How Strong Is Gorilla Wood Glue: 7 Hard Truths for Stronger Joints

Gorilla Wood Glue is very strong—its published shear strength is about 3,900–4,000 PSI (ASTM D905 on maple), and with tight joints, proper clamping, and a full 24-hour cure, the bond can be as strong as the wood itself.

How strong is Gorilla Wood Glue comes down to joint fit, clamping, and full cure. If you’re wondering whether it’s “strong enough,” the short answer is yes for most interior woodworking, because the bond can rival the wood itself when the joint is tight and properly clamped.

Contents Here

- 1 Gorilla Wood Glue vs Original Gorilla Glue vs Gorilla “Ultimate”

- 2 What “strong” means in wood glue terms

- 3 Published strength specs for Gorilla Wood Glue

- 4 What affects bond strength most in practice

- 5 Water resistance and outdoor use

- 6 Best project uses and joint types for Gorilla Wood Glue

- 7 How to apply Gorilla Wood Glue for maximum strength

- 8 Troubleshooting weak joints and common mistakes

- 9 Gorilla Wood Glue vs Titebond vs Elmer’s

- 10 Safety, storage, and shelf life

- 11 FAQs on Gorilla Wood Glue strength

- 11.1 Is Gorilla Wood Glue waterproof?

- 11.2 What is the shear strength of Gorilla Wood Glue?

- 11.3 How long should I clamp Gorilla Wood Glue?

- 11.4 How long does it take to fully cure?

- 11.5 Does Gorilla Wood Glue expand like Original Gorilla Glue?

- 11.6 Can I use Gorilla Wood Glue on stained or painted wood?

- 11.7 What temperature should I use it in?

- 12 Conclusion

Gorilla Wood Glue vs Original Gorilla Glue vs Gorilla “Ultimate”

Before we talk strength, make sure you’re looking at the right bottle.

Gorilla Wood Glue is a cross-linking PVA wood glue (water-based). It’s meant for wood-to-wood joints, dries a natural color, and cleans up with water while wet.

Original Gorilla Glue is a moisture-cured polyurethane adhesive. It foams as it cures and sticks to many materials besides wood, but it’s fussier on clean-up and can push joints apart if clamping is sloppy.

Gorilla “Ultimate” / waterproof wood glue (naming varies by market) is typically positioned for higher water resistance than standard PVA formulas, but you still want to read the label and match it to your exposure. When people say “Gorilla glue expands,” they’re usually talking about the polyurethane versions, not the PVA wood glue.

If you’re building furniture, trays, shelves, or cabinet parts, the PVA Gorilla Wood Glue is usually the one you want.

What “strong” means in wood glue terms

Glue strength isn’t a single thing. In woodworking, most published numbers you’ll see are about shear strength—how well the joint resists sliding when force is applied parallel to the glue line.

That matters, but here’s what matters more in the shop: a good wood glue joint often fails as wood fiber tear-out, not a clean “glue popped loose” break. In plain terms, the glue didn’t give up—the wood did.

That’s why the same glue can feel “amazing” in a tight mortise-and-tenon, and “weak” on a sloppy butt joint with gaps. Wood glue is happiest when it’s bonding two surfaces that fit well.

Published strength specs for Gorilla Wood Glue

If you like numbers, Gorilla’s technical data sheet gives you a solid reference point.

- Shear strength (ASTM D905): 3,900 to 4,000 psi (listed on maple in the data sheet).

- Open working time: 5–10 minutes.

- Clamp time: 20–30 minutes.

- Full cure: 24 hours.

- Minimum use temperature: 55°F / 12°C.

- Water resistance: passes ANSI/HPVA Type II and EN204/205 D3 (more on what that means below).

A quick reality check: PSI isn’t a “weight limit.” That number comes from a standardized lab test on specific wood, with specific joint geometry. Your joint strength depends on surface area, grain direction, wood species, and how well you clamp.

Still, that 3,900–4,000 psi range tells you Gorilla Wood Glue is in the “serious woodworking glue” category, not a craft glue that turns rubbery.

What affects bond strength most in practice

If you want Gorilla Wood Glue to hit its potential, these factors matter more than the label.

Joint fit and surface contact

Wood glue doesn’t like gaps. It’s strongest when the parts mate closely and the glue line stays thin. A well-jointed edge glue-up will usually beat a gappy joint, even with the same glue.

If your edges aren’t meeting cleanly, fix the fit before you blame the glue.

