What Is a Dowel Rod? 7 Fast Facts Every Woodworker Needs

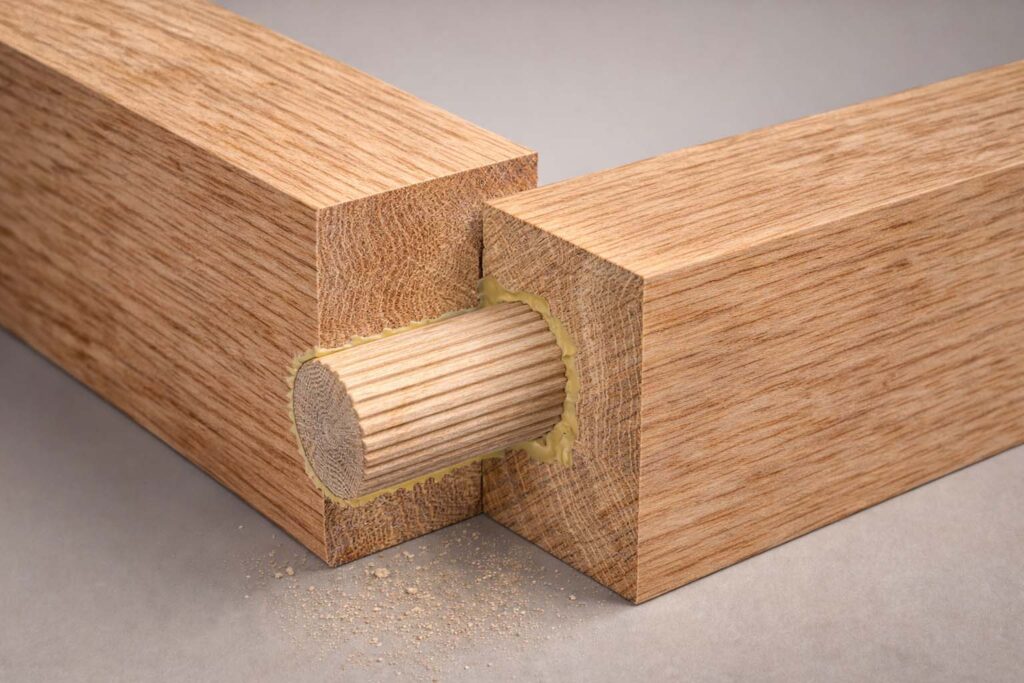

A dowel rod is a straight, round wooden rod sized to fit a drilled hole so it lines up parts and reinforces a joint, usually with glue. Woodworkers use dowel rods to build strong, hidden joints because the dowel adds long-grain-to-long-grain glue surface inside the hole. You’ll see dowel rods in furniture, cabinets, toys, and plenty of tray and stand builds where clean joinery matters.

Contents Here

- 1 Dowel rod basics: what it is (and what it isn’t)

- 2 What are dowel rods made from?

- 3 Common dowel rod sizes (and why size matters)

- 4 How dowel rods are shaped: smooth, fluted, grooved, spiral

- 5 What is a dowel rod used for?

- 6 How a dowel joint actually gets its strength

- 7 Choosing a dowel rod that won’t fight you

- 8 How to use a dowel rod for joinery (clean, repeatable method)

- 9 Cutting dowel rods safely (and getting a square end)

- 10 Fit problems: too tight, too loose, or splitting

- 11 When dowel rods make the most sense (and when they don’t)

- 12 FAQs on Dowel Rod

Dowel rod basics: what it is (and what it isn’t)

A dowel rod is a cylindrical rod made to a consistent diameter so it can fit into matching holes for alignment and fastening. Most “dowel rods” sold at home centers are long lengths you cut down. Short pre-cut pieces are often sold as “dowel pins.” In woodworking, people use the terms loosely, but the job stays the same: locate parts and strengthen joints.

A dowel rod is not the same thing as a wood plug used to hide screws. Plugs are typically short, end-grain “caps” sized for counterbores. A dowel rod is meant to live inside a hole, usually with glue, taking shear and racking loads across the joint.

What are dowel rods made from?

Most dowel rods you’ll find are hardwood because hardwood holds crisp edges, stays straighter, and resists crushing during clamp-up better than softwood. Common species include birch, maple, beech, poplar, and oak (availability varies by region and supplier). Hardwood dowels generally carry higher density and wear resistance than softwood dowels, which matters for joints that get bumped, rocked, or loaded.

You can also buy dowels in metal or plastic for jigs and hardware work, but for furniture-style joinery, hardwood dowels are the usual pick.

