Best Plywood for Cabinets (2026): 8 Picks to Avoid Warp, Sag & Voids

Are you looking for the best plywood for cabinets but don’t want to waste money on sheets that warp, chip, or blow out around screws? You’re in the right place. Cabinet plywood shopping gets confusing fast because two sheets labeled “birch” can perform completely differently.

In this guide, I’ll walk you through what “cabinet-grade” actually means, how to choose the right core and face for your finish, and what thickness works for cabinet boxes, shelves, and backs.

Contents Here

- 1 Quick Checklist: The 8 Best Plywood Sheets for Cabinets

- 2 What “best” means for cabinet plywood

- 3 Cabinet-grade plywood basics

- 4 Choose plywood by cabinets part

- 5 Thickness and sheet sizing that simplifies planning

- 6 Face species and panel options

- 7 Plywood vs MDF vs particleboard for cabinets

- 8 Reviews of the 8 Best Plywood Sheets for Cabinets

- 8.1 VKIZA 5 Pack Walnut Plywood Sheets

- 8.2 Vemkyrio 12 Pcs Walnut Unfinished Plywood for Cabinets

- 8.3 ROBOTIME 3mm Walnut Plywood Sheets for Cabinets

- 8.4 Woodpeckers 12mm Baltic Birch Plywood Sheets for Cabinets

- 8.5 Woodpeckers 3mm Baltic Birch Plywood Sheets for Cabinets

- 8.6 Rowood 3mm Colored Plywood Sheets for Cabinets

- 8.7 Ninekong 3mm Black Walnut Plywood Sheets for Cabinets

- 8.8 Vemkyrio 3mm Mahogany Plywood Sheets

- 9 How to shop and inspect plywood before you buy

- 10 Finishing and edge protection that makes cabinets last

- 11 Common plywood cabinet mistakes to avoid

- 12 FAQs on Plywood for Cabinets

- 13 Conclusion

Quick Checklist: The 8 Best Plywood Sheets for Cabinets

- VKIZA 5 Pack Walnut Plywood Sheets

- Vemkyrio 12 Pcs Walnut Unfinished Plywood

- ROBOTIME 3mm Walnut Plywood Sheets

- Woodpeckers 12mm Baltic Birch Plywood Sheets

- Woodpeckers 3mm Baltic Birch Plywood Sheets

- Rowood 3mm Colored Plywood Sheets

- Ninekong 3mm Black Walnut Plywood Sheets

- Vemkyrio 3mm Mahogany Plywood Sheets

What “best” means for cabinet plywood

“Best” isn’t a single species or brand. It’s the sheet that fits your cabinet job and your finish. Cabinets fail in predictable ways—shelves sag, sides bow, screws strip, and edges swell—so good plywood prevents those failures with the right core, a usable face veneer, and a glue bond that matches your space.

- Core integrity: consistent thickness and minimal voids so dados fit and screws bite.

- Face quality: a clean veneer that sands evenly and doesn’t telegraph patches through paint or stain.

- Moisture and indoor-air fit: a panel that handles your humidity level and meets your emissions preference.

Cabinet-grade plywood basics

Start with the definition. A clear cabinet-grade plywood definition and what to ask a supplier for will keep you from paying hardwood prices for construction-quality cores.

Hardwood plywood vs. construction plywood

Construction plywood is built for sheathing and subfloors, not for crisp cabinet joinery or clean faces. It often carries more core gaps and surface repairs that show up as blowouts when you cut dados, rout hinges, or drive screws near an edge. Hardwood cabinet plywood targets flatter sheets and better faces for furniture and millwork.

Plywood face grades (A, B, C, D) and where they belong

Face grade describes appearance, not strength. Use higher grades where people see and touch the panel, and save money on hidden surfaces. A practical approach is simple: pay for the face you’ll finish and the core you’ll depend on.

- Exposed ends, finished sides, and visible panels: choose an A face when you want a cleaner look.

- Cabinet interiors: a B face usually looks good once installed and lit normally.

- Hidden structural parts: lower faces work if the sheet is flat and the core stays solid.

Core types that change screw-holding and flatness

Core choice drives how the cabinet performs. A pretty face won’t save a weak core. Match the core to how you build—pocket screws, dados, shelves, doors—and how you finish.

- Veneer core: stronger screw-holding and better edge strength; a solid choice for cabinet boxes and shelves.

- MDF core: very flat and paint-friendly; heavier and more sensitive to water at exposed edges.

- Combination core: balances flatness with better fastening; often used for larger, flat panels.

