Plywood Sheet Sizes, Standard Dimensions, and Square Footage

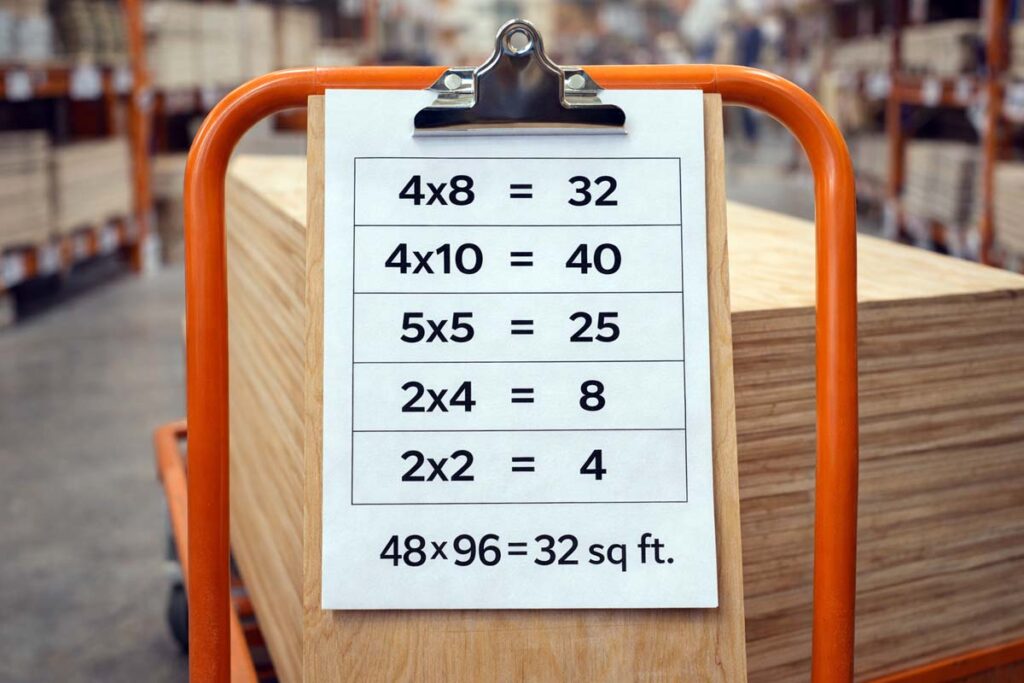

Plywood sheet sizes answer one core question fast: most plywood in U.S. lumberyards and big-box stores sells as a 4 ft × 8 ft sheet, and that sheet covers 32 square feet. Builders also buy 4×10 and 5×5 sheets, plus smaller “project panels” for shelves, trays, and quick repairs. The only catch is that plywood can be nominal (sold by the name size) while the measured size varies slightly by manufacturer. This guide lays out the common sizes, the square-foot math, and what “a piece” usually means in the store.

Contents Here

- 1 Standard sheet sizes you’ll see at most stores

- 2 How big is a piece of plywood?

- 3 What size are sheets of plywood?

- 4 What are the standard dimensions of a sheet of plywood?

- 5 How many square feet is a sheet of plywood?