Common dowel rod sizes (and why size matters)

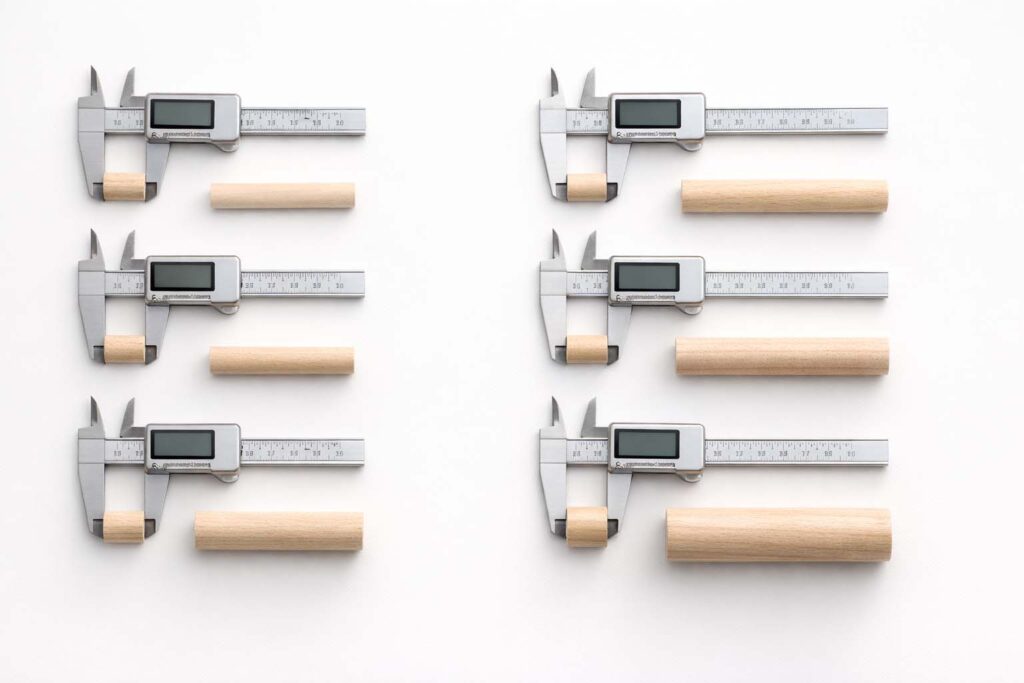

Dowel rods come in standard diameters. In the U.S. you’ll commonly see 1/4″, 3/8″, 1/2″, 5/8″, and 3/4″. In metric markets, 6 mm, 8 mm, 10 mm, and 12 mm are common.

Diameter choice is mostly about meat around the hole:

- Thin stock needs smaller dowels so you don’t blow out the side wall.

- Wider parts can take larger dowels, or multiple smaller dowels spaced out.

Length matters too, but the big rule is simple: the dowel should embed deep enough in both parts to resist racking without starving the joint of glue space.

How dowel rods are shaped: smooth, fluted, grooved, spiral

You’ll see a few surface styles:

- Smooth dowels: fine for many jobs, but they can hydraulic-lock if the fit is tight and glue has nowhere to go.

- Fluted or grooved dowels: the channels give glue and air somewhere to move, so clamp-up feels controlled and seating is easier.

- Spiral-grooved dowels: similar idea, with continuous glue pathways.

If you’ve ever tapped a smooth dowel into a glue-filled hole and it stops short with a springy feel, that’s trapped air and glue pressure. Flutes reduce that headache.

What is a dowel rod used for?

A dowel rod earns its keep when you need alignment plus strength without visible fasteners.

Common shop uses include:

- Edge-to-edge panel alignment (keeping faces flush during glue-up)

- Frame joints (rails to stiles, aprons to legs)

- Shelf pinning and indexing (temporary or permanent locating)

- Toy axles, pegs, and handles

- Tray and tiered-stand parts (spacers, risers, and hidden reinforcement)

For most furniture-style work, the dowel is doing two jobs at once: it indexes the parts so they don’t skate during clamp-up, and it reinforces the joint against racking.

How a dowel joint actually gets its strength

A dowel joint works because the dowel adds long-grain glue surface inside the hole and bridges the two parts like a buried tenon. When the joint sees a load, the dowel resists shear and helps keep the parts from rotating out of square.

The glue line still matters. If you want a deeper glue refresher, TrayEdit has a solid explainer on what PVA wood glue is used for in woodworking projects, and a practical guide on choosing wood glue that works well in tight-fitting joinery.

Choosing a dowel rod that won’t fight you

Most dowel problems come from three things: poor straightness, wrong moisture, or bad fit.

Here’s what I check at the rack:

- Straightness: roll it on the floor or a flat shelf. If it wobbles, it’s going to telegraph that wobble into your assembly.

- Clean grain: avoid rods with torn grain, crushed fibers, or fuzzy patches. Those spots swell unevenly with glue.

