How Does Polyurethane Glue Work? 7 Proven Rules for Strong Joints

Understanding how does polyurethane glue work comes down to a moisture-triggered chemical cure that hardens into plastic while it expands into foam.

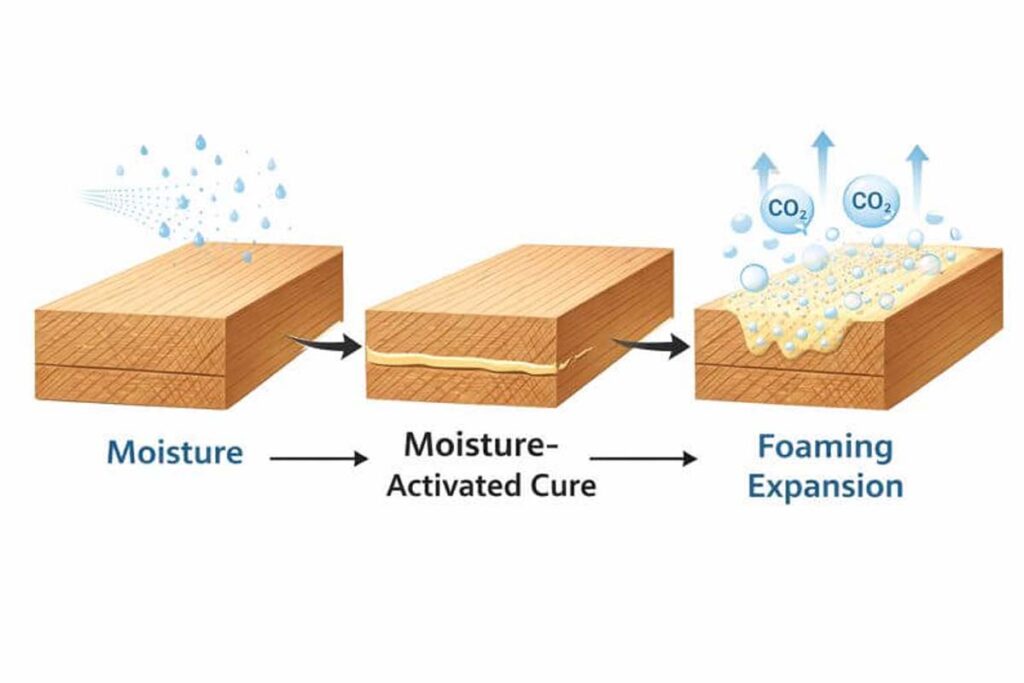

Polyurethane glue cures when moisture triggers a chemical reaction inside the glue line. That reaction builds a tough, crosslinked polymer and releases carbon dioxide gas, which is why the glue foams as it sets.

If you treat it like yellow PVA wood glue, polyurethane glue makes a mess and delivers weaker joints. If you treat it like a moisture-cure adhesive that needs tight clamping, it earns its keep on mixed-material repairs and wet environments.

Contents Here

- 1 What is polyurethane glue?

- 2 What actually happens when polyurethane glue cures?

- 3 Why does polyurethane glue foam and expand?

- 4 What materials does polyurethane glue bond well?

- 5 When does polyurethane glue beat PVA (yellow) wood glue?

- 6 How do you apply polyurethane glue for a clean, strong joint?

- 7 How long does polyurethane glue take to set and fully cure?

- 8 How do you clean up polyurethane glue without wrecking the work?

- 9 What mistakes make polyurethane glue joints fail?

- 10 Is polyurethane glue safe to use in a small shop?

- 11 FAQs about polyurethane glue

- 12 Final Thoughts

What is polyurethane glue?

Polyurethane glue is a one-part “urethane” adhesive that cures by reacting with moisture instead of drying by evaporation.

Most shop bottles are the brown, expanding type sold for wood and multi-surface bonding. Brands market it as waterproof and suited to dissimilar materials, which is the main reason woodworkers reach for it.

Learn more: How Long Does Loctite Polyurethane Glue Take to Dry – 3 Timing Rules

What actually happens when polyurethane glue cures?

Polyurethane glue cures when reactive “NCO” groups in the prepolymer react with water. That reaction forms new chemical links (including urea bonds) that turn the liquid into a solid adhesive network.

The same moisture reaction releases carbon dioxide (CO₂) as a by-product. CO₂ creates bubbles in the curing adhesive, which shows up as foam in the squeeze-out and sometimes inside the bond line.

Why does polyurethane glue foam and expand?

Polyurethane glue foams because the cure reaction releases CO₂ gas inside the glue.

