What Is PVA Wood Glue Used For: 9 Strong Uses + Pro Tips

PVA wood glue used for bonding tight-fitting wood joints, repairs, and laminations on porous materials, creating strong, durable holds once clamped and fully cured. It’s the everyday adhesive behind panel glue-ups, furniture repairs, trim work, and clean laminations. Once you know where it shines—and where it doesn’t—you’ll get stronger joints with fewer surprises.

Contents Here

What is PVA wood glue?

PVA stands for polyvinyl acetate (often written as PVAc). It’s a water-based adhesive that soaks slightly into wood fibers, then dries into a tough plastic-like film. Because wood is porous, PVA bonds extremely well when two pieces fit tightly and make full contact.

Most “wood glue” sold for indoor projects is a PVA-style glue. Some versions dry clear, while many woodworking versions dry a light yellow. Either way, the goal is the same: strong fiber-to-fiber bonding without messy fumes or complicated mixing.

Is PVA the same as white glue or “carpenter’s glue”?

They’re related, but they aren’t always the same product.

- White school glue is usually a PVA designed for paper and light crafts. It can work on wood for low-stress projects, but it’s not always as strong or as tacky for joinery.

- Carpenter’s glue / yellow wood glue is usually a woodworking-focused PVA (often called “aliphatic resin” in marketing). It grabs faster, handles clamp pressure well, and is made for wood joints.

If you want dependable results on furniture or shop projects, choose a PVA labeled for woodworking rather than general craft glue.

What PVA wood glue is used for

PVA earns its reputation because it’s simple, strong, and forgiving—when you use it in the right places. Here are the most common jobs it handles well.

Joining wood-to-wood joints for furniture and shop projects

This is PVA’s home turf: edge-gluing boards, building panels, attaching face frames, assembling boxes, and bonding clean joinery like dados and rabbets. The key is joint fit. PVA isn’t a gap filler, so you’ll get the best strength when parts meet cleanly with even pressure.

If you’re curious about what “strong” really means in practical terms, it helps to understand how glue strength compares to wood fiber strength in a tight joint—this breakdown on how strong a typical glued joint can be is a solid reference: how strong a typical glued joint can be.

Repairs and reinforcement on cracked or loose parts

PVA is excellent for re-gluing chair rungs, loose trim, small splits, and broken edges—especially when the break fits back together neatly. Work the glue into both surfaces, press the parts together, clamp, and clean squeeze-out before it skins over.

For repairs, patience matters. A joint can feel firm early, but it’s still building strength. If you want a clear timeline, use this reference on the full cure timeline for glued joints: full cure timeline for glued joints.

Veneer work, laminations, and flat bonding

PVA can bond veneer and laminated layers when you can apply even pressure across the whole surface. It’s especially useful for laminating thin stock, building curved forms with layers, and bonding sheet goods in low-moisture environments.

The success factor here is coverage. Dry spots and puddles are both problems, so aim for a thin, consistent layer.

Bonding other porous materials in a pinch

PVA bonds more than wood. It also works on porous materials like paper, cardboard, and some fabrics. That said, if your main goal is a structural wood joint, treat these as side uses—not the reason to choose a wood glue.

Types of PVA glue and which one to use

“PVA” is a family. Picking the right version is mostly about moisture and expectations.

Regular PVA vs woodworking PVA

- Craft PVA (white glue): fine for light-duty wood crafts, kids’ projects, and non-structural bonds.

- Woodworking PVA (often yellow): better initial grab, stronger bonds for joinery, and better handling under clamp pressure.

If the label says “wood glue” and it’s meant for furniture or carpentry, it’s usually the right starting point.

Water-resistant PVA for kitchens, bathrooms, and humidity

Some PVAs are formulated to resist moisture better than standard indoor glue. These are useful for projects that live near sinks, steamy rooms, or damp garages. “Water-resistant” still doesn’t mean “okay underwater,” though. If a project will face standing water or constant weather exposure, you’ll want a different adhesive.

PVA as a sealer or primer

You’ll sometimes see “PVA” used as a primer/sealer for porous surfaces, especially drywall. That product is not the same as woodworking glue, even if they share the same base chemistry. For woodworking, a thinned PVA glue wash can stiffen fibers on some porous materials, but it’s not a universal best practice and can interfere with some finishes if overdone. When the goal is a strong joint, focus on proper joinery and clean glue-up instead.

How to use PVA wood glue for maximum strength

Good glue-ups are mostly routine: fit, coverage, pressure, time, and cleanup. If one of those gets sloppy, the joint usually tells on you later.

Prep and test-fit first

Dry-fit your parts before opening the bottle. Look for tight contact along the whole joint and fix any rocking, gaps, or twist. PVA performs best when the wood surfaces meet fully. Dust, oily residue, or finish overspray can also weaken a bond, so start clean.

Apply a thin, even coat

For most joints, a small bead spread into a thin film is enough. You want full coverage without puddles. A brush, small roller, or scrap of wood works well as a spreader.

If you tend to over-apply, it helps to follow a simple rule of thumb for coverage—this reference on how much adhesive to apply for clean squeeze-out keeps glue-ups tidy: how much adhesive to apply for clean squeeze-out.

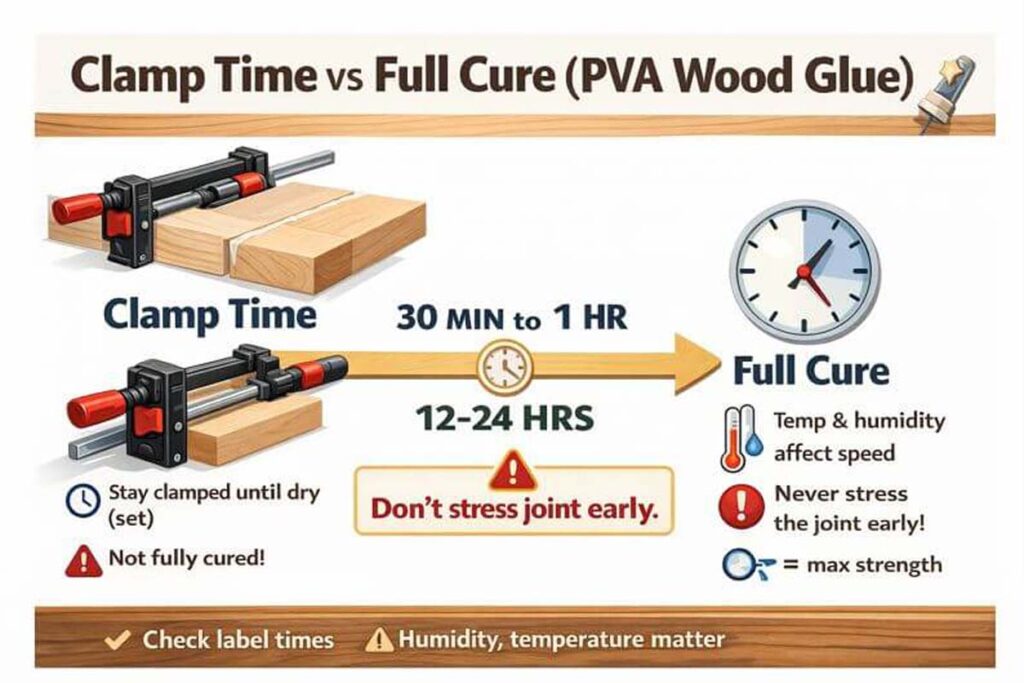

Clamp time is not the same as full cure

Clamps hold parts in position while the glue sets. Full strength comes later. Temperature, humidity, wood species, and joint thickness all influence timing, so rely on the manufacturer’s label and don’t rush the joint into service.

If you want practical clamp timing ranges, keep this on hand for typical clamp times by project type: typical clamp times by project type.

Cleanup matters for finishing

Wipe wet squeeze-out with a damp cloth before it skins over. If you let it dry, scrape it cleanly rather than smearing it into the grain. Glue residue can block stain and leave shiny patches under finish, which is one of the most common “why does my finish look weird?” problems.

Where PVA wood glue is not the best choice

PVA is excellent, but it’s not universal.

- Gaps and sloppy joints: PVA needs contact. If the joint has gaps, fix the fit or choose an adhesive designed to fill.

- Non-porous materials: Glass, metal, many plastics, and glossy finishes aren’t reliable matches.

- Constant water exposure: Water-resistant PVA helps with humidity, not long-term soaking.

- High heat needs: Heat can soften many PVAs over time.

- Outdoor structures: Sun, wet, and seasonal movement push PVA beyond its comfort zone unless the product is rated for that environment.

When you truly need gap filling or high durability in harsh conditions, epoxy is often the better tool. If you’re weighing options, this comparison on when epoxy beats standard wood glue lays out the tradeoffs clearly: when epoxy beats standard wood glue.

Safety, storage, and handling

Most PVA wood glues are low-odor and clean up with water while wet. Still, basic habits help:

- Avoid prolonged skin contact and wash up after glue-ups.

- Keep caps clean so dried chunks don’t fall into your next joint.

- Store at stable temperatures. Freezing can ruin many water-based glues.

- Check date and consistency if a bottle has been sitting for a long time.

If you’re not sure whether an old bottle is still dependable, this quick check on signs your glue has expired can save a project: signs your glue has expired.

FAQs about PVA Wood Glue

Is PVA wood glue waterproof?

Most PVA wood glues aren’t truly waterproof. Standard formulas are for indoor use, while “water-resistant” versions handle humidity and occasional splashes but still aren’t meant for constant soaking or outdoor weather.

How does PVA wood glue work?

PVA glue works by soaking slightly into wood fibers, then drying into a tough film that locks those fibers together. When the joint fits tight and stays clamped, the bond can be extremely strong.

How to use PVA wood glue?

Dry-fit the parts first, then spread a thin, even coat on the joint surfaces. Press together, clamp until set, wipe squeeze-out while wet, and wait for full cure before stressing the joint.

Is PVA wood glue food safe?

Some PVA wood glues can be safe for indirect food contact once fully cured, but it depends on the exact product. Check the manufacturer’s label or datasheet before using it on cutting boards or utensils.

Is PVA wood glue toxic?

PVA wood glue is generally low-odor and considered low-toxicity for normal use, especially once cured. Still, avoid ingesting it, keep it off your eyes, and wash skin after glue-ups.

What is PVA wood glue made of?

PVA wood glue is made from polyvinyl acetate (PVAc) dispersed in water, plus additives that control tack, open time, and strength. Some formulas include modifiers for water resistance or faster setting.

The Verdict

PVA wood glue is mainly used for tight-fitting wood joints, clean repairs, and flat laminations where you can clamp evenly. Choose a woodworking-grade PVA for joinery, step up to water-resistant formulas for humid locations, and avoid using it as a gap filler or for constant wet exposure. Fit and pressure do most of the work—glue just locks it in.