Does Wood Glue Expire? 12 Quick Answers for PVA, Epoxy, and CA

Does wood glue expire depends on storage, but every bottle eventually goes bad. In short, yes—wood glue does expire over time, and once it thickens, separates, smells off, or fails a quick scrap-wood test, it should be replaced.

When an older joint pops, it’s usually glue trouble or rushed prep. You can check a questionable bottle in minutes, then decide whether it’s worth trusting. I’ll also show you the storage habits that keep glue usable longer.

Contents Here

- 1 Does wood glue expire or just “age out”?

- 2 How long wood glue lasts (unopened vs. opened)

- 3 What makes wood glue expire faster

- 4 How to tell if wood glue is bad (fast checks)

- 5 Can you use wood glue after the expiration date?

- 6 Can you revive old wood glue?

- 7 How to store wood glue so it lasts longer

- 8 FAQs on does wood glue expire

- 9 Conclusion

Does wood glue expire or just “age out”?

Most woodworking glues have a shelf life, because their chemistry changes in the bottle. With PVA (yellow or white carpenter’s glue), the emulsion can start to break down. With polyurethane glue, moisture exposure after opening starts the countdown. Epoxy and CA (super glue) age too, just in their own ways.

A printed date is a warning, not a verdict you must obey. What matters is performance on wood, not the label. Good glue spreads smoothly, wets the fibers, and cures hard. Bad glue drags, clumps, separates, or stays rubbery after curing.

Why the date on the bottle isn’t the whole story

Manufacturers assume average storage and steady temperatures during that shelf-life estimate. Your garage might freeze in winter or bake in summer, and both shorten life fast. A cool indoor shelf can stretch a bottle well beyond the date.

Treat the date as a nudge to inspect and test. Don’t treat it like an on/off switch.

Learn more on: How Long Should Wood Glue Dry Before Removing Clamps: 5 Pro Tips

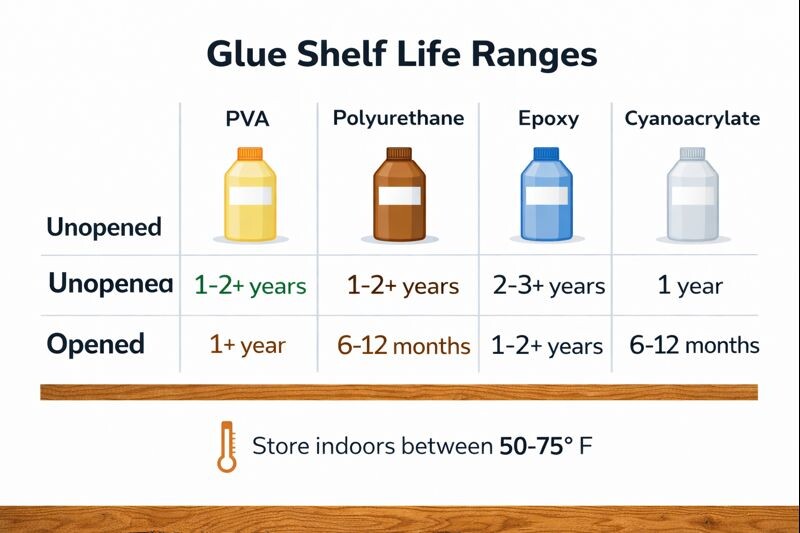

How long wood glue lasts (unopened vs. opened)

Unopened bottles usually last longer, because less air and dust get inside. Once you open a bottle, storage habits matter more than the calendar. That’s why two “same age” bottles can behave very differently.

These ranges keep expectations realistic:

- Unopened PVA (yellow/white glue): often usable for a couple of years indoors.

- Opened PVA: commonly fine for a year or more with decent storage.

- Polyurethane glue: often short-lived after opening, due to moisture reaction.

- Epoxy: can store well, but parts may thicken or crystallize over time.

- CA glue: usually loses punch fastest, especially in warm rooms.

Timing can fool you when you judge glue quality. “Set” is not “fully cured,” and early tests can mislead. Use a clamp-time reference for handling joints when you’re deciding when to unclamp. When the joint must hold, check this full-strength curing reference before stressing it.

Shelf life by glue type (what most readers need)

PVA (carpenter’s glue): Best for tight wood-to-wood joints with good clamping pressure. It’s forgiving in use, but it hates freezing and big temperature swings.

Polyurethane glue: Useful on mixed materials and slightly damp wood, but it’s fussy after opening. As it ages, it can thicken and foam in ways you can’t predict.