Emissions labels to look for (if indoor air matters to you)

If the cabinets go into a tight home, kids’ room, or a small apartment, look for panels marketed as low‑emissions. Suppliers often mark sheets as compliant with common formaldehyde limits (for example, CARB/TSCA-style labeling). If you’re sensitive to odors, ask for a low‑emissions option and let panels acclimate before installing.

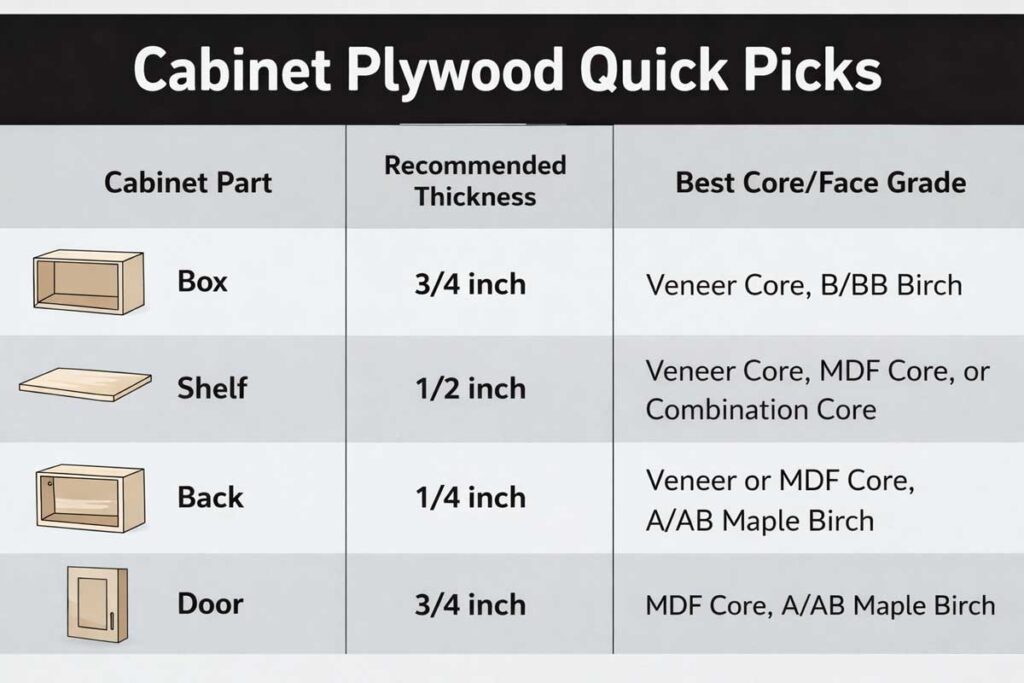

Choose plywood by cabinets part

Design drives material. A drawer box wants clean edges and strong joinery. A sink base wants sealed edges and a core that won’t crumble. Use the right panel in the right place and your build gets easier.

Cabinet boxes and sides

For most kitchens and built-ins, 3/4‑inch hardwood plywood with a consistent core is the workhorse for sides, tops, bottoms, and stretchers. Veneer core and combination core both work well. If you rely on pocket screws or confirmat-style fasteners, prioritize veneer core for stronger bite.

Shelves that resist sag

Shelf sag comes from span and load. Use 3/4‑inch material for shelves and add support when spans grow. A front stiffener, a face frame, or a mid-span divider reduces deflection more than switching species.

Cabinet backs

Backs do two jobs: close the cabinet and help it stay square. Captured backs (set in a dado or rabbet) add stiffness. Nail-on backs close the box but don’t stiffen it as much. Choose thickness based on how the back is attached and how the cabinet mounts to the wall.

Doors and drawer fronts

Plywood works best for slab doors and flat panels when the core stays stable. For frame-and-panel doors, many builders use solid-wood frames with a plywood center panel to keep movement controlled and edges protected.

If you’re still deciding between plywood and solid wood parts, this guide to wood choices for cabinet frames and trim helps you match materials to wear, style, and budget.

