Torx Wood Screws 2026: 11 Best Picks by Head, Size, and Coating

Torx wood screws are star-drive (6-lobe) wood screws that are great for strong bit grip and high torque with less cam-out, so you get faster driving, fewer stripped heads, and cleaner, more controlled installs in woodworking and decking.

This guide breaks down Torx drive basics, common bit sizes, head styles, coatings for indoor and outdoor work, and the driving habits that produce straight, flush screws without splitting boards.

Contents Here

- 1 Quick Checklist: Top 11 Best Torx Wood Screws

- 2 What are Torx wood screws?

- 3 Why woodworkers use Torx drives

- 4 Torx bit sizes and how to pick the right one

- 5 Head styles you’ll see on Torx wood screws

- 6 Materials and coatings for indoor vs outdoor work

- 7 Reviews of the 11 Best Torx Wood Screws

- 7.1 Deck Plus 3 Inch Torx Wood Screws

- 7.2 LIONMAX 3 Inch Torx Wood Screws

- 7.3 Bobibbi T25 Star Torx Drive Flat Head Wood Screws

- 7.4 Bonost 450Pcs Wood Screws Assortment Kit

- 7.5 YLYEEU 240Pcs Wood Screws Assortment Kit

- 7.6 TK Excellent Torx Drive Screw

- 7.7 FIXLINK 310 PCS Wood Screws

- 7.8 JOUGU Torx Star Drive Deck Screws

- 7.9 JOUGU Wood Screws Yellow Torx Star Drive

- 7.10 Nuvo Iron T25 Torx Head Screws

- 7.11 Bobibbi T25 Star Torx Drive Flat Head Deck Screws

- 8 How to choose the right Torx wood screw for your project

- 9 How to drive Torx wood screws cleanly

- 10 Troubleshooting common problems

- 11 Torx vs Phillips vs Pozidriv for woodworking

- 12 FAQs on Torx Wood Screws

- 13 What to Remember

Quick Checklist: Top 11 Best Torx Wood Screws

- Deck Plus #10 x 3 Star Drive Screws

- LIONMAX #10 x 3 Deck Screws

- Bobibbi #8 x 1-1/4 Tan Ruspert Screws

- Bonost 450-Piece Torx Assortment

- YLYEEU 240-Piece Black Epoxy Kit

- T.K.Excellent #10 x 3 Deck Screws

- FIXLINK #10 x 3 Exterior Screws

- JOUGU #10 x 3 Black Torx Deck Screws

- JOUGU #6 x 1 Yellow Torx Screws

- Nuvo Iron #8-32 x 1-1/4 Torx Screws

- Bobibbi #10 x 5 Green Ruspert Screws

What are Torx wood screws?

Torx wood screws are wood screws that use a 6-lobe, star-shaped recess (often labeled Torx, TX, or “star drive”) to let a driver bit grip the head with high contact area and low slippage. The Torx drive pattern traces back to Camcar’s TORX system developed in 1967.

In practice, “Torx wood screw” describes a broad family of screws: construction screws, deck screws, cabinet screws, and general-purpose wood-to-wood fasteners that share the same star drive.

If you’re building for outdoor or damp areas, stainless steel Torx wood screws are a smart upgrade, see our guide to corrosion-resistant wood screws options.

Why woodworkers use Torx drives

Torx drives reduce cam-out, which is the bit slipping out of the screw head once torque rises past what the recess can hold. That slip chews the recess, rounds over the bit, and leaves a scarred head that turns into a removal problem later.

Torx solves that in a simple way: the lobes increase engagement between bit and screw. More engagement delivers three shop-friendly results.

- The bit stays seated, so the driver runs steadier and straighter.

- The recess resists stripping, so you waste fewerzif fewer screws and bits.

- The head survives high-torque driving, which matters in dense hardwood, exterior framing, and long deck screws.

If you want a clean baseline on screw anatomy before shopping, start with this guide on how wood screws work in common joints.

