Are Plywood Cabinets Good? 7 Tough Checks Before You Buy

Are plywood cabinets good is a fair question, and the short answer is yes when the boxes use cabinet-grade plywood, solid joinery, and a sealed finish.

Plywood gets a bad rap because people lump every “plywood” sheet into one bucket. In the shop, I treat plywood cabinets like any other build: the material matters, but the construction details decide whether they last 5 years or 25.

Contents Here

- 1 Are plywood cabinets good for kitchens and bathrooms?

- 2 What makes one plywood cabinet box better than another?

- 3 What plywood should cabinets use?

- 4 How do plywood cabinets compare to particleboard and MDF?

- 5 When do plywood cabinets fail or disappoint?

- 6 How can you spot quality plywood cabinets before you buy?

- 7 Do plywood cabinets hold hinges and drawer slides well?

- 8 Are plywood cabinets worth the extra cost?

- 9 How do you maintain plywood cabinets so they last?

- 10 FAQs on Plywood Cabinets

- 10.1 Is 1/2-inch plywood thick enough for cabinet boxes?

- 10.2 Are plywood cabinets better than solid wood cabinets?

- 10.3 Do plywood cabinets warp?

- 10.4 Are plywood cabinets safe for indoor air quality?

- 10.5 What does “cabinet-grade plywood” actually mean?

- 10.6 Are plywood cabinets good if I want painted cabinets?

- 11 Final thoughts

Are plywood cabinets good for kitchens and bathrooms?

Plywood cabinets perform well in kitchens and bathrooms when the cabinet box edges are sealed and the hardware is installed into solid material, not crumbly core.

Plywood’s cross-laminated plies fight racking (that side-to-side wobble) better than many budget composites. Water is still the enemy, though: standing leaks and unsealed edges cause swelling and delamination no matter what the box is made of.

Shop rule: If you can keep the sink base dry and the toe-kick from soaking up mop water, plywood boxes hold up for a long time.

Read more: What Wood Is Better for Kitchen Cabinets: 5 Pro Picks for Paint or Stain

What makes one plywood cabinet box better than another?

A plywood cabinet box earns its strength from plywood grade, core type, thickness, joinery, and back panel design, not from the word “plywood” on a sales tag.

Here’s what I look at first:

- Core quality: Clean, tight plies with minimal voids support hinges and drawer-slide screws better than “gappy” cores.

- Panel thickness: Thicker sides and bottoms resist flex; thicker shelves resist sag.

- Joinery: Dados, rabbets, dowels, or confirmat screws hold alignment better than butt joints stapled together.

- Back panel: A full back captured in a dado stiffens a cabinet more than a thin tack-on panel.

- Finish and edge sealing: A sealed surface and sealed edges slow moisture pickup and make cleaning safer.

What plywood should cabinets use?

Cabinets stay predictable when builders use hardwood plywood made to a recognized grading and construction standard and match the bond type to the room’s moisture.

The hardwood plywood industry commonly references ANSI/HPVA HP-1, which lays out veneer grades, core constructions (veneer core, MDF core, particleboard core, combination cores), and plywood “types” based on bond water-resistance (Technical/Type I/Type II).

What that means in plain terms:

- Veneer core plywood makes a tough, light cabinet box when the plies are tight and voids are minimal.

- MDF-core plywood gives a flatter, smoother face for paint-grade panels, but it needs careful edge sealing.

- Type I / exterior bond matters when you expect higher moisture exposure; Type II / interior bond fits dry, conditioned interiors.

