Gap Filling Wood Glue in 2026: 8 Smart Picks for Stronger Joints

Gap filling wood glue is useful when a joint won’t close perfectly under clamps. It can also be misunderstood, because most wood glues reach peak strength in a thin glue line. This guide shows what “gap filling” truly means, which adhesives actually handle gaps, and how to get reliable joints without guesswork.

Contents Here

- 1 Quick Checklist: Top 8 Gap Filling Wood Glue Picks

- 2 What “gap filling” really means in woodworking

- 3 Types of “gap-filling” adhesives competitors mention and what they’re best at

- 4 Reviews of the 8 Best Gap Filling Wood Glues

- 4.1 Gorilla Max Strength Construction Adhesive

- 4.2 Gorilla All Purpose Wood Filler

- 4.3 Starbond Thick Super Glue Pro Kit

- 4.4 LOOCTOT 60g Thick CA Glue for Gap Filling

- 4.5 Titebond 1413 III Ultimate Wood Glue for Gap Filling

- 4.6 J-B Weld ClearWeld 5 Minute Epoxy

- 4.7 Loctite Epoxy Instant Mix 5 Minute

- 4.8 Gorilla Heavy Duty Construction Adhesive for Gap Filling

- 5 How to choose the right product by gap size and project type

- 6 How to apply gap-filling wood glue so the joint actually holds

- 7 Sanding, staining, and finishing after a “gap-filled” glue-up

- 8 Common mistakes people make with gap filling wood glue

- 9 Safety, storage, and shelf-life basics

- 10 FAQs on Gap Filling Wood Glue

- 10.1 Can wood glue really fill gaps, or does it need a tight joint?

- 10.2 Is epoxy better than wood glue for gap filling and repairs?

- 10.3 Does polyurethane glue actually “expand to fill gaps,” and how much is too much?

- 10.4 What’s the strongest glue for a loose or wobbly joint with gaps?

- 10.5 Can you stain and finish over glue lines or squeeze-out without blotches?

- 10.6 How long should I clamp gap-filling wood glue before sanding or stressing the joint?

- 10.7 Which wood glues are more water-resistant for outdoor projects?

- 11 Parting Notes

Quick Checklist: Top 8 Gap Filling Wood Glue Picks

- Gorilla Max Strength Construction Adhesive

- Gorilla All Purpose Wood Filler

- Starbond Thick Super Glue Pro Kit

- LOOCTOT 60g Thick CA Glue

- Titebond 1413 III Ultimate Wood Glue

- J-B Weld ClearWeld 5 Minute Epoxy

- Loctite Epoxy Instant Mix 5 Minute

- Gorilla Heavy Duty Construction Adhesive

Are you searching for a strong wood glue for repairs that actually holds up on chair legs and loose joints? If so, then check now.

What “gap filling” really means in woodworking

“Gap filling” describes how an adhesive behaves when two wood surfaces do not touch everywhere. Some glues can bridge tiny inconsistencies. Other products can cure into a solid mass that supports a real void. Those are not the same job.

A practical way to think about gaps:

- Hairline gap: the joint touches, but the seam shows.

- Small visible gap: contact is uneven, but parts still register.

- Void or missing wood: there is space that wood no longer occupies.

If there is missing wood, glue alone is not a wood replacement. You either improve the fit, add a patch, or use a structural filler approach.

Structural gap filling vs cosmetic filling

Cosmetic filling is about hiding a line before finishing. Structural gap filling is about keeping the joint from loosening later.

A chair rung, a table apron, or a door rail needs strength first. In those cases, a glue that merely “fills the space” visually can still fail. If the joint is load-bearing, treat the gap as a strength problem.

