MDF vs Birch Plywood: Way to Pick the Right Sheet for Furniture

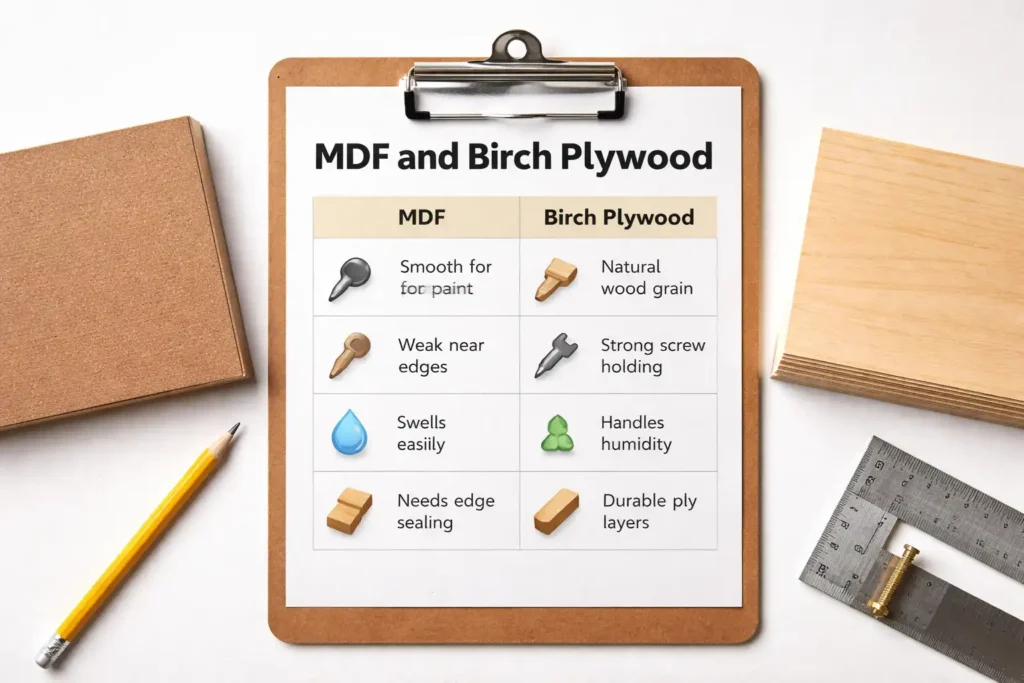

MDF vs birch plywood comes down to surface, strength, and where the project lives. MDF gives a flat, paint-ready face with no grain to telegraph, so it suits smooth painted panels and routed details. Birch plywood holds screws and edges better and takes abuse in cabinets, shelves, and shop builds. In this guide I break down what each sheet is, when each one wins, and how to build so the weak spots do not bite you.

Choose MDF for the smoothest painted panels in dry rooms. Choose birch plywood for cabinets, shelves, and parts that rely on screws and durable edges. Skip MDF in damp locations unless you seal every cut edge, and skip low-grade birch plywood where core voids and thin face veneers will show.

| If you care most about… | Pick | What tips the scale |

|---|---|---|

| Paint-smooth faces | MDF | No grain, uniform density |

| Screw holding and hinges | Birch plywood | Veneers resist stripping near edges |

| Durable edges | Birch plywood | Plies take bumps better than fiber edges |

| Flat panels for laminate | MDF | Stays flat when supported and sealed |

| Humidity tolerance | Birch plywood | Cross-laminated layers handle swings better |

What is MDF, and what is birch plywood?

