How Many Sheets of Plywood Are in a Bundle, Bunk, or Pallet

How many sheets of plywood are in a bundle, bunk, or pallet? There isn’t one universal count. Lumberyards, wholesalers, and big-box stores stack plywood to match their supplier packaging, forklift limits, and delivery habits. Most stacks look “standard” from a distance, but the sheet count can change with thickness, product grade, and even the mill that shipped it. Use the ranges below to get close, then confirm the exact count from the unit tag or invoice before you place an order or schedule a drop.

Contents Here

- 1 Bundle vs bunk vs unit vs lift vs pallet

- 2 How many sheets of plywood in a bundle?

- 3 How many sheets in a bunk of plywood?

- 4 How many sheets of 1/2 plywood in a pallet?

- 5 What affects bundle count?

- 6 Why counts vary

- 7 Typical ranges you’ll often see (and how to use them)

- 8 How to confirm the count fast

- 9 Delivery and storage tips for flat, usable sheets

- 10 FAQs: Common Questions

- 11 Bottom Line

Bundle vs bunk vs unit vs lift vs pallet

Lumber dealers use overlapping words, and the same yard may use two terms for the same stack.

- Bundle: A strapped stack of sheets packaged for shipping. Some yards use “bundle” for smaller counts, others use it for any strapped unit.

- Bunk: A stack handled as one unit with forks. Many people picture a taller stack when they say “bunk,” but the count still varies.

- Unit: A general term for one shippable stack from a supplier or distribution center.

- Lift: A stack that gets lifted by forklift as one piece. “Lift” often equals “unit” in practice.

- Pallet: Sometimes plywood sits on an actual pallet, but lots of plywood ships on runners or stickers and still gets called a “pallet.”

The key point: the word tells you how it moves, not how many sheets it contains.

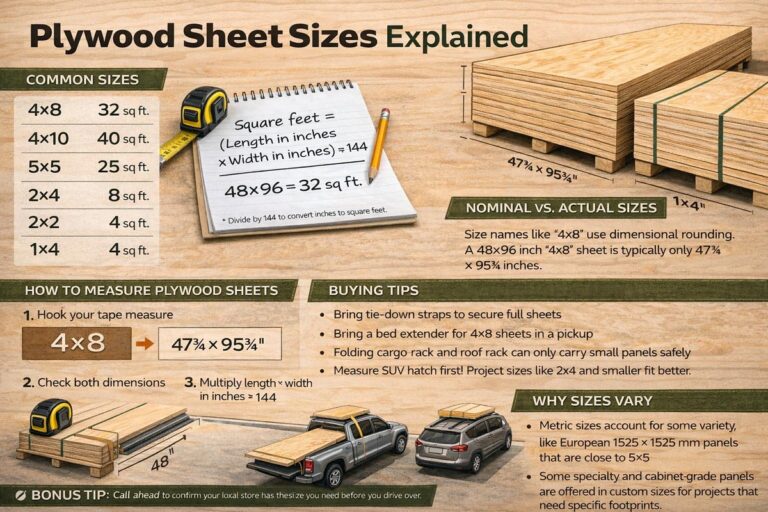

Read more: Plywood Thickness Guide: 9 Must-Know Sizes (Nominal vs Actual)

How many sheets of plywood in a bundle?

A plywood bundle often lands in a predictable range, but the exact number depends on thickness and what the supplier decided to strap.

For common 4×8 construction plywood, yards often see these “often-seen” ranges:

- 1/4-inch plywood: often 50–80 sheets per bundle (thin sheets stack high before they hit weight limits).

- 3/8-inch plywood: often 40–70 sheets per bundle.

- 1/2-inch plywood: often 40–60 sheets per bundle.

- 5/8-inch plywood: often 30–50 sheets per bundle.

- 3/4-inch plywood: often 20–40 sheets per bundle.

Those ranges describe what shows up frequently at U.S.-style lumber distribution, but supplier packaging decides the count. Two bundles can look the same height and still differ if the core species, glue line, moisture, or grade changes the weight per sheet.

