What Is the Thickest Plywood You Can Buy? 7 Powerful Facts

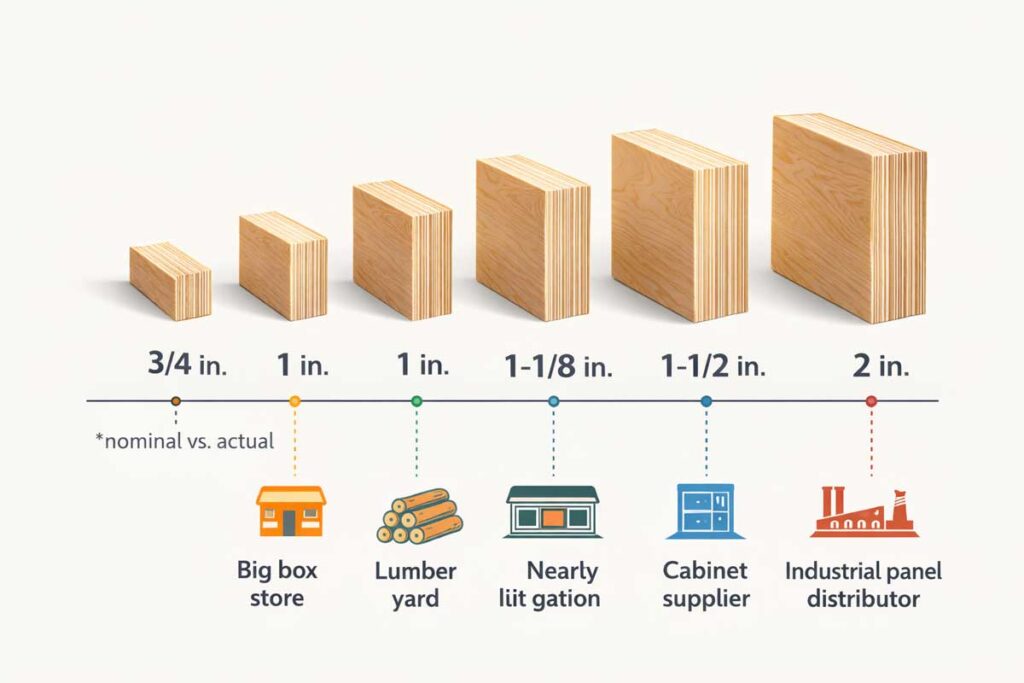

What is the thickest plywood you can buy? In most lumberyards and big-box stores, the thick end of the rack tops out at 1-1/8 in. structural panels. Specialty panel suppliers go thicker: some manufacturers list 1-1/2 in. (18-ply) and even 2 in. (22-ply) plywood for industrial and custom work.

In this guide, I’ll break down what “thickest” means in real-world buying, where the thickness limits come from, what you’ll actually find locally, and how to order the thick panels without getting burned by nominal sizing.

In a short answer, the thickest commonly standardized plywood panel thickness is 1-1/8 in., and the thickest specialty plywood panels sold by industrial suppliers reach 2 in.

Also know: Is Birch Plywood Good for Cabinets? 7 Fast Ways to Avoid Voids

Contents Here

- 1 Why most “regular” plywood stops at 1-1/8 in.

- 2 The “thickest plywood” you’ll actually see in stores

- 3 The true maximum: 1-1/2 in. and 2 in. plywood exists, but it’s specialty stock

- 4 “Plywood” vs. “panel”: don’t accidentally buy the wrong product

- 5 Nominal vs. actual thickness: how to avoid a bad fit

- 6 Where to buy the thickest plywood

- 7 What to ask for when ordering 1-1/2 in. or 2 in. plywood

- 8 Practical shop reality: thick plywood gets heavy fast

- 9 When thick plywood is the right move—and when it isn’t

- 10 FAQs on What Is the Thickest Plywood You Can Buy

Why most “regular” plywood stops at 1-1/8 in.

Panel standards and building-code categories shape what stores stock. APA’s plywood page lists panel performance categories topping out at 1-1/8. That thickness covers the heavy structural use cases where plywood earns its keep—subfloors and certain roof/deck situations—without getting so heavy and expensive that it becomes a special-order item.

There’s also the manufacturing reality: thicker panels need more veneer plies, more adhesive, and longer press time. Mills and distributors focus on the sizes that move fastest.

The “thickest plywood” you’ll actually see in stores

If you walk into a typical Home Depot/Lowe’s-style aisle, the “thick” end usually looks like this:

- 3/4 in. (23/32 category): the everyday workhorse for cabinets, shop fixtures, jigs, and general carpentry.

- 1 in.: less common in big-box stores, more common at hardwood and cabinet suppliers.

- 1-1/8 in. (often sold as a subfloor panel): stocked in fewer SKUs, often tongue-and-groove, aimed at flooring systems. APA lists 1-1/8 as a performance category.

One detail that trips people: the label might say 1-1/8 CAT and the caliper reads slightly under. For example, Georgia-Pacific lists 1-1/8 CAT = 1.091 in. (27.71 mm) on a Sturd-I-Floor spec sheet.

Read more: Is 1/2 Plywood Good for Cabinets? 7 Tough Truths & Fixes

The true maximum: 1-1/2 in. and 2 in. plywood exists, but it’s specialty stock

When you step outside the retail channel and into industrial panel suppliers, thicker plywood shows up as a catalog option. North American Plywood Corporation lists thicknesses including 1-1/2 in. (18-ply) and 2 in. (22-ply).

