/4 in).

Quick #8 screw reference (shop-friendly):

| Spec you’re looking for | Typical #8 value |

|---|---|

| Major (outside) diameter | 0.164 in (≈ 4.17 mm) |

| Common machine-screw threads | #8-32 (coarse), #8-36 (fine) |

| Tap drill for #8-32 (cut tap) | #29 drill (0.1360 in) |

| Wood-screw pilot (typical starting points) | Softwood: 3/32 in • Hardwood: 7/64 in |

Contents Here

- 1 What diameter is a #8 screw?

- 2 What does “#8” mean on a screw?

- 3 What is a #8 screw in metric?

- 4 What thread pitches come on #8 machine screws?

- 5 What drill bit do you use to tap #8 threads?

- 6 What pilot hole size works for a #8 wood screw?

- 7 How long is a #8 screw supposed to be?

- 8 How do you measure a #8 screw at the bench?

- 9 Which #8 screw should you choose for woodworking?

- 10 What mistakes cause the most confusion with #8 screws?

- 11 FAQs about #8 Screw Size

- 12 Final thoughts

What diameter is a #8 screw?

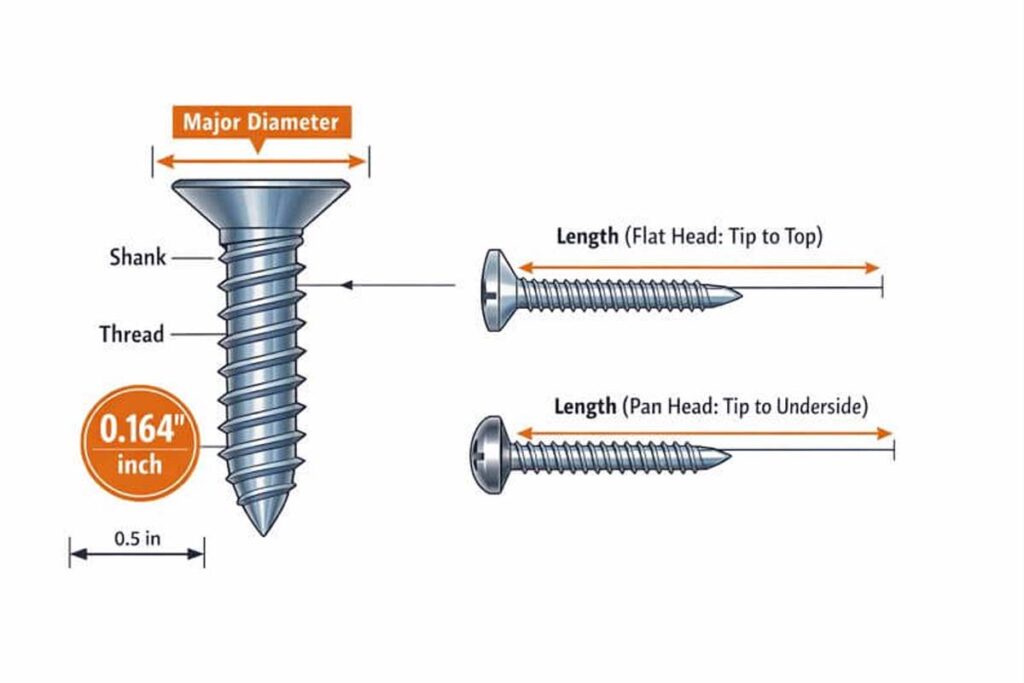

A #8 screw has a nominal major diameter of 0.164 inches, measured across the outside of the threads.

That number matters because it tells you whether the screw will fit a clearance hole, hardware slot, or a pre-drilled pilot without splitting the wood.

What does “#8” mean on a screw?

“#8” is a screw gauge number that specifies the screw’s nominal outside thread diameter (about 0.164 in / 4.17 mm), not its length.

One common way it’s expressed is the numbered-screw formula for major diameter: (screw # × 0.013) + 0.060 inches, which lands #8 right at about 0.164 in.