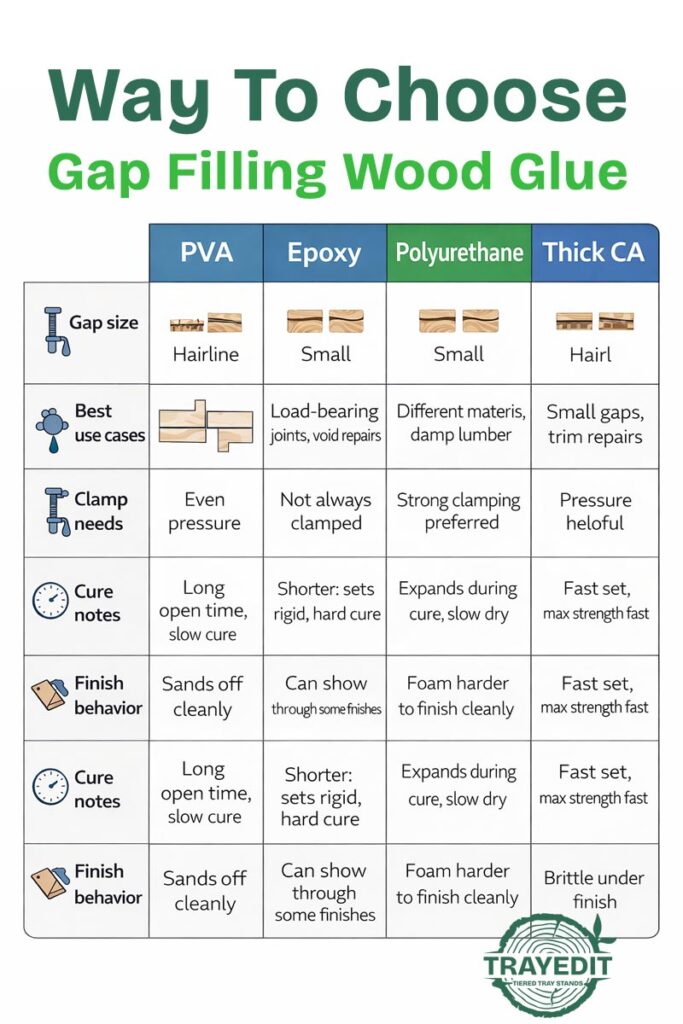

Types of “gap-filling” adhesives competitors mention and what they’re best at

Most top pages cover the same adhesive families because they solve different problems. You can write this section as a clear comparison, then apply it later to real situations.

High-solids PVA wood glues

PVA wood glue is the standard choice for tight joinery and panel glue-ups. Thicker, higher-solids formulas can tolerate minor imperfections, but they still want wood-to-wood contact. They are easy to spread, easy to clean, and easy to sand.

Use PVA when the joint closes with clamping pressure and the gap is minor. If you want a realistic feel for what a proper glue joint can handle, read this piece on how strong a well-made glue joint can be.

Avoid relying on PVA when the parts do not meet in the middle. In bigger gaps, PVA shrinks as water leaves the glue. That shrinkage lowers strength and leaves a weak glue ridge.

Epoxy

Epoxy is a true gap-filling adhesive because it cures into a solid plastic-like mass. It does not depend on evaporation like PVA. It can bond uneven surfaces and remain strong across small voids. Epoxy is also useful when you are bonding wood to metal, stone, or composites.

Epoxy takes more steps because it must be mixed correctly. It also needs time to cure and a little more cleanup planning. When a joint will not close or a repair must carry load, epoxy is usually the safest move. If you want a direct comparison, this guide on choosing between epoxy and common woodworking glue will support the decision.

Polyurethane glue

Polyurethane glue expands as it cures, which is why people call it “gap filling.” The expansion can help it reach into tiny voids, but the foamed material is not the same as solid adhesive. In wide gaps, the foam can be weak and crumbly.

Polyurethane glue can still be useful when materials differ or moisture is involved. It also benefits from good clamping because expansion can push joints apart. Treat it as a specialized option, not a cure-all.

Thick and gel CA glue

CA glue works for fast fixes, small chips, and tiny gaps in non-structural areas. Thick and gel CA can bridge small spaces better than thin CA. It can also be handy for quick trim repairs and small corner dings.

CA glue is not a great choice for joints that flex or carry load. It can be brittle in furniture joinery. If you need help placing CA in the big picture, see this breakdown of when super glue makes sense on wood projects.