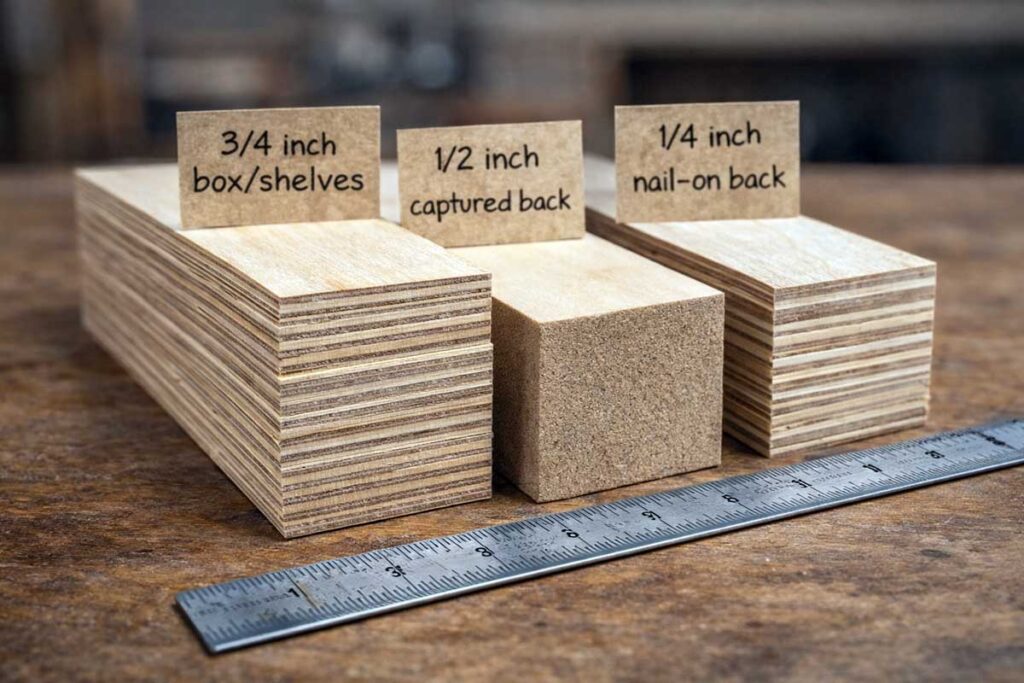

Thickness and sheet sizing that simplifies planning

Most cabinet plywood shopping goes smoother when you decide thickness first, then choose the face and core. Here’s the setup that covers the majority of cabinet builds.

- 3/4 inch: cabinet boxes, shelves, fixed dividers, and most structural parts.

- 1/2 inch: captured backs, some drawer parts, and lighter dividers when well supported.

- 1/4 inch: panel backs and bottoms only when fully supported and protected.

For deeper cut planning, use a cabinet plywood thickness guide and a sheet-size and cut-planning reference.

A quick note on Baltic birch sizing

Baltic birch often shows up in metric thicknesses and sometimes in non‑4×8 sheet sizes. That’s not a problem—just test dados and confirm sheet dimensions before you finalize your cut list.

Face species and panel options

Hardwood plywood is named by the face veneer species. The face drives the look; the core drives performance. Pick the face that matches your finish, then verify the sheet stays flat and void‑free enough for your joinery.

Baltic birch for boxes and drawer parts

Baltic birch earns its reputation because it typically uses more, thinner plies and fewer voids. That build produces cleaner edges, stronger joinery, and predictable screw-holding—especially helpful for drawers and frameless cabinet boxes.

Maple for a clean, modern look

Maple plywood suits clear finishes and bright interiors. It tends to look calm and uniform, and it resists dents better than softer faces. If you want a light cabinet interior that stays crisp, maple is a safe pick.

Birch for value and paint-friendly surfaces

Birch plywood gives a smooth surface for the money and works well for paint when you prime properly. Quality varies by supplier, so check the edge for voids and the face for patches before buying.

If you’re on the fence, this birch plywood cabinet breakdown explains where it shines and where it disappoints.

Oak when you want visible grain

Oak plywood delivers bold grain that looks great under stain and clear coats. If you paint oak, plan on grain filling or you’ll see texture telegraph through the finish.

Prefinished plywood for cabinet interiors

Prefinished hardwood plywood saves finishing time and keeps cabinet interiors bright and easy to wipe clean. It’s a strong choice for closets and pantry cabinets where a durable, clean interior matters more than matching a perfect stain color.

Plywood vs MDF vs particleboard for cabinets

Each panel type solves a different problem. Plywood wins on screw-holding and shelf strength. MDF wins on flat, paint-smooth surfaces. Particleboard wins on cost, but it loses quickly around water.

- Plywood: strong edges, good fastening, better long-term shelf performance when sealed.

- MDF: flat and paint-smooth; heavier and vulnerable to swelling when water reaches raw edges.

- Particleboard: budget-friendly and flat; fast to swell and weaken in sink bases and damp areas.

If you’re deciding on construction style, this practical look at plywood cabinet durability helps set expectations for real-life kitchens.