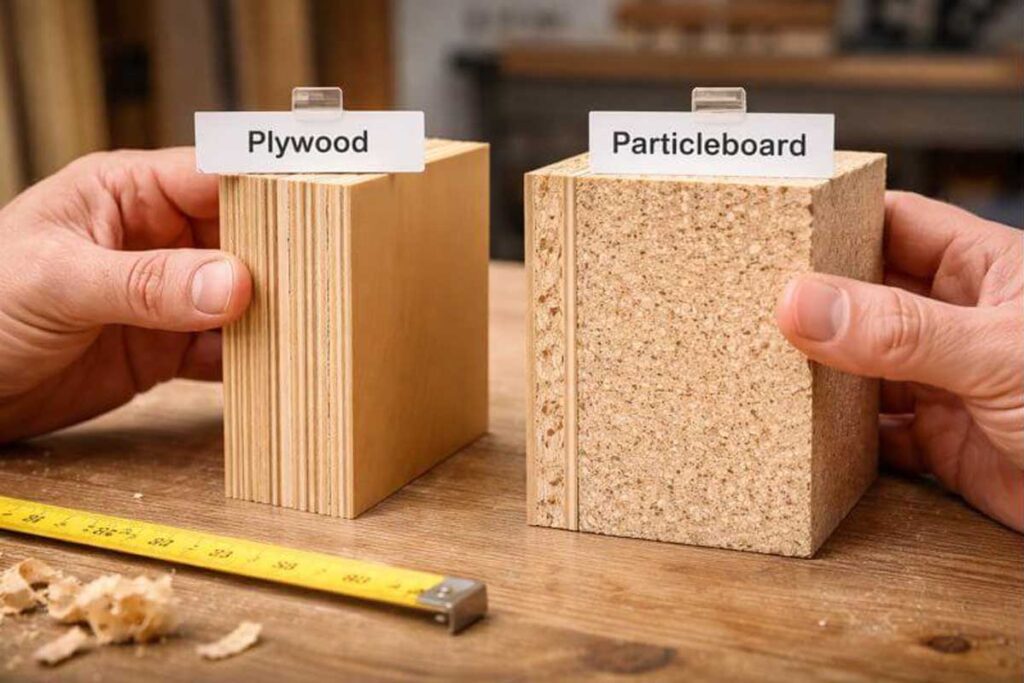

How do plywood cabinets compare to particleboard and MDF?

Plywood cabinet boxes usually win on durability under fasteners and resistance to racking, while particleboard and MDF can win on flatness and cost (especially for painted doors).

A practical breakdown:

- Plywood (box panels): Good screw-holding in many real builds, good stiffness, lighter than MDF, and generally forgiving during installation.

- Particleboard (box panels): Uniform and cheap, but edges and fastener zones can fail sooner when they get wet or when screws are over-tightened.

- MDF (doors and painted panels): Paint lays smooth, profiles machine cleanly, and the surface stays consistent; the downside is weight and poor performance when water gets into exposed edges.

ANSI/HPVA HP-1 even calls out that performance properties like screw withdrawal, water absorption, and thickness swell depend on core/spec and should be agreed on when performance matters.

When do plywood cabinets fail or disappoint?

Plywood cabinets disappoint when manufacturers cut corners on sheet quality, edge treatment, and hardware anchoring.

The most common failures I see:

- Delamination: Water intrusion + weak bond line = plies separating.

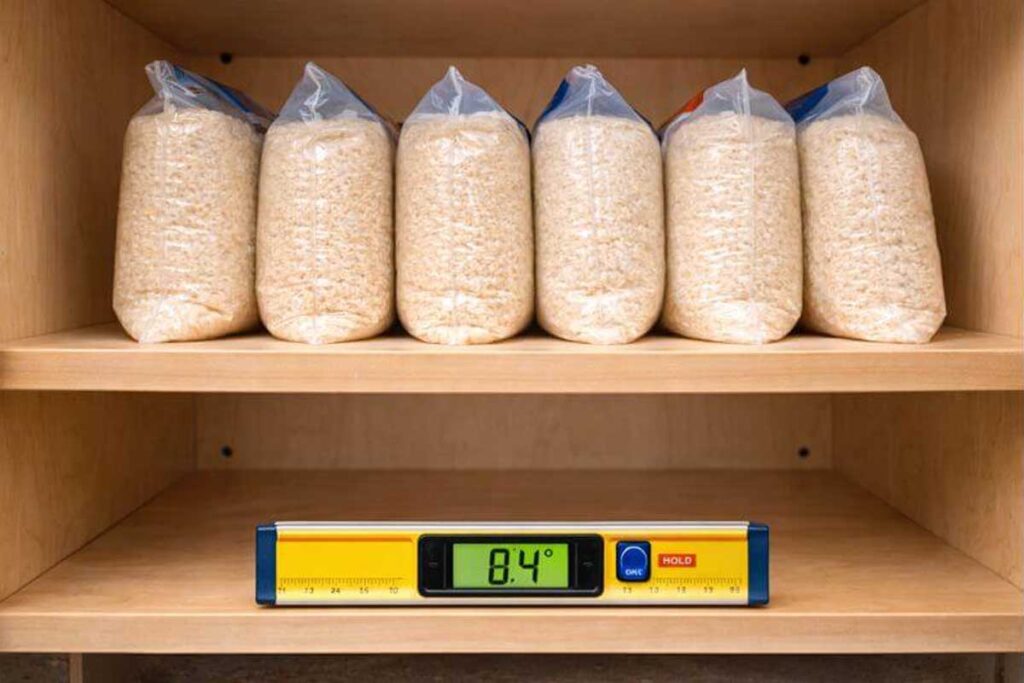

- Shelf sag: Long spans + thin shelves + heavy dishes = permanent bow.

- Loose hinges/slides: Screws bite into voidy core or thin panels and work loose.

- Swollen edges: Unbanded or poorly banded edges soak humidity and spills.

If you want one place to put your attention, put it here: sink base edges, dishwasher side panels, and toe-kick areas.