- 6 Square footage math

- 7 Quick reference table: sheet size to square feet

- 8 Why plywood sizes vary

- 9 Buying tips: full sheet vs project panel

- 10 FAQs about Plywood Sheet Sizes

- 11 Final Remarks

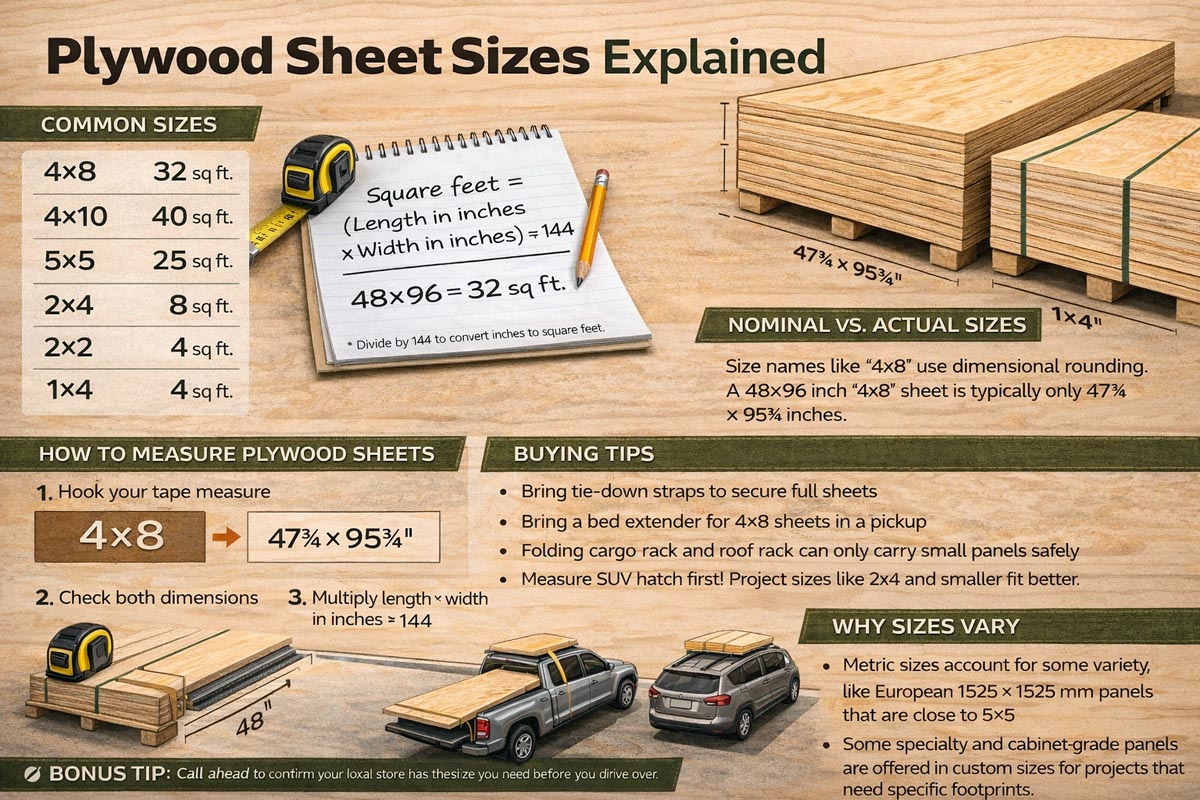

Standard sheet sizes you’ll see at most stores

Most retailers stock a mix of full sheets and smaller panels. These are the sizes I see most often in the aisle:

- 4×8 (48 in × 96 in): the default “full sheet” for walls, floors, cabinets, and furniture parts

- 4×10 (48 in × 120 in): longer runs for fewer seams (some yards stock it more than big-box stores)

- 5×5 (60 in × 60 in): common for Baltic birch-style panels and some specialty plywood lines

- 2×4 (24 in × 48 in) and 2×2 (24 in × 24 in): typical “project panel” sizes for small builds

Thickness is a separate topic, but it affects how a sheet feels and travels. A 3/4-in panel handles differently than 1/4-in, even when the length and width match. See more on what thickness plywood for cabinets.

How big is a piece of plywood?

Most people mean a full sheet, usually 4 feet by 8 feet. In stores, “piece” can also mean a pre-cut project panel like 2×4 or a custom cut from a full sheet. In the store, “piece” can also mean:

- A cut panel the store ripped from a full sheet

- A project panel sold pre-cut (2×4, 2×2, 1×4, and similar)

- An offcut from the cull or discount rack

If you’re ordering for a cut list, say “full 4×8 sheet” or say the exact cut size in inches. That prevents mix-ups at the saw. See more on plywood size for cabinets.

What size are sheets of plywood?

The most common sheet is 4×8, but you’ll also see 4×10, 5×5, and smaller project panels like 2×4 and 2×2. Stock varies by store and plywood type. Sheets of plywood come in full sheets and project panels.

Full sheets usually follow building layout conventions. That’s why 4×8 dominates: it pairs well with 16-in and 24-in framing layouts and standard construction modules.

Project panels target DIY use. Stores sell them because a lot of cars and small shops cannot move a full 4×8 safely.

One more note: some plywood lines sell nominal sizes (labeled 4×8) but measure slightly under in real life due to trimming and squaring. Measure the sheet you plan to build from if tight joinery matters.

If you’re building kitchen boxes or built-ins, cabinet grade plywood is usually worth the upgrade because it’s flatter, cleaner on the face, and easier to finish without fighting knots and patches.

What are the standard dimensions of a sheet of plywood?

“Standard” usually means 4×8 for construction and many hardwood panels, with 4×10 and 5×5 also common. Exact measured size can run slightly under the labeled size. In plain terms, “standard” depends on what you build and where you buy:

- Construction plywood most often sells as 4×8 and sometimes 4×10.

- Hardwood plywood (cabinet-grade faces like birch, maple, oak) still commonly sells as 4×8, with more variation by brand.

- Baltic birch-style panels often show up as 5×5.

If your project needs repeatable sizing, use a tape measure on the stack and read the edge stamp or product tag. Retailers sometimes stock multiple brands with slightly different real sizes.