Reviews of the 8 Best Plywood Sheets for Cabinets

VKIZA 5 Pack Walnut Plywood Sheets

Walnut veneer craft sheets for cabinet handle and hinge templates

VKIZA’s walnut plywood sheets fit best when you need clean, repeatable cabinet templates—handle drilling guides, hinge routing patterns, toe-kick vent covers, or small accent panels. The walnut texture looks “finished” fast, and the smooth face makes marking and taping reliable. It’s a good buy because the 5-pack gives you matching material for multiple jigs without committing to a full hardwood sheet. One honest limitation: at 3mm, these panels are for light-duty parts and shop aids, not cabinet boxes or shelves.

$27.99 at AmazonSpecifications

- Finish & size: Unfinished walnut, 12 x 18 in

- Thickness: 3 mm (1/8 in)

- Quantity: 5 sheets

- Grade: Commercial

- Cutting: Laser, knife, engraving

Pros

- Attractive walnut look for visible small parts

- Easy to cut for precise jigs

- Smooth, burr-free surface saves prep

- Lightweight and easy to store

Cons

- Too thin for structural cabinet construction

Vemkyrio 12 Pcs Walnut Unfinished Plywood for Cabinets

Unfinished walnut squares for closet mockups and repeatable shop jigs

These walnut squares work best for layout mockups in closets and cabinets, spacer blocks, story sticks, and small dividers where consistent sizing matters. The surface arrives smooth and the edges usually need little cleanup, which speeds up quick fixture-making. It’s a good buy because 12 identical 12×12 panels let you batch templates and test cuts without burning through larger stock. One honest limitation: like most thin plywood packs, you still need to inspect for flatness and store it dry to avoid warping.

$29.99 at AmazonSpecifications

- Finish & size: Unfinished walnut, 12 x 12 in

- Thickness: 1/8 in

- Quantity: 12 sheets

- Use: Scroll saw, utility knife, laser

- Maker: Vemkyrio

Pros

- Great for batching templates and blocks

- Smooth faces take paint or clear coat well

- Easy cutting for beginners and pros

- Convenient size for shop storage

Cons

- Not a full-sheet option for cabinet carcasses

ROBOTIME 3mm Walnut Plywood Sheets for Cabinets

Walnut-colored laser panels for cabinet labels and accessory parts

ROBOTIME’s “walnut” craft sheets fit best for laser-cut cabinet labels, pull templates, decorative panels, and small organizers where crisp engraving matters. The panels are made from poplar, but the walnut color and clean surface make projects look polished quickly. It’s a good buy because the sizing is generous for craft stock, and the stated thickness tolerance helps when you need repeatable parts. One honest limitation: these are not cabinet-grade hardwood plywood sheets for boxes or long shelves—treat them as precision craft panels.

$31.99 at AmazonSpecifications

- Finish & size: Walnut-colored, 12 x 16.5 in

- Thickness: 3 mm (1/8 in), ±0.2 mm

- Quantity: 6 sheets

- Material: Poplar

- Use: Laser, engraving, burning, UV printing

Pros

- Cuts and engraves cleanly for detailed work

- Larger craft size fits longer templates

- Useful tolerance info for precision builds

- Versatile for multiple making methods

Cons

- Not structural plywood for cabinet carcasses

Woodpeckers 12mm Baltic Birch Plywood Sheets for Cabinets

Thick Baltic birch blanks for cubbies and small cabinet shelving (Woodpeckers 12mm B/BB)

These 12mm Baltic birch pieces are best for sturdy closet cubbies, small cabinet shelves, drawer components, and shop organizers that need real stiffness and clean edges. The multi-ply build and B/BB grading support glue and screws well, which helps when you’re assembling tight, square boxes. It’s a good buy because you get thick, ready-to-use panels in a convenient size—great for quick builds and prototypes without breaking down full sheets. One honest limitation: the pieces are pre-cut, so they won’t cover large cabinet sides or full kitchen carcasses.

$18.48 at AmazonSpecifications

- Finish & size: Unfinished Baltic birch, 11-7/8 x 7-7/8 in

- Thickness: 12 mm (about 1/2 in)