Epoxy: Strong and gap-filling when mixed correctly and applied cleanly. If either part won’t blend smooth, or you can’t measure accurately, skip it.

Cyanoacrylate (CA): Great for quick fixes and small parts where clamps are awkward. It can gel in the bottle and lose strength over time.

Hide glue: Traditional and reversible, with its own storage quirks and spoilage risk. If it smells off or looks funky, toss it.

Brand notes people search for (Titebond, Elmer’s, Gorilla)

Most brand-name PVA glues behave similarly in storage, even if labels differ. Cool temperatures help, and tight caps help even more than people think. Freezing is still the biggest risk for typical carpenter’s glue. Polyurethane “expanding” glues tend to be fussier once opened.

When you’re unsure, trust the condition and the test. The label can’t tell you what happened in your shop.

What makes wood glue expire faster

Glue doesn’t fail randomly; it gets pushed there by temperature, air, and contamination. The faster you control those three, the longer your glue stays usable. This is why one bottle lasts years and another dies in a season.

Freezing and freeze/thaw cycles

Freezing can ruin many PVA glues, and repeated freeze/thaw cycles are worse. You’ll often see clumps, separation, or a glue that never cures right. If you store glue in an unheated space, this is the first habit to fix. Keep PVA indoors if winters get cold.

Heat and temperature swings

Heat speeds up aging and thickening, especially in partly used bottles. Temperature swings also pump air in and out of the container, which encourages skinning. The nozzle clogs sooner, and the glue inside changes sooner.

Air exposure, dirty nozzles, and contamination

Loose caps let moisture and air do damage, even if the bottle looks fine. Dirty tips let glue dry at the opening, then chunks fall back inside. Sawdust in the bottle can seed lumps and spoilage. Wipe the tip and cap it right away.

How to tell if wood glue is bad (fast checks)

You don’t need lab gear; you need your eyes and a couple scraps of wood. Start with the bottle, then confirm with a simple joint test. If anything looks suspicious, don’t gamble on a real project.

Common red flags include:

- Lumps, gels, or a “cottage cheese” look

- Stringy glue that drags and won’t level out

- Separation that won’t remix after shaking

- Sour or rotten odor

- Mold or fuzzy growth

- Skinning inside the bottle or thick pudding texture

- Glue that cures tacky and stays soft

If it looks borderline, test it before you commit. A quick test can save hours of rework later.

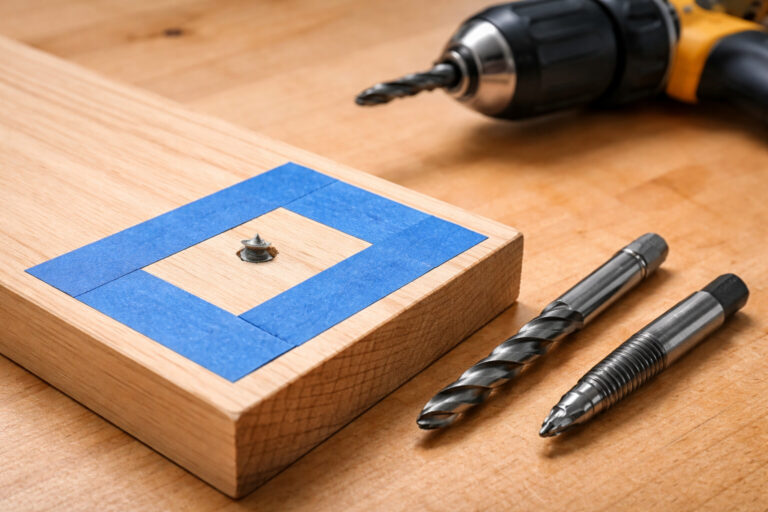

A simple scrap-wood test (the one I trust)

- Prep two scraps so they fit tight and flat.

- Spread a normal, even coat of glue.

- Clamp like you would on a real joint.

- Wait at least your usual clamp time.

- Break the joint and read the failure.

A good PVA bond usually tears wood fibers rather than peeling clean. A bad bond often releases right at the glue line, like tape lifting off glass. Don’t judge the test too early, though, because cure time matters. Need a timing check for your shop temperature? Use this dry-time cheat sheet for common glues.

Can you use wood glue after the expiration date?

Sometimes, yes, especially with PVA, if it still behaves like fresh glue. It must spread normally, cure hard, and pass a scrap test. If any of those fail, the date no longer matters.

I’m conservative with load-bearing joinery, and I’m conservative with time-heavy builds. Glue is cheap compared to a rebuild, especially on furniture. For quick crafts, you can be a little looser, as long as you test first.

