Does Wood Glue Work on MDF? 7 Quick Ways to Stop Swelling

Does wood glue work on MDF? The answer is yes, when the joint is prepped and clamped right. MDF (medium-density fiberboard) can bond extremely well, but its cut edges love to soak up glue. In this article, I’ll show you what works, what fails, and how to get a clean, strong joint every time.

Contents Here

What MDF Is and Why Gluing It Can Be Tricky

MDF is wood fiber and resin pressed into a dense, smooth sheet. The faces are fairly consistent, which helps glue spread evenly. The edges are a different story, because they’re porous and fuzzy. If you glue edges like solid wood, MDF can “drink” the glue and leave a weak bond.

MDF also hates excess moisture. Most wood glues are water-based, so overapplying glue can swell fibers near the joint. The fix usually isn’t a different product. It’s better prep, less glue, and the right clamping pressure.

Face-to-Face vs. Edge Joints on MDF

Face-to-face MDF joints are usually straightforward, because surface area is generous. A thin, even film of glue and firm clamping often does the job. Edge joints are where people get burned. The edge can absorb glue so fast that the joint ends up “starved.”

If you’re building shelves, boxes, or trim details, treat MDF edges like end grain. That mindset alone prevents most failures.

Does Wood Glue Work on MDF?

Wood glue works on MDF for most indoor projects, including cabinets, trays, and painted builds. You’ll get the best results when the surfaces are clean, lightly scuffed, and clamped until set. The biggest reason people think it “doesn’t work” is rushed timing or dusty edges.

If your project will see standing water, heavy outdoor humidity, or repeated wet wiping, standard glue may not be enough. In those cases, use a more moisture-tolerant adhesive and seal the finished piece properly.

If you’re unsure what “set” and “cure” really mean, read this quick breakdown on how long wood glue takes to set and then check how long for wood glue to fully cure.

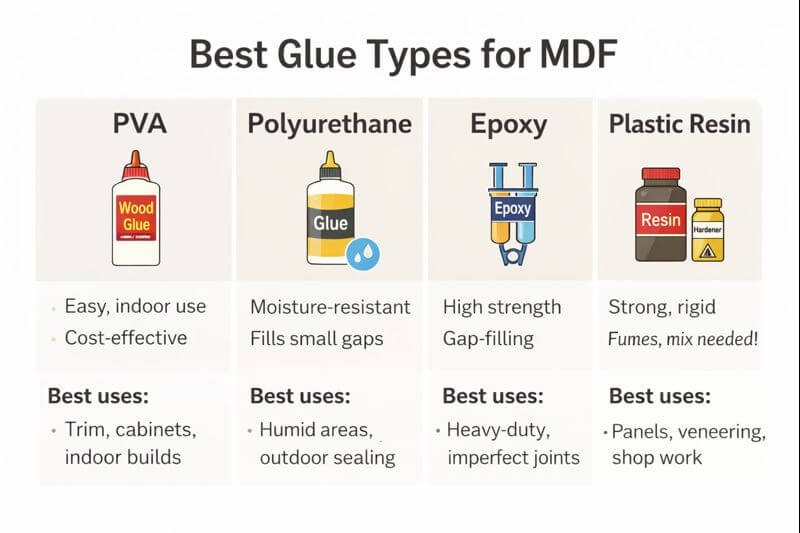

Best Glue Types for MDF and When to Use Each

You don’t need a fancy glue for every MDF job. You need the right match for moisture, stress, and joint style. Here’s how I choose in the shop.

PVA Wood Glue for Everyday MDF Builds

For most indoor MDF assemblies, PVA (carpenter’s glue) is the workhorse. It spreads easily, bonds well, and sands clean once fully cured. Use it for panels, trim returns, and most cabinet carcass joints that also have mechanical support.

If you want a refresher on what you’re actually using, here’s a simple explainer on what PVA wood glue is and how it behaves. If you’re shopping and want proven options, see my picks for best PVA glue choices for woodworking projects.

Polyurethane Glue When Moisture Is a Real Concern

Polyurethane glue can handle damp conditions better than basic PVA. It also expands slightly as it cures, which can help with small gaps. That expansion can be messy, though, and squeeze-out is harder to clean.

For pieces that live in humid rooms, consider pairing a suitable glue with a good finish. This overview of the best waterproof wood glue options can help you pick the right category for your situation.