That’s the practical answer to the original question: 2-inch plywood is available, but you’re buying it through specialty distribution, not grabbing it off the shelf next to 1/2-inch sheathing.

What thick specialty panels get used for

Thick plywood gets ordered for jobs where stiffness, fastener bite, and machining depth matter:

- Industrial jigs and machine bases

- Heavy work surfaces and thick fixtures

- Architectural panels and specialty fabrication

- Some transport, staging, and commercial build-outs (application drives the spec)

“Plywood” vs. “panel”: don’t accidentally buy the wrong product

People ask for “the thickest plywood” when they really need “the stiffest sheet good” or “the thickest flat panel.”

Here’s how I separate them at the counter:

- Structural plywood (APA/PS-rated): thicknesses commonly run up to 1-1/8 in standard performance categories.

- Industrial/hardwood plywood: often available in 1 in., and sometimes 1-1/2 in. or 2 in. through specialty suppliers.

- MDF/particleboard: also comes thick (MDF is commonly sold in 1-1/2 in. sheets), but it’s not plywood and it behaves differently with screws and moisture.

If your project lives in a damp space, thick MDF solves the “flat and thick” problem and creates a new moisture problem. Plywood holds up better when humidity swings, especially when the faces and edges are sealed.

Nominal vs. actual thickness: how to avoid a bad fit

Plywood rarely measures exactly what the name suggests, especially in structural categories. The Georgia-Pacific example is a good illustration: 1-1/8 CAT panels list an actual thickness of 1.091 in.

In the shop, that gap matters when you’re cutting joinery, setting router bit height, or building a dado that needs a dead-tight fit.

Buying tip: bring calipers or a decent tape and measure the stack. If your design needs a true 1.125 in. panel, plan on either:

- adjusting the joinery to the panel you can actually buy, or

- ordering a calibrated/sanded panel line that lists a net thickness.

Where to buy the thickest plywood

Big-box stores cover common construction categories. The thick specialty panels usually come from:

- Industrial plywood and panel suppliers (the folks who sell odd sizes, overlays, specialty cores, and custom layups)

- Hardwood lumber dealers/cabinet supply houses (more likely to stock 1 in. hardwood plywood)

- Commercial formwork suppliers for thick, abuse-resistant panels in the 1-1/8 in. range (often overlaid products aimed at concrete work)

If you call around, use the language that gets you a clean answer:

- “Do you stock plywood thicker than 1-1/8? I’m looking for 1-1/2 or 2 inch.”

- “What core and ply count is it?”

- “What are the actual thickness and tolerances?”

- “How much does a 4×8 sheet weigh in that thickness?”

What to ask for when ordering 1-1/2 in. or 2 in. plywood

Thick panels vary a lot by build. Two 2-inch sheets can behave differently if one uses a softwood core and the other uses a dense hardwood layup.

A quick ordering checklist that keeps you out of trouble:

- Core type: veneer core, composite core, lumber core (fastener holding and flatness change with the core).

- Ply count: thicker, higher ply counts often machine cleaner and stay flatter. One supplier lists 2 in. as 22-ply.

- Adhesive/exposure rating: match it to the environment (interior, Exposure 1, exterior).

- Face grade: pick a paint-grade face if you plan to cover it, and a higher face grade if the surface stays visible.

- Actual thickness: confirm the number in writing, especially if joinery depends on it.

Practical shop reality: thick plywood gets heavy fast

A 2-inch plywood sheet turns into a handling job. Plan your cuts so you don’t fight the material:

- Break down full sheets with a track saw or panel saw support.

- Use sawhorses and a sacrificial foam sheet to keep the panel stable.

- Keep fingers out of pinch points—thick panels fall harder and trap hands faster than 1/2-inch stock.

If you work solo, ask the supplier to rough-cut it to manageable sizes before pickup.

When thick plywood is the right move—and when it isn’t

Thick plywood shines when you need mass + stiffness + screw bite in one slab: workbench tops, heavy jigs, thick router table surfaces, fixture plates.

If you only need thickness for a look (like a chunky tabletop edge), laminating two thinner sheets often costs less and is easier to source. A pair of flat 3/4-inch sheets glued properly often produces a dead-stable 1-1/2-inch slab, and you can stagger seams and control grain direction for stability.

FAQs on What Is the Thickest Plywood You Can Buy

Is 1-1/8 inch the thickest plywood at Home Depot or Lowe’s?

Most big-box stores treat 1-1/8 in. as the top-end plywood thickness, often sold as a subfloor panel with a performance category like 1-1/8 CAT (and an actual thickness listed around 1.091 in. on some products).

Can you buy 2-inch plywood?

Yes. Some industrial panel suppliers list plywood up to 2 in. (22-ply) as a standard thickness option, but it typically sells through specialty distribution rather than retail aisles.

What’s thicker than plywood if I need a flat 1-1/2 inch panel?

MDF is commonly sold in 1-1/2 in. thickness, and it stays flat and machines clean, but it handles moisture and edge-screw holding differently than plywood. If your panel sees humidity swings or needs strong edge fasteners, plywood (or a plywood laminate build-up) usually fits better.

If you tell me what you’re building (bench top, stair tread, machine base, countertop core, trailer deck), I’ll point you toward the thickness and panel type that hits strength, weight, and budget without creating new problems.