How Much Do Plywood Sheets Cost? Price Factors + 1/2-Inch and 3/4-Inch Costs

Plywood prices change by region and week, so the number you see online often shifts by the time you’re standing at the rack. Big-box stores also localize pricing by ZIP code, and lumberyards price by truckload timing. In this guide, I’ll give you realistic price bands by plywood category, plus common “today” examples from major retailers, so you can budget without guessing. Then I’ll show what drives cost, how 1/2-inch and 3/4-inch sheets compare, and how to spot junk panels before you pay.

After you understand grades, it’s easier to pick the right panel for visible work like cabinetry. If that’s your lane, start with my guide to what cabinet-grade plywood is and how it’s graded, then come back here for pricing.

Contents Here

- 1 What drives plywood sheet price?

- 2 Price bands by category

- 3 Comparison table: type/grade, use, and why it costs more or less

- 4 How much are plywood sheets?

- 5 How much is a half inch sheet of plywood?

- 6 How much is 3/4 in plywood?

- 7 Shopping tips: compare apples to apples

- 8 How to avoid junk sheets

- 9 Checklist at the rack

- 10 FAQs about Plywood Sheets Cost

- 11 Concluding Notes

What drives plywood sheet price?

Plywood mills set price around what the panel does and how hard it is to produce consistently.

- Grade and face quality. A clean A or B face costs more because the mill uses better veneer and spends more time patching and sanding. Lower faces like C or D allow knots and repairs, so the sheet costs less.

- Species. Softwood panels (pine, fir, spruce) often land in the “structure first” aisle. Hardwood-faced panels (birch, maple, oak, sapele, etc.) cost more because appearance and veneer yield matter.

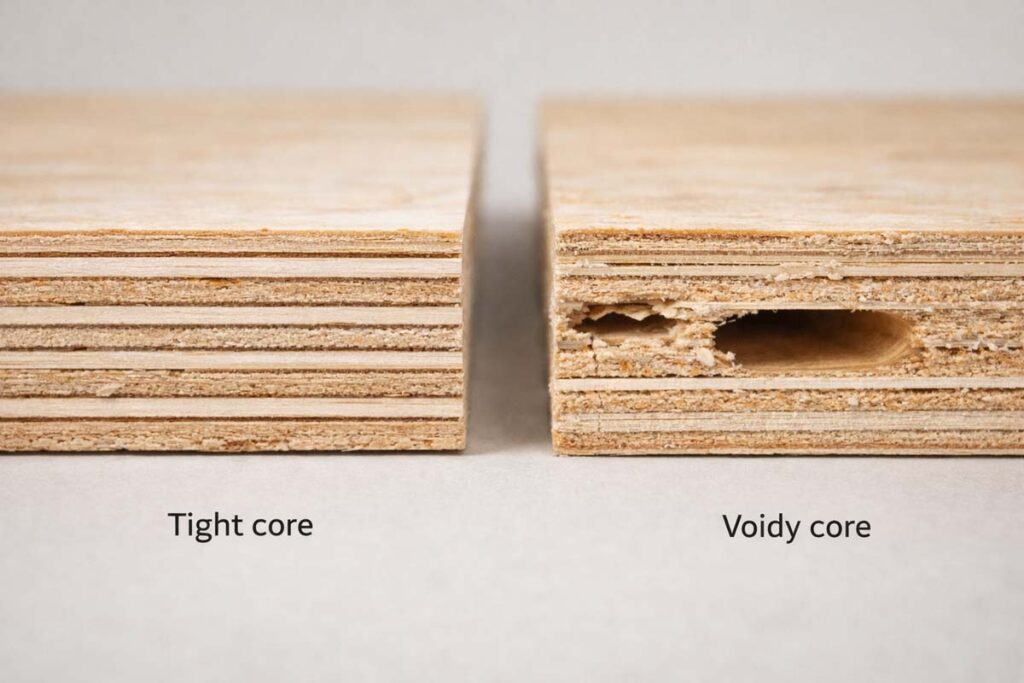

- Core type and core quality. A sheet with tight inner plies and fewer voids costs more because it machines cleaner and holds fasteners better. That core quality shows up fast on routed edges and dadoes.

