How Strong Is Wood Glue? 7 Proven Truths (PSI + Joint Tips)

How strong is wood glue is a shop question that deserves a real answer. Most modern wood glues are strong enough that, on a well-made joint, the wood breaks before the glue line does. The catch is that “strength” depends on the test, the joint, and your technique.

If you’ve ever popped a joint apart and felt betrayed by the bottle, don’t blame the label yet. Glue strength is half chemistry and half craftsmanship, and the craftsmanship part is the one you control.

Contents Here

- 1 What wood glue “strength” actually means

- 2 Typical PSI ranges and what they really tell you

- 3 In-the-shop strength is mostly joint design and grain direction

- 4 Clamp pressure and fit decide whether you get full strength

- 5 The big factors that change wood glue strength

- 6 Is wood glue stronger than screws or nails?

- 7 How to read a glue data sheet like a woodworker

- 8 FAQs on How Strong Is Wood Glue

- 9 Conclusion

What wood glue “strength” actually means

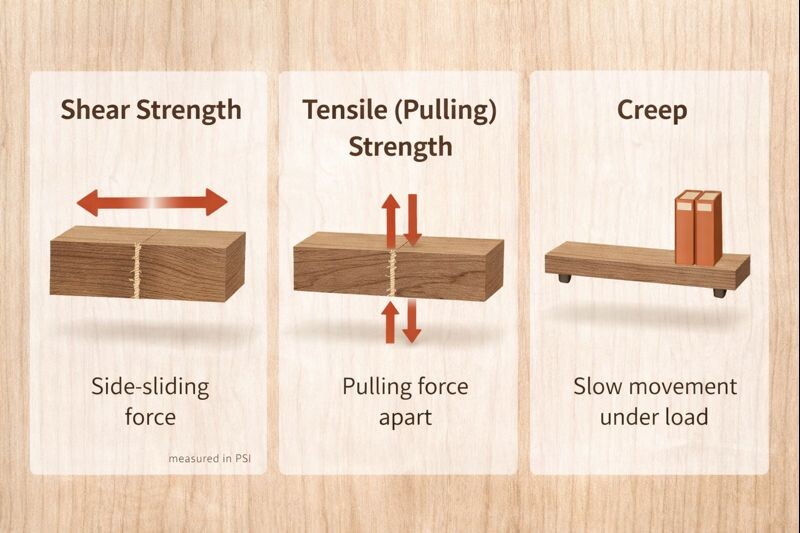

When people say a glue is “strong,” they usually mean it resists sliding forces. In lab terms, that’s shear strength, and it’s often reported in PSI. That number is useful, but it’s not the whole story.

A good glue joint can fail in two different ways:

- Wood failure: the fibers tear and the glue line stays intact.

- Glue-line failure: the bond lets go cleanly at the seam.

In woodworking, you’re aiming for wood failure on long-grain joints. If you’re getting glue-line failure, something about surface prep, fit, pressure, or timing is off.

Shear strength vs tensile strength vs creep

Shear strength covers most furniture stress, especially racking and side loading. Tensile strength is pulling straight apart, which happens less often in typical joinery. Then there’s creep, the slow movement of a joint under constant load.

Creep is why a shelf can sag over time even when nothing “breaks.” Some glues resist creep better than others, and joint design matters just as much.

Typical PSI ranges and what they really tell you

Most quality PVA wood glues land in a “very strong” band for wood-to-wood joints. You’ll commonly see reported shear strengths in the ballpark of 3,000–4,000 PSI on data sheets, depending on product and test conditions.

Here’s the practical translation in plain shop talk: if your joint faces are tight, clean, and clamped correctly, glue strength usually isn’t the limiting factor. The wood fibers and the joint geometry decide the outcome.