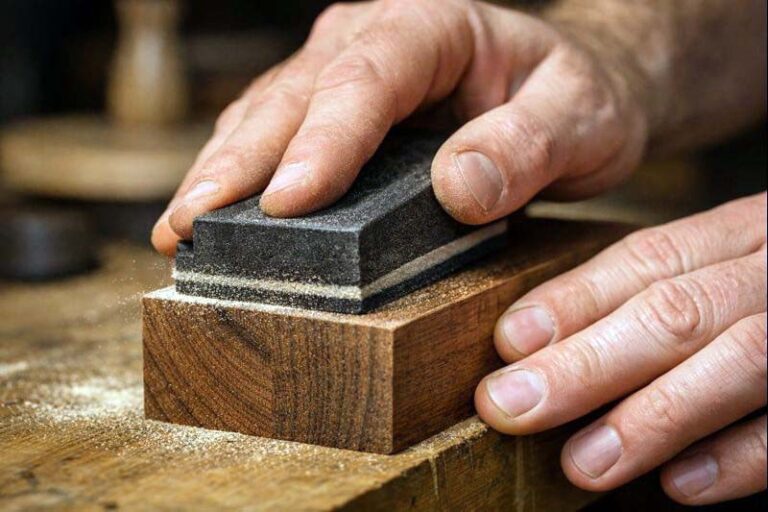

Clean, bare wood beats finished wood every time

Glue sticks to wood fibers, not to wax, oil, dust, or a glossy finish. Sand back to fresh wood anywhere you expect a bond.

If you’re repairing a finished tray or stand, remove finish in the joint area, then re-finish after the repair. For projects where end grain is involved, it also helps to prep the surface properly—this approach pairs well with the technique in sanding end grain smooth for cleaner joints.

Moisture, temperature, and clamping pressure

PVA glues behave best above the minimum use temperature, and they cure more predictably when the wood isn’t soaking wet or bone-dry. The data sheet lists a 55°F / 12°C minimum for use.

Clamping pressure should be firm enough to bring surfaces into contact, but not so aggressive that you squeeze all the glue out and create a “glue-starved” joint.

Time matters more than impatience

Gorilla Wood Glue can feel “set” fast, but strength builds as it cures. The sheet lists 80% dry in 1–2 hours and full cure in 24 hours.

If you’re comparing glues, timing is part of the choice. If you want a deeper breakdown, these TrayEdit references help you match expectations to reality:

- wood glue drying time for typical clamp-ups

- how long wood glue takes to set before handling

- when wood glue is fully cured and ready for real load

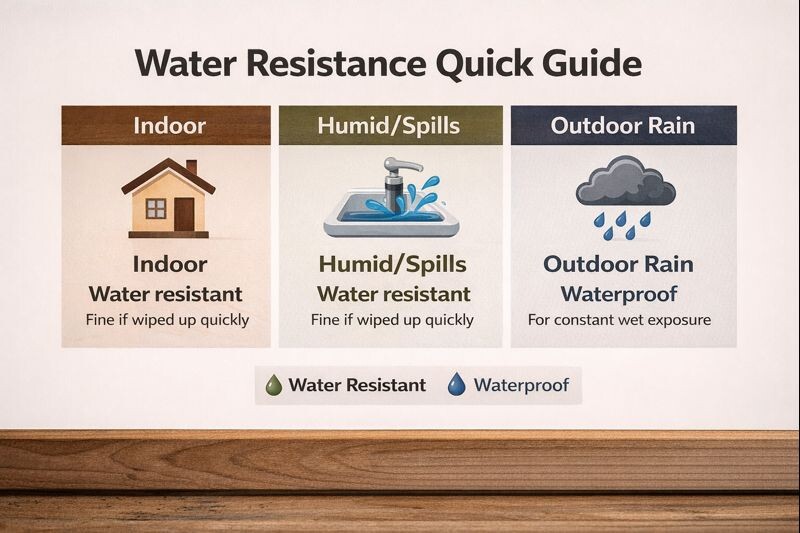

Water resistance and outdoor use

Gorilla Wood Glue is described as water resistant, and the technical sheet backs that up with standards: ANSI/HPVA Type II and EN204/205 D3.

Here’s how I explain that to folks at the bench:

- Water resistant is fine for occasional dampness, kitchen humidity, and the odd spill that gets wiped up.

- It’s not the same as constant wet exposure, soaking, or a joint living outdoors without protection.

If you’re building something that will sit outside in rain, or you expect repeated soak-and-dry cycles, move to an adhesive designed for that job (often a waterproof PVA rated Type I, polyurethane, or epoxy—depending on the joint and materials).

Best project uses and joint types for Gorilla Wood Glue

Used in the right spot, Gorilla Wood Glue is excellent for:

- Edge-gluing panels (table tops, tray bottoms, shelves)

- Furniture joinery where parts fit well (rungs, rails, aprons)

- General wood-to-wood assembly on hardwood, softwood, and natural wood composites

It’s less ideal for:

- Big gaps or broken chunks missing from the joint

- Painted, oily, or waxy surfaces unless you remove the contamination first

- Wood-to-metal or wood-to-plastic situations where a different adhesive type usually performs better

If your main goal is repair work—chairs, loose joints, serving trays—this is a good place to compare options before you buy. TrayEdit’s best glue picks for furniture repair jobs is a handy companion read.

How to apply Gorilla Wood Glue for maximum strength

The directions are simple, but the details are where strength is won.