- Thickness. More wood equals more cost, and thicker panels also trigger higher freight costs.

- Brand and certification. Panels stamped and graded under recognized rules and performance categories tend to cost more because the manufacturer has to hit tighter targets.

- Import vs. domestic. Imported hardwood plywood can swing in price with shipping and currency. Domestic panels often track regional mill output and housing demand.

- Supply swings. Storms, rebuilding demand, mill downtime, and building cycles move sheathing prices quickly. The same is true for specialty plywood when a supplier runs short.

If you’re staring at a stack labeled “shop grade,” it often means the faces and core vary more than true cabinet grade. Here’s a quick explainer on what shop-grade plywood is so you know what corners got cut.

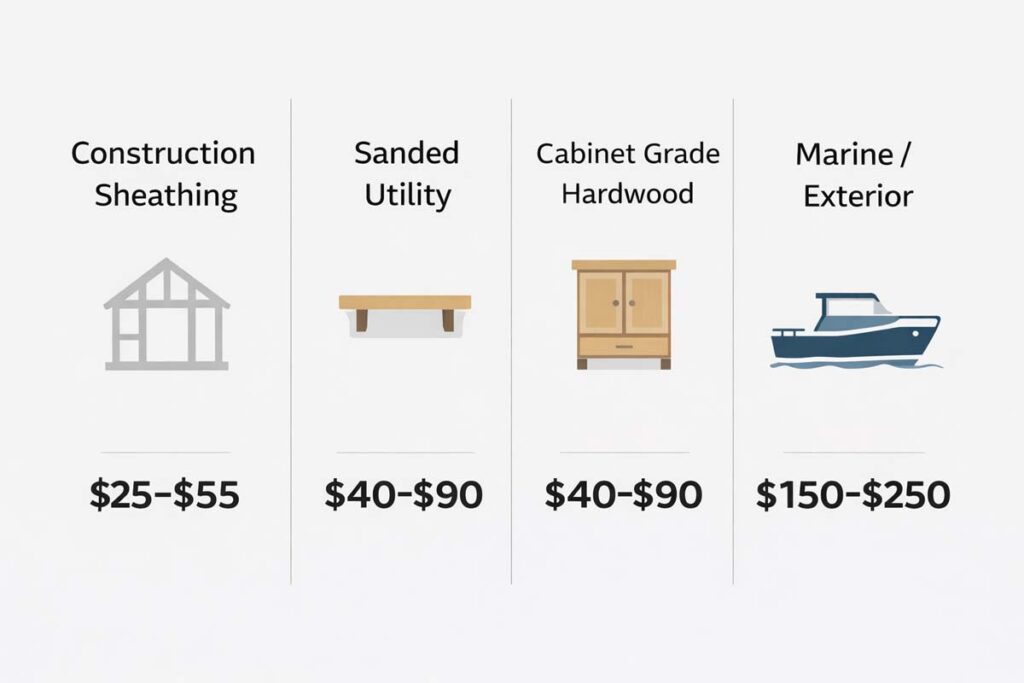

Price bands by category

These are practical budgeting ranges for a 4×8 sheet, using retail price bands and current shelf examples. Your local number can land outside the band during shortages or sales.

Construction sheathing (OSB, CDX, rated sheathing)

- Typical band: about $25–$40 for common 4×8 sheathing, with thicker construction panels often $45–$55.

- Shelf examples: Home Depot shows 7/16 OSB listings in the teens to 30s depending on product and features (basic OSB vs. ZIP-style coated panels).

Sanded utility panels (sanded pine, sande, “project” sheets)

- Typical band: often $40–$90, depending on thickness and face quality.

- Shelf example: Home Depot lists 1/2-in sande plywood (4×8) at $45.55 (store/location dependent).

Cabinet-grade hardwood plywood (birch/maple/oak faces)

- Typical band: commonly $40–$90 (species and face grade drive the spread).

- Shelf examples: Home Depot lists 1/2-in PureBond birch (4×8) at $69.58, and 3/4-in PureBond birch in the mid-$80s on one listing page.

