What Is Cabinet Grade Plywood? 5 Powerful Signs It’s Worth It

Cabinet grade plywood is a higher-quality plywood made for visible furniture and cabinet work, with smoother face veneers, fewer defects, and better flatness than construction sheathing. In plain terms, it’s plywood you can confidently put on the outside of a cabinet and finish nicely. In this article I’ll break down what “cabinet grade” actually means in the lumberyard (it’s not always an official grade), what to look for in the face, core, and glue, and how to choose the right sheet for paint, stain, or clear finish.

Contents Here

- 1 What “cabinet grade” really means

- 2 Hardwood plywood face grades (the part you see)

- 3 Core types (the part that makes or breaks your build)

- 4 Glue and exposure rating (don’t skip this)

- 5 Cabinet grade plywood vs. other common plywood types

- 6 How to identify cabinet grade plywood in the store

- 7 Choosing the right cabinet plywood for your project

- 8 Common sizes and what they actually mean

- 9 Typical uses for cabinet grade plywood

- 10 Mistakes I see beginners make

- 11 Quick buying checklist

- 12 FAQs about Cabinet Grade Plywood

- 13 Bottom line

What “cabinet grade” really means

Here’s the honest truth: “cabinet grade” is often a sales term, not a single standardized stamp you’ll find across every mill. Most sellers use it to mean plywood that’s:

- Flat and stable enough for casework and doors

- Nicely faced (smooth veneer, minimal patches)

- Predictable to machine (less voids, fewer surprises at the router table)

- Suitable for finishing (paint or clear coat, depending on the face)

The actual grade is usually described by a face/back veneer rating (common in hardwood plywood) and sometimes by the core type.

Learn more: Know more about shop grade plywood.

Hardwood plywood face grades (the part you see)

For cabinets, the face veneer matters because it determines how the sheet will look under stain, clear coat, or paint.

Many hardwood plywood sheets are sold with a two-part grade like A1, A2, B2, etc. While naming conventions vary by supplier, the idea is consistent:

Face grade (letter): how clean the show face is

- A face: best appearance, minimal defects, consistent grain/color

- B face: very good but may allow small patches or minor color variation

- C/D faces: more defects—fine for interiors or utility work

Back grade (number or letter): how nice the back is

- A “better back” matters for doors, end panels, and open shelving, where both sides might be seen.

If you’re building standard cabinets with a visible exterior and hidden interior faces, you’ll often buy a good face and a serviceable back. For doors and panels, it’s worth paying for better both sides.

Core types (the part that makes or breaks your build)

Two sheets can look identical on the outside and behave totally differently in the shop. Core quality affects strength, screw holding, edge durability, and how cleanly it machines.

Veneer core

Veneer core is built from stacked wood veneers. Good veneer core plywood is light, strong, and generally stable.

What I like about it: it’s strong for its weight and tends to hold screws well.

What to watch for: cheaper veneer core can hide voids that show up when you cut dados or route hinge cups.

MDF core

MDF core is very flat and smooth, which is why it’s common in high-end painted work and some veneered panels.

What I like about it: dead flat, great for veneer stability.

What to watch for: heavier, doesn’t hold screws in edges as well, and edges need careful sealing.

Particleboard core

Particleboard core is common in euro-style cabinets and big-box “cabinet plywood” products because it’s flat and affordable.

What I like about it: flat, consistent, usually void-free.

What to watch for: edge durability and moisture sensitivity; you’ll want proper edge banding and good fasteners/hardware.

Multi-ply / Baltic birch style core

These have many thin plies and are known for strength and clean edges.

What I like about it: great screw holding, strong, edges look nice for modern “ply-edge” designs.

What to watch for: verify it’s truly multi-ply and not a look-alike with fewer, thicker plies.

Glue and exposure rating (don’t skip this)

“Cabinet grade” doesn’t automatically tell you the glue type. Look for an exposure rating, especially for kitchens, baths, and mudrooms.

- Interior: fine for dry spaces, not for sinks or damp areas

- Exterior/Exposure 1: better moisture resistance (not the same as “marine” plywood, but a step up)

If the plywood is going near plumbing, dishwashers, or entryway humidity, I lean toward a better exposure rating and good finishing practices (sealed edges, proper toe-kick protection, etc.).