- Grade: B/BB

- Quantity: 2 pieces

- Use: Shelving, cabinetry, laser/scroll saw

Pros

- Rigid and strong for small shelving

- Clean birch edges for joinery

- Good glue and screw holding

- Takes stain nicely

Cons

- Size limits it to smaller cabinet parts

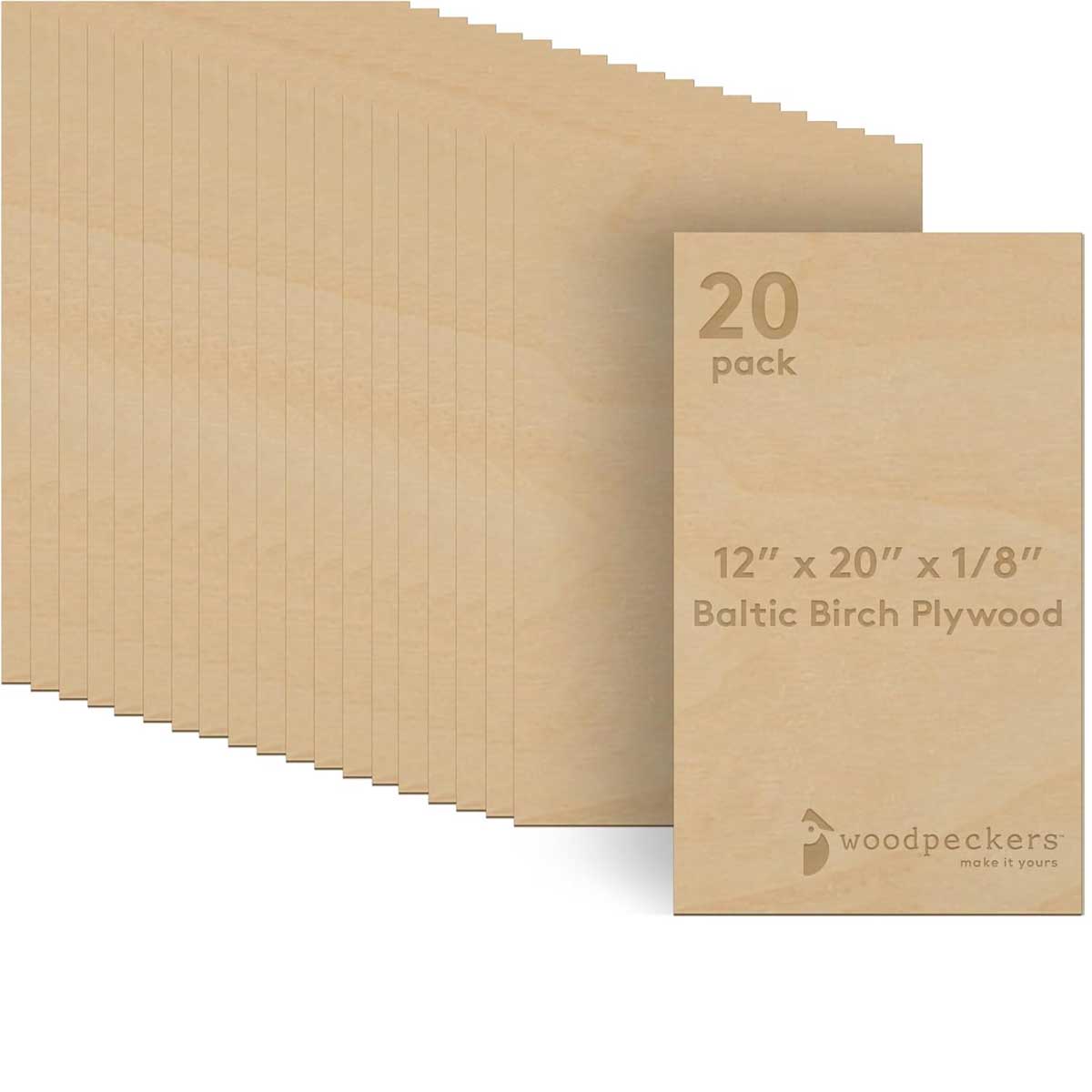

Woodpeckers 3mm Baltic Birch Plywood Sheets for Cabinets

Thin Baltic birch panels for cabinet labels, templates, and clean detail work

Woodpeckers 3mm Baltic birch sheets fit best for cabinet hardware templates, closet/cabinet labels, drawer dividers, and light-duty panels that need crisp cuts and stable edges. It’s a good buy because the multi-ply Baltic birch build stays rigid for its thickness, takes stain well, and gives glue and small screws better bite than many craft boards. The B/BB grade also means a smoother face for CNC, engraving, and wood burning, with minor patches typically limited to the back. One honest limitation: at 3mm (about 1/8 inch), it’s not structural material for cabinet boxes, long shelves, or hinge mounting.