Marine and true exterior specialty panels

- Typical band: often $150–$250 per sheet for marine/specialty panels because veneer and glue standards tighten up.

- Reality check: some “exterior” plywood is still a construction-grade face with waterproof glue, not a pretty, void-free core.

Read more: How Many Sheets of Plywood Are in a Bundle, Bunk, or Pallet

Comparison table: type/grade, use, and why it costs more or less

| Type / grade | What it’s used for | Why it costs more / less |

|---|---|---|

| OSB sheathing (7/16, 15/32) | Walls/roofs when covered fast | Lowest-cost structural option; edges can swell if soaked; price stays low to compete with plywood |

| CDX / rated sheathing | Roof/wall sheathing, subfloor underlayment | Structural stamp and thickness add cost; face allows knots/patches so it stays affordable |

| Sanded sande / utility panels | Paint-grade shelves, shop projects | Sanded faces cost more than CDX; core and grading vary by product line |

| Cabinet-grade birch/maple/oak | Cabinet boxes, furniture parts | Better face veneers and tighter cores cost more; saves labor in sanding and finishing |

| Marine-grade | Boats, docks, wet-service panels | Higher veneer quality + waterproof glue standards push price into triple digits |

How much are plywood sheets?

Most 4×8 plywood sheets run about $25–$40 for basic sheathing, $40–$90 for sanded or cabinet-grade, and $150+ for marine/exterior. Your local price changes with supply and store type. For a fast budget number, most DIYers land in these lanes:

- Budget sheathing: mid-$20s to low-$40s for a 4×8 sheet in many markets.

- Thicker construction panels (subfloor/roof): often $45–$55.

- Cabinet-grade hardwood plywood: often $40–$90, sometimes more for premium faces and specialty cores.

- Marine/specialty wet-service plywood: often $150–$250.

If you’re shopping big-box listings, keep in mind the product mix matters. One “3/4 plywood” filter page can include MDF, melamine, hardwood plywood, and treated panels all together, with prices from the 40s up into the 90s.

Learn more: Plywood Sheet Sizes, Standard Dimensions, and Square Footage

How much is a half inch sheet of plywood?

A 1/2-inch sheet is usually cheaper than 3/4 because there’s less material and it ships lighter. Expect roughly $35–$70 depending on face grade, species (sande vs birch), and core consistency.

It’s usually cheaper than 3/4 because it uses less material and ships easier.

Here are current retail examples for 1/2-in, 4×8 listings:

- Sande plywood: $45.55 on one Home Depot listing.

- PureBond birch hardwood plywood: $69.58 on one Home Depot listing.

What usually makes 1/2-inch cheaper

A 1/2-inch sheet costs less when the panel uses:

- a lower face grade (more patches/knots)

- a softer species or utility face

- a less-controlled core with more voids

What makes 1/2-inch more expensive

A 1/2-inch sheet costs more when it uses:

- a cleaner face veneer (A/B faces)

- more consistent inner plies (fewer voids)

- a branded hardwood panel line built for cabinetry

One practical note: “1/2-inch” is often nominal. For example, one 1/2-inch birch panel listing shows an actual thickness around 0.453 inches, which matters if you’re cutting dados for a tight fit.

If you’re building cabinets, thickness ties directly to joinery and hardware choices. This guide on what thickness plywood works for cabinets helps you match the panel to the build.

How much is 3/4 in plywood?

3/4-inch plywood often lands around $45–$55 for construction-grade panels and $65–$90+ for cabinet-grade hardwood faces. Core quality and flatness matter a lot at this thickness, so cheaper sheets can cost you time.

Retail examples for 3/4-inch pages show how wide the category gets:

- Home Depot’s 3/4 plywood listings include panels around $65–$90+ depending on whether it’s sanded utility plywood, hardwood plywood, or specialty product lines.

- One 3/4-inch treated CDX sheathing item appears at $64.98 on a Home Depot filter page.

- Hardwood birch listings show 3/4-in PureBond birch in the mid-$80s on one page.