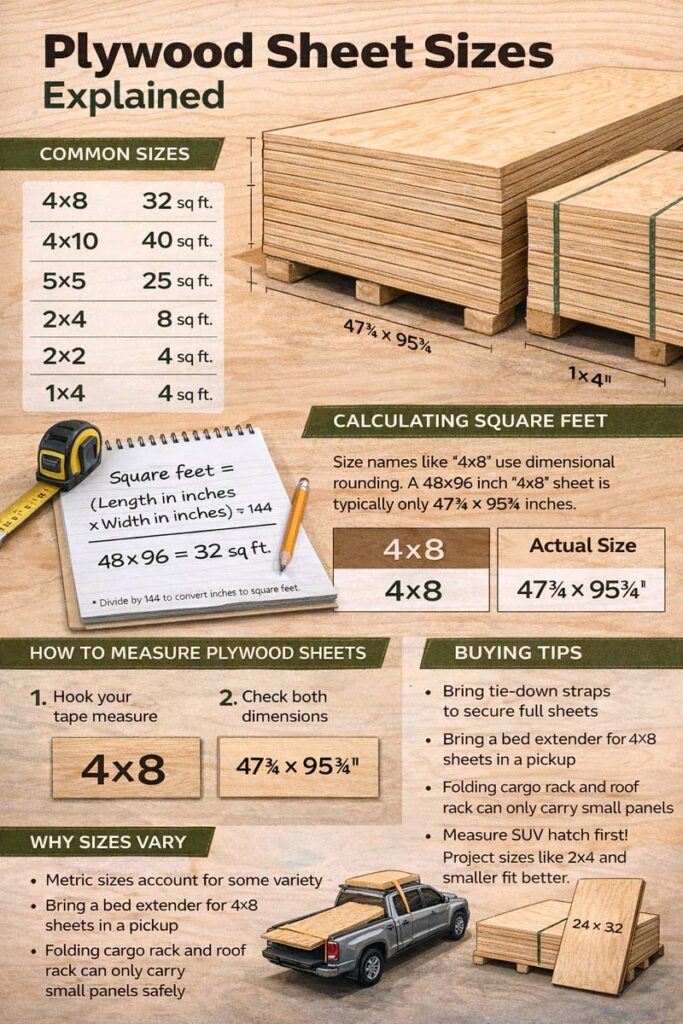

How many square feet is a sheet of plywood?

Square feet depend on the sheet size. A 4×8 sheet is 32 square feet, a 4×10 is 40, and a 5×5 is 25. Multiply length by width in feet to confirm. Square footage equals length × width, measured in feet.

A few common examples:

- 4×8 = 4 × 8 = 32 sq ft

- 4×10 = 4 × 10 = 40 sq ft

- 5×5 = 5 × 5 = 25 sq ft

- 2×4 = 2 × 4 = 8 sq ft

That’s the number you use for coverage, budgeting, and figuring waste.

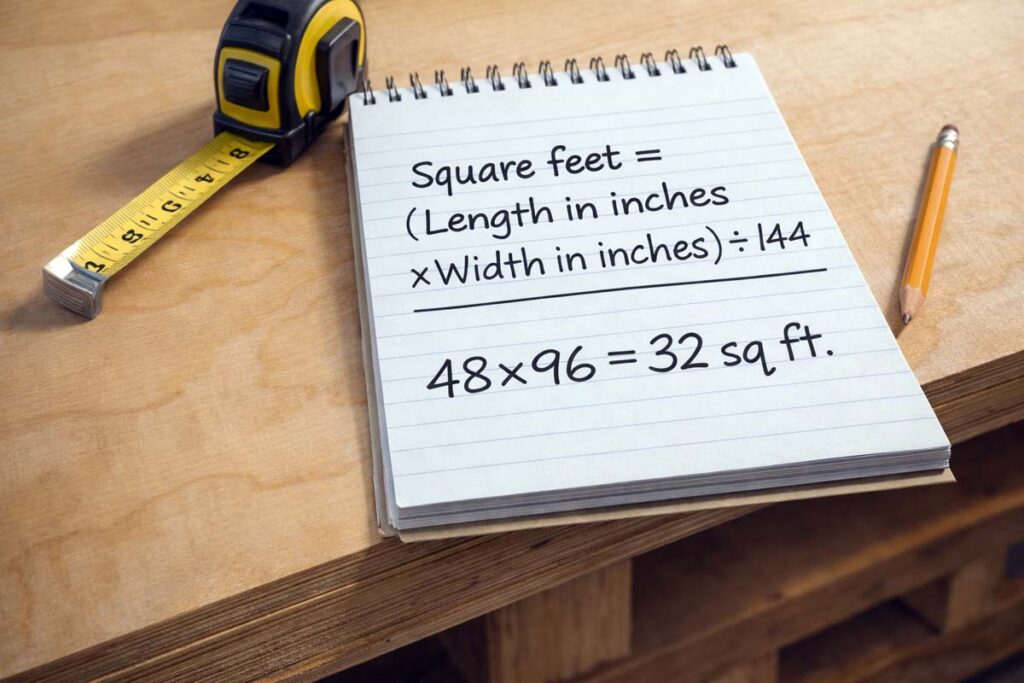

Square footage math

If you measure in inches, use this shop-friendly formula:

Square feet = (Length in inches × Width in inches) ÷ 144

Why 144? Because 12 inches × 12 inches = 144 square inches per square foot.

Example: a 48 in × 96 in sheet

48 × 96 = 4608

4608 ÷ 144 = 32 sq ft

Quick reference table: sheet size to square feet

| Sheet size (ft) | Size (in) | Square feet |

|---|---|---|

| 4×8 | 48×96 | 32 |

| 4×10 | 48×120 | 40 |

| 5×5 | 60×60 | 25 |

| 2×8 | 24×96 | 16 |

| 2×4 | 24×48 | 8 |

| 2×2 | 24×24 | 4 |

| 1×4 | 12×48 | 4 |

| 1×2 | 12×24 | 2 |

Use the table for quick estimating, then confirm the label if you need tight layouts.

How to measure a sheet in the store:

Put your tape hook on one factory corner. Measure width across the short side, then measure length along the long side. Check both ends. If the sheet is out of square or has corner damage, the two diagonal readings will not match.

Why plywood sizes vary

Plywood sizes vary for practical reasons tied to how mills produce and how stores sell panels.

Specialty panels: Some plywood targets specific uses, like underlayment, wall sheathing, or drawer stock. Manufacturers sometimes choose dimensions that reduce seams or match common layouts.

Import panels: Imported plywood often follows metric production standards, then gets marketed in approximate imperial sizes. The label might round to a familiar name size.

Shop panels: Hardwood dealers and cabinet shops sometimes stock sizes that match common casework breakdown patterns, including 5×5 or oversized sheets in certain product lines.

Project panels: Retailers cut full sheets into smaller rectangles because customers want easier transport and fewer big saw operations at home.

Buying tips: full sheet vs project panel

A full sheet costs less per square foot in most cases, but it asks more from your vehicle, storage, and cutting setup.

Choose a full sheet when:

- You need large, continuous parts like cabinet sides, backs, or long shelves.

- You want the best cost per square foot and can break it down safely.

- You can transport 8-foot material flat and supported.

Choose a project panel when:

- You only need small parts and want less waste.

- You work alone and want easier handling.

- You need a quick replacement panel and don’t want to wrestle a full sheet.

Transport and handling tips that keep you out of trouble:

- Support sheets along their length to prevent cracking and face damage.

- Strap loads tight, but avoid crushing corners.

- If you cut at home, break down sheets with a track saw or a straightedge guide and a circular saw, then move to the table saw for final sizing.

If you plan to glue plywood parts, match your adhesive to the job and read clamp time guidance. This guide helps: choosing wood glue that bonds plywood well.

FAQs about Plywood Sheet Sizes

Is plywood always 4×8?

No. 4×8 is the most common, but stores also stock 4×10, 5×5, and project panels like 2×4 and 2×2. Specialty and import plywood adds more variation.

What size is a sheet of plywood?

Most sheets are 4 ft × 8 ft, which is the standard size in many stores. You’ll also find 4×10 and 5×5, plus smaller project panels like 2×4 for easier transport.

Do stores cut plywood?

Many big-box stores cut plywood, but the service varies by location and staffing. Ask for rough breakdown cuts for transport, then do final sizing at home for clean, accurate edges.

Is a 4×8 sheet exactly 48 inches by 96 inches?

Not always. A sheet is often sold as 4×8, but the measured size can vary slightly by manufacturer and product line. Measure the actual panel if your joinery or layout needs tight tolerances.

How many square feet are in half a sheet of plywood?

Half of a 4×8 sheet equals 16 square feet (because 32 ÷ 2 = 16). A common “half-sheet” panel size is 2×8.

Final Remarks

Plywood sheet sizes stay simple once you anchor on the basics: 4×8 covers 32 square feet, 4×10 covers 40, and 5×5 covers 25. After that, the job is matching the sheet to your cut plan, your vehicle, and how you prefer to break down panels. Measure the stack when precision matters, use the inches-to-square-feet formula when you’re working from a tape, and lean on project panels when handling and waste matter more than cost per square foot.