What Is Shop Grade Plywood? 9 Smart Uses for Cheap Sheets

Shop grade plywood is a discounted “seconds” plywood label for sheets sold with cosmetic defects or minor damage, making it fine for utility work but not guaranteed for appearance. The key detail is that “shop grade” is a sales label, not a universal grading standard. In this guide, I’ll explain what that label usually means, how it differs from stamped plywood grades, what defects to expect, and how to sort the good sheets from the headaches before you load up your cart.

Contents Here

- 1 Shop grade plywood is a label, not a standardized grade

- 2 Why plywood ends up in the shop-grade pile

- 3 What “shop grade” usually means for performance

- 4 Where shop grade plywood shines in a woodshop

- 5 When shop grade plywood is the wrong pick

- 6 How to choose shop grade plywood without getting burned

- 7 Tips for building clean work with shop grade plywood

- 8 Shop grade vs cabinet grade vs construction sheathing

- 9 Indoor air and adhesives: what to look for on interior projects

- 10 FAQs about Shop Grade Plywood

- 11 The bottom line

Shop grade plywood is a label, not a standardized grade

Plywood has real standards and real stamps—but “shop grade” usually isn’t one of them.

Structural plywood in the U.S. commonly references U.S. Department of Commerce/NIST voluntary product standards such as PS 1 (Structural Plywood), and many panels carry grade stamps tied to those systems. Hardwood and decorative plywood commonly references ANSI/HPVA HP-1, which lays out recognized classifications and quality criteria for appearance and performance.

By contrast, shop grade plywood is typically a retailer or supplier category used to move panels that don’t fit their normal “first-quality” bins—often for appearance reasons, sometimes for damage. That’s why two yards can sell “shop grade” that looks and behaves totally different, even at the same thickness.

Older consumer-facing explanations also describe shop grade as plywood downgraded because of defects or damage, and that it can originate from many original grades.

Why plywood ends up in the shop-grade pile

In practice, shop-grade sheets usually land there for one (or more) of these reasons:

- Cosmetic face defects: knots, mineral streaking, color variation, sanding swirls, veneer overlaps, patches, or open defects on one face.

- Handling damage: crushed corners, chipped edges, forklift scars, strap marks, dents, or water staining from storage.

- Manufacturing “seconds”: mis-press marks, telegraphing from core to face, glue bleed-through, or veneer splits.

- Inconsistent matching: sheets that don’t match color/figure within a lift (a bigger deal for cabinet shops buying matched sets).

- Overstock or mixed lots: sometimes the panel is fine; it’s the inventory that’s odd.

Some sellers also use “shop” or “commercial” grade wording to describe an economical, general-purpose panel that meets basic performance needs but doesn’t target premium appearance.

What “shop grade” usually means for performance

Here’s the honest rule: shop grade tells you more about the seller’s tolerance for looks than it tells you about engineering.

That said, shop-grade sheets often come with a higher chance of the problems that woodworkers actually feel in the build:

Face and veneer realities

A shop-grade face veneer can be thin, patched, or inconsistent. Thin veneers limit sanding and make it easier to sand through at edges or over high spots.

Core realities

Some shop-grade panels have more core voids or overlaps. Voids matter when you’re driving screws near an edge, routing joinery, or depending on a crisp edge profile.

Flatness realities

Handling damage and storage conditions can leave a sheet twisted or bowed. A bowed panel can fight your assembly and leave doors and drawers out of square.

Glue-bond and delamination risk

If the panel is shop grade due to appearance only, glue bond can still be solid. If it’s shop grade due to manufacturing defects or moisture abuse, delamination risk rises—so you inspect before you buy.

Where shop grade plywood shines in a woodshop

Shop grade earns its keep when you control the design around its flaws.

I reach for it when the work is utility-first:

- Jigs, templates, and router fixtures

- Shelving, shop cabinets, and tool stands

- Cabinet carcasses where the faces get covered (paint, laminate, edge banding, or a face frame)

- Drawer boxes (especially if you’re painting)

- Back panels and dust panels

- Mock-ups and test cuts when dial-in matters more than pretty

If you need a clean show surface—tabletops, exposed end panels, modern slab doors—shop grade turns into extra labor fast.

When shop grade plywood is the wrong pick

Skip shop grade (or at least inspect ruthlessly) when any of these are true:

- The face stays visible with a clear finish.

- Tight joinery depends on clean core edges (dados, rabbets, box joints, CNC pockets).

- Moisture exposure is likely (utility sinks, unconditioned spaces, damp basements).

- Flatness drives the outcome (cabinet doors, wide drawer fronts, long spans).

Moisture rating and adhesive bond classification matter more than the “shop grade” label. Structural standards classify plywood by items like bond classification, and the stamp tells you what the panel is built to handle.