3/4-inch pricing, plus weight and core quality effects

Weight changes how the sheet behaves and how much it costs to move. Thicker sheets cost more partly because they add freight and handling load. They also punish bad cores. A heavy sheet with a voidy core still feels stiff until you route an edge and hit air.

Core quality changes your labor time. A tighter core:

- holds screws better at the edges

- routes cleaner for shelves and dados

- sands and finishes with fewer telegraphed voids

If you want fewer surprises on cabinet builds, use a panel that’s built for that job. This roundup on the best plywood for cabinets focuses on the traits that matter when the edges are exposed and the boxes have to stay square.

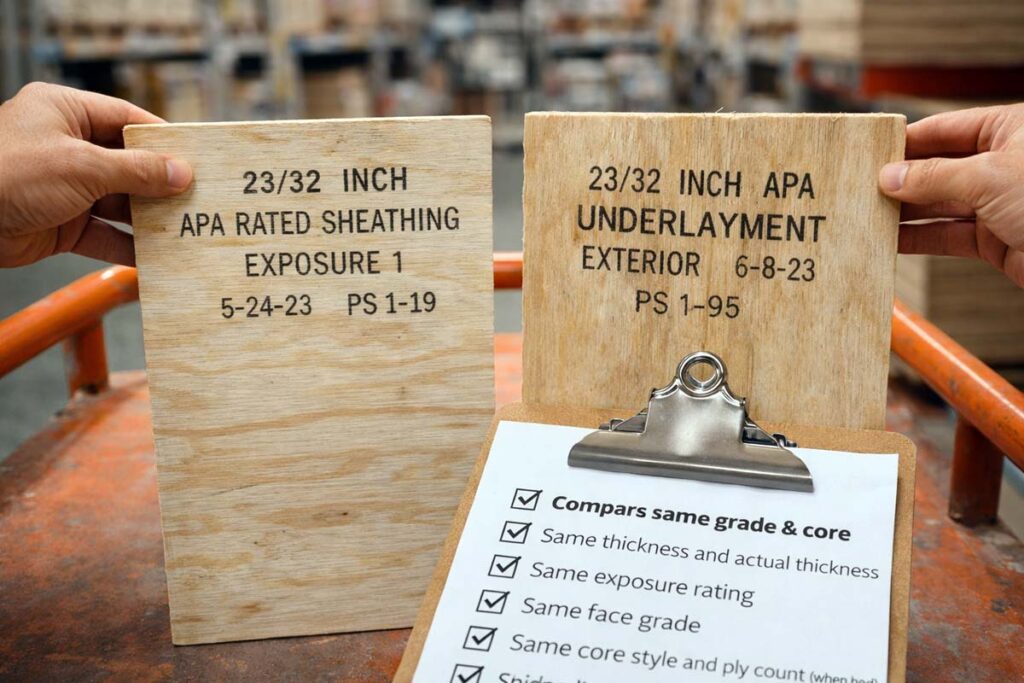

Shopping tips: compare apples to apples

Plywood pricing only makes sense when you compare the same spec.

Use these checkpoints before you decide one sheet is “cheaper”:

- Same thickness and actual thickness. Nominal 3/4 vs. 23/32 matters for joinery.

- Same exposure rating. Interior panels do not belong in wet service. APA performance categories and intended uses help you match panel to job.

- Same face grade. A “pretty” face costs more because it saves sanding and patching.

- Same core style and ply count (when listed). More plies often means a flatter, more stable sheet, depending on the product.

- Same store conditions. Localized price and stock affect what you’ll pay that day.

How to avoid junk sheets

Bad plywood wastes time in the shop. I’d rather pay a bit more than fight a bowed sheet on the table saw.

Warp checks

Sight down the long edge and the face.

- Skip sheets with a corkscrew twist.

- Avoid panels with a pronounced cup if you need flat cabinet sides.

Face checks and splits

Look for hairline cracks running with the grain on the face veneer. Those cracks can open up under finish.

Edge void checks

Look at the edge for gaps between plies.

- Voids at the edge can blow out when you route.

- Voids also weaken screws driven near the edge.