Epoxy for High-Stress or Imperfect MDF Joints

Two-part epoxy is great when joints aren’t perfect or loads are heavy. It fills gaps, bonds strongly, and isn’t as water-sensitive once cured. It’s slower, costs more, and requires accurate mixing.

If you’re stuck between “regular glue” and epoxy, this comparison of wood glue vs epoxy for real repairs makes the tradeoffs easy to understand.

Plastic Resin Glue for Flat Panels and Shop-Style Work

Urea-formaldehyde (often sold as plastic resin glue) is popular for flat, rigid laminations. It can be very strong and creep-resistant. It also requires mixing, careful handling, and decent ventilation. If you’re new to adhesives, stick with PVA or epoxy first.

How to Glue MDF With Wood Glue Step by Step

This is my go-to process for clean, strong MDF bonds. It’s simple, but every step matters.

Tools and supplies

- MDF parts, cut and dry-fit

- Sandpaper (120–180 grit)

- Vacuum or tack cloth

- PVA glue and a small brush or roller

- Clamps and scrap pads

- Damp rag for cleanup

Surface Prep That Actually Matters

Lightly scuff glossy areas so glue has something to bite into. Don’t gouge the faces, just dull the sheen. Then remove dust completely, because MDF dust acts like a release agent. Vacuum first, then wipe.

If you’re gluing over paint or primer, you’ll usually need to remove it first. Wood glue bonds wood fibers, not slick coatings. Here’s a quick read on whether wood glue sticks to paint so you can plan the prep.

Edge Sealing and “Sizing” for Stronger Edge Joints

For MDF edges, I almost always size the edge first. Brush on a very thin coat of glue, just enough to wet the fibers. Let it soak in for a few minutes, then add your normal glue coat. This reduces absorption and keeps the final joint from starving.

If you’ve ever wondered whether you’re using too much glue, this guide on how much wood glue to apply without starving a joint is worth a quick look.

Gluing and Clamping Without Overdoing It

- Dry-fit the parts and plan clamp placement first.

- Apply a thin, even glue film to both mating surfaces.

- Assemble the joint and clamp with firm, even pressure.

- Wipe squeeze-out with a damp rag while it’s fresh.

- Leave clamps on until the joint is set, then let it cure.

Clamping too hard can squeeze out most of the glue. You want contact, not crushing pressure. If you want practical timing guidance, use these references on how long to clamp wood glue for reliable strength and when it’s safe to remove clamps.

Common MDF Gluing Problems and Fast Fixes

Problem: Weak edge joints

Cause is usually glue starvation or dusty edges. Size the edge, clean dust, and use moderate clamping pressure.

Problem: Swelling along the joint line

Cause is usually too much water-based glue or heavy wipe-down. Apply less glue, wipe lightly, and avoid soaking the seam.

Problem: Joint slips during clamping

MDF faces are smooth, so parts can skate around. Use light clamp pressure first, align, then tighten. Cauls or clamp pads help a lot.

Problem: Ugly squeeze-out on visible corners

Apply a thinner coat and use painter’s tape along the seam. Pull tape while glue is rubbery, not fully hard.

Problem: Glue won’t hold on sealed surfaces

Finish and primer block glue from soaking into fibers. Sand back to raw MDF where the joint needs strength.

If you’re curious about strength expectations, these explainers on how strong wood glue really is and how much weight a glued joint can hold help set realistic limits.

When to Reinforce MDF Joints

Glue alone is fine when you have lots of surface area, like laminating panels. For shelves, boxes, and frames, reinforcement makes MDF builds feel solid and last longer. My favorites are dados, rabbets, corner blocks, and screws used correctly.

If you’re using screws, always predrill in MDF. Choose the right fastener style and depth, and don’t muscle it. These basics on how to screw into wood without causing splits translate well to MDF when you predrill. If your joint design relies on screws, this walkthrough on joining two pieces with screws cleanly can save you a headache.

When a screw hole strips out, MDF can crumble fast. Keep this fix handy for repairing a stripped screw hole before you rebuild the whole corner.

Final Snapshot

Wood glue absolutely works on MDF when you respect the edges and clamp smart. Use a good PVA for most indoor builds, and switch to epoxy or moisture-tolerant glue when conditions demand it. Keep glue thin, surfaces dust-free, and give the joint full cure time before loading it.