How Much Weight Can Wood Glue Hold? 7 Shocking Truths (PSI)

How much weight can wood glue hold is usually in the thousands of PSI in a well-made long-grain joint—so in real projects it can hold very heavy loads, but the true limit depends on bonded area, joint design, and full cure time.

The weight can wood glue hold depends on joint design, bonded area, and full cure. Wood glue strength is usually discussed in PSI, then translated into real-world joint performance. This article shows what those numbers mean on shelves, cabinets, and furniture joints, so you can build strong assemblies without guessing.

Contents Here

- 1 How much weight can wood glue hold in real life?

- 2 PSI vs pounds: the simple conversion most articles skip

- 3 What “stronger than wood” really means when a joint breaks

- 4 Typical strength ranges you’ll see for wood glues

- 5 The biggest factors that control how much weight a glued joint can handle

- 6 Wood glue vs screws and nails: which really holds more?

- 7 If you want a real number, here’s the safest way to estimate it

- 8 FAQs on how much weight can wood glue hold

- 8.1 Is glue alone strong enough for furniture?

- 8.2 Is wood glue stronger than screws?

- 8.3 Is wood glue stronger than nails?

- 8.4 Is carpenter’s glue stronger than super glue for wood?

- 8.5 How long should I wait before putting weight on a glued joint?

- 8.6 Can glued shelves really hold heavy weight?

- 8.7 What’s the strongest glue type for wood projects?

- 9 Conclusion

How much weight can wood glue hold in real life?

Most quality carpenter’s glues can create a bond that’s strong enough that the surrounding wood fails first. That’s why you’ll hear the shop phrase “stronger than wood.” It’s often true in a well-made long-grain joint, but it’s not a promise that a glued shelf can hold a certain number of cinder blocks forever.

Here’s the practical way to think about it:

- Glue strength numbers are stress-based (PSI), not weight-based.

- Your joint “holds weight” through the bonded area, plus the shape of the joint.

- Loads aren’t always straight down—racking, peel, and shock loads can wreck a joint that looks fine on paper.

If your project is safety-critical or overhead, don’t rely on glue math alone. Build in mechanical support and a generous safety factor.

Learn more: How Strong Is Wood Glue? 7 Proven Truths (PSI + Joint Tips)

PSI vs pounds: the simple conversion most articles skip

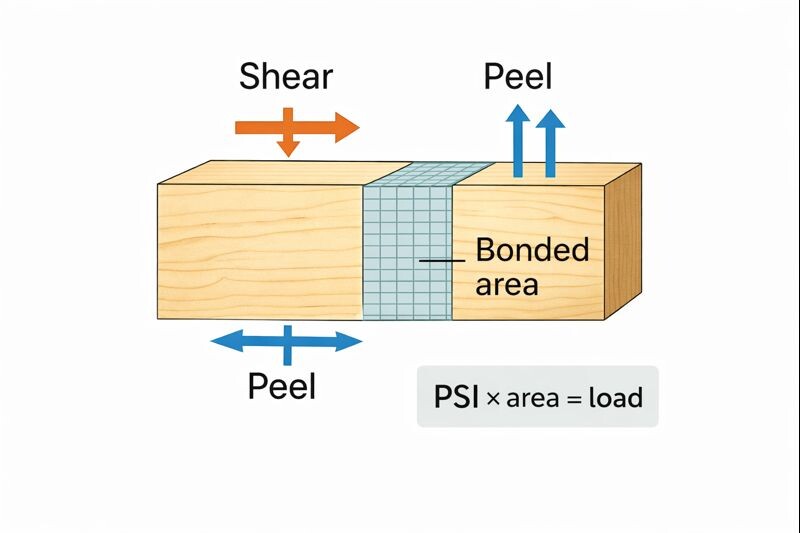

PSI means “pounds per square inch.” So, in the most basic sense:

Estimated load capacity (in pounds) ≈ PSI × bonded area (in²)

That sounds straightforward, but here’s the catch: most furniture joints don’t load the glue line in perfect lab-style shear. Real joints see peel forces, twisting, vibration, wood movement, and long-term creep.

A quick back-of-the-envelope example

Let’s say a typical PVA glue joint tests around 3,000–4,000 PSI in ideal conditions (varies by product and test method). If you had 10 in² of well-mated long-grain bonding area:

- 3,000 PSI × 10 in² = 30,000 pounds (theoretical lab-stress number)

That number is not what your shelf can hold. Wood fibers crush, joints peel, screws loosen, and loads aren’t evenly distributed. For furniture thinking, you use the formula only to understand why more bonding area and better joinery matter so much.

