What Is a Wooden Dowel? 9 Powerful Uses Every DIYer Should Know

A wooden dowel is a straight, round rod made from wood, usually with a smooth surface and a consistent diameter. People use dowels to align parts, reinforce joints, connect pieces, and act as pins, pegs, or axles in woodworking, furniture, crafts, and light construction.

Contents Here

- 1 Wooden Dowel: Simple Definition

- 2 What a Wooden Dowel Is Made Of

- 3 What Wooden Dowels Are Used For

- 4 How Wooden Dowels Work in Joinery

- 5 Types of Wooden Dowels

- 6 Standard Wooden Dowel Sizes

- 7 Strength of Wooden Dowels

- 8 Wooden Dowels vs Other Joinery Options

- 9 Choosing the Right Wooden Dowel

- 10 Pros and Cons of Wooden Dowels

- 11 FAQs about Wooden Dowel

- 12 Summary

Wooden Dowel: Simple Definition

A wooden dowel is essentially a cylindrical stick of hardwood or softwood that’s been machined to a precise size (like 6 mm, 8 mm, 10 mm, 1/4″, 3/8″, etc.). That simple shape solves a lot of problems:

- Alignment: Keeps two parts from sliding during glue-up.

- Strength: Adds long-grain surface area inside a joint.

- Repeatability: Makes assembly more consistent than “eyeballing” a butt joint.

- Utility: Works as pegs, toys, closet rods, garden supports, handles, and jigs.

Dowels are used in everything from flat-pack furniture to heirloom cabinets—not because they’re fancy, but because they’re reliable when done right.

What a Wooden Dowel Is Made Of

At its core, a wooden dowel is just straight-grain wood turned into a consistent round shape. That simplicity is exactly why it works so well.

Most dowels are made from:

- Hardwoods like birch, maple, oak, or beech

- Softwoods like pine or poplar for lighter-duty uses

Birch is probably the most common. It’s affordable, reasonably strong, and machines cleanly. Maple and oak are tougher and hold better in high-stress joints, while pine dowels are easy to cut but weaker and more prone to crushing.

Quality dowels are milled with the grain running straight along the length. If the grain spirals or runs off the side, the dowel will be weaker and more likely to snap during assembly.

What Wooden Dowels Are Used For

Wooden dowels show up in a lot more places than most people realize. In the shop, they’re primarily used for joinery, but they also serve structural and decorative roles.

Common woodworking uses

- Edge-to-edge panel glue-ups

- Cabinet and furniture joints

- Chair rungs and stretchers

- Shelving supports

- Alignment pins during glue-up

A dowel joint works by increasing glue surface area and keeping parts aligned while the glue cures. When sized and placed correctly, dowels can rival more complex joints in strength for many applications.

Outside the shop, you’ll see dowels in curtain rods, toy making, craft projects, and even light construction tasks like concrete form alignment.

How Wooden Dowels Work in Joinery

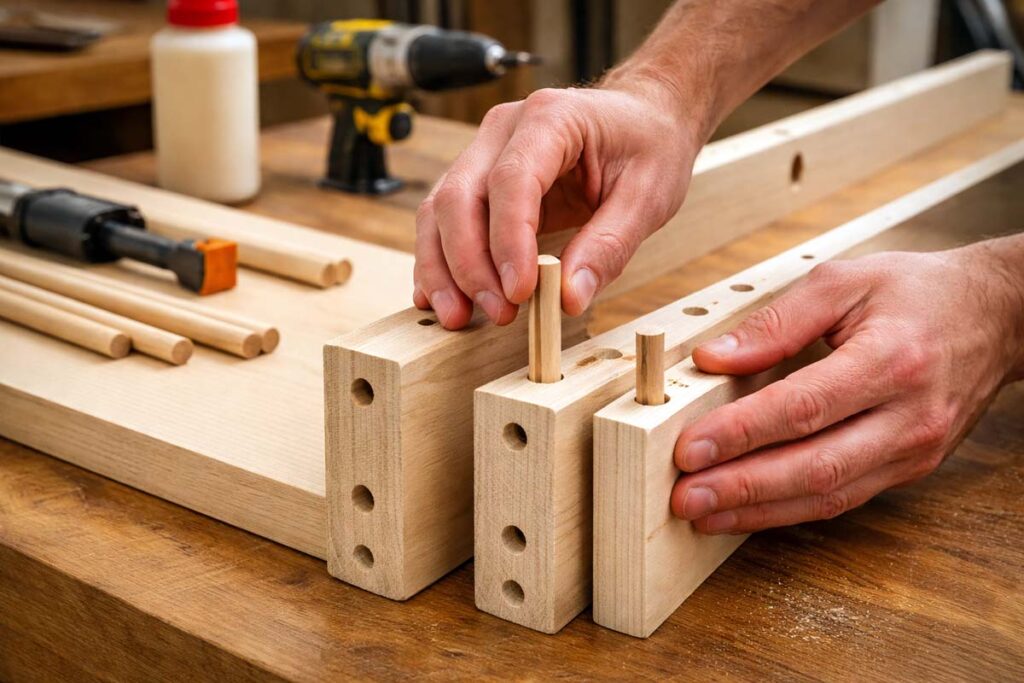

Dowels function as internal reinforcement. You drill matching holes in two pieces of wood, add glue, and insert the dowel so it bridges both parts.