How many sheets in a bunk of plywood?

A bunk usually means “a full forklift-handled stack,” which makes people assume a fixed number. It is not fixed.

For 4×8 sheets, a bunk commonly lines up with these ranges:

- 1/2-inch plywood bunk: often 40–60 sheets

- 3/4-inch plywood bunk: often 20–40 sheets

- Thicker specialty panels (like 1-inch and up): often 10–30 sheets depending on weight and handling

Why the wide swing? A bunk is built to be moved safely. Dealers adjust counts so a forklift can pick it, a delivery truck can carry it, and the stack stays stable on uneven ground.

How many sheets of 1/2 plywood in a pallet?

For 1/2-inch plywood, “pallet” often means a single shippable unit from the supplier. The often-seen count is commonly in the 40–60 sheet range for 4×8 panels.

Here are the situations that push the count up or down:

- Heavier panel types (denser cores, extra glue, some imported panels) often ship at the lower end of the range.

- Big-box retail handling sometimes favors counts that break down neatly for stocking, so you may see consistent “store units,” but they still vary by region and supplier.

- Moisture-resistant or specialty panels can arrive with different counts because they weigh more per sheet or get packaged for protection.

If you need an exact number for ordering, treat “pallet” as “one unit,” then confirm the unit count from the tag.

What affects bundle count?

Bundle sheet count changes when the supplier changes any of these.

- Thickness: thicker sheets hit weight limits fast.

- Product type: sheathing, sanded, cabinet-grade, marine, treated, and specialty cores stack differently.

- Supplier packaging: mills and distributors choose counts that match their equipment, wrappers, and freight targets.

Why counts vary

Thickness changes weight fast

Thicker plywood adds weight per sheet, so suppliers reduce the sheet count to keep the unit movable and shippable.

Supplier and mill packaging sets the “unit”

Mills package panels in standard units for their own lines and shipping routines. Your yard often receives those units intact.

Weight limits and freight rules shape the stack

Forklifts, trucks, and racks have limits. Dealers build units that stay under safe handling weights and that fit on delivery trucks without shifting.

Store handling affects what you see on the floor

Retail stores may break units down or re-stack for sales space. What looks like a “bundle” on the floor may be a partial unit.

Typical ranges you’ll often see (and how to use them)

Use typical ranges for planning, not for billing.

- Estimating for a jobsite: ranges help you guess how many “units” fit on a truck.

- Estimating for a shop: ranges help you plan storage space and sticker material.

- Ordering: ranges do not replace the unit tag or invoice line item.

If you need a safe habit: assume the lower end of the range when you plan weight and space. That keeps you from overloading racks or running short on room.

How to confirm the count fast

What to ask the yard

Ask questions that force a number tied to their current stock.

- “How many sheets are in your current lift of 1/2-inch 4×8?”

- “Is that a full unit from the mill or a broken unit?”

- “Can you read me the unit tag quantity before I pay?”