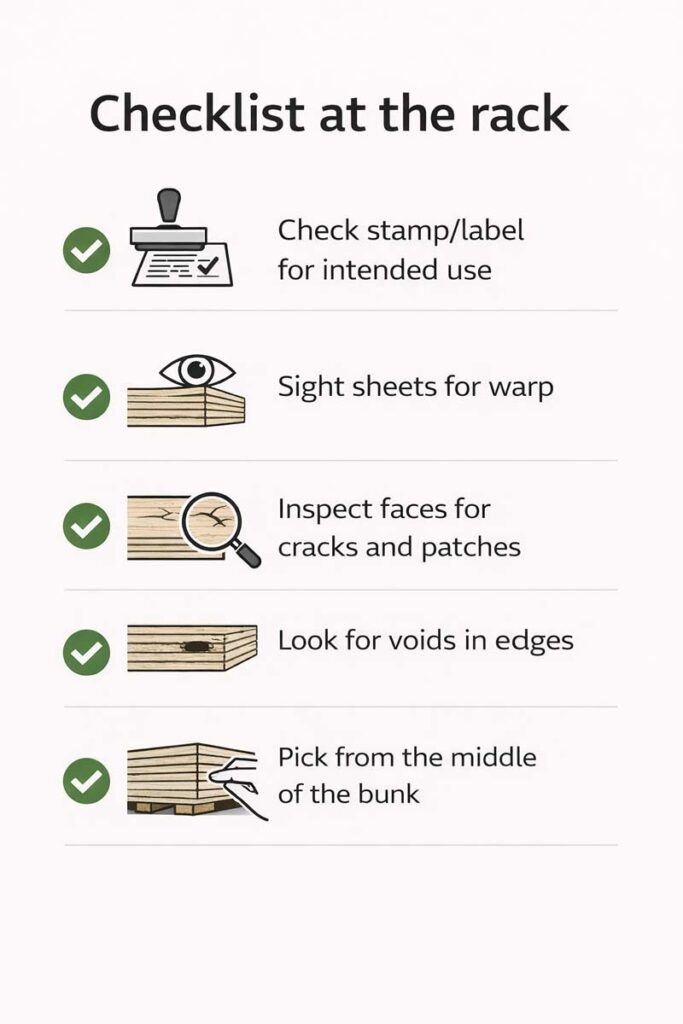

Checklist at the rack

Bring this quick list into the aisle:

- Check the stamp/label for intended use (sheathing vs. hardwood panel)

- Sight the sheet for bow, cup, and twist

- Inspect both faces for patches, knots, and hairline cracks

- Look at the edge for voids and delamination

- Pick from the middle of the bunk when possible (top sheets get abused)

- Buy one extra sheet when the project is finish-critical (best odds of matching faces)

FAQs about Plywood Sheets Cost

How much does a sheet of plywood cost?

Most 4×8 plywood sheets run about $25–$40 for basic construction sheathing, $40–$90 for sanded or cabinet-grade, and $150+ for marine/exterior. Prices shift weekly by region.

How much does a sheet of 3/8 plywood cost?

A 3/8-inch 4×8 sheet often falls around $20–$45, depending on whether it’s sheathing, underlayment, or a sanded project panel. Thinner sheets vary a lot by grade and flatness.

How much does 1 sheet of plywood cost?

“One sheet” usually means a 4×8 panel, and cost depends on type more than anything. Budget sheathing might be $25–$40, while hardwood cabinet plywood commonly lands $50–$90+.

How much does a 3/4 sheet of plywood cost?

3/4-inch plywood often costs $45–$55 for construction-grade panels and $65–$90+ for cabinet-grade hardwood faces. Better cores cost more but save headaches when cutting dados and edges.

Concluding Notes

Plywood sheet cost depends on what the panel is built to do. Sheathing stays in a lower band because it’s graded for structure, not looks. Cabinet-grade sheets cost more because the faces and core stay tighter and cleaner. When you shop, compare the same thickness, the same exposure rating, and the same grade. Then inspect for warp, face checks, and edge voids before the sheet goes on your cart.