Reviews of the 8 Best Gap Filling Wood Glues

Gorilla Max Strength Construction Adhesive

Clear, heavy-duty gap-bridging adhesive for mixed-material repairs

This is a high-viscosity hybrid adhesive that works more like construction caulk than joinery glue. It’s best when wood meets stone, glass, fiberglass, or foam and you want a strong bond plus a cleaner-looking, clear cure. Use it for trim, wall repairs, and exterior fixes—not fine furniture joints that need tight wood-to-wood contact.

$13.84 at AmazonSpecifications:

- Form: Paste (tube), high viscosity

- Full cure: 24 hours

- Water resistance: Waterproof

- Feature: Dries clear, repositionable

- Bonds: Wood, glass, stone, fiberglass, foam

Pros:

- Strong hold on many materials

- Dries clear and paintable

Cons:

- Price bit expensive

Gorilla All Purpose Wood Filler

Water-resistant crack and hole repair for cleaner seams before finishing

This isn’t glue—it’s a filler that’s useful when gaps are cosmetic. Use it to level cracks, gouges, nail holes, and small voids after the joint is already structurally sound. It spreads easily, sands smooth, and can be stained or painted, which helps hide imperfect seams on trim and furniture. It also holds nails and screws better than many soft fillers.

$8.42 at AmazonSpecifications:

- Material: Acrylic

- Full cure: 6 hours

- Water resistance

- Form: Paste (tube)

- Finish: Paintable, stainable, sandable

Pros:

- Doesn’t shrink or crack easily

- Good for stain-grade touchups

Cons:

- Not a structural adhesive

Starbond Thick Super Glue Pro Kit

Thick CA for tiny gaps, knots, and fast woodworking fixes

This thick cyanoacrylate is a smart pick for small-gap bonding, knot filling, and quick repairs where clamps are awkward. It gives you a little positioning time, then locks up fast—especially with an accelerator. Keep expectations realistic: it’s great for small gaps and rigid parts, but it’s not the best choice for joints that flex or live outdoors.

$14.79 at AmazonSpecifications:

- Material: Cyanoacrylate (CA), thick liquid

- Viscosity: 2000 cps (honey-like)

- Gap fill: ~0.01–0.02 in

- Full cure: ~30 seconds

- Water resistance: Not water resistant

Pros:

- Fast, clean, precise repairs

- Excellent for knots and small voids

Cons:

- Brittle on stressed joints

LOOCTOT 60g Thick CA Glue for Gap Filling

Waterproof thick CA for quick bonding and small seam filling

This thick CA is aimed at quick gap filling with a controlled-flow bottle and anti-clog cap. It grabs in 20–30 seconds, then reaches waterproof performance after a full 24-hour cure. It’s useful for small cracks, trim corners, and tight repairs where you need speed. Wear gloves and avoid overuse—CA can leave a hard ridge that sands slower than wood.

$9.99 at AmazonSpecifications:

- Material: Cyanoacrylic (CA)

- Viscosity: 2000 cps

- Set time: 20–30 seconds

- Full cure: 24 hours

- Tensile strength: 3500 PSI

Pros:

- Fast grab with clear finish

- Waterproof after full cure

Cons:

- Can be brittle on flexible joints

Titebond 1413 III Ultimate Wood Glue for Gap Filling

Waterproof PVA gel for tight joints and slightly imperfect fits

Titebond III is a high-viscosity PVA gel that excels when parts fit well but need longer open time and strong water resistance. It’s a go-to for cutting boards, outdoor furniture (not submerged), and general woodworking because it sands well and cleans up with water. It can tolerate minor imperfections, but it’s not a “fill big gaps” product—joint fit still matters.

$7.48 at AmazonSpecifications:

- Form: Gel, high viscosity

- Clamp time: ~1 hour

- Full cure: 24 hours

- Water resistance: Waterproof

- Note: Indirect food-contact approved

Pros:

- Strong, reliable, easy cleanup

- Great open time for assemblies

Cons:

- Needs temperatures above 47°F

J-B Weld ClearWeld 5 Minute Epoxy

Clear two-part epoxy for repairs that need strength fast

ClearWeld is a quick-setting epoxy that bonds wood plus many non-wood materials, making it great for repairs, hardware fixes, and small voids that need real strength. The syringe makes 1:1 mixing simple, and it cures clear. Because it’s low viscosity, it can run on vertical surfaces—mask and brace your work so it stays where you want it.