Torx bit sizes and how to pick the right one

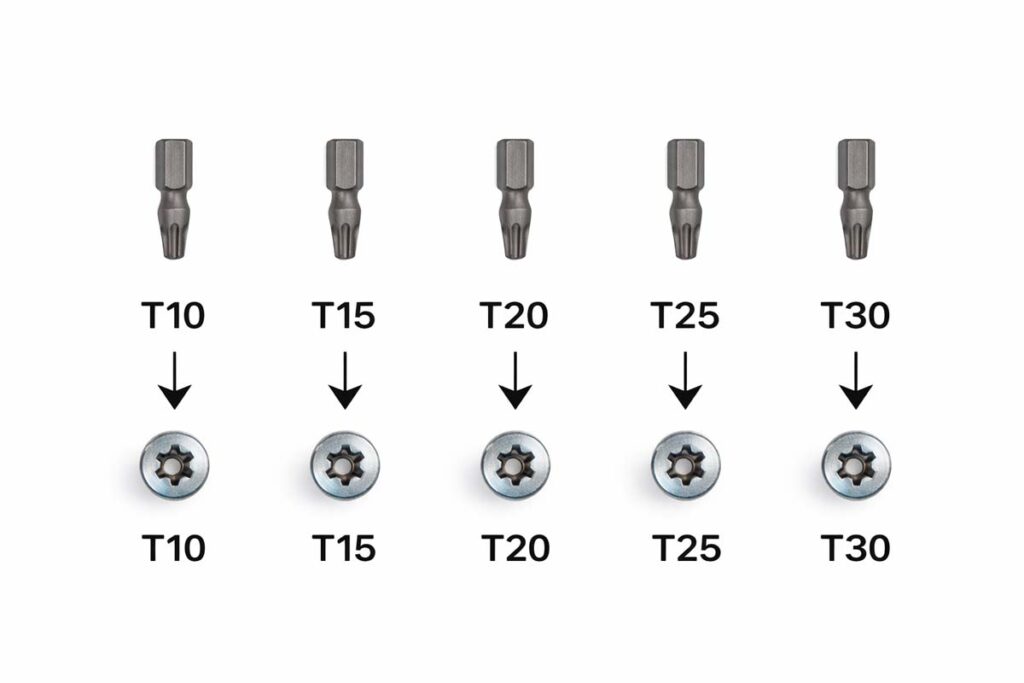

Torx sizing uses a “T” number (T10, T15, T20, T25, T30). In woodworking, T15, T20, and T25 show up often, with T25 being a common pick for many deck and construction screws.

Bit choice follows one rule in the shop: match the bit to the screw head so the bit bottoms out and fills the recess.

Here’s the quick fit check I use at the bench:

- Seat the bit fully into the recess before pulling the trigger.

- Twist the bit by hand. A correct fit feels snug with minimal wobble.

- Replace worn bits early. A rounded tip behaves like the wrong size.

When you run into confusing package markings, this sizing explainer helps: how screw sizes are measured and what screw numbers mean on the box.

Head styles you’ll see on Torx wood screws

Countersunk and raised countersunk

Countersunk Torx screws use a tapered head that cuts into a countersink so the head sits flush with the surface. Raised countersunk heads leave a slight dome, which suits hardware, trim, and applications where a tiny proud head looks cleaner than a cratered surface.

For furniture and finish work, countersunk heads pair well with a pilot hole and a controlled driver clutch. That combo keeps the head flush without crushing surrounding fibers.

Bugle head for decking and construction

Bugle heads use a smooth, curved underside that spreads pressure as the head sinks. That shape reduces surface tearing and fiber blowout compared with a sharp, flat underside. Deck screws and many structural wood screws use bugle heads because they seat fast and leave a neat, consistent finish across large runs of boards.

Bugle heads also help when you drive at volume, because they tolerate slight depth variation without leaving harsh rings around every screw.

