Is 1/2 Plywood Good for Cabinets? 7 Tough Truths & Fixes

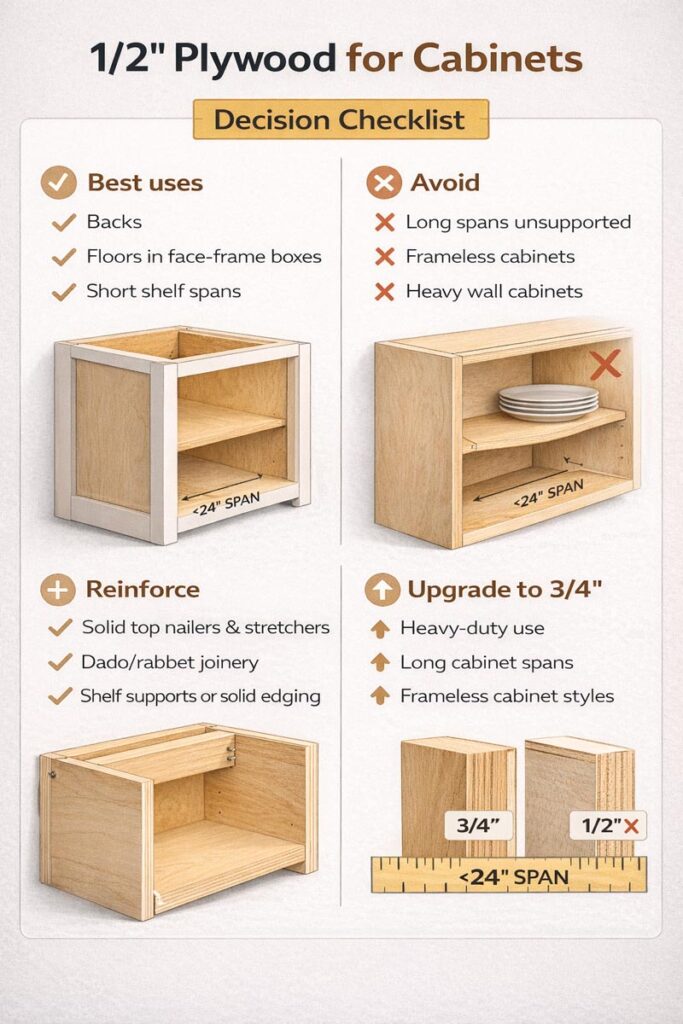

1/2 plywood is good for cabinets when it’s used in supported parts (like backs and framed boxes) and reinforced with solid joinery, but it’s a poor choice for long shelves, frameless cases, or heavy wall cabinets without upgrades.

A well-braced face-frame cabinet, a captured back panel, and short shelf spans let 1/2-inch panels work reliably. Frameless boxes, wide drawers, long shelves, and heavy wall-hung loads push 1/2-inch material into flex and fastener trouble. This guide breaks down where 1/2 plywood performs well, where it fails, and how to design cabinets so they stay square, stay tight, and stay safe.

Contents Here

- 1 Is 1/2 plywood good for cabinets?

- 2 What “1/2-inch plywood” means at the lumber rack

- 3 Where 1/2 plywood works well in cabinet construction

- 4 Where 1/2 plywood causes problems

- 5 Shelf sag: what the numbers say about 1/2 plywood

- 6 How to make 1/2 plywood cabinets behave like thicker material

- 7 Fasteners and screw holding: what matters with 1/2 plywood

- 8 Wall cabinets: when 1/2 plywood is acceptable

- 9 What plywood type to choose for cabinets

- 10 When 3/4 plywood is the better cabinet decision

- 11 Buying checklist for 1/2 plywood meant for cabinets

- 12 FAQs about 1/2 Plywood for Cabinets

- 13 Bottom line

Is 1/2 plywood good for cabinets?

1/2-inch plywood works for cabinet backs, drawer bottoms, partitions, and some light-duty cabinet boxes. It struggles in frameless construction, long shelves, and heavy wall cabinets because it bends sooner and gives screws less bite in the edge. Build success comes from matching thickness to the cabinet part, the span, the load, and the joinery.

What “1/2-inch plywood” means at the lumber rack

Sheet goods rarely measure a true 0.500 inches. Many “1/2-inch” panels land closer to a performance category like 15/32 (0.469″) or a labeled 1/2 category depending on the standard and mill run. APA lists both 15/32 and 1/2 as distinct panel performance categories, which is your hint that “half-inch” is a bucket, not a guarantee.

That thickness difference matters when you’re setting dado depth, choosing hinge screws, or counting on stiffness.