$13.02 at AmazonSpecifications:

- Type: Two-part epoxy, clear

- Set time: 5 minutes

- Full cure: 1 hour

- Tensile strength: 3900 PSI

- Water resistance: Water resistant

Pros:

- Strong bond on mixed materials

- Fast cure for quick repairs

Cons:

- Can drip if not contained

Loctite Epoxy Instant Mix 5 Minute

Self-mixing epoxy for rigid gap filling and permanent fixes

This epoxy is built for speed and convenience. The self-mixing nozzle dispenses resin and hardener evenly, which helps avoid weak mixes. It sets in about 5 minutes and reaches handling strength in around an hour. It’s also useful as a filler because it doesn’t shrink and can be sanded, drilled, and painted after cure.

$14.10 at AmazonSpecifications:

- Type: Two-part epoxy, self-mixing nozzle

- Set time: 5 minutes

- Full cure: 1 hour

- Viscosity: Moderate

- Water resistance: Water resistant

Pros:

- Easy mixing, consistent results

- Sands and paints well after cure

Cons:

- Nozzle can waste product

Gorilla Heavy Duty Construction Adhesive for Gap Filling

Fast-grab gap-filling adhesive for trim, panels, and jobsite repairs

This is another hybrid construction adhesive designed for broad surface contact and quick grab—useful for trim, paneling, masonry-to-wood, and outdoor fixes. It’s paintable, waterproof after cure, and handles wet surfaces better than typical wood glue. For fine woodworking joints, it’s usually overkill and can be messy; it shines when you need a strong, forgiving bond in home projects.

$8.91 at AmazonSpecifications:

- Form: Cartridge, high viscosity

- Grab time: ~30 seconds

- Full cure: 24 hours

- Water resistance: Waterproof

- Use: Indoor/outdoor, multi-surface

Pros:

- Fast hold for vertical work

- Works on many building materials

Cons:

- Cleanup is tougher than PVA

How to choose the right product by gap size and project type

This is a buying decision guide. Follow the given below steps before picking your perfect one.

If the gap is hairline to barely visible

Choose a quality PVA and focus on fit and clamping technique. A thin glue line is stronger than a thick one. Dry-fit, clamp lightly, and check alignment before you spread glue. Then glue and clamp with even pressure.

For timing, use a consistent clamp schedule instead of guessing. This guide on how long clamps should stay on glued joints is a solid reference for common shop conditions.

If the gap is visible but still small

First, try to improve the fit. A few passes with a plane, a better caul, or a fresh cut usually beats any “gap filling” claim.

If you cannot improve the fit and the joint matters structurally, move toward epoxy. And If the joint is low-stress and the gap is tiny, a thicker PVA may still work when the parts touch enough.

If there’s a void, missing corner, or chunky damage

Do not expect wood glue to replace missing wood fibers. A void needs a structural repair approach. That often means epoxy for strength, or a patch and re-cut for clean joinery.

A simple rule helps here: if you can press the parts together and they stay registered, glue can do its job. If the parts float, rock, or wobble, fix the structure first.

How to apply gap-filling wood glue so the joint actually holds

Strong bonds come from surface prep, correct assembly time, and correct pressure. Many glue failures come from skipping one of those basics.

Surface prep and dry-fit checklist

Start with clean surfaces that mate correctly:

- Remove dust and sanding fuzz at the joint.

- Dry-fit and confirm the joint seats fully.

- Stage clamps and cauls before opening the glue.

- Check that clamps pull straight, not sideways.

Temperature matters more than most people think. Cold shops slow curing and increase clamp time needs. If you need to speed things up, do it safely with warmth and airflow. This guide on speeding drying without weakening the bond covers the safe approach.

Open time, clamp time, and full cure

These are three different stages, and mixing them up causes problems.

Open time is how long you can assemble after spreading glue. Clamp time is how long the joint must stay under pressure. Full cure is when the joint reaches full strength.