Pan and washer heads for clamping and hardware

Pan and washer heads spread load across a wider area. That wider bearing surface helps when you mount hardware, clamp plywood, or work in softer woods where countersunk heads tend to bury themselves. If the head remains visible, pan/washer styles also look tidy because the rim stays even.

Materials and coatings for indoor vs outdoor work

The screw material and coating decide how long the fastener survives moisture, treated lumber chemicals, and temperature swings. Indoors, zinc-plated or standard coated steel screws cover most cabinet and shop tasks. Outdoors, corrosion resistance becomes the first filter.

Stainless steel grades commonly show up as A2 (often associated with 304) and A4 (often associated with 316). A4 delivers higher corrosion resistance and gets picked more often for coastal air and high-exposure installations.

A practical way to choose:

- Indoor, dry areas: zinc-plated or standard coated screws.

- Outdoor, exposed: exterior-rated coated screws or stainless.

- Coastal, salt air, wet zones: stainless A4/316 grades.

Reviews of the 11 Best Torx Wood Screws

Deck Plus 3 Inch Torx Wood Screws

Best Torx wood screws for pressure-treated decking

Deck Plus positions these clearly for outdoor work: exterior wood, composite, and trim. The listing highlights a 4-layer epoxy coating and recommends use with treated lumber types (ACQ/CA/CCA), which is a key concern for deck builders.

$26.80 at AmazonThe Type 17 point and coarse threads are meant to reduce the need for pilot holes, and the T25 bit is included. If you want a widely “deck-standard” spec set in a manageable tub, this one reads well on paper.

One honest limitation: it’s still carbon steel, so stainless remains the safer bet for harsh coastal exposure.

Specifications:

- Size: #10 x 3″

- Drive: T25 Torx/Star (bit included)

- Material: Carbon steel

- Finish: 4-layer epoxy / ceramic (listed)

- Qty: 310

Pros

- Coating and treated-lumber compatibility focus

- Type 17 start for easier driving

- Torx drive reduces cam-out

- Warranty claim included in listing

Cons

- Screws feel undersized and lightweight, and the box count info seems inconsistent.

LIONMAX 3 Inch Torx Wood Screws

Best Torx drive wood screws for outdoor builds

If you’re building decks, fences, or framing outdoors, these are aimed at long-term exposure. The tan coating is tested to 1500 hours salt spray, and the T25 Torx drive helps keep the bit seated when torque climbs.

$19.99 at AmazonThe self-tapping point and aggressive coarse thread are meant to start fast without pre-drilling, which is handy in pressure-treated lumber. The smooth “finger protection” shank is a small touch, but it’s nice when you’re grabbing screws by hand all day.

Specifications:

- Size: #10 x 3″

- Drive: T25 Torx/Star (bit included)

- Material: Carbon steel

- Finish: Tan coated

- Qty: 300

Pros

- Strong corrosion-focus (1500-hour salt spray claim)

- Starts fast with self-tapping point

- Torx drive reduces cam-out

- Organized storage case

Cons

- Hard to start; the tip struggles to bite, so driving takes heavy pressure.

Bobibbi T25 Star Torx Drive Flat Head Wood Screws

Best T25 wood screws for trim and rails

These #8 x 1-1/4″ screws fit jobs like deck trim, guardrails, and light exterior woodworking where you want a smaller fastener.

$26.99 at AmazonThe listing calls out Tan Ruspert coating and a Type 17-style tail for easier starts without pre-drilling. It also mentions ribs under the head to help the screw seat smoothly. The included T25 bit is helpful, especially if you’re buying screws for a one-off project and don’t want to hunt for the right driver. The set is built around one short length, so it’s not ideal for thicker decking or structural fastening.

Specifications:

- Size: #8 x 1-1/4″

- Drive: T25 Torx (bit included)

- Material: 1022A carbon steel

- Finish: Tan Ruspert / coated

- Qty: ~974 (5 lb)

Pros

- Good “small screw” option for exterior details

- Torx head grips well under torque

- Type 17-style start helps reduce splitting

- Large count for the money

Cons

- Packaging was poor, and the container arrived split even though the screws worked.