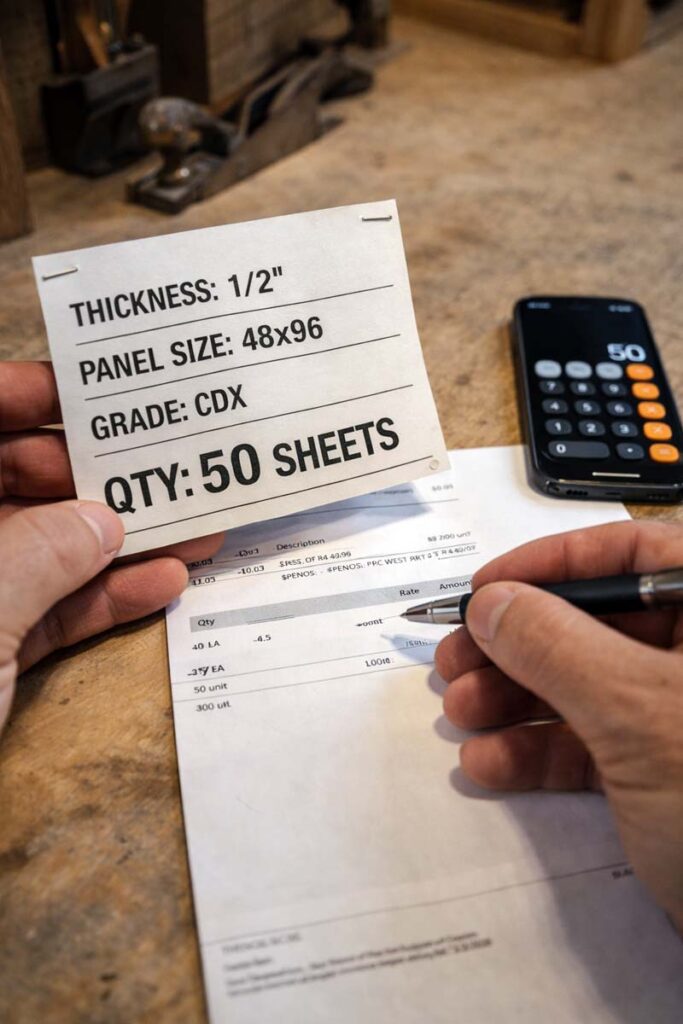

Most strapped units carry a tag or printed wrap. Look for:

- Quantity (QTY) or Count

- Thickness (actual vs nominal)

- Panel size (4×8, 4×10, 5×5)

- Grade or rating (sheathing, sanded, cabinet-grade)

If you see a unit tag, trust the printed quantity over guesses based on stack height.

What to check on invoices and pickup tickets

On paperwork, the count usually shows up as:

- EA (each sheet) with a number

- Unit quantity with a note like “1 unit” plus a sheet count in the description

- A line description that includes “X sheets per unit”

If the invoice says “1 unit” but does not show sheet count, ask for the expanded description before you leave the counter.

Delivery and storage tips for flat, usable sheets

Plywood stays straight when it stays supported, flat, and protected from wet cycling.

Delivery checks that prevent ugly surprises

- Check that the stack sits on even runners and that forks did not crush corners.

- Look for strap damage that lets sheets slide and rack out of square.

- If rain is in the forecast, confirm the driver has a cover or bring your own tarp.

Storage that keeps sheets flat

- Support the stack on level stickers or runners with support points lined up.

- Keep the stack off concrete to reduce moisture pickup.

- Put a flat top sheet or sacrificial panel on top, then add light weight if needed.

A practical sticker approach in most shops: place stickers at regular spacing, keep them aligned vertically, and avoid gaps where sheets can sag.

Moisture protection that works in a yard or shop

- Cover the top, then leave the sides able to breathe so condensation does not get trapped.

- If sheets arrive wet, separate a few and let air move before you wrap the whole stack tight.

FAQs: Common Questions

How many sheets are in a bundle of plywood?

Most plywood bundles land in a supplier-set range, not a fixed number. Depending on thickness and product type, you’ll often see roughly 20–80 sheets, with 1/2-inch commonly around 40–60.

Is a bunk always 48 sheets?

No. Some yards often stack certain panels around 48 sheets, but a bunk count changes with thickness, weight limits, and how the supplier ships units. Always verify the unit tag or invoice.

Does “bundle” always mean a partial stack?

Not always. Some yards use “bundle” for a full mill unit that’s strapped and shipped as-is, while others mean a broken-down stack. The banding tag and paperwork tell you which.

Do sheet counts change with panel size?

Yes. A 4×10 or 5×5 sheet weighs more and stacks differently than a 4×8, so suppliers adjust the unit count to stay within handling and shipping limits. Expect different counts.

Bottom Line

Bundle, bunk, lift, unit, and pallet all describe how plywood moves through a supply chain, not a guaranteed sheet count. Thickness drives weight, mills choose packaging, and yards adjust stacks for safe handling. Use typical ranges to estimate, then confirm the real number from the unit tag and your invoice. That quick check saves return trips, prevents short counts on deliveries, and keeps your storage plan honest.