A safer mindset is: use that math to compare joints, then apply a big safety factor and add mechanical reinforcement when the consequences matter.

What “stronger than wood” really means when a joint breaks

A well-glued joint often fails with wood fibers stuck to both sides of the glue line. That’s a good sign because the bond did its job and the wood became the weak link.

A weak joint usually shows one of these:

- A clean, shiny glue line with little wood fiber tear-out (poor adhesion).

- A starved joint where too much glue was squeezed out.

- Failure right at end grain, where glue soaks in and leaves little structure behind.

- A split that starts from peel or racking forces, not straight shear.

If you ever test a sample on scrap, you want to see torn wood fibers, not a neat separation.

Typical strength ranges you’ll see for wood glues

Most articles that rank well mention broad ranges rather than one perfect number, and that’s the honest approach. In general shop terms:

- PVA carpenter’s glues (yellow/white): often reported in the high-thousands PSI range in shear tests, with many popular products commonly cited around 3,000–4,000 PSI under ideal conditions.

- Polyurethane glue: strong and water resistant, but messy and foams, so joint fit matters even more.

- Epoxy: excellent gap-filling and strong on tricky materials, but overkill for many tight wood joints.

- CA (super glue): great for small parts and quick fixes, but not my pick for structural wood joints.

- Hide glue: classic, reversible, and strong in the right application, especially for traditional joinery.

When you’re repairing furniture or building something that gets daily handling, it’s usually smarter to pick the right glue type for the job than to chase the biggest PSI number. If you’re deciding what to keep on the shelf, this guide on choosing the best glue for furniture repair joints fits nicely alongside this topic: choosing the best glue for furniture repair joints.

The biggest factors that control how much weight a glued joint can handle

If you remember only one thing, make it this: joint design beats “stronger glue” almost every time.

Long-grain vs end-grain bonding

Wood glue loves long-grain-to-long-grain contact. End grain drinks up glue like a bundle of straws, leaving less adhesive structure where you need it.

If you must bond end grain, increase mechanical engagement and surface area with real joinery—think shoulders, tenons, splines, dowels, rabbets, or dados—so the glue isn’t doing all the work.

Bonded surface area and stress distribution

Bigger bonded area spreads the load. This is why edge-glued panels can be incredibly strong, while a tiny butt joint can fail easily.

A small upgrade in joint geometry often outperforms a fancy adhesive:

- A lap joint beats a butt joint.

- A dado/rabbet supports a shelf better than a flat edge.

- A tenon gives you long-grain contact where it matters.

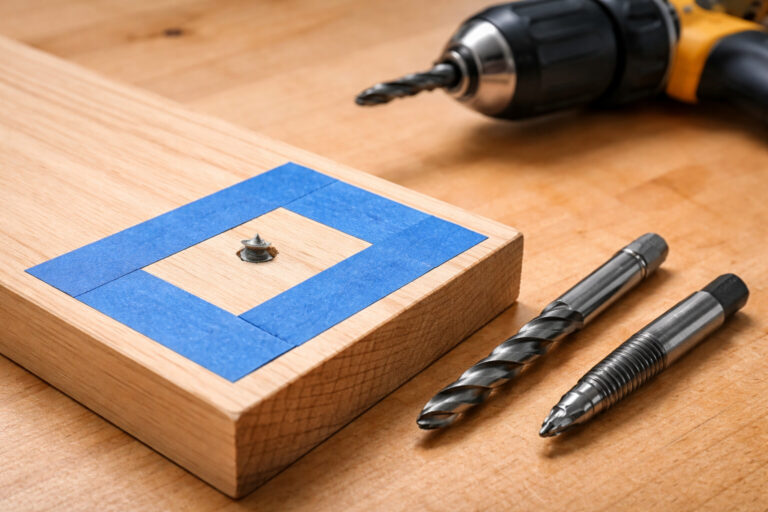

Surface prep and fit

Glue doesn’t fill problems the way people hope it will. For maximum strength:

- Mating faces should be flat and make full contact.

- Remove dust and oils.

- Avoid polishing the surface so much that it gets burnished and slick.

If you’re working with different species, strength and movement can change how a joint behaves. This piece on comparing pine, oak, and maple for strength-sensitive builds helps you plan smarter: comparing pine, oak, and maple for strength-sensitive builds.