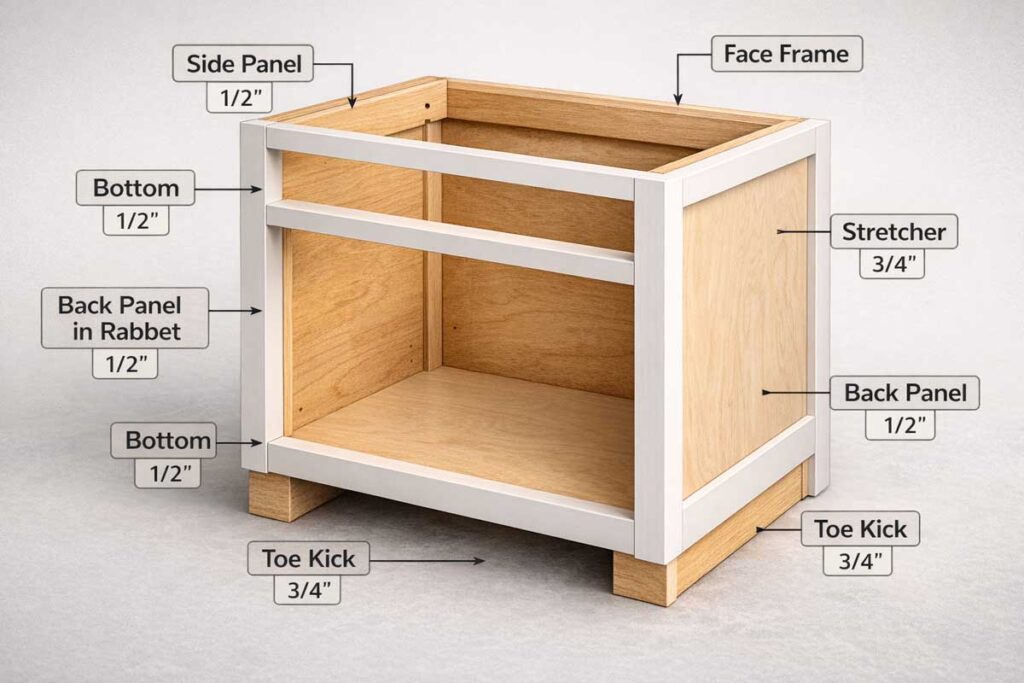

Where 1/2 plywood works well in cabinet construction

I reach for 1/2-inch plywood when the part gets support from surrounding structure or when the panel mainly closes a box.

- Cabinet backs captured in dados/rabbets (especially when the back helps resist racking)

- Toe-kick skins and end panels where the frame carries the load

- Vertical partitions inside a larger cabinet that get support at the top and bottom

- Drawer bottoms when the bottom sits in a groove and the drawer stays shallow

- Web frames and stretchers (rails that keep a cabinet square under a top)

These uses lean on geometry and joinery, not raw thickness.

Where 1/2 plywood causes problems

1/2-inch plywood usually disappoints in spots where the panel must stay stiff on its own or hold hardware in its edge.

- Frameless (European) cabinet boxes: the box sides carry racking forces and hinge/slide screws land close to edges.

- Long shelves: dishes and food load a shelf for years, not minutes.

- Wide base cabinets: a 30–36″ box wants to rack unless the back and top structure are stout.

- Wall cabinets with heavy contents: the hanging system demands strong screw holding and low flex at the rail.

The failures show up as doors that stop lining up, shelves that sag, and boxes that go out of square.

See more: What Size Plywood for Cabinets: 5 Simple Sizes That Work Every Time

Shelf sag: what the numbers say about 1/2 plywood

Sag is the complaint that brings most people to thicker material.

APA’s Load-Span Tables give a useful reality check. For Group 1 sanded plywood at 1/2-inch thickness, 24-inch spans under a deflection limit of L/360 show an allowable uniform load of 61 psf (Table 3).

Translate that to a cabinet shelf and you’ll see why span matters:

- A 24″ × 12″ shelf has 2 square feet of area.

- 61 psf × 2 sq ft = 122 lb of evenly distributed load in that table’s test setup.

Two important shop-floor realities still apply:

- Cabinet shelves often act as single spans, not multi-span panel conditions.

- Cabinets see long-term loading (creep), plus point loads (stacks of plates) that spike sag.

In practice, 1/2-inch plywood shelves behave best when you keep spans short or add a stiff front edge.