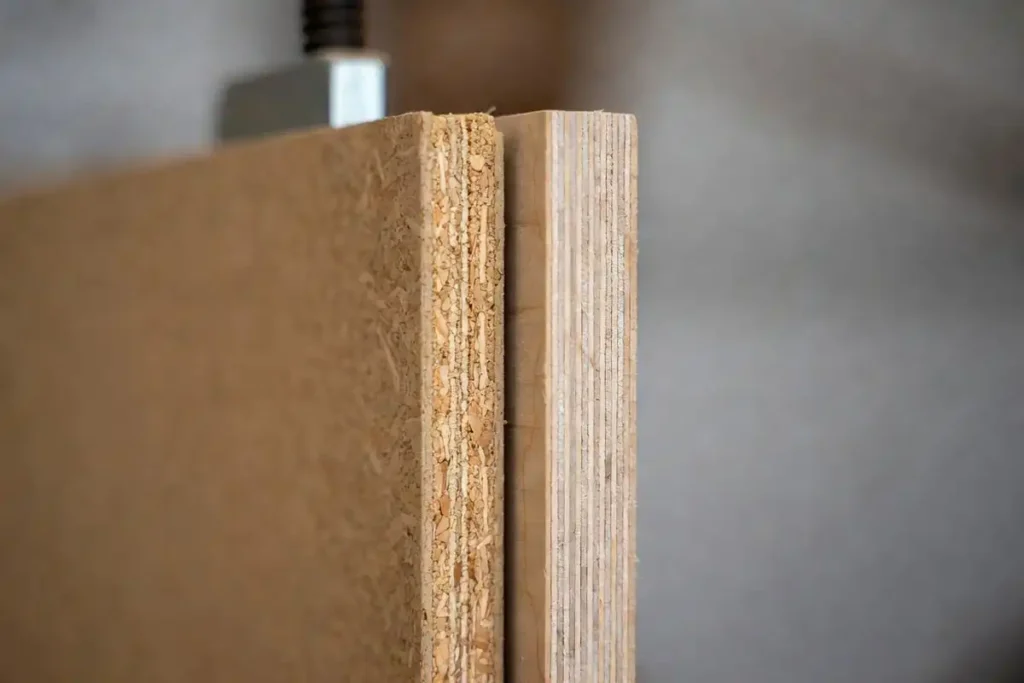

MDF is a fiberboard panel made from wood fibers and resin pressed into a dense, uniform sheet. Birch plywood is a layered panel made from thin veneers, with birch on the face and a cross-laminated core that resists warping.

MDF behaves like a consistent block. It routs cleanly on the face, but its edges are porous and crush under hard fasteners.

Birch plywood behaves like stacked grain directions. It holds screws and staples well, but the face veneer is thin and sands through fast.

What you are buying at the store

MDF is sold as standard MDF and moisture-resistant MDF. Moisture-resistant MDF slows swelling, but cut edges still need sealing around sinks, basements, and garages.

Birch plywood shows up as “birch,” “cabinet grade,” and “Baltic birch.” Some panels use a birch face on a mixed hardwood core, and core quality decides how clean the edges look.

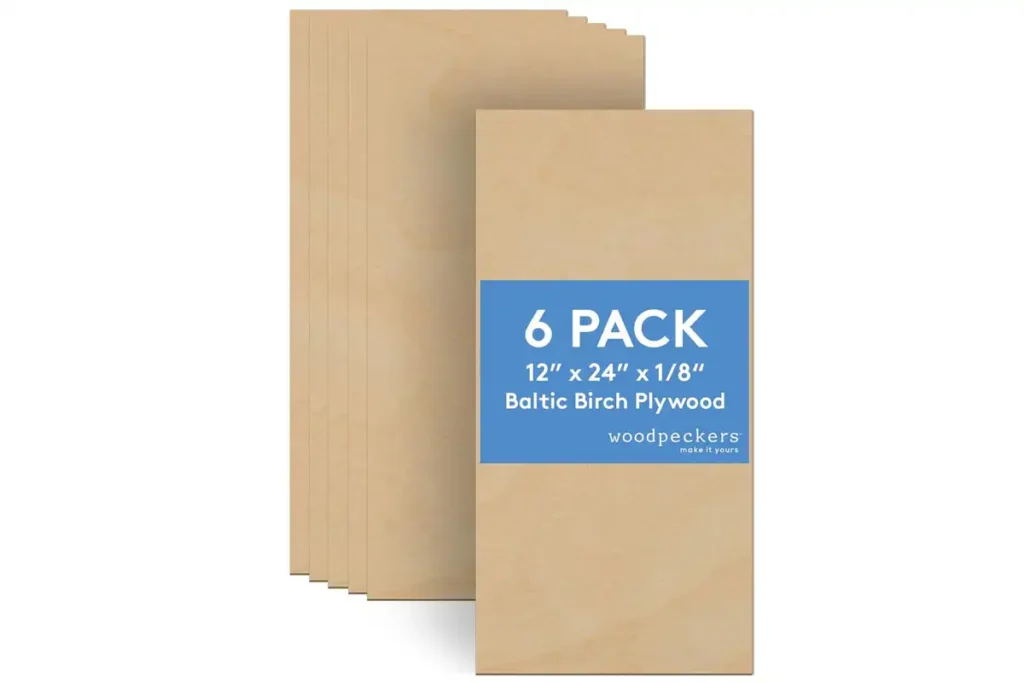

Baltic birch often comes in 5×5 sheets and uses a multi-ply core. Big-box “birch plywood” often comes in 4×8 sheets and varies more by brand and mill run.

When does MDF beat birch plywood, and when does birch win?

MDF wins when a project needs a dead-flat, paint-smooth surface. Birch plywood wins when the build needs screw holding, impact resistance, and panels that are easier to move and hang.