If you want the bigger picture, my guide on how the U.S. screw sizing system works from gauge to length is here: how screw sizing actually works in the U.S. system.

What is a #8 screw in metric?

A #8 screw is about 4.17 mm in outside thread diameter (since #8 is roughly 0.164 in). And there isn’t a perfect metric twin because the systems aren’t matched one-to-one.

In the aisle, you’ll often see 4.2 mm wood/sheet-metal screws sold for similar jobs, and M4 machine screws are close-but-smaller—so don’t assume interchangeability when holes are tight.

What thread pitches come on #8 machine screws?

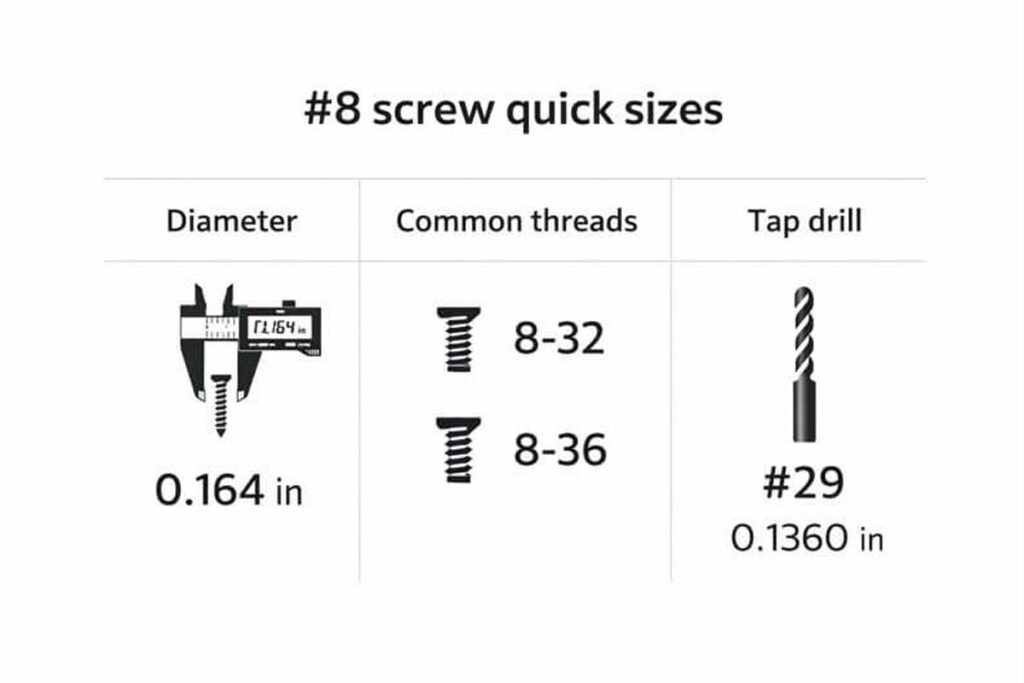

Most #8 machine screws show up as #8-32 (UNC) or #8-36 (UNF).

- #8-32 uses fewer threads per inch (coarser), which tolerates rougher holes and softer materials a bit better.

- #8-36 uses more threads per inch (finer), which fits better in thin nuts and tapped metal when everything is aligned.

What drill bit do you use to tap #8 threads?

For common shop tapping, a #29 drill bit (0.1360 in) is the standard tap drill for #8-32, and many charts also pair #29 with #8-36 for cutting taps.

Two practical notes before you cut threads:

- A tap drill chart assumes a target thread percentage, and real holes can drill slightly oversize depending on bit and material.

- Use cutting fluid on steel, keep the drill square, and back the tap out to break chips. Your threads come out cleaner and the tap lasts longer.

What pilot hole size works for a #8 wood screw?

A good starting pilot hole for a #8 wood screw is 3/32 in for softwood and 7/64 in for hardwood.