For repairs, the “right glue” matters as much as freshness. If you’re fixing furniture, start with this repair-glue selection approach for stressed joints. Pick strength over convenience, and test on scraps first.

When you should toss it immediately

Throw it out when:

- It’s hardened or full of firm chunks that won’t mix out.

- It smells rotten, or you see any mold.

- It separates and won’t recombine after shaking.

- It fails the scrap test twice in a row.

- It cures tacky and never really firms up.

Also toss it if you strongly suspect it froze, and you can’t confirm otherwise. If you can’t trust the history, trust the test.

Can you revive old wood glue?

Sometimes you can, but only within limits, and only after testing. Don’t expect a spoiled bottle to become “like new” again. Think of this as a last chance for non-critical work.

Slightly thick PVA glue: Warm it to room temperature and shake it hard. If it’s only a bit thick, add a tiny splash of water and mix again. Then do the scrap test before using it on anything real. If it’s lumpy or sour, replace it.

Polyurethane glue: Thickening usually means it’s reacting already, and results become unreliable. I don’t try to save it for important joints.

Epoxy: Gentle warming can help if resin crystallizes, but only if it mixes smooth afterward. If it won’t blend cleanly, don’t use it.

If speed is the real issue, change your process instead of thinning glue. Use safe tricks for faster tack time when you’re on a schedule. They’ll keep you away from shortcuts that backfire.

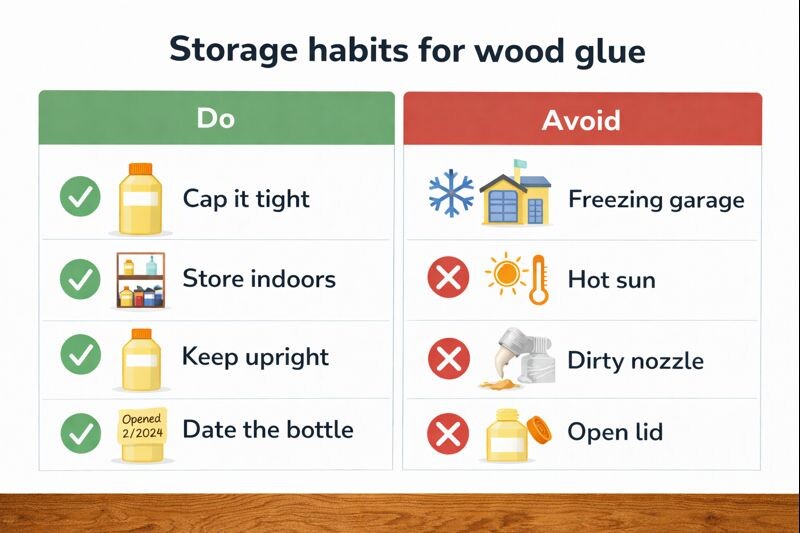

How to store wood glue so it lasts longer

Good storage is simple, and it prevents wasted glue and weak joints. You don’t need fancy containers or special cabinets. You just need consistency.

- Keep it from freezing, especially PVA.

- Keep it away from heat and direct sun.

- Cap it tight every single time.

- Store bottles upright to reduce leaks and clogs.

- Wipe the nozzle before recapping.

- Date the bottle when you open it.

- Buy smaller bottles if you glue only sometimes.

A tidy shop routine supports all of this. TrayEdit’s newbie-friendly tool-care routine pair well with good glue storage. The same routine mindset keeps both problems from stacking up.

FAQs on does wood glue expire

Can old glue still work if it looks normal?

Yes, sometimes, but you still need to test it. Make sure it spreads smooth and cures hard. Then confirm with a scrap break test.

Does freezing always ruin carpenter’s glue?

Not always, but it often does enough to cause failures later. If it froze, test it before using it on a project.

What does bad wood glue look like?

Bad glue often shows lumps, gels, separation, or stringy texture. Some bottles also show skinning inside, especially near the cap.

Is expired glue okay for small crafts?

It can be, if the joint isn’t stressed and you test first. Let it cure fully before you handle the piece.

Does a cured glue joint lose strength over time?

A well-made joint is usually stable for years indoors. Failures usually come from moisture, wood movement, or poor prep.

Conclusion

Wood glue can expire, but you don’t have to guess or waste good work. Check the texture, smell, and how it spreads, then run a quick scrap test.

Store glue cool, sealed, and unfrozen, and it will last far longer. When a joint truly matters, fresh glue is cheap insurance.