If you are sorting plywood grades for cabinetry, my cabinet-grade plywood overview helps you decode faces, cores, and what “grade” means on real parts.

If you are building with birch faces, my Baltic birch primer explains why the multi-ply core and void control matter for drawers, jigs, and exposed edges.

Choose MDF for these jobs

MDF fits projects where paint and machining matter more than screw strength.

- Painted cabinet doors and drawer fronts (flat or with applied molding)

- Routed profiles, flutes, and shallow relief work

- Built-in panels and paint-grade trim parts

- Speaker boxes and shop jigs that stay dry

- Laminate tops where the substrate needs to stay flat

Choose birch plywood for these jobs

Birch plywood fits projects that carry load, hold hardware, or take bumps.

- Cabinet boxes, toe kicks, and stretchers

- Shelves and bookcases that span distance

- Drawer boxes, trays, and shop storage

- Workbenches and utility fixtures

- Any part that needs strong screws near an edge

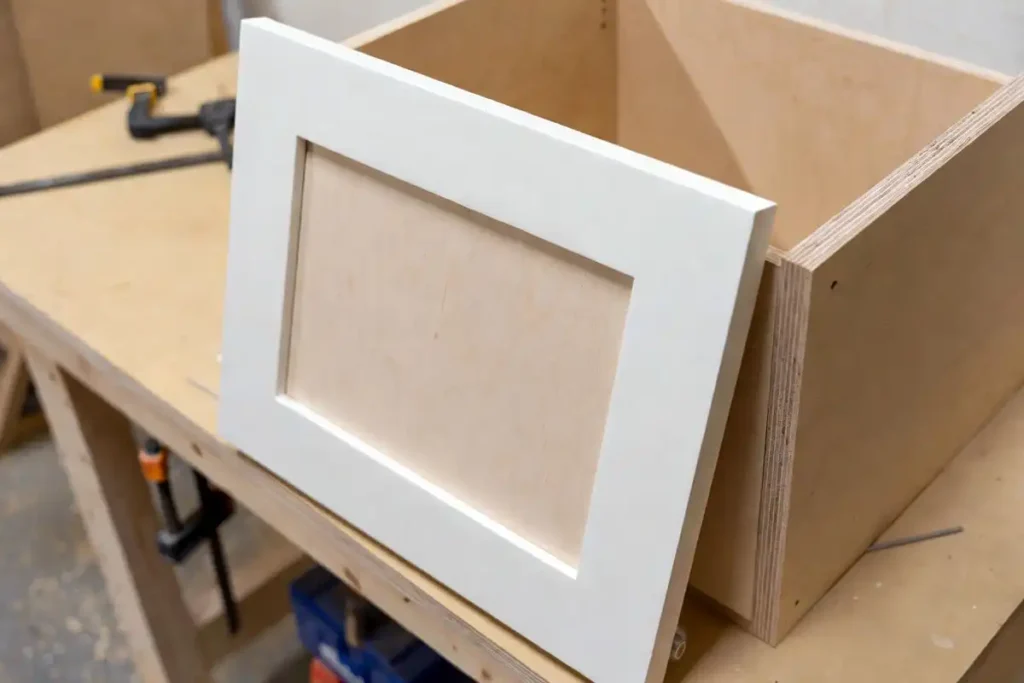

A common “best of both” approach

Many cabinet shops pair birch plywood boxes with MDF doors and drawer fronts. The plywood carries hinges and loads, and the MDF delivers smooth paint on the visible faces.

Where does each sheet belong in a project?

MDF belongs in dry, conditioned spaces and in parts that stay supported. Birch plywood belongs where humidity, impacts, and fasteners do the work.

Dry rooms, painted furniture, and wall panels

MDF excels on broad painted faces. The lack of grain makes finishing predictable, and routed details stay crisp.

Kitchens, mudrooms, garages, and basements

Birch plywood handles seasonal moisture swings better than MDF. It still needs finished faces and sealed edges, but it does not swell through a cut edge as quickly.

Outdoor or wet exposure

Neither MDF nor interior birch plywood is a good outdoor panel. For exterior work, use exterior-rated plywood or a weatherproof sheet made for that use.

Shelves and spans

Birch plywood generally sags less than MDF at the same thickness because the veneers act like a beam. MDF shelves hold up when you shorten spans, add a front stiffener, or build a torsion box.

How do you choose between MDF and birch plywood?

Choose the sheet by walking through the job in order: environment, joinery, fasteners, finish, and edges.

- Start with the room. Dry, heated interiors favor MDF. Damp, unconditioned, or splash zones favor birch plywood.