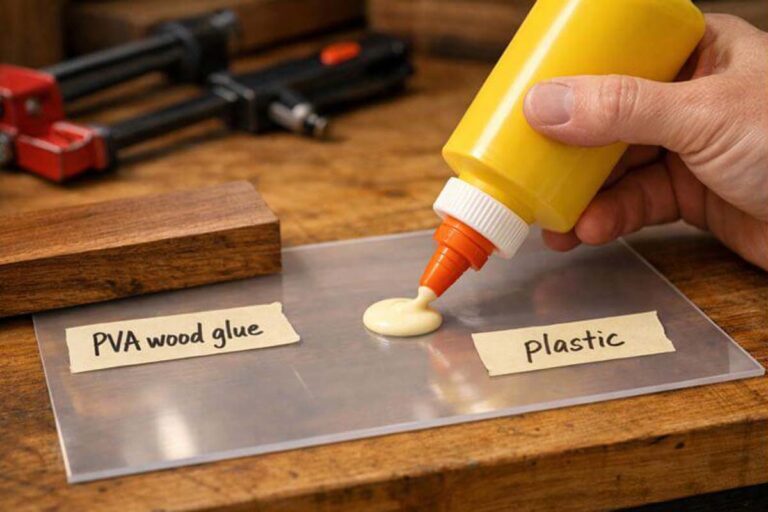

PVA (yellow and white carpenter’s glue)

PVA is the everyday workhorse because it’s predictable. It wets wood fibers well, it grabs reliably, and cleanup is simple. For interior furniture, a good yellow PVA is hard to beat when the joint fit is right.

If you’re still sorting out timing, it helps to understand the difference between “set,” “dry,” and “cured.” My breakdown on the moment a glue joint actually stops shifting clears up what those terms mean in real use.

Polyurethane glue

Polyurethane glue cures with moisture and can bond mixed materials well. It also expands as it cures, which is a blessing for odd gaps and a curse for tight joinery.

If you rely on the foam to “fill” a sloppy joint, you usually lose strength. Polyurethane is best when the parts still fit reasonably well, and you want water resistance or a tricky material bond.

Epoxy

Epoxy is the repair glue, the gap-filler, and the problem-solver. It can be incredibly strong, and it doesn’t need the same tight wood-to-wood contact that PVA prefers.

Epoxy shines on cracked parts, missing fibers, and mixed material bonds. If you’re choosing glue specifically for a fix, my guide on picking the right adhesive for furniture repairs that must last will point you toward the right category without guesswork.

Hide glue and other traditional glues

Hide glue is still respected for a reason. It can be plenty strong, it’s reversible with heat and moisture, and it behaves nicely in restorations. It’s not the best choice for wet environments, but it’s a smart choice when you want repairability later.

In-the-shop strength is mostly joint design and grain direction

Glue doesn’t create strength out of thin air. It ties together wood fibers that already have strength, and the grain direction decides how well that works.

Long grain bonds are where glue shines

Long grain to long grain is the sweet spot. The glue penetrates slightly, the fibers interlock with the adhesive, and the joint becomes one continuous structure.

Edge-glued panels, face laminations, and well-fitted joinery can be ridiculously strong. That’s why a properly glued tabletop can survive decades of seasonal movement and daily abuse.

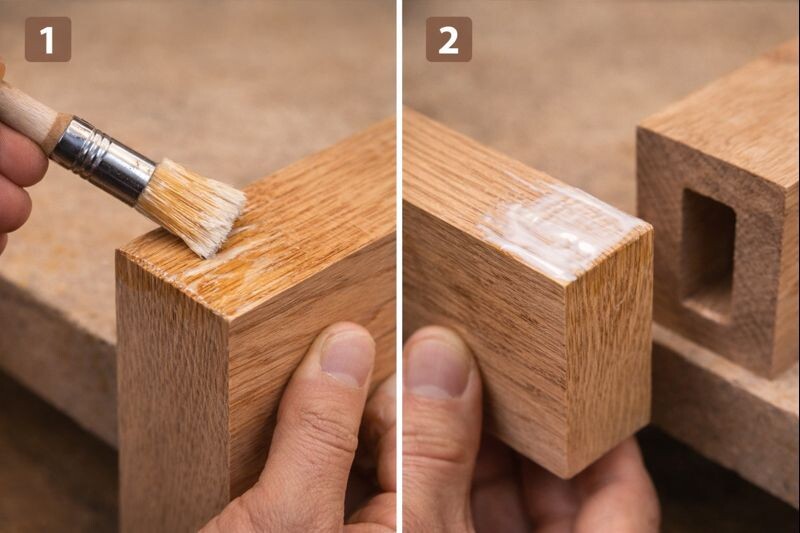

End grain is weak unless you treat it right

End grain acts like a bundle of straws. It drinks glue fast, and that can starve the joint before you ever clamp it.