How to choose shop grade plywood without getting burned

This is where you save money and avoid building problems. Use a quick process at the stack.

- Sight the sheet for flatness. Stand it on edge and look for bow, cup, and twist. Check both directions.

- Check the edges for voids and gaps. Look along the edge plies. Big voids near edges can weaken screw holding.

- Inspect corners and edges for crush damage. Corner blowout can telegraph into your final dimensions.

- Look for delamination clues. Bubbles, ripples, or separated plies near edges are a no-go.

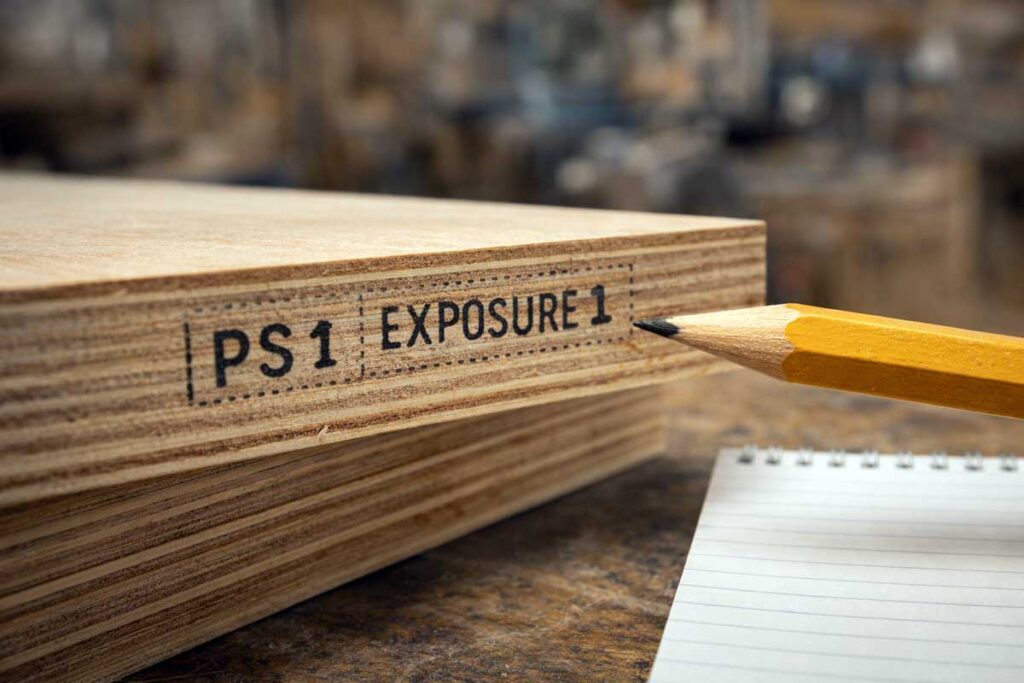

- Find the stamp or label (when present). Structural panels often carry a grade stamp with standard references (PS 1 / PS 2, span ratings, exposure ratings).

- Confirm the exposure rating matches the job. “Exposure 1” panels handle temporary construction moisture; “Exterior” bond is built for longer-term weather exposure, depending on the product.

- Match sheet quality to where it lands in the build. Put the worst faces inside, down, or hidden.

- Buy one extra sheet if the project is large. Shop-grade batches vary, and an extra sheet gives you freedom to cut around defects.

Tips for building clean work with shop grade plywood

You can make shop grade behave like a better sheet if you plan your cuts and treat the edges right.

Cut planning

Lay out parts so defects land in hidden zones: behind face frames, under stretchers, or inside toe-kicks. If the panel has one good face, treat it like a “one-side” sheet and design around it.

Edge strategy

Exposed plywood edges advertise core quality. If the core has voids or overlaps, an edge band or lipping strip cleans it up.

Filling and surfacing

For paint-grade, you can fill patches, dents, and grain defects, then prime and sand for a uniform surface. For clear finish, shop grade often stays a compromise because veneer thickness and color variation still read through.

Fasteners and joinery

If the core looks voidy, avoid relying on edge screws. Shift to dados, rabbets, confirmat-style screws (where appropriate), or glue blocks—depending on the build and loads.