Bonost 450Pcs Wood Screws Assortment Kit

Best star drive wood screws assortment for home repairs

This kit is built for people who do a mix of repairs, furniture fixes, and light outdoor work. You get multiple #8 and #10 lengths plus matching anchors, so you’re not stuck forcing one screw to do every job.

$29.99 at AmazonThe Torx drive helps with controlled driving, and the “auger tip” description suggests it’s meant to cut into wood cleanly. If you like keeping one box that covers common sizes, this is the style that saves trips back to the store. The coating details are general, so for heavy coastal exposure you may still prefer a clearly rated exterior deck screw.

Specifications:

- Sizes: #8 and #10, multiple lengths

- Drive: Torx

- Material: Carbon steel

- Thread: Partially threaded

- Qty: 450 + anchors

Pros

- Covers many common lengths in one kit

- Good for mixed DIY and maintenance

- Torx drive supports higher torque

- Anchors included for general fastening

Cons

- Mixed bit sizes needed; the smallest screws use a different Torx bit.

YLYEEU 240Pcs Wood Screws Assortment Kit

Best Torx head screws for wood in a starter set

This assortment targets DIYers who want a practical range: #8 and #10 in multiple lengths with matching star bits.

$16.99 at AmazonThe standout is the 4-layer black epoxy coating and a 1500-hour salt spray claim, which points it toward outdoor use as well as shop work. It also calls out a self-tapping tip, a knurled shoulder, and serrations under the head to bite and lock. That’s useful when you need a screw to seat without walking.

One honest limitation: black finish can stand out in light woods unless you plan for plugs or hidden fasteners.

Specifications:

- Sizes: #8 and #10, multiple lengths

- Drive: Torx/Star (bits included)

- Material: Carbon steel

- Finish: 4-layer black epoxy

- Qty: 240

Pros

- Useful mix of common lengths

- Coating focus for outdoor conditions

- Features aimed at clean seating and grip

- Starter-friendly kit design

Cons

- No real downside for indoor jobs, but the corrosion-resistant coating is overkill.

TK Excellent Torx Drive Screw

Best T25 star drive screws for budget deck work

These are aimed at outdoor decking and general construction where you want a standard 3″ deck screw with a Torx drive.

$20.82 at AmazonThe listing claims a three-coating system for rust protection and a self-starting point to skip pre-drilling in many situations. It also calls out “tail cutting,” which is the kind of feature that helps reduce splitting and driving resistance when you’re working fast. Two T25 bits come in the box, which is practical if you burn through bits on big installs.

One honest limitation: coating is described broadly, so if you need a verified exterior system for harsh coastal zones, look for more defined corrosion specs.

Specifications:

- Size: #10 x 3″

- Drive: Torx/Star (2 bits included)

- Material: Carbon steel

- Finish: Painted / multi-coating

- Qty: 315

Pros

- Solid all-around 3″ deck screw format

- Bit bundle reduces setup hassle

- Self-start point speeds repetitive work

- Tail cutting feature targets splitting

Cons

- Cheap plastic case arrived broken and spilled screws everywhere when opened.

FIXLINK 310 PCS Wood Screws

Best Torx decking screws for treated lumber

These are designed specifically around exterior performance: the listing claims about 1500 hours salt spray and mentions compatibility with pressure-treated lumber and composite decking.

$17.99 at AmazonThe screw design focuses on fast starts without pre-drilling, using a sharp point, thread cutting, and serrated threads to reduce splitting. The tan plating is meant to blend into wood better than bright zinc in visible applications. If you’re rebuilding a deck or doing outdoor framing where consistency matters, this is a straightforward “buy one box and run screws all day” pick.

One honest limitation: you only get one size, so it won’t cover smaller trim or lighter interior tasks.