If you must bond end grain, use one or more of these approaches:

- Size the end grain first: brush on a thin coat, let it soak, then apply fresh glue.

- Increase surface area: use joinery that creates more long-grain contact.

- Reinforce mechanically: dowels, tenons, splines, or fasteners where appropriate.

Even sanding plays a role here, because a fuzzy, torn surface doesn’t bond as well. If you want end grain to glue and finish better, the tricks in getting end grain smooth without burnishing it shut are surprisingly relevant.

Joint surface area beats “stronger glue” almost every time

A tiny butt joint with perfect glue won’t outperform a well-designed joint with more surface area. That’s why mortise-and-tenon, lap joints, and long scarf joints are legendary.

If your project will see racking forces, build the geometry first. Then let glue do what it does best.

Clamp pressure and fit decide whether you get full strength

Clamps aren’t there to “make it strong.” They’re there to bring two surfaces into full contact and hold them still while the adhesive cures.

Here’s what you’re aiming for:

- A tight, even fit before glue touches the wood.

- Enough pressure to close the joint fully.

- Not so much pressure that you squeeze out all the glue.

A thin glue line is good, but “glue starvation” is real. If you crank down until the joint is bone dry, you’ve pushed out the adhesive that actually bonds fibers.

When in doubt, focus on fit first, then clamp with steady pressure. If you’re wondering how long to leave clamps on, it helps to separate handling strength from full strength. My article on when a glue joint reaches full cure, not just dryness will keep you from rushing a joint that feels solid but isn’t.

The big factors that change wood glue strength

Two people can use the same bottle and get different results. That’s normal, because wood and shop conditions are part of the system.

Temperature and humidity

Most PVAs hate cold shops. Low temperatures slow curing and can weaken the bond if the glue never forms a proper film. High humidity can also extend cure times, especially in tight joints.

If you’re working in winter or in an unheated garage, don’t just “wait longer” and hope. Use gentle warmth, good airflow, and correct clamp time. If you need ideas, this guide on speeding up a glue-up without weakening the bond covers safe, practical options.

Wood moisture content

Wood that’s too wet can lead to weak bonds and warping later. Wood that’s too dry can steal moisture from some glues too fast. Stable, acclimated stock is always easier to bond.

Dirty, oily, or polished surfaces

Dust is a bond breaker. Oil is worse. Some tropical hardwoods and resinous softwoods can challenge standard PVAs.

Your best move is simple:

- Plane or sand fresh right before glue-up.

- Vacuum and wipe dust away, not with your hand.

- Consider epoxy or polyurethane for truly oily species.

Too much glue or too little glue

A light, even coat that wets both surfaces is ideal. Dry spots are weak spots. Big puddles can keep joints from closing fully, leaving a thick glue line that doesn’t perform as well.

Aim for full coverage, then clamp and let squeeze-out tell you the surfaces met properly.

Not respecting set time vs full cure

A joint can feel solid quickly and still be weak internally. That’s why chair rungs can loosen months later after “looking fine” on day one.

If you want a quick reality check, read my overview of how long wood glue really takes to dry in normal conditions. Dryness is not the same thing as strength, and that distinction matters.

Is wood glue stronger than screws or nails?

Glue and fasteners do different jobs. Glue creates a continuous bond across the whole surface. Screws and nails create point pressure and mechanical resistance, especially against pull-out.

In a well-designed wood joint, glue can outperform fasteners for stiffness and long-term stability. Fasteners still win when you need immediate holding power, adjustability, or extra reinforcement.

When glue alone is enough

Glue alone is usually plenty for:

- Tight-fitting long-grain joinery

- Edge-glued panels and laminations

- Light-duty boxes and trays

- Trim and molding where load is minimal

If the joint fit is clean and the surfaces mate fully, glue can be the “structure,” not just the helper.

When you should add joinery or fasteners

Add joinery or mechanical reinforcement when the joint will see heavy racking, impact, or repeated stress. Chairs, stools, outdoor pieces, and anything with leverage loads deserve extra insurance.