$65.25 at AmazonSpecifications

- Finish & size: Unfinished Baltic birch, true 11-7/8 x 19-7/8 in

- Thickness: 3 mm (about 1/8 in)

- Grade: B/BB

- Material: Birch wood (Baltic birch plywood)

- Best tools: Laser cutter, scroll saw, CNC, engraving

Pros

- Clean, multi-ply edges for tighter joinery

- Smooth face takes stain and finishes evenly

- Cuts cleanly for detailed templates and labels

- Good glue bond and light screw holding

Cons

- Too thin for load-bearing cabinet parts

Rowood 3mm Colored Plywood Sheets for Cabinets

Rowood’s colored plywood works best for closet labeling, organizer inserts, drawer dividers, and lightweight cabinet accessories where color saves finishing time. The pre-colored sheets help you build a system that’s easy to sort—great for pantries, kids’ closets, or shop storage. It’s a good buy because you get multiple colors in one pack, and the 3mm thickness stays easy to cut with knives, scroll saws, or lasers. One honest limitation: basswood is softer than birch, so it dents easier and doesn’t hold hardware screws like cabinet-grade panels.

$33.24 at AmazonSpecifications

- Finish & size: Colored sheets, 12 x 12 or 12 x 16 in

- Thickness: 3 mm (1/8 in)

- Quantity: 7-pack (multicolor)