How can you spot quality plywood cabinets before you buy?

You can spot good plywood cabinets by checking one exposed cabinet edge, one shelf span, one back panel, and one hinge mount.

Use this quick in-store checklist:

- Ask for a cutaway or look under the sink for a visible panel edge. Tight plies beat voids.

- Check shelf thickness and support. Wide shelves need thickness and/or a front edge stiffener.

- Look for a captured back panel (set into a groove) instead of a thin stapled-on back.

- Inspect edge banding. Clean, fully bonded banding protects the most vulnerable part of plywood.

- Test the hardware feel. Doors should not rack; drawers should not sag when extended.

If you want an objective stamp beyond brand promises, look for a cabinet line that carries KCMA A161.1 certification, which includes structural and finish testing. KCMA’s published test description includes shelves/bottoms loaded at 15 lb per square foot for 7 days and wall-mounted cabinets loaded up to 600 lb without visible failure.

Do plywood cabinets hold hinges and drawer slides well?

Plywood cabinets hold hinges and slides well when installers pre-drill, use the right screws, and avoid the “gorilla-tight” overdrive that strips threads.

A hinge screw is only as good as the bite it gets. If you want extra insurance on a high-use door (trash pull-out, pantry, kids’ snack cabinet), upgrade screws and installation habits first. My go-to read on fasteners is this piece on choosing corrosion-resistant cabinet screws for damp areas.

Are plywood cabinets worth the extra cost?

Plywood cabinets are worth the extra cost when you expect heavy daily use, occasional moisture events, and a long remodel cycle (the “I don’t want to do this again” crowd).

Plywood tends to earn its keep in:

- Sink bases and trash pull-outs

- Large drawers with pots/pans

- Full overlay doors that stress hinges

- Homes with kids, rentals, or high cooking frequency

If the kitchen is light-use and the budget is tight, you can still get good service out of other materials—just prioritize good hardware, good finish, and good installation.

How do you maintain plywood cabinets so they last?

Plywood cabinets last longer when you control water exposure, cleaning chemistry, and edge damage.

- Wipe spills instead of letting them sit at seams.

- Keep cleaners mild; harsh chemicals can soften finishes over time.

- Seal any fresh chips or raw edges promptly so moisture can’t wick into plies.

- Fix loose joints early. When a plywood corner starts to open up, a proper adhesive and clamp pressure stops the problem from growing—this guide on picking an adhesive that bonds plywood layers helps you match glue to the repair.

If you’re working in wet zones (sink base, laundry), I keep a waterproof adhesive on hand; here’s my rundown on waterproof glue options for wood projects that see moisture.

FAQs on Plywood Cabinets

Is 1/2-inch plywood thick enough for cabinet boxes?

1/2-inch plywood can work for cabinet sides when the cabinet uses a solid back, good joinery, and sensible spans, but shelves and wide spans usually benefit from thicker stock. A stiffer shelf reduces sag, and a captured back panel reduces racking.

Are plywood cabinets better than solid wood cabinets?

Plywood cabinet boxes usually outperform solid wood boxes because plywood stays more dimensionally stable across seasons. Solid wood shines on face frames, doors, and trim, where movement can be designed around instead of fighting the box’s square.

Do plywood cabinets warp?

Plywood resists warping better than most solid wood panels, but it can twist if it’s stored wet, finished unevenly, or built from low-grade sheets with uneven core stresses. Flat storage, acclimation, and a balanced finish keep panels behaving.

Are plywood cabinets safe for indoor air quality?

Plywood cabinets are safer for indoor air when the panels meet modern formaldehyde rules and carry compliant labeling. In the U.S., EPA notes that composite wood products (including hardwood plywood) have required TSCA Title VI labeling, with earlier CARB Phase II reciprocity during the transition period.

What does “cabinet-grade plywood” actually mean?

“Cabinet-grade plywood” usually means hardwood plywood made for appearance and interior millwork, with defined veneer grades and core constructions. ANSI/HPVA HP-1 is one of the standards that spells out veneer grades, core types, bond types, and product identification/marking.

Are plywood cabinets good if I want painted cabinets?

Plywood cabinets work fine under paint when the visible surfaces are smooth and properly prepped, but many shops use MDF for painted doors because it paints flatter and routes cleaner. If you’re chasing a glassy finish, this walkthrough on getting a smooth painted surface without brush marks is the same prep mindset I use on cabinetry.

Final thoughts

Plywood cabinets are a strong choice when you buy with your eyes: check the core, check the edges, check the back panel, and check the hardware anchoring. The best plywood cabinet in the world still fails if it sits in a wet sink base for a month, so plan for leaks, seal edges, and repair chips fast. Good luck, and holler if you want a quick checklist tailored to your cabinet quote or showroom options.