Fasteners also make sense when you’re clamping awkward shapes, or when you need the assembly held in perfect alignment while the glue cures.

And if you do choose screws, avoid the common mistake that ruins both strength and appearance. This piece on preventing splits when fastening wood near edges pairs nicely with glue-first construction.

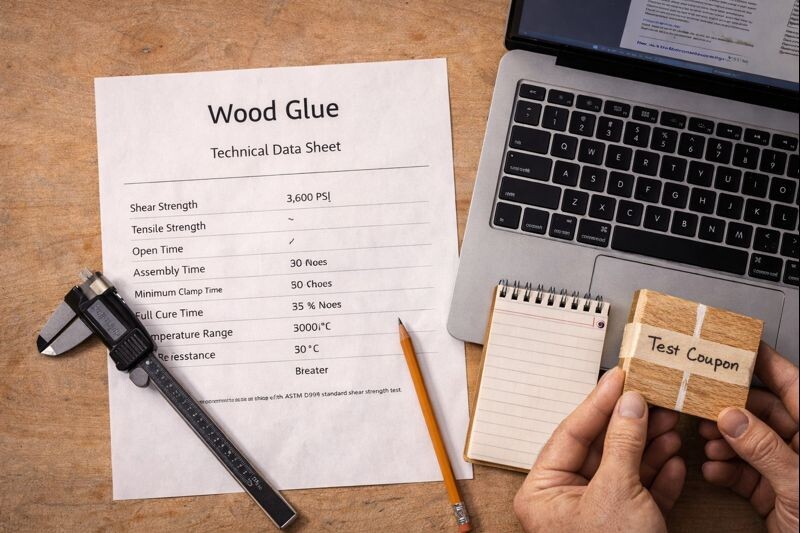

How to read a glue data sheet like a woodworker

Labels are marketing. Data sheets are closer to reality. You don’t need to be an engineer to use them, but you should know what to look for.

Pay attention to these points:

- Test method: a standard like ASTM tests gives useful context.

- Strength type: shear strength is most relevant for wood joints.

- Open time and assembly time: tells you how fast you must work.

- Clamp time: tells you when the joint can be handled safely.

- Cure time: tells you when it reaches full performance.

- Temperature range: tells you if your shop conditions are risky.

- Water resistance rating: matters for kitchens, bathrooms, and outdoors.

Use PSI to compare glues, not to predict your exact results. Joint fit, surface prep, clamping, and cure time decide how strong it ends up.

FAQs on How Strong Is Wood Glue

How strong is wood glue in PSI?

Many common PVAs list shear strengths roughly in the 3,000–4,000 PSI range under test conditions. That number varies by product and test method, and it won’t automatically match what you’ll see on your project. A poor joint can fail at far lower loads.

How much weight can wood glue hold?

Weight capacity depends on joint size, surface area, grain direction, and leverage. A wide long-grain joint can hold far more than most people expect. A small end-grain butt joint can fail under light loads even with “strong” glue.

Is wood glue alone strong enough for furniture?

For many pieces, yes, especially with proper joinery and long-grain contact. Chairs, stools, and other racking-heavy furniture usually benefit from mechanical reinforcement like tenons, dowels, or well-placed fasteners.

Why do end-grain glue joints fail so easily?

End grain absorbs glue like straws, leaving too little adhesive at the bond line. Size the end grain first, redesign for more long-grain contact, or reinforce with joinery. End grain butt joints are a classic weak link.

Is polyurethane glue stronger than wood glue?

Polyurethane can be excellent in wet or mixed-material situations, but it’s not automatically “stronger” in tight wood joinery. The foaming expansion can reduce strength if it prevents full contact. For tight-fitting joints, PVA is often the better choice.

Is epoxy stronger than PVA wood glue?

Epoxy is often stronger in gap-filling and repair scenarios, and it’s very water resistant. For tight long-grain joints, PVA can be equally strong and sometimes more practical. Choose based on fit, environment, and repair needs.

Conclusion

Wood glue is remarkably strong when the joint is designed well and clamped correctly. In most furniture-grade long-grain joints, the wood fibers give up before the adhesive does. Choose PVA for tight wood-to-wood joinery, epoxy for gaps and repairs, and polyurethane for tricky conditions where moisture resistance matters.