Surface prep that actually matters

- Dry fit the joint first. Make sure it closes without force.

- Brush or wipe off dust. If the wood is oily or finished, sand to bare wood.

- Plan your clamps and cauls before you spread glue.

That last step sounds obvious, but it’s where most glue-ups go sideways.

Glue amount, spread, and squeeze-out control

Apply enough glue to wet the surface evenly. For long edges, I like a thin bead, then spread it so you don’t get dry pockets.

A small, consistent line of squeeze-out is usually a good sign. Wipe it with a damp cloth while it’s wet, or let it gel and scrape it later, depending on your finishing plan.

Clamping and curing timeline

From the technical sheet:

- Work time: 5–10 minutes

- Clamp: 20–30 minutes

- Full cure: 24 hours

If you want the joint to be as strong as it can be, don’t stress it hard until the next day. That’s especially true for chair parts, tray handles, or anything that sees racking forces.

If you’re in a hurry, speed helps are possible, but they’re easy to overdo. Use this instead of guessing: ways to make wood glue dry faster without weakening the joint.

Troubleshooting weak joints and common mistakes

When a Gorilla Wood Glue joint fails, the cause is usually visible.

“The joint popped right apart”

That’s often finish, dust, or poor contact. Sand back to clean wood, improve the fit, and clamp evenly.

“It held until I put weight on it”

That’s usually early loading. The joint may have been “set,” but not cured. Give it the full cure window, especially on hardwoods and tight joinery.

“My end grain feels weak”

End grain drinks glue like a straw. A good fix is pre-sizing: brush on a thin coat, let it soak a minute, then add a second coat and assemble. Better still, redesign the joint so you have long-grain contact where possible.

“The glue got thick or separated in the bottle”

The sheet notes you can shake or stir back to original consistency after certain conditions, and it lists a storage life around 2 years, depending on storage.

If the glue smells off, strings weirdly, or won’t spread smoothly, it’s cheaper to replace the bottle than to rebuild a project.

Gorilla Wood Glue vs Titebond vs Elmer’s

Most woodworkers end up choosing between a few familiar PVA glues. Here’s the useful way to compare, without getting lost in brand loyalty.

Choose based on water exposure first

If the piece lives indoors, most reputable PVAs are plenty strong when joints fit well.

If the piece will see wet conditions, pick the glue that matches the exposure rating you need. Gorilla Wood Glue is water resistant (Type II / D3), which is great for many household projects.

Choose based on working time and workflow

Some glues give a little more open time for complicated assemblies. Others grab faster for simple clamp-ups. Your shop temperature also changes how forgiving the glue feels.

Choose based on cleanup and finishing

PVA glues generally sand well when cured, but glue squeeze-out left on the surface can cause finish issues. Whatever brand you use, cleaning strategy is part of getting a clean result.

If you’re fixing furniture joints or a wobbly tray stand, your “best” glue might be the one that gives you enough working time to align parts, clamp correctly, and let it cure fully.

Safety, storage, and shelf life

Gorilla Wood Glue is water-based PVA, which is generally easy to live with, but treat it like any shop chemical.

- Avoid getting it in your eyes or mouth.

- Wash it off skin before it dries.

- Keep the nozzle clean so the cap seals properly.

The technical sheet lists about a 2-year storage life, depending on storage conditions, and freeze-thaw stability up to 5 cycles with acclimation and mixing back to consistency.

If you’re building good habits, it helps to keep your basics in one place. This safety checklist pairs well with glue-ups: essential safety gear for woodworking builds.

FAQs on Gorilla Wood Glue strength

Is Gorilla Wood Glue waterproof?

It’s best described as water resistant, not “always waterproof.” The data sheet lists ANSI/HPVA Type II and EN204/205 D3 classifications.

What is the shear strength of Gorilla Wood Glue?

Gorilla’s technical sheet lists 3,900–4,000 psi shear strength (ASTM D905) on maple.

How long should I clamp Gorilla Wood Glue?

The data sheet lists 20–30 minutes of clamp time under nominal conditions.

How long does it take to fully cure?

Full cure is listed as 24 hours.

Does Gorilla Wood Glue expand like Original Gorilla Glue?

No. The expanding foam behavior is associated with polyurethane “Gorilla Glue” products, not the PVA Gorilla Wood Glue.

Can I use Gorilla Wood Glue on stained or painted wood?

It can fail if you glue to the finish instead of wood fibers. Sand back to bare wood in the joint area, then glue.

What temperature should I use it in?

The technical sheet lists a 55°F / 12°C minimum use temperature. Colder shops can slow curing and reduce reliability.

Conclusion

Gorilla Wood Glue is strong enough for serious woodworking when your joint fits well and you clamp it correctly. With a published 3,900–4,000 psi shear strength and a straightforward clamp-and-cure schedule, it’s a dependable PVA for furniture and indoor projects.

If you take one thing from this, let it be this: tight joints, clean wood, steady clamping, and a full cure beat hype every time.