Many consumer formulas expand several times their applied volume during cure, so a thick bead turns into a big ridge of foam. Gorilla’s instructions warn that squeeze-out expands and note expansion in the 3–4× range.

Foam helps the glue wet irregular surfaces, but the foam itself is not a substitute for a tight-fitting joint. A strong joint still comes from wood-to-wood contact and steady clamping pressure.

What materials does polyurethane glue bond well?

Polyurethane glue bonds well when surfaces are clean, fitted, and clamped tight.

Manufacturers list wood-to-wood bonding plus many non-wood materials such as metal, ceramic, stone, and some plastics.

Two shop realities matter here:

- Surface energy rules the day. Some plastics still resist glue even if the label says “most plastics.”

- Fit matters more than “gap filling.” Polyurethane glue can bridge small voids, but the strongest bonds come from tight mating faces.

If your project is strictly wood-to-wood, compare your options before committing. My breakdown of wood glue vs epoxy helps you pick based on load, gap size, and moisture exposure.

When does polyurethane glue beat PVA (yellow) wood glue?

Polyurethane glue wins when moisture and mixed materials are the problem you’re solving.

Use polyurethane glue when:

- The joint sees water or weather and you want a waterproof bond line.

- You’re bonding dissimilar materials like wood to metal or ceramic.

- You need a longer assembly window than fast-setting glues; product specs often list assembly/working times in the 20–30 minute range.

Avoid polyurethane glue when:

- You need a structural adhesive for load-rated applications; Titebond explicitly lists a “not for structural applications” limitation.

- You can’t clamp reliably. Polyurethane glue needs mechanical pressure while it cures.

If your real need is “waterproof wood glue” for wood-only joints, start with this guide to waterproof wood glues and choose based on joint type and cleanup tolerance.

How do you apply polyurethane glue for a clean, strong joint?