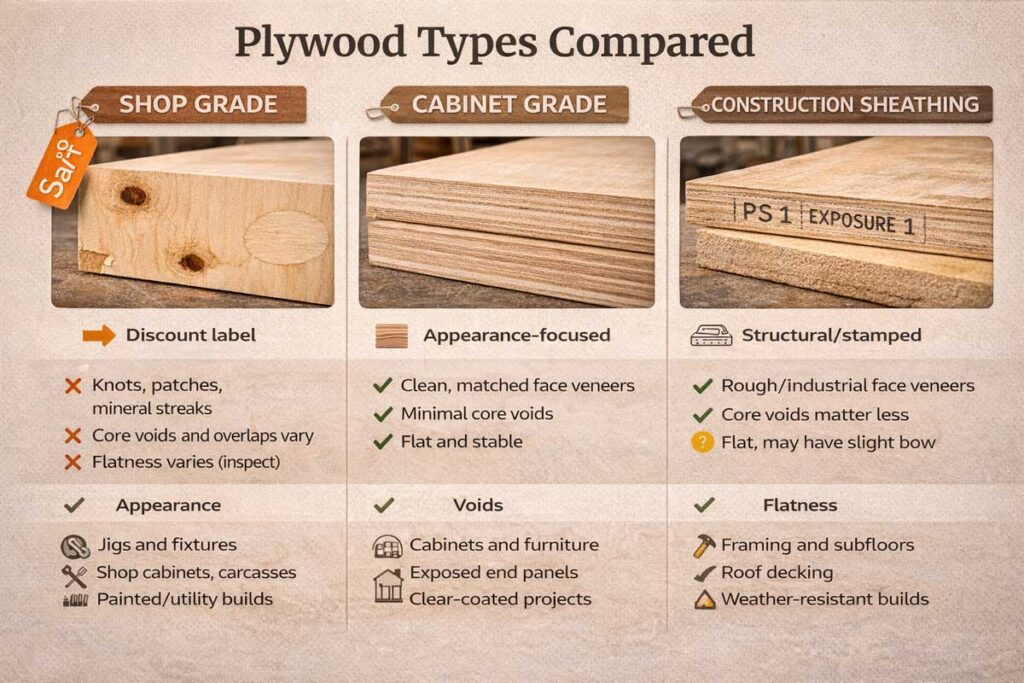

Shop grade vs cabinet grade vs construction sheathing

People mix these up because yards use casual language. Here’s a practical way to separate them:

Cabinet/appearance-grade plywood

This category focuses on clean faces, predictable veneer thickness, and consistent looks, often aligned with recognized hardwood/ декоратив plywood grading systems (ANSI/HPVA HP-1 is the backbone standard).

Construction-rated sheathing

This category focuses on structural performance and code-recognized stamps (PS 1 / PS 2 systems, span ratings, exposure ratings).

Shop grade plywood

This category is usually a price-and-defects bucket that can include panels from either world. That’s why you inspect the sheet and read the stamp rather than trusting the bin tag.

Indoor air and adhesives: what to look for on interior projects

If the plywood goes into a bedroom, nursery, or any tight indoor space, pay attention to formaldehyde emissions and labeling.

In the U.S., EPA rules set formaldehyde emission standards for composite wood products. For hardwood plywood (veneer core or composite core), the limit is 0.05 ppm under 40 CFR § 770.10. The EPA also explains that formaldehyde is used in resins (glues) common in composite wood products and that exposure can affect health.

Practical shop advice: if the sheet has no labeling, no paperwork, and it’s headed indoors, treat that as a reason to ask questions or choose a clearly labeled alternative.

FAQs about Shop Grade Plywood

Is shop grade plywood the same as cabinet grade?

No—shop grade plywood is usually a discount label for sheets with cosmetic defects or damage, while cabinet grade targets consistent appearance and predictable veneer quality. Cabinet-grade products often align with recognized hardwood/decorative plywood grading systems, such as ANSI/HPVA HP-1, which defines classifications and quality criteria used in the trade.

Is shop grade plywood still strong?

Sometimes. Strength depends on the panel’s construction, glue bond, core quality, and whether it carries a structural stamp tied to standards such as PS 1. Shop grade may be downgraded for looks only, but it can also be downgraded for damage or defects that reduce performance. Read the stamp when present, then inspect for voids, delamination, and warp.

Can I use shop grade plywood for cabinets?

Yes—for many shop cabinets and a lot of home cabinet carcasses—if you place defects where they stay hidden and the sheets are flat. Use better material for doors, exposed end panels, and any clear-finished surfaces. If the core looks voidy, avoid edge-screw designs and lean on joinery that spreads load.

What should I avoid when buying shop grade plywood?

Avoid sheets with twist, delamination, water-soaked edges, or deep core voids where fasteners or joinery will land. Also avoid unknown panels for indoor use if you need verified emissions compliance; EPA rules define formaldehyde limits for hardwood plywood at 0.05 ppm under 40 CFR § 770.10.

The bottom line

Shop grade plywood is a money-saver when you treat it like a “sort-and-select” material, not a guaranteed grade. Pick flat sheets, reject delamination, plan cuts around defects, and protect exposed edges. When the surface stays visible or the room is sensitive, buy plywood with the face quality and labeling that matches the job.