- Decide how the part carries load. Long shelves, cabinet sides, and work surfaces favor plywood.

- Choose the main fastener. Screws, hinges, and pocket-hole joinery favor plywood. Captured panels and large glue surfaces favor MDF.

- Plan the edges. Exposed edges favor birch plywood, or MDF with edge banding plus edge sealing.

- Pick the finish. Painted, dead-smooth faces favor MDF. Clear finishes that highlight grain favor birch plywood.

- Account for tool wear and handling. MDF dulls cutters faster and feels heavier in full sheets, so plan support and sharp tooling.

- Match thickness to the job. Use a thickness that supports the span and hardware. My complete plywood thickness guide helps when you are choosing panels for cabinets, shelves, and backs.

Common starting points in the shop:

- 3/4-inch birch plywood for cabinet sides, bottoms, and fixed shelves

- 1/2-inch birch plywood for drawer parts and lighter shelves

- 1/4-inch plywood for backs and drawer bottoms

- 3/4-inch MDF for paint-grade doors, panels, and built-ins

What solutions make each material work better?

Joinery, edge work, and the right fasteners turn “good enough” sheet goods into reliable builds.

Make MDF stronger at edges and screws

MDF edges drink finish and compress under hardware. These fixes tighten it up.

- Seal edges before paint with shellac, sanding sealer, or a thin glue size, then sand smooth

- Use dadoes, rabbets, and full-length glue surfaces instead of relying on butt-joint screws

- Use fasteners made for composites, such as confirmat screws, when a joint relies on screws

- Add solid wood edging where shelves take abuse

If glue is part of the plan, my wood glue on MDF guide covers prep, clamp pressure, and the failure modes to watch.

Make birch plywood look cleaner and last longer

Birch plywood rewards clean cuts and light sanding.

- Use a sharp, high-tooth-count blade and support the exit side to prevent tearout

- Use a zero-clearance insert or backer board on crosscuts

- Ease edges lightly and avoid aggressive sanding on the face veneer

- Cover raw edges with iron-on banding, hardwood edging, or a veneer edge strip

- Seal edges before paint so primer does not sink in

How do you troubleshoot MDF and birch plywood problems?

Most failures come from moisture, fasteners, or edges. Fix the cause first, then repair the surface.

MDF swells, mushrooms, or turns fuzzy on edges

Swelling points to water exposure or unsealed cuts. Dry the part, trim back damaged fibers, and seal with shellac or a glue size before repainting. In wet zones, replace the part with plywood or moisture-resistant MDF and seal every edge.

MDF screw joints strip out

Stripped holes point to short screws, thin material, or overdriving. Move the screw to fresh material, use a longer fastener, or switch to a joint that captures the panel in a dado. Threaded inserts also help in thicker MDF.

Birch plywood chips on the face veneer

Chips point to dull tooling or cutting without support. Score cut lines, keep the good face oriented for the cut, and use sharp blades. For small chips, fill, sand lightly, and refinish.

Birch plywood shows core voids on an exposed edge

Voids point to panel grade and core type. Edge banding hides minor voids. For exposed edges, buy panels with better core construction, or use Baltic birch where the ply stack is consistent.

Shelves sag over time

Sag points to long spans or thin panels. Add a front stiffener, move to thicker stock, shorten the span with a divider, or switch to plywood with a stronger face-to-core structure.

What mistakes ruin MDF or birch plywood builds?

These missteps create most of the complaints I hear in the shop.

- Buying the cheapest “birch” panel and expecting clean, void-free edges

- Skipping edge sealing on MDF before primer and paint

- Using drywall screws for cabinets instead of cabinet or composite-rated fasteners

- Sanding birch plywood faces like solid wood and burning through the veneer

- Leaving sheet goods unsealed in a garage or basement

- Relying on butt joints without dados or glue surface

What safety rules matter with MDF and plywood dust?

Dust control matters with both materials, and MDF dust feels finer and more irritating.

Wear a properly fitted respirator, run dust collection at the source, and keep a clean filter in the shop vacuum. Use sharp blades and bits so the saw does not labor and throw more dust. Support full sheets with outfeed tables or helpers, because sheet goods tip and bind fast when they shift.

When you buy panels, look for products labeled to meet low-emission standards such as TSCA Title VI or CARB Phase 2, especially for indoor furniture and cabinets.

Final Words: which one should you buy?

MDF vs birch plywood has a clear pattern in real projects. MDF excels as a smooth, paint-grade panel in dry rooms, especially when you seal edges and build with dados and glue surfaces. Birch plywood earns its keep in cabinets, shelves, and shop builds where screws, edges, and daily knocks matter. If the project sees moisture or heavy loads, birch plywood is the safer default.