Specifications:

- Size: #10 x 3″

- Drive: T25 Torx/Star

- Material: Carbon steel

- Finish: Epoxy coated / RUSPERT (listed)

- Qty: 310

Pros

- Exterior-focused corrosion claim

- Built for treated lumber and composites

- Thread cutting helps reduce splitting

- Tan color looks cleaner on wood

Cons

- Partial threads can let screws spin if overdriven, and some tips start slowly.

JOUGU Torx Star Drive Deck Screws

Best star drive deck screws with included accessories

This is a smaller pack (50 screws) that’s useful for repairs, test builds, or small projects where you don’t want a 5-lb bucket.

$7.99 at AmazonIt’s listed as grade 8.8 galvanized carbon steel and uses a T25 Torx drive. The included extras are the real draw: a bidirectional bit (longer life) and a magnetic ring to stabilize driving. That’s helpful if you’re working overhead or trying to keep the screw steady on a bit tip.

One honest limitation: 50 pieces disappear fast on decking or fencing runs.

Specifications:

- Size: #10 x 3″ (M5 x 75)

- Drive: T25 Torx

- Material: Galvanized carbon steel (grade 8.8 listed)

- Finish: Black / zinc (listed)

- Qty: 50 + accessories

Pros

- Great for small jobs and repairs

- Useful accessories included

- Torx drive supports solid engagement

- Clear size labeling for quick matching

Cons

- Included bit is low quality and strips quickly; a better Torx bit works.

JOUGU Wood Screws Yellow Torx Star Drive

Best T10 wood screws for small fasteners

These are genuinely small screws: #6 x 1″ with a T10 Torx drive and a big quantity (700). That makes them a practical choice for lighter woodworking, sheet goods, MDF, and smaller assemblies where a #10 deck screw would be overkill.

$22.98 at AmazonThe listing also calls out grade 8.8 galvanized carbon steel and includes a bidirectional bit plus a magnetic ring, which helps keep the tiny screws from tipping.

One honest limitation: these are not a structural screw; the small diameter limits them for load-bearing outdoor builds.

Specifications:

- Size: #6 x 1″ (M3.5 x 25)

- Drive: T10 Torx

- Material: Galvanized carbon steel (grade 8.8 listed)

- Finish: Yellow / zinc (listed)

- Qty: 700 + accessories

Pros

- Excellent count for frequent small work

- T10 drive helps avoid tiny Phillips stripping

- Handy accessories included

- Fits MDF and sheet material tasks well

Cons

- Included bit is junk and strips fast; swap to a quality Torx bit.

Nuvo Iron T25 Torx Head Screws

Best Torx construction screws for indoor-outdoor wood-to-wood

These are a different beast: #8-32 thread suggests a more machine-screw style than typical deck screws, yet the listing positions them as construction screws for wood-to-wood fastening.

$5.49 at AmazonThe yellow zinc plating aims at corrosion resistance, and the countersunk head helps seat flush. If your project needs a smaller, cleaner-looking fastener with a Torx head and you want a consistent thread profile, this could fit certain builds, jigs, or hardware-style applications.

One honest limitation: the unusual #8-32 thread spec can confuse shoppers expecting standard wood screw sizing.

Specifications:

- Size: #8-32 x 1-1/4″

- Drive: Torx (T25 referenced in title)

- Material: Carbon steel

- Finish: Yellow zinc plating

- Qty: 188

Pros

- Flush seating countersunk head

- Corrosion-resistant coating focus

- Torx drive helps prevent slip

- Good count for repeat installs

Cons

- #8-32 thread may not match typical wood-screw expectations

Bobibbi T25 Star Torx Drive Flat Head Deck Screws

Best long T25 Torx screws for fencing and framing

At 5 inches long, this is for thick stock: fencing, heavy framing, and outdoor lumber where shorter deck screws won’t reach.

$5.99 at AmazonThe listing calls out Green Ruspert/ceramic coating, 1022A carbon steel, and a Type 17 tail for starting without pre-drilling in many cases. You also get a free T25 bit. This is the kind of screw you buy when you know the job needs reach and bite, not a “general box” for random repairs.