- Moisture fit for indoor work: indoor wood typically lives around 6%–9% moisture content when a building is kept roughly in the normal comfort range. If dowels are stored damp and you glue them in dry parts (or the other way around), the joint fit changes over time.

- Species match (when it matters): if the project is hardwood, a hardwood dowel behaves more predictably under clamp pressure.

If you’re building something that sees humidity swings (kitchens, laundry rooms), moisture control becomes a joinery decision, not just a lumber decision. Purdue Extension’s guidance on equilibrium moisture content points back to the USDA Wood Handbook for that reason.

How to use a dowel rod for joinery (clean, repeatable method)

If order matters anywhere with dowels, it’s in layout and drilling. Here’s the sequence that keeps parts aligned.

- Mark reference faces and edges on both parts (pencil arrows). Always register your jig from the same faces.

- Lay out dowel locations with clear spacing. Keep dowels away from ends to reduce splitting risk.

- Drill the first part using a doweling jig or a drill press fence for consistent hole placement.

- Transfer the hole locations to the mating part using dowel centers or the same jig settings.

- Drill the mating part to the same depth.

- Dry fit with dowels—no glue—to confirm seating and alignment.

- Glue and assemble: coat the hole walls (a small brush works), add a light coat on the dowel, and clamp until the joint closes.

Glue time and clamp time drive your workflow. TrayEdit breaks that down in how long wood glue takes to set and how long to clamp wood glue for a reliable bond. If you’re specifically doing dowel joinery, this guide on wood glue choices for dowel joints fits the job.

Cutting dowel rods safely (and getting a square end)

Dowel rods love to roll, which makes them easy to pinch or launch if you cut them carelessly.

Safety checkpoints that work in a small shop:

- Trap the dowel: use a V-block, a handscrew clamp, or a simple V-notch jig so the rod can’t spin.

- Support both sides of the cut: especially on long rods, so the offcut doesn’t tear fibers at the end.

- Choose the right tool: a fine-tooth saw cuts cleaner; a miter box helps keep ends square.

- Sand the end grain lightly after cutting so it seats without shaving glue off the hole walls.

If you want the ends to look clean (handles, pegs, exposed joinery), TrayEdit’s technique guide on sanding end grain to a smooth finish is worth keeping bookmarked.

Fit problems: too tight, too loose, or splitting

Why does my dowel stop halfway into the hole?

A dowel that stalls usually means the hole is slightly undersized, the dowel is slightly oversized, or glue/air is trapped. Fluted dowels reduce hydraulic pressure, and a clean drilled hole helps. If you force it, you risk splitting the workpiece or scraping glue off where you need it.

What if the dowel fit is loose?

A loose dowel usually points to bit wear, wobble, or drilling off-angle. In structural joinery, a sloppy fit reduces alignment and makes clamp-up unpredictable. A better fix is drilling cleanly and sizing correctly rather than “fattening” the dowel with tape or random shims.

How do I prevent splitting around dowel holes?

Splits come from drilling too close to an edge, using too large a dowel for the stock, or driving a tight dowel into dry wood without relief for glue/air. Back your layout away from edges, drill straight, and use fluted dowels or slightly eased holes when clamp pressure is high.

When dowel rods make the most sense (and when they don’t)

Dowels shine when you want:

- Hidden joinery with strong alignment

- Repeatable production (cabinet parts, frames, trays)

- Reinforcement without metal fasteners

Dowels are less convenient when:

- You can’t clamp the joint reliably

- The parts are too thin for safe hole spacing

- You need on-the-fly adjustability (screws win there)

FAQs on Dowel Rod

What are dowel rods made from?

Dowel rods are usually made from hardwoods like birch, maple, beech, poplar, or oak, because they stay straighter and resist crushing. You’ll also see softwood, plastic, or metal dowels for special uses.

What is a weight 16 x 48 dowel rod?

A “16 x 48 dowel rod” usually means a dowel that’s 16 mm in diameter and 48 inches long (some sellers use mm/inch mixes). “Weight” depends on species and moisture, so check the listing.

Are dowel rods strong enough for furniture?

Yes, dowel rods hold up well in furniture when the holes are drilled straight, the fit is snug, and the glue joint closes tight. Multiple dowels spaced properly often beat one oversized dowel.

Do dowel rods have to be hardwood?

No, softwood dowels work for light-duty crafts, paint-grade projects, and spacers. Hardwood dowels are the better pick when the joint carries load, needs crisp alignment, or sees wear like pegs and handles.

What are hardwood dowel rods?

Hardwood dowel rods are round rods made from dense woods like birch, maple, beech, or oak. They take glue well, resist denting, and keep their diameter more reliably during clamp-up and seasonal humidity changes.