There are three things happening at once:

- Alignment – the dowel keeps parts from slipping during glue-up

- Shear strength – the dowel resists sideways force

- Glue bond – long-grain glue contact adds holding power

Unlike screws or nails, dowels don’t rely on threads or metal. That makes them ideal for clean-looking furniture where you don’t want visible fasteners.

One important detail: dowels are strongest when the hole fit is snug but not forced. If you have to hammer hard, you risk splitting the workpiece or scraping off all the glue.

Types of Wooden Dowels

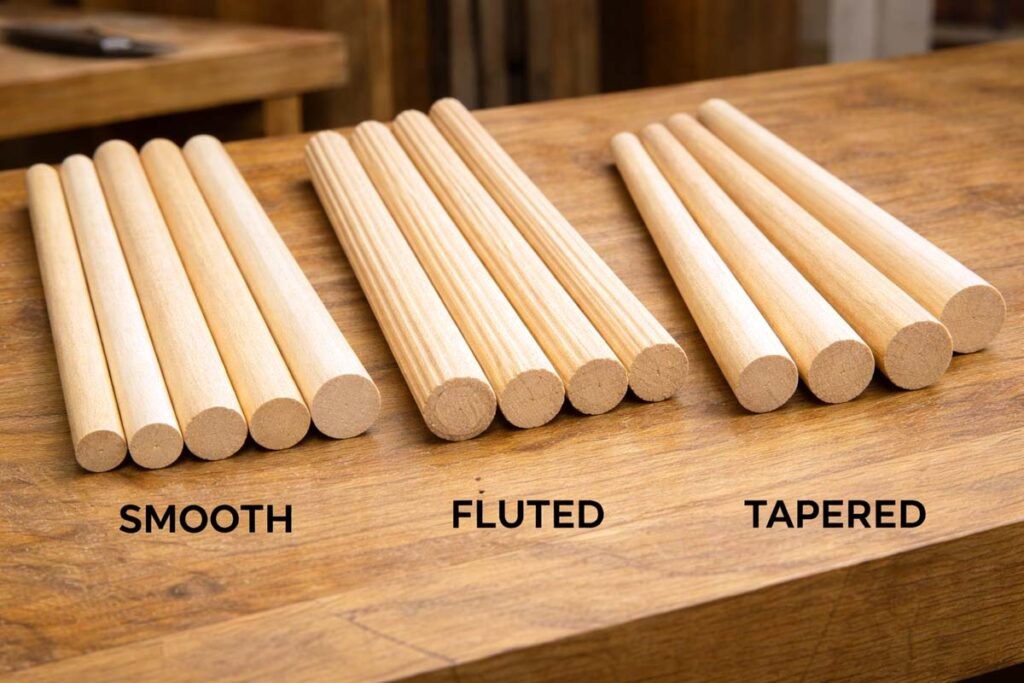

Not all dowels are created equal. Choosing the right type makes a real difference in performance.

Smooth dowels

- Plain cylindrical rods

- Often used for craft or decorative work

- Rely entirely on glue for holding power

Fluted or grooved dowels

- Have straight or spiral grooves along the length

- Allow air and excess glue to escape

- Provide better glue distribution

Tapered dowels

- Slightly conical shape

- Common in chairmaking and traditional joinery

- Lock tightly as they’re driven in

For most furniture work, fluted hardwood dowels are the safest bet. They’re forgiving during glue-up and give consistent results.

Standard Wooden Dowel Sizes

Dowels are sold by diameter and length. Common diameters include:

- 1/4 inch

- 5/16 inch

- 3/8 inch

- 1/2 inch

Length is usually trimmed to fit the joint, but pre-cut options are available.

As a rule of thumb:

- The dowel should penetrate each workpiece at least 1 to 1½ times its diameter

- Leave a small gap at the bottom of the hole for glue buildup

Drilling depth accurately matters. Too shallow and the joint won’t close; too deep and the dowel won’t engage properly.

Know more: Wood Glue for Dowels: 9 Strong Choices for Tight, Clean Fits

Strength of Wooden Dowels

A well-made dowel joint can be surprisingly strong. In many furniture applications, dowels outperform screws because the force is spread across the joint instead of concentrated at a single point.