- Material: Basswood

- Colors: 14 colors listed

Pros

- No-paint organization parts and labels

- Smooth surface for engraving and printing

- Easy cutting for quick projects

- Great for visual sorting systems

Cons

- Soft wood isn’t ideal for hinges or slides

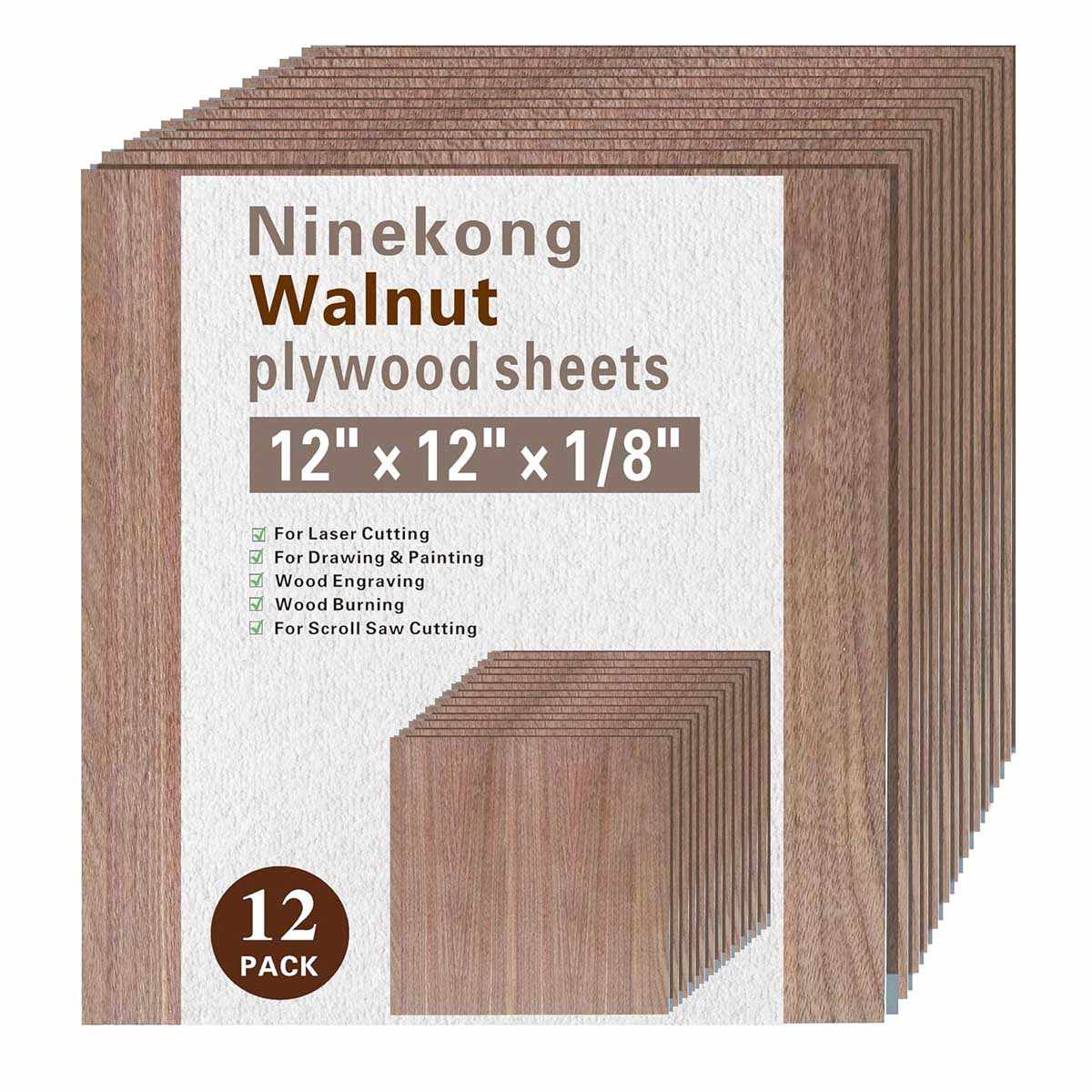

Ninekong 3mm Black Walnut Plywood Sheets for Cabinets

Black walnut face panels for precision drilling guides and small accents

Ninekong’s black walnut plywood panels are best for cabinet hardware drilling templates, routing guides, corner blocks, and small walnut-faced accents where a clean surface matters. The walnut face paired with a poplar core balances looks and workability, and the sheets arrive finely cut for quick use. It’s a good buy because the 12-sheet pack supports repeatable jigs—make one, test it, and keep a spare without changing material thickness. One honest limitation: thin plywood can move with humidity after unwrapping, so store it flat and seal leftovers.

$36.99 at AmazonSpecifications

- Finish & size: Unfinished black walnut face, 12 x 12 in

- Thickness: 3 mm (1/8 in)

- Quantity: 12 sheets

- Core: Poplar

- Grade: Residential

Pros

- Clean walnut look for visible small parts

- Poplar core cuts smoothly

- Great pack size for repeat templates

- Works with laser, scroll saw, engraving

Cons

- Not suitable for load-bearing cabinet components

Vemkyrio 3mm Mahogany Plywood Sheets

Mahogany craft panels for warm-tone cabinet details and inlays

These mahogany plywood sheets are best for decorative cabinet accents, small door inlays, toe-kick details, and warm-tone organizer faces where you want consistent grain across many parts. The smooth, burr-free surface reduces sanding time, and the large 24-pack helps when you’re repeating the same design—like matching closet dividers or decorative panels. It’s a good buy because you get a lot of usable material in a stable, easy-to-cut thickness for lasers, knives, or scroll saws. One honest limitation: at 3mm, it’s detail stock, not cabinet carcass plywood.

$66.49 at AmazonSpecifications

- Finish & size: Unfinished mahogany, 12 x 18 in

- Thickness: 1/8 in (3mm class)

- Quantity: 24 sheets

- Use: Scroll saw, craft knife, laser

- Surface: Smooth, minimal burrs

Pros

- Rich, warm look for accents

- Big pack supports multi-piece projects

- Easy to cut for detailed shapes

- Finishes well with clear coats

Cons

- Too thin for shelves or cabinet boxes

How to shop and inspect plywood before you buy

A sheet can look fine from ten feet away and still fight you at the saw. Spend two minutes inspecting and you’ll save hours of filling, shimming, and re-cutting.

- Sight down the long edge to spot bow, twist, or a corner that wants to lift.

- Check corners and faces for moisture swelling, crushed edges, and deep dents.

- Inspect the edge plies for voids, gaps, and soft spots where screws will fail.

- Look closely at the face veneer thickness—over-sanding thin veneers creates blotches fast.

- Buy from the same stack when possible; consistency matters more than one ‘lucky’ sheet.

Where to buy cabinet-grade plywood

Lumberyards and sheet-goods suppliers usually carry flatter, more consistent cabinet plywood than many big-box racks. Ask for the face grade and core type, then inspect the edges before you load up. If you need prefinished interiors, a cabinet supplier often has more options than a home center.

Finishing and edge protection that makes cabinets last

Most plywood cabinet problems start at edges, seams, and the sink base. Protect those areas and the rest of the cabinet tends to behave.