Those sizes work because the pilot gives the screw’s core room while leaving enough wood for the threads to bite. If you’re working near an edge, a pilot hole stops a lot of heartbreak—if you want a deeper walkthrough, I’d link my shop routine for preventing splits while driving screws here: how to stop wood splitting when screwing.

Safety note: clamp the workpiece and wear eye protection—small bits snap fast when they catch.

How long is a #8 screw supposed to be?

A #8 screw has no “standard length” because #8 only describes diameter, and length is listed separately (like #8 × 1-1/4 in).

Manufacturers measure length by head style:

- Flat/countersunk heads measure tip to top of head.

- Pan/round/truss heads measure tip to underside of head.

For tray builds and small shop projects, I usually pick length so the screw sinks deep into the second piece without poking through—this guide explains the depth rule clearly: how far the screw should bite into the second board.

How do you measure a #8 screw at the bench?

You can confirm a #8 screw by measuring major diameter with calipers across the outside of the threads and looking for ~0.164 in.

Then read the label:

- Wood/sheet-metal screws often show #8 × length (thread pitch varies by design).

- Machine screws show #8-32 × length or #8-36 × length.

Which #8 screw should you choose for woodworking?

A #8 screw for woodworking works best when you match thread type, head style, and material to the job.

- Cabinet hinges / hardware: #8 screws are common, but pre-drill clean pilots to avoid lifting the hinge leaf.

- Softwood trays and stands: coarse threads bite well; wax on the threads reduces torque and snapping.

- Outdoor or damp use: choose corrosion resistance (stainless or coated) so the joint doesn’t stain the wood.

If you ever overdrive and strip the hole, this repair is quick and strong: fixing a stripped screw hole in wood.

What mistakes cause the most confusion with #8 screws?

Mix-ups happen for the same three reasons in most shops:

- Reading “#8” as a metric diameter. #8 is a gauge designation, not 8 mm.

- Skipping the pilot in hardwood. Hardwood pushes back and splits faster; pilot first.

- Using the wrong driver bit. A driver that cams out chews the head, then you’re hunting for extraction tricks—if that happens, here’s the fix: remove a stripped screw from wood.

If you’re deciding length for strength, this helps: how deep a screw needs to bite into wood to hold well.

FAQs about #8 Screw Size

What’s the difference between #8-32 and #8-36?

Both have the same major diameter, but #8-32 has 32 threads per inch and #8-36 has 36 threads per inch, which changes how they fit nuts and tapped holes.

Is a #8 screw the same as an M4?

No—#8 is larger than M4. A #8 major diameter is 4.166 mm, while M4 is 4.0 mm, so threads and hole sizing don’t match cleanly.

Is #8 the same as 8-32?

Not always. “#8” tells you diameter; “8-32” tells you diameter plus thread pitch (32 TPI), which matters for nuts and tapped holes.

What’s the strongest #8: 8-32 or 8-36?

8-36 packs more threads per inch, while 8-32 has deeper, coarser threads. In practice, 8-32 tolerates dirt and minor damage better; 8-36 can hold well in harder materials when everything is aligned and clean.

What pilot hole keeps #8 screws from snapping in hardwood?

A pilot that matches your hardwood and the screw shank prevents most snap-offs. Start with the hardwood pilot sizes in the chart (straight 1/8″ or tapered 11/64″), lubricate the screw, and drive with steady pressure.

How do I fix it if I strip out a #8 screw hole?

A glued-in wood plug or a dowel repair restores holding power better than jamming in toothpicks. This walkthrough shows the steps: repair a stripped screw hole in wood.

Final thoughts

What size is a #8 screw comes down to one solid number you can trust in the shop: 0.164″ (4.166 mm) major diameter, with common machine-screw threads of 8-32 and 8-36 depending on the job.

If you tell me whether you mean wood screw, sheet-metal screw, or machine screw, and what material you’re fastening into, I can point you to a pilot/tap setup that drives clean without splitting. Good luck.