Strength depends on:

- Wood species of the dowel

- Grain orientation

- Hole accuracy

- Glue quality and coverage

Hardwood dowels in tight-fitting holes with modern wood glue can handle racking forces, especially in cabinets, tables, and shelving.

For heavy structural loads or outdoor exposure, traditional mortise-and-tenon or mechanical fasteners may still be the better choice.

Wooden Dowels vs Other Joinery Options

It helps to know where dowels fit compared to other methods.

Dowels vs screws

- Dowels are hidden and cleaner looking

- Screws are faster and removable

- Dowels don’t risk splitting thin stock

Dowels vs biscuits

- Dowels provide more structural strength

- Biscuits mainly aid alignment

- Dowels require more precise drilling

And Dowels vs pocket holes

- Dowels are invisible from the outside

- Pocket holes are quicker and adjustable

- Dowels create a more traditional joint

In my shop, dowels are a go-to when I want strength without visible hardware and don’t want to cut full mortises.

Choosing the Right Wooden Dowel

When you’re standing in the aisle or ordering online, look for a few key signs of quality:

- Straightness with no visible warp

- Tight, even grain

- Cleanly milled surface without tear-out

Avoid dowels with fuzzy fibers or visible cracks. If possible, lightly flex the dowel—cheap ones often snap easily.

If strength matters, match the dowel wood to the project wood when you can. Similar expansion rates help keep joints stable over time.

Pros and Cons of Wooden Dowels

Advantages

- Clean look (hidden joinery)

- Strong in shear when sized correctly

- Low cost and widely available

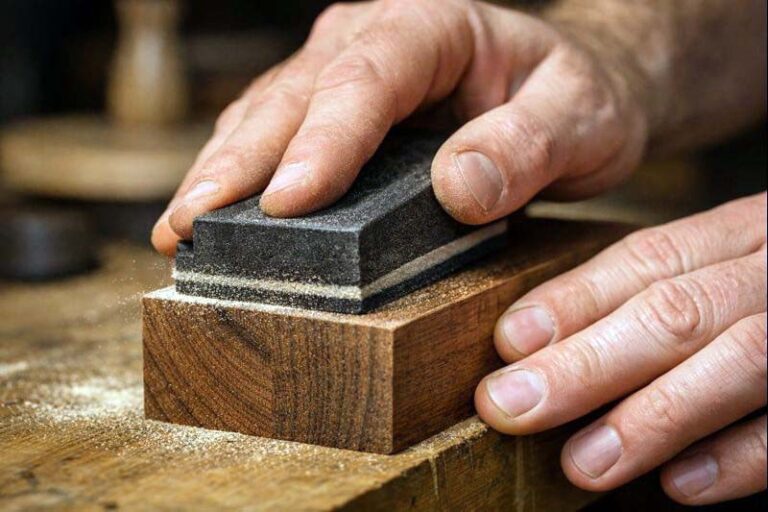

- Easy to cut, sand, and finish

Limitations

- Requires accurate drilling

- Wood movement and moisture can affect fit

- Not ideal for outdoor exposure unless protected

FAQs about Wooden Dowel

What is a common wood dowel made from?

Most common wood dowels are made from birch because it’s affordable, fairly strong, and machines cleanly. You’ll also see maple, beech, oak, and sometimes pine for lighter-duty uses.

What is a wood dowel rod?

A wood dowel rod is a straight, round wooden stick with a consistent diameter. It’s used for joinery, alignment, craft builds, and parts like handles, pegs, or simple furniture components.

Are wooden dowels strong?

Yes—when they’re hardwood, straight-grained, and fit properly in clean holes. A well-glued dowel joint can be very strong in shear and racking, especially for cabinets, shelves, and furniture frames.

Can I use a wooden dowel instead of a screw?

Often, yes. Dowels are great when you want a hidden, clean-looking joint and the parts won’t need to be taken apart later. Screws still win for quick assembly or removable connections.

Do wooden dowels need glue?

For joinery, yes—glue is what makes dowels lock in and add strength. Dry-fit dowels can work as alignment pins, but they won’t hold under load unless the joint is glued.

Can you paint or stain dowels?

Definitely. Sand lightly first to remove fuzz, then apply stain, paint, or a clear finish. For even stain, use a pre-stain conditioner on softwoods like pine to reduce blotching.

Summary

A wooden dowel is a precision round wooden rod used to join, align, reinforce, and build—from furniture frames to simple DIY crafts. The best results come from choosing the right wood type (often hardwood), diameter, and fit, and using dowels where hidden, strong connections matter.

If you want, tell me what you’re using dowels for (furniture joint, craft, repair, or decor) and I’ll recommend the best diameter/wood and a simple drilling layout.