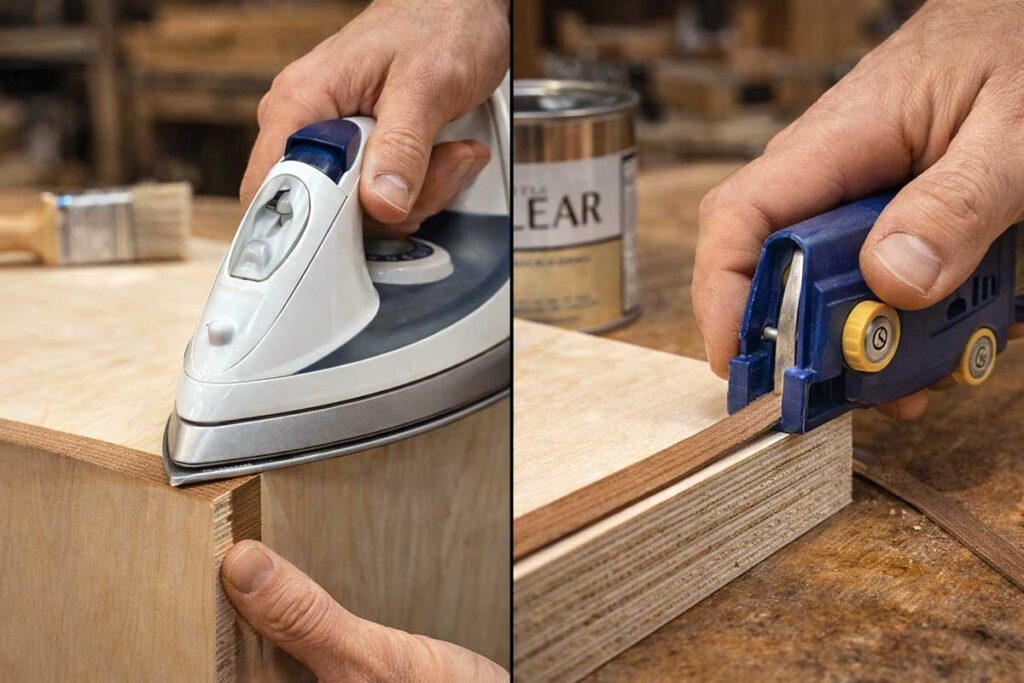

Edge banding and sealing

Cover exposed edges with veneer edge banding, solid-wood edging, or durable PVC/ABS banding. Then seal and topcoat the edge. Raw edges absorb moisture faster than faces, so treat them as the first priority.

Paint and clear finishes

For paint, use a bonding primer that grips hardwood veneers and seals patchy areas, then apply a cabinet-grade enamel. For clear finishes, a durable waterborne clear coat keeps interiors bright and resists yellowing.

If brush marks frustrate you, this smooth-finish routine for painted wood walks through the prep that makes the finish look sprayed, even with a brush and roller.

Fasteners and pilot holes

Plywood holds screws well when you drill proper pilots and avoid forcing screws into thin veneers. In dense panels, pilots prevent splitting; in softer cores, pilots prevent stripping.

If you fight splitting or blowouts, these practical steps to prevent wood splitting while screwing translate directly to cleaner cabinet assembly.

Common plywood cabinet mistakes to avoid

- Buying sheathing or “shop” panels for visible cabinetry and then chasing voids and tear-out.

- Using 1/2-inch plywood for long shelves without a stiffener or divider.

- Over-sanding thin face veneers and exposing the core at edges and corners.

- Skipping edge sealing in sink bases, dishwashers, and bath vanities.

- Choosing by species name only and ignoring core quality and sheet flatness.

FAQs on Plywood for Cabinets

What thickness plywood should I use for cabinets?

Use 3/4‑inch for cabinet boxes and shelves in most builds. Use 1/2‑inch for captured backs and light dividers when supported. Use 1/4‑inch only for backs or bottoms that are fully supported and well protected.

How do I properly seal plywood edges for cabinet use?

Apply edge banding or a glued-on hardwood strip, then prime and topcoat the edge. Focus on sink bases and dishwasher panels—edges absorb moisture faster than faces and start swelling first.

How does plywood compare to MDF for cabinet doors?

MDF paints flatter and hides grain, making it popular for smooth painted doors. Plywood holds screws better and handles humidity better. Choose MDF for dry rooms and plywood for kitchens or high-wear areas.

What are the best finishes for plywood cabinets?

For clear wood, use a durable waterborne clear coat after sanding and sealing. For paint, use a bonding primer followed by a cabinet-grade enamel. Protect edges with extra coats where water and cleaning happen.

Where can I buy cabinet-grade plywood?

A lumberyard, cabinet supplier, or sheet-goods distributor usually offers flatter stock and clearer grade choices than big-box racks. Ask for face grade and core type, then inspect the edge for voids before purchasing.

Conclusion

The best cabinet plywood choice comes down to three checks: a stable, low-void core; a face veneer that matches your finish; and thickness that fits the cabinet part. For most cabinet boxes and shelves, a flat 3/4‑inch hardwood plywood with a consistent core delivers reliable screw-holding and better long-term stiffness. Seal edges, especially near water, and inspect every sheet before you buy—those two habits prevent most cabinet failures.