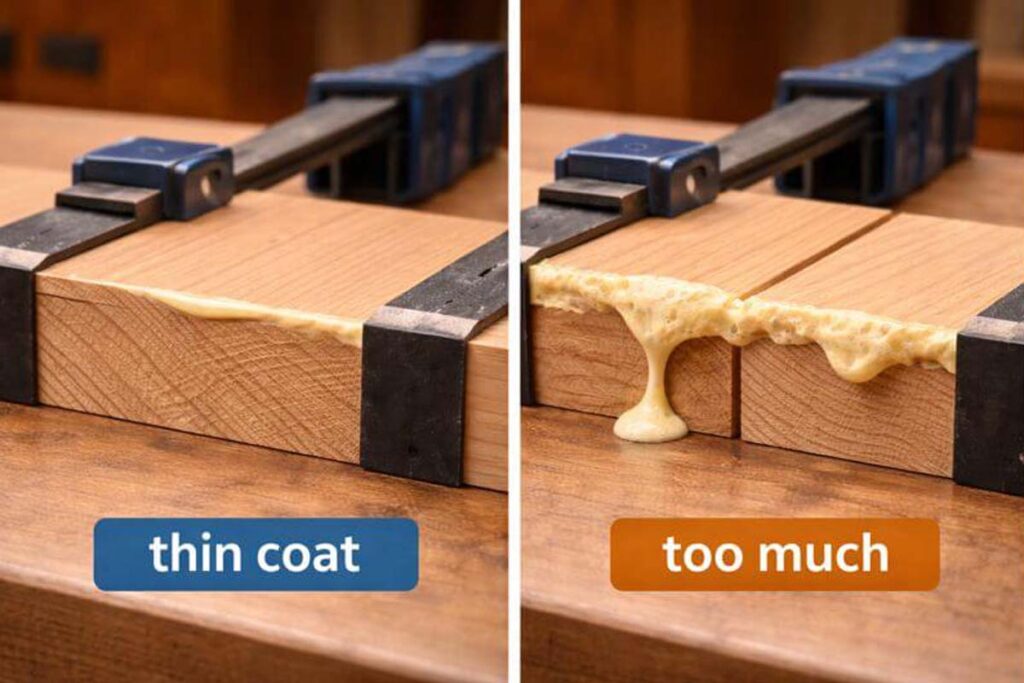

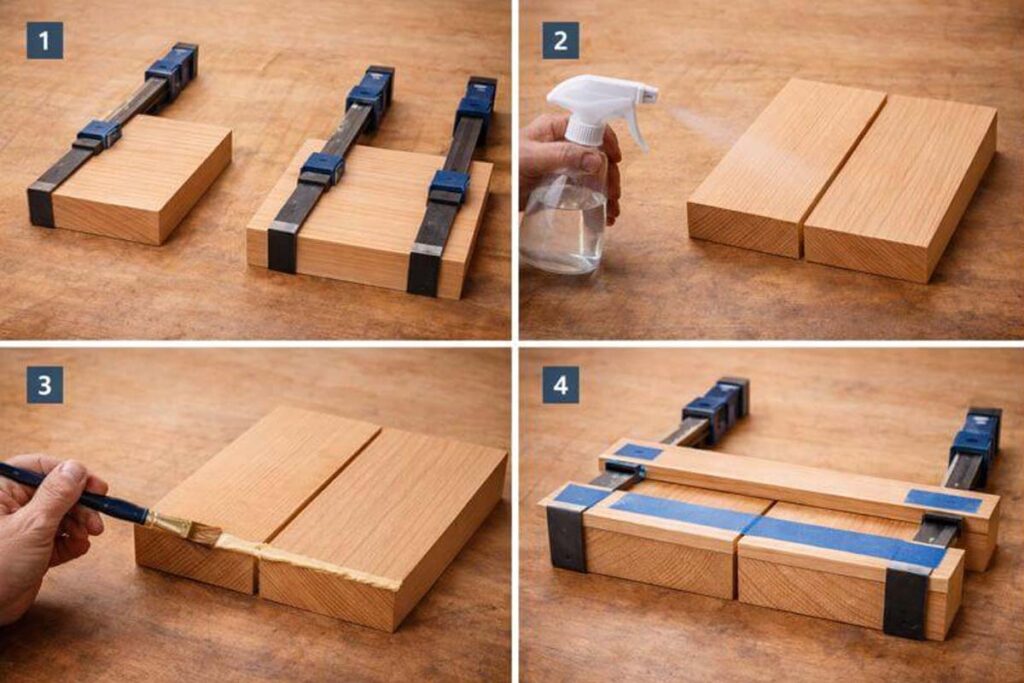

Polyurethane glue applies best as a thin film on a tight joint with light moisture and firm clamping.

- Dry-fit and clamp rehearsal: A dry run confirms the joint closes fully and your clamps land where you need them. If you want a quick clamp-time baseline, see how long to clamp wood glue and then follow the polyurethane label for your specific product.

- Dampen one surface lightly: A light mist activates the cure without soaking the fibers. Gorilla’s directions call for lightly dampening a surface and avoiding saturation.

- Spread a thin layer of glue: A thin coat reduces foam, reduces cleanup, and keeps the joint from being pushed open. Gorilla’s instructions explicitly warn against over-application because the glue expands.

If you tend to overdo glue, use this sizing mindset from how much wood glue to use and then scale down for polyurethane. - Clamp tight until the joint stops moving: Clamping holds alignment while the glue expands and cures. Gorilla calls for gripping/clamping for 1–2 hours, and Titebond lists a short clamp time on its polyurethane product page.

- Control squeeze-out early: Tape the seam with painter’s tape before glue-up if you care about finish. Pull the tape while the squeeze-out is still rubbery, then scrape what remains after cure.

How long does polyurethane glue take to set and fully cure?

Polyurethane glue reaches handling strength under clamp and reaches full cure later, with humidity and temperature driving the speed.

One common reference point is Original Gorilla Glue: it calls for gripping/clamping for 1–2 hours and lists full cure at 24 hours.

Product specs also set minimum temperatures; Titebond lists an application temperature above 50°F (10°C) for its polyurethane glue.

Treat those numbers as product-specific, not universal. Read your bottle’s label and match your shop conditions to the spec sheet.

How do you clean up polyurethane glue without wrecking the work?

Polyurethane glue cleans up easily only while it’s still wet.

Titebond lists mineral spirits for wet cleanup and scraping or sanding after cure. Gorilla notes that cured squeeze-out generally comes off by mechanical removal like sanding, scraping, or chiseling.

Two practical tricks:

- Masking tape at the seam keeps foam off surrounding grain.

- A sharp card scraper removes cured ridges without digging like coarse sandpaper.

If glue ends up on your hands, start with this first-aid style walkthrough: how to get wood glue off skin (the mechanics—peel, wash, avoid solvents on skin—translate well).