One honest limitation: the pack is only 42 pieces, so large fences will need multiple boxes.

Specifications:

- Size: #10 x 5″

- Drive: T25 Torx (bit included)

- Material: 1022A carbon steel

- Finish: Green Ruspert / green ceramic (listed)

- Qty: 42

Pros

- Long length for thick outdoor assemblies

- Coating aimed at wet/high-salt conditions

- Type 17 start helps reduce pre-drilling

- Torx head supports higher torque driving

Cons

- Some screws have excess paint in the head, so the bit won’t fit properly.

How to choose the right Torx wood screw for your project

Match length and diameter to the joint

A screw works by clamping the first piece tight while threading into the second piece. That means the diameter (gauge) and length need to match the thickness and load.

Selection logic stays simple:

- Pick a length that gives strong bite into the second board without poking through.

- Use thicker screws for higher load and wider boards.

- Use thinner screws for trim, narrow stock, and delicate edges.

If you want a step-by-step method, TrayEdit lays it out here: how to screw into wood without fighting the grain.

Choose thread style for the material

Thread design changes how the screw pulls wood together.

- Partial thread (smooth shank near the head) pulls two boards tight because threads grab the far piece while the shank slides through the near piece.

- Full thread grips along the full length, which suits single-piece fastening, hardware mounting, or situations where continuous holding strength matters.

Dense hardwood benefits from pilot holes because the fibers resist displacement. This guide helps prevent cracked ends and split edges: how to stop wood splitting when screwing.

How to drive Torx wood screws cleanly

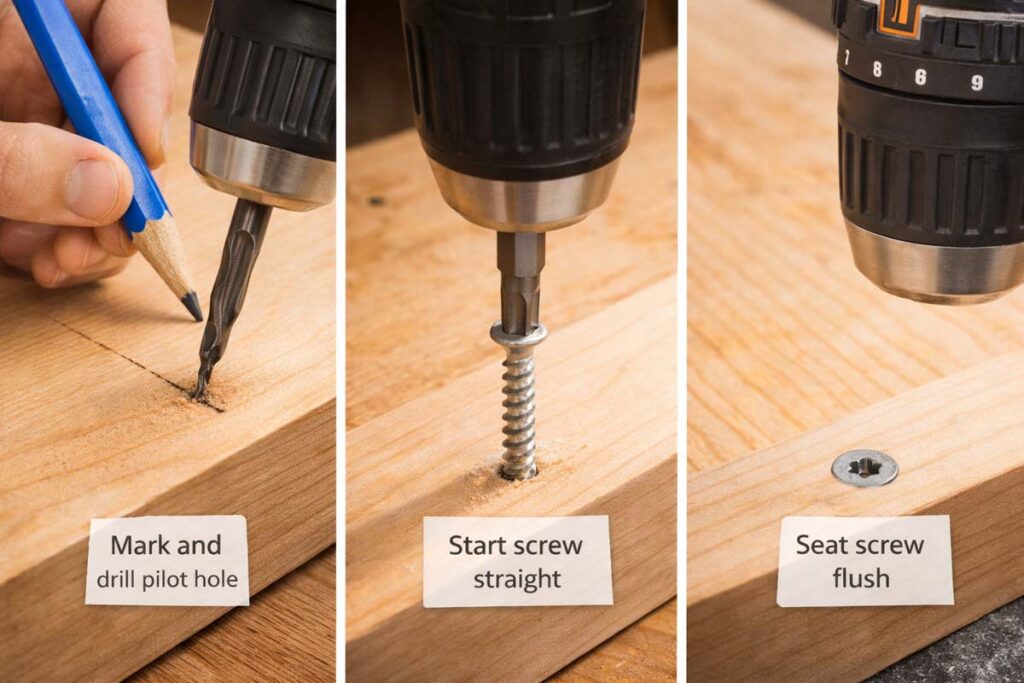

Clean driving comes from alignment, bit fit, and torque control. A high-torque impact driver drives fast, but speed without depth control buries heads and strips wood fibers.