Read more: Are Plywood Cabinets Good? 7 Tough Checks Before You Buy

How to make 1/2 plywood cabinets behave like thicker material

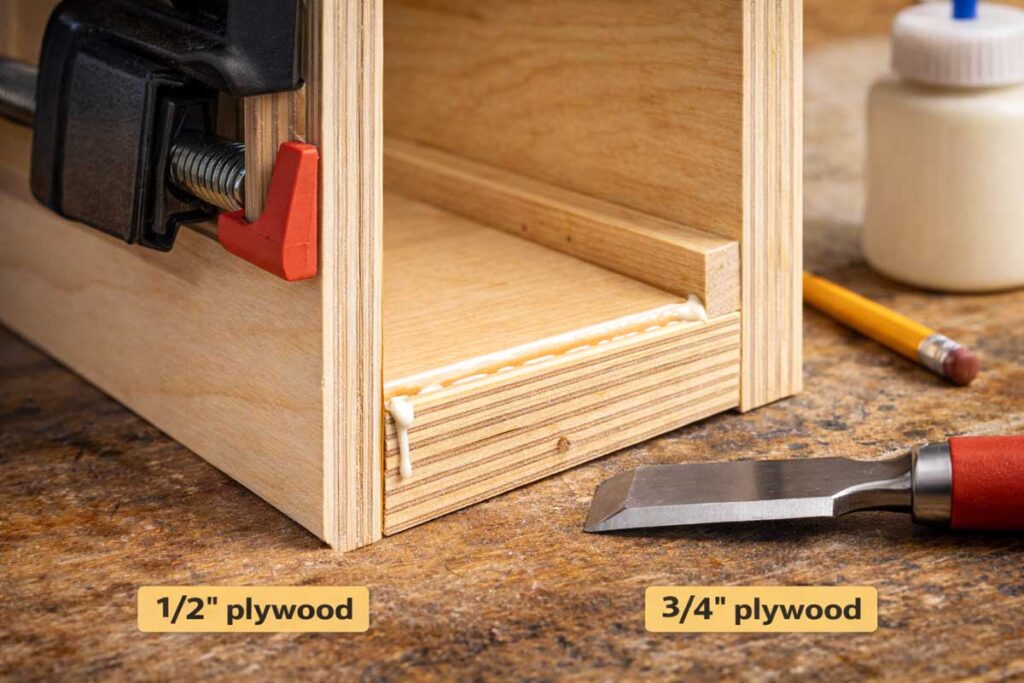

If you want 1/2-inch boxes to last, build them like a torsion structure: capture panels, lock corners, and make the back do real work.

Use joinery that carries load without relying on edge screws

A glued dado or rabbet turns a weak edge into a strong joint because the glue line carries shear across a wide surface.

Good options include:

- Dados for bottoms and fixed shelves

- Rabbets at the cabinet back

- Lock rabbets at corners when you want fast assembly plus alignment

Pocket screws alone put too much faith in the edge plies unless the joint also has glue and mechanical registration.

Let the back panel prevent racking

A thin back stapled on can close the box, but it won’t stop twist like a captured back.

A back that resists racking has these traits:

- It sits in a rabbet/dado on all sides

- It bonds with glue (not only fasteners)

- It ties into the top and bottom, not floating behind them

Add stiffness where shelves need it

A hardwood nosing (or a properly glued-on plywood lipping) increases stiffness at the front edge, where sag shows first. The stiffener works because it increases the section depth at the edge, similar to how an I-beam gains rigidity from its flanges.

Fasteners and screw holding: what matters with 1/2 plywood

Cabinet failures often start at the fasteners, not the panel.

The American Wood Council’s NDS gives a clear point many cabinet builders learn the hard way: wood screws don’t hold withdrawal load in end grain (it assigns an end-grain factor of 0.0 for withdrawal).

Plywood edges behave more like “bad grain direction” than solid side grain, especially with voids or thin core veneers. That’s why these habits pay off with 1/2-inch material:

- Pre-drill near edges to prevent splitting plies.

- Increase bearing area with glue blocks, corner blocks, or a face frame.

- Choose hardware that spreads load, like a full-length hanging rail or French cleat for wall cabinets.

- Avoid short screws into the edge for hinges and slides when you can land screws into a face frame or a thicker rail.

Wall cabinets: when 1/2 plywood is acceptable

A wall cabinet succeeds or fails at the hanger line. If you build a 1/2-inch wall box, treat the hanger as a structural member.

A reliable setup uses:

- A continuous hanging rail (often thicker stock than the cabinet side)

- Stud-fastened cabinet screws, not drywall screws

- A hanger design that puts screws into side-grain-like material, not the plywood edge

The NDS also provides an engineering withdrawal equation for wood screws (reference withdrawal per inch of thread penetration depends on specific gravity and screw diameter). That’s the formal version of the shop truth: more penetration into better material holds better.