If you want a simple baseline, use these two references: typical drying timelines before handling and what “fully cured” means for strength.

Cleanup and controlling squeeze-out

Squeeze-out is normal, but it should be controlled. Too much glue creates finishing problems and extra sanding.

Use tape near visible seams when you want clean edges. Wipe fresh squeeze-out carefully without pushing it into pores. If you prefer a cleaner finish, let squeeze-out gel slightly, then slice it off.

If dried glue ends up where it should not be, this guide on removing glue without chewing up the wood surface will help you recover cleanly.

Sanding, staining, and finishing after a “gap-filled” glue-up

Most adhesives do not take stain the same way wood does. Glue smears block stain and leave pale spots. That issue shows up even when the joint is strong.

Your best protection is prevention. Keep glue off the show faces and clean squeeze-out early. If you plan to stain, you will benefit from this explanation of why glue residue causes blotches under stain.

Epoxy can also telegraph under certain finishes if it sits proud of the surface. Keep filled areas flush, sand evenly, and test on scrap when the repair will be visible.

Common mistakes people make with gap filling wood glue

- Using glue as a filler for missing wood. Glue is not wood, and big gaps stay weak.

- Trusting foaming glue for wide voids. Foam can look filled but lack strength.

- Skipping the dry-fit. Dry-fit shows where clamps must go and how parts seat.

- Clamping too lightly. Without pressure, gaps stay open and strength drops.

- Clamping too hard. Over-clamping can starve joints by squeezing glue out.

- Over-applying glue. More glue usually means more mess, not more strength. This guide on how much glue is enough for a strong bond keeps application realistic.

Safety, storage, and shelf-life basics

- PVA wood glue is generally mild, but you still want basic shop habits. Keep glue off skin and out of eyes.

- Epoxy and polyurethane deserve more caution because they can irritate skin and lungs.

- Use gloves when handling epoxy or polyurethane. Keep ventilation decent and avoid prolonged skin contact. If you do get glue on your hands, this guide on cleaning glue off skin without harsh scraping is a safer method.

- Shelf-life matters. Old glue can fail even if it pours out of the bottle. If glue looks separated, lumpy, or stringy, replace it. This article on whether wood glue expires and how to spot bad glue is worth keeping bookmarked.

FAQs on Gap Filling Wood Glue

Can wood glue really fill gaps, or does it need a tight joint?

Wood glue works best when the parts touch and the glue line stays thin. It can handle tiny imperfections, but it won’t stay strong in wide gaps where the joint has poor wood-to-wood contact.

Is epoxy better than wood glue for gap filling and repairs?

Yes, epoxy is usually better for true gap filling because it cures into a solid mass instead of shrinking as it dries. It’s a strong choice for repairs, loose joints, and uneven mating surfaces.

Does polyurethane glue actually “expand to fill gaps,” and how much is too much?

Polyurethane glue does expand, but the foam isn’t very strong in large voids. If it’s pushing parts apart, making a bubbly mess, or filling a wide gap, you’ve used too much.

What’s the strongest glue for a loose or wobbly joint with gaps?

For loose joints with real gaps, epoxy is often the strongest option because it can fill space and still cure hard. Even better, tighten the fit first, then glue for maximum strength.

Can you stain and finish over glue lines or squeeze-out without blotches?

You can, but only if you remove glue residue completely. Even a thin smear blocks stain and leaves pale patches. Scrape squeeze-out clean, sand evenly, and test stain on scrap first.

How long should I clamp gap-filling wood glue before sanding or stressing the joint?

Clamp time depends on the glue, temperature, and joint fit, but most PVAs need at least 30–60 minutes before unclamping. For sanding or loading the joint, wait overnight or until full cure.

Which wood glues are more water-resistant for outdoor projects?

Type I glues offer higher water resistance for heavy exposure, while Type II handles occasional moisture and outdoor humidity. For outdoor furniture and wet conditions, Type I is usually the safer pick.

Parting Notes

Gap filling wood glue works best when the gap is small and the joint still closes under pressure. When gaps are larger or the joint will carry load, epoxy is often the stronger and safer choice. Start by improving the fit, then choose the adhesive that matches the job.