A reliable driving routine looks like this:

- Mark the screw line and keep the driver square to the surface.

- Start slow until the threads bite and the screw stands straight.

- Increase speed for the middle of the drive.

- Slow down for the last few turns and stop at flush depth.

Pilot holes matter in hardwood, near board ends, and in thin stock. A countersink keeps the head from crushing the surface when you want a flush finish. Eye protection and hearing protection fit into this work because screws eject chips and bits can snap under torque.

Troubleshooting common problems

“My Torx head is stripping”

A Torx recess strips when the bit size mismatches, the bit fails to seat fully, or the bit edge rounds over. The fix starts with the tool, not the screw.

Do this in order:

- Swap to a fresh bit that matches the head size exactly.

- Press the bit fully into the recess before driving.

- Drive straight. A tilted bit loads one lobe and tears the recess.

- Reduce speed for the last turns and finish with a controlled clutch setting.

If you already damaged the wood around the hole, this repair guide helps restore holding strength: how to fix a stripped screw hole in wood.

“The screw snaps or stalls”

Snapped screws come from high torque in dense wood, insufficient pilot holes, or a screw that isn’t designed for the load. Stalling often points to a driver setting that pushes too much torque too early.

Wood-level fixes:

- Drill a pilot hole sized for the core of the screw in hardwood.

- Increase pilot depth for long screws.

- Use a construction-grade screw for structural work instead of a light-duty wood screw.

“The head sinks too deep”

Overdriving crushes fibers and reduces clamping strength, especially in softwoods and plywood faces. Depth control fixes it.

- Set the drill clutch to stop at flush.

- Slow down for the last 3 to 5 turns.

- Use a countersink when you want the head flush without surface bruising.

When a screw head is already damaged and needs removal, these two guides cover the common shop methods: how to remove a stripped screw from wood without tearing the surface and how to get a broken screw out of wood.

Torx vs Phillips vs Pozidriv for woodworking

Phillips drives slip out under higher torque because the angled surfaces push the bit upward as torque rises, which drives cam-out. Torx drives reduce that behavior by keeping more contact surface engaged in the recess.

Pozidriv improves on Phillips in many applications, but Torx stays popular in woodworking because it pairs well with modern drill/drivers and impact drivers. The practical difference in the shop is simple: Torx heads survive repeated driving and removal with less damage.

FAQs on Torx Wood Screws

What does Torx (Hexlobe / T-STAR) mean on wood screws?

Torx means the screw has a 6-lobe star-shaped recess (also called hexlobe or T-STAR) that a matching bit locks into, giving better grip and cleaner torque transfer.

Are Torx (star drive) screws better than Phillips for woodworking?

Most of the time, yes. Torx bits stay seated and slip less, so you strip fewer heads and drive faster, especially in hardwood, long screws, and repetitive installs like cabinets or decking.

What Torx bit size do most wood screws use?

T15, T20, and T25 are the common ones, with T25 showing up a lot on deck and construction screws. Always match the box label and test-fit so the bit seats snug.

Can I use Torx wood screws for decking and outdoor projects?

Yes, as long as the screw is rated for exterior use. Choose a corrosion-resistant coating or stainless steel, and match the screw style to decking, like bugle heads for clean seating.

Do I need to pre-drill holes for Torx wood screws?

Sometimes. Pre-drill in hardwood, near board ends, or when splitting is likely. In softer lumber many Torx construction screws drive fine without pilots, but a pilot improves accuracy.

What to Remember

Torx wood screws deliver reliable bit grip, steady torque transfer, and fewer stripped heads during installation. Good results come from matching the Torx bit size, picking a head style that fits the surface, and choosing a coating that fits the environment. Drive straight, control the last few turns, and use pilot holes in dense wood to protect the workpiece and the fastener.