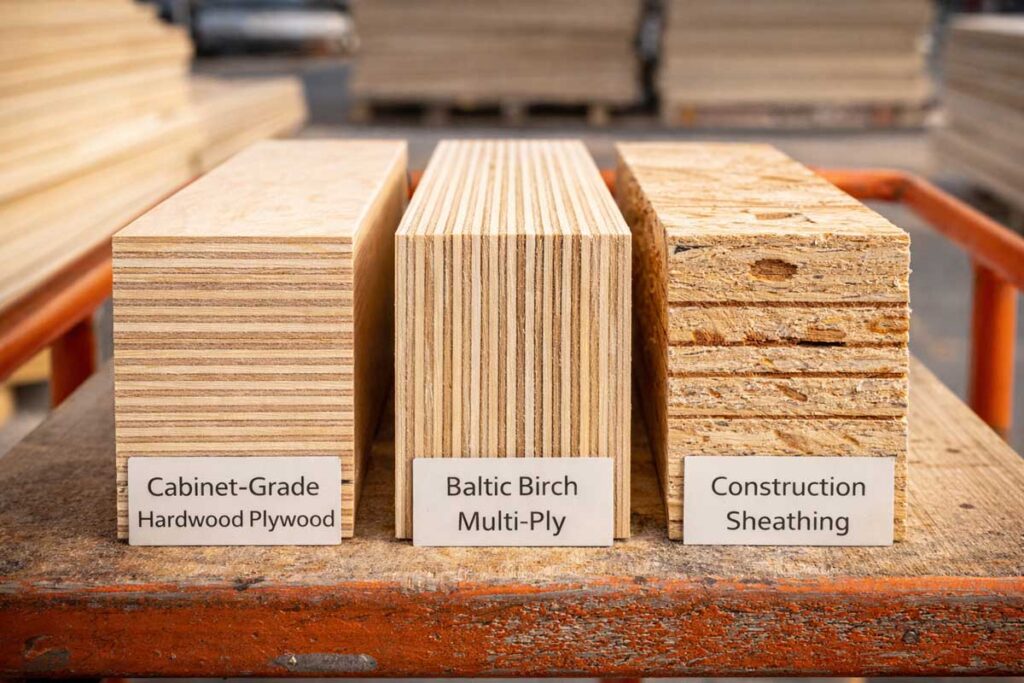

What plywood type to choose for cabinets

Not all plywood behaves the same at 1/2-inch thickness.

- Hardwood “cabinet grade” plywood usually gives flatter panels and cleaner faces for finishing.

- Baltic birch-style multi-ply cores usually give better edges for joinery and fewer void surprises.

- Construction sheathing can work structurally, but it often brings voids, patches, and face defects that fight fine cabinet work.

APA notes plywood is used in many applications, including furniture, which is the broad category cabinets live in. Your job is picking a panel built for appearance and machining, not only structural rating.

When 3/4 plywood is the better cabinet decision

If you’re building a kitchen that gets used hard, 3/4-inch plywood usually buys you fewer callbacks and easier hardware installation.

I treat 3/4-inch as the smarter choice when:

- The cabinet is frameless

- Shelf spans exceed 24 inches without stiffeners

- The box is 30–36 inches wide

- The cabinet hangs on a wall and holds heavy dishes or small appliances

- You need strong, repeatable holding for hinges and slides

Buying checklist for 1/2 plywood meant for cabinets

Use this quick inspection at the store:

- Flat sheet with minimal twist (check both diagonals)

- Few visible voids on the edge

- Face veneer thickness that sands without burning through

- Core that machines cleanly (less tear-out in dados)

- Panel thickness that matches your dado setup (measure it)

FAQs about 1/2 Plywood for Cabinets

How much for 1/2 inch plywood?

In the U.S., a 4×8 sheet of 1/2-inch plywood often lands around $18–$75+ depending on grade. Home Depot examples range from about $17.88 to $72.58.

Is 1/2 plywood strong enough for kitchen cabinets?

Yes, if you build a face-frame box with a captured back and solid stretchers, 1/2 plywood holds up. For frameless cabinets or heavy wall units, 3/4 stays straighter.

Is 1/2 plywood OK for cabinet shelves?

It’s fine for shelves with short spans, especially with a hardwood nosing. APA load-span tables show 1/2-inch Group 1 plywood at a 24-inch span reaches 61 psf at L/360.

Can I use screws in the edge of 1/2 plywood for cabinet assembly?

You can, but don’t rely on edge screws—plywood edges strip easily. Use glued dados/rabbets, add blocking, or land screws in a face frame; NDS doesn’t assign design withdrawal strength to end-grain screw loading.

Bottom line

1/2 plywood is “good for cabinets” when it acts as a supported panel inside a well-joined structure. It becomes a problem when it must span, stay stiff, and hold hardware by itself. If you keep spans short, capture the back, use glue-friendly joinery, and reinforce hanging and shelf edges, 1/2-inch plywood can build clean, durable cabinets. For frameless kitchens and heavy-duty use, 3/4-inch plywood stays the more forgiving choice.