Clamping pressure and glue coverage

You want firm, even pressure that closes the joint without squeezing it bone-dry. Too little pressure leaves gaps. Too much pressure can create a starved joint if the fit isn’t already good.

A thin, consistent glue film is the goal, not a thick layer. The best joints start with good milling, not extra adhesive.

Dry time vs full cure time

A joint can feel solid long before it reaches full strength. If you’re building something load-bearing, the “when can I unclamp it?” question matters less than “when can it carry weight?”

For timing, use these as internal references while you write:

- How long wood glue takes to set before unclamping

- How long wood glue takes to dry for handling

- What full cure time really means for a load-bearing joint

If you’re tempted to rush, do it carefully. Gentle warmth and airflow can help, but shortcuts can weaken results. This is worth reading before you try to speed things up: speed up glue drying without weakening the bond.

Environment and moisture exposure

Humidity and temperature change open time, cure behavior, and long-term durability. If the project lives in a damp kitchen, a mudroom, or outdoors, choose an appropriate water-resistant or waterproof-rated adhesive and design the joint so it’s not relying on glue alone.

Wood glue vs screws and nails: which really holds more?

Glue and fasteners do different jobs.

- Glue spreads load across an entire surface when the joint fits well.

- Screws and nails concentrate load at points, but they resist immediate movement and provide clamp-like force during assembly.

- In many furniture joints, the best answer is both: glue for continuous strength, mechanical reinforcement for racking, shock, and long-term creep.

If I’m building a shelf, a chair, or anything that might get bumped hard, I prefer joinery that creates shoulders and long-grain contact, then I decide whether hidden screws, dowels, or corner blocks add insurance.

Practical examples you can apply today

- Shelves: Downward load can turn into peel forces at the front edge. A dado, cleat, or face frame supports the shelf so the glue line isn’t fighting alone.

- Chairs and stools: These see racking forces from side-to-side movement. Use mechanical joinery and reinforcement, not just a glued butt joint.

- Cabinets: Glue is great, but long-term creep and humidity cycles matter. Back panels, corner blocks, and proper joinery keep things square.

- Trays and handles: Lifting adds twisting force. Reinforce handles with joinery, not only adhesive.

If you want a real number, here’s the safest way to estimate it

If you absolutely need an estimate for a non-critical project, use a conservative process instead of a bold claim.

- Identify how the joint is loaded (shear, tension, peel, racking).

- Estimate true bonded long-grain area (ignore gaps and end-grain-only contact).

- Use a conservative glue strength assumption, not a best-case spec.

- Apply a big safety factor (because your load is not a lab test).

- Reinforce the joint if failure would damage something or hurt someone.

In the shop, I’d rather overbuild with good joinery than trust a single “pounds held” number. That’s especially true when wood movement and real-life bumps enter the picture.

FAQs on how much weight can wood glue hold

Is glue alone strong enough for furniture?

Often, yes—when the joint is well-designed and long-grain-to-long-grain. For chairs, shelves, and high-stress parts, add joinery or reinforcement for racking and shock loads.

Is wood glue stronger than screws?

They’re strong in different ways. Glue spreads load across a whole surface, while screws resist movement and add clamp-like force. Many of the strongest builds use both.

Is wood glue stronger than nails?

For tight-fitting joinery, a good glue bond can outperform nails for long-term rigidity. Nails help with speed and holding alignment, but they don’t replace proper joint design.

Is carpenter’s glue stronger than super glue for wood?

For most structural wood joints, PVA carpenter’s glue wins because it bonds long-grain surfaces well and remains tough. CA glue shines for small parts and quick fixes.

How long should I wait before putting weight on a glued joint?

Don’t judge by “dry to the touch.” Wait for full cure when the joint must carry weight. Use the product instructions, and reference what full cure time really means for a load-bearing joint for planning.

Can glued shelves really hold heavy weight?

They can, but shelves introduce peel and racking forces. Use a dado, cleat, or mechanical support so the glue isn’t doing the entire job by itself.

What’s the strongest glue type for wood projects?

For tight-fitting wood joinery, a quality PVA glue is hard to beat. For gaps, oily woods, or mixed materials, epoxy can be the better choice. The “strongest” depends on the joint and environment.

Conclusion

Wood glue can hold an impressive amount of weight when the joint fits well and cures fully. The real limit comes from bonded surface area, grain direction, joint geometry, and the forces trying to peel or rack the joint apart. Build for long-grain contact, let it cure, and reinforce anything that matters.