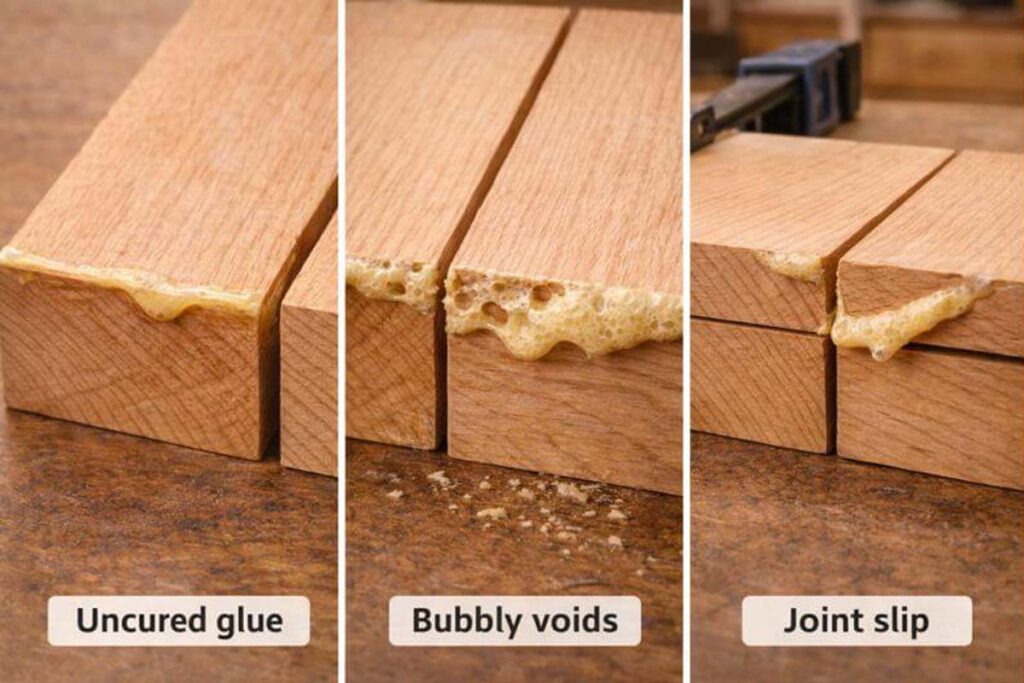

What mistakes make polyurethane glue joints fail?

Polyurethane glue fails most often from missing moisture, too much glue, or weak clamping.

- Dry joint + dry air = slow or incomplete cure. Gorilla states the adhesive requires moisture to start the curing process.

- Over-application forces foam into the joint line. Expansion increases squeeze-out and can push parts out of alignment.

- “Gap filling” becomes “bubble filling.” CO₂ bubbles can create voids that reduce final properties when moisture is excessive.

- No clamp pressure leaves a weak, foamy bond. Both Gorilla instructions and Titebond guidelines emphasize holding parts tightly together.

Is polyurethane glue safe to use in a small shop?

Polyurethane glue is safe to use when you control skin contact and ventilation, because polyurethane chemistry often involves isocyanate-reactive components that can irritate and sensitize people.

OSHA notes isocyanates can affect the skin and mucous membranes and that hazardous exposures can lead to lung problems, including occupational asthma.

Basic shop controls that actually help:

- Wear nitrile gloves and long sleeves for glue-ups.

- Ventilate the bench area, especially on big surface-area laminations.

- Read the SDS for your specific product and follow its exposure guidance.

FAQs about polyurethane glue

Does polyurethane glue work without clamping?

Polyurethane glue needs mechanical pressure to hold parts in contact while it cures. Gorilla’s directions call for gripping/clamping for 1–2 hours, and its FAQ warns that skipping clamping risks failure because the glue is not fast-acting.

Does polyurethane glue dry clear?

Most expanding polyurethane glues cure to a light amber/yellow and leave a foamy texture in squeeze-out. Gorilla describes a pale yellow cured color with a foam consistency.

Can I use polyurethane glue for underwater repairs?

Many polyurethane wood glues are waterproof after cure, but that does not automatically make them “below the waterline” adhesives. Titebond lists a limitation that its polyurethane glue is not for use below the waterline.

What’s the cleanest way to avoid foam squeeze-out on visible joints?

Painter’s tape and thin glue application control squeeze-out best. Gorilla’s instructions warn that over-application increases expansion and squeeze-out, so a thin film plus tight clamping keeps the glue where you need it.

Final Thoughts

How polyurethane glue works is simple: moisture triggers a cure that hardens into polymer while expansion creates foam and squeeze-out. Tight joinery, controlled moisture, and firm clamping deliver the strongest results. Clean squeeze-out with intention, and choose epoxy or PVA when the job calls for gap filling or stain-friendly glue lines.