Cabinet grade plywood vs. other common plywood types

Cabinet grade vs. construction/sheathe plywood

Construction plywood (like CDX) is made for strength and fastening, not looks. It can be warped, patched, and full of voids—totally normal for sheathing, frustrating for cabinets.

Cabinet work needs:

- flatter sheets

- cleaner faces

- more consistent thickness

- fewer voids

Cabinet grade vs. “marine” plywood

Marine plywood is built to stricter void-free standards and uses waterproof glue, intended for boats and extreme moisture. It’s overkill for most cabinetry unless you’re building for high moisture conditions and you know why you need it.

Cabinet grade vs. furniture grade

People use these interchangeably, but “furniture grade” often implies even better veneer appearance and consistency for clear finishing. In practice, a good cabinet-grade hardwood plywood can absolutely be furniture grade—depends on the sheet.

How to identify cabinet grade plywood in the store

You don’t need lab tools—just a good eye and a few habits.

Check the face veneer

Stand the sheet so light rakes across it.

Look for:

- smoothness (no ripples or “telegraphing” from core)

- minimal football patches and filler

- consistent grain and color (especially if staining)

If you see lots of putty streaks, torn grain, or wavy veneer, that sheet will fight you at finishing time.

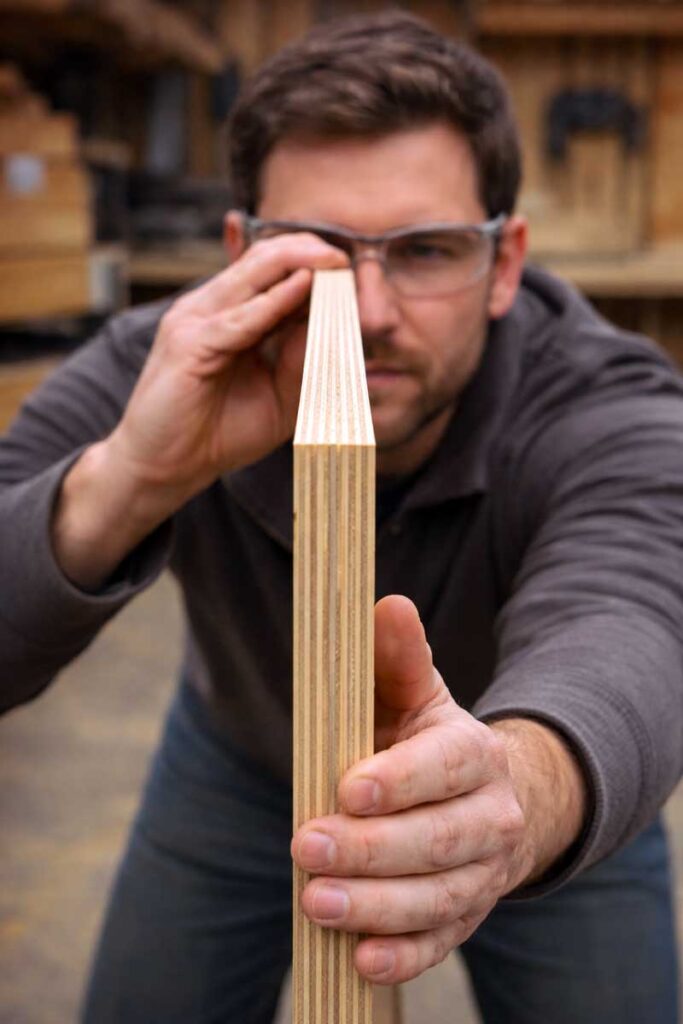

Look at the edges for voids

On a cut edge (or a damaged corner), check for gaps between plies. A few small voids happen, but big gaps mean headaches when you cut dados or expose edges.

Verify thickness consistency

Cabinet joinery cares about thickness. Some imported sheets can be undersized. If you’re cutting dadoes for 3/4″ material, a sheet that’s 18mm or 23/32″ can change your fit.

A quick check:

- measure with calipers if you have them

- or bring a test dado setup mindset: plan to fit the dado to the sheet, not the other way around

Check flatness the practical way

Sight down the long edge, then lay it on the floor if possible. Minor bow is manageable; twist is trouble.

If you’re buying multiple sheets, pick from the same stack and choose the flattest ones you can.

Smell and emissions (especially for indoor projects)

Some plywood and composite cores can off-gas more than others. If you’re sensitive to odors or building for a tight indoor space, look for panels marketed as low-emission or CARB/TSCA compliant (common in the U.S. market). Even then, it’s smart to let sheets acclimate and seal surfaces.

Choosing the right cabinet plywood for your project

For painted cabinets

Paint hides grain but it doesn’t hide dents, voids, or fuzzy edges.

Good options:

- MDF core with paint-grade face for flat panels

- Birch or maple veneer if you want tougher faces

Pay attention to edges—plan for edge banding, hardwood edging, or a paintable edge treatment.

For stained or clear-finished cabinets

This is where face veneer quality matters most.

Look for:

- A face (or the best you can get)

- consistent color across sheets (ask to pull from a matched bunk if available)

- species that finishes predictably (maple, birch, cherry, walnut—depending on your look)

Avoid bargain “pretty-face” sheets that hide core problems. A gorgeous veneer over a voidy core still causes joinery headaches.

For shop cabinets and utility builds

You can step down a notch. A solid B face and decent core is usually plenty if it’s not a showpiece.

Common sizes and what they actually mean

Most cabinet plywood is sold as 4′ x 8′ sheets, but you’ll also see 5′ x 5′ (common in Baltic birch formats) and occasional 4′ x 10′.

Thickness naming can be sloppy:

- “3/4” cabinet plywood” might be 23/32″, 18mm, or something close

- “1/2” can be 15/32″ or 12mm

Build your joinery around real measured thickness, especially for dadoes, rabbets, and hardware boring.

Typical uses for cabinet grade plywood

Cabinet grade plywood shines where you need flat, stable panels:

- cabinet sides, bottoms, tops, and stretchers

- toe kicks and partitions

- shelves (especially with front edging)

- finished end panels

- drawer bottoms (in thinner stock)

- cabinet backs (often 1/4″ or 3/8″ in a matching veneer)

For long shelves, remember plywood can sag too—use thicker stock, add a stiffener, or design shorter spans.

Mistakes I see beginners make

Buying based on the face alone is the big one. The second is assuming all “cabinet plywood” is created equal.

A few shop-tested cautions:

- Don’t trust the label—trust the sheet. Check voids, flatness, and veneer quality.

- Plan your edge strategy early. Exposed plywood edges need banding, hardwood lipping, or a design that celebrates the ply edge.

- Acclimate sheets. Let them sit in the shop so they move before you build tight-fitting casework.

- Seal edges in wet zones. The edge is where moisture gets in first.

Quick buying checklist

If you want a fast sanity check at the yard, here’s what I’d focus on:

- Face veneer looks clean and consistent under angled light

- Core shows minimal voiding on an edge

- Sheet is acceptably flat (no obvious twist)

- Thickness matches your joinery plan

- Exposure rating makes sense for the room (kitchen/bath = be picky)

- You have a plan for edges (banding, hardwood, or ply-edge design)

FAQs about Cabinet Grade Plywood

Is cabinet grade plywood the same as hardwood plywood?

Often, yes—people use “cabinet grade” to mean hardwood plywood with better faces and a suitable core. But you can also find cabinet-grade panels with composite cores (MDF/particleboard) and hardwood faces.

Can I use cabinet grade plywood for shelves?

Absolutely. Just design for span and load. Add a hardwood face strip or edge banding to stiffen the front edge and reduce sag.

Is “cabinet grade” worth it over big-box plywood?

For cabinetry, usually yes. The cost difference is often paid back in time saved: fewer bad sheets, better finishing results, fewer void repairs, and less fighting warp.

What’s the best cabinet plywood species?

It depends on your finish. Maple and birch are common for clean, bright looks; cherry and walnut for richer tones. For paint, a paint-grade face over a stable core can be a great choice.

Bottom line

Cabinet grade plywood is plywood chosen for cabinet work because it’s flatter, cleaner-faced, and more reliable to machine and finish than construction panels. But the label alone doesn’t guarantee quality—your best results come from checking the veneer grade, core type, thickness consistency, and exposure rating before you buy. Pick the sheet that matches your finish plan, protect the edges, and you’ll end up with cabinets that look sharp and stay straight.